Liquid filling device

A filling device and liquid technology, applied in liquid bottling, liquid processing, packaging, etc., can solve the problems of high labor intensity and low processing efficiency, and achieve the effect of high production efficiency, stable operation and automatic filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

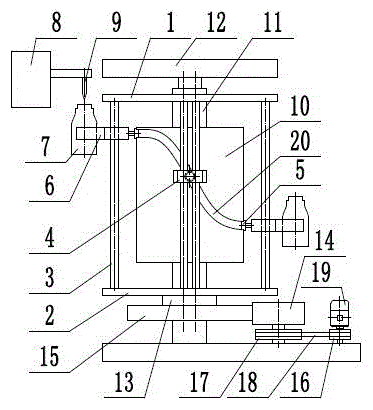

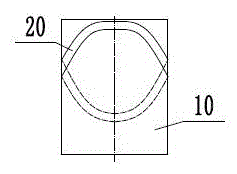

[0014] like figure 1 and figure 2 As shown, a liquid filling device includes an upper turntable 1, a lower turntable 2, a guide rod 3, a slider 4, a roller 5, a holder 6, a bottle body 7, a liquid storage tank 8, and a needle filling head 9. Cylindrical cam 10, support pillar 11, frame 12, turntable pivot 13, first gear 14, second gear 15, first pulley 16, second pulley 17, transmission belt 18, drive motor 19, the cylinder The cam 10 is vertically fixed on the frame 12 by the support pillar 11, and the outer side of the cylindrical cam 10 is provided with a curved cam groove 20, and the highest end of the curved cam groove 20 is provided with a horizontal section, which is beneficial to the bottle body 7 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com