Semi-automatic single welding machine for solar cell slices

A solar cell, semi-automatic technology, applied in welding equipment, auxiliary equipment, metal processing, etc., can solve the problems of not necessarily increasing the output, high input cost and maintenance cost, and difficult to control product quality, etc., to achieve Extensive market application prospects, meeting product upgrading needs, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

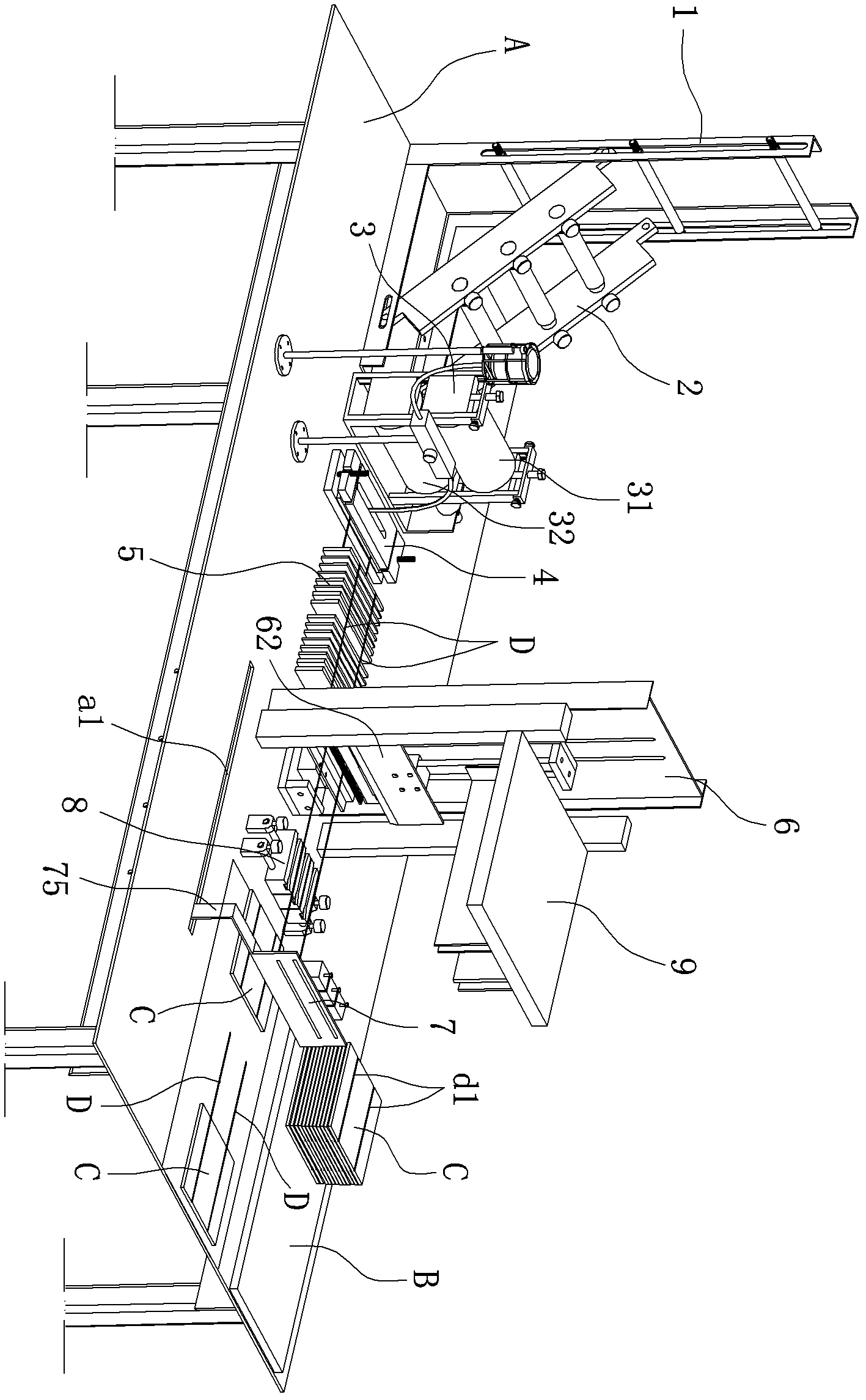

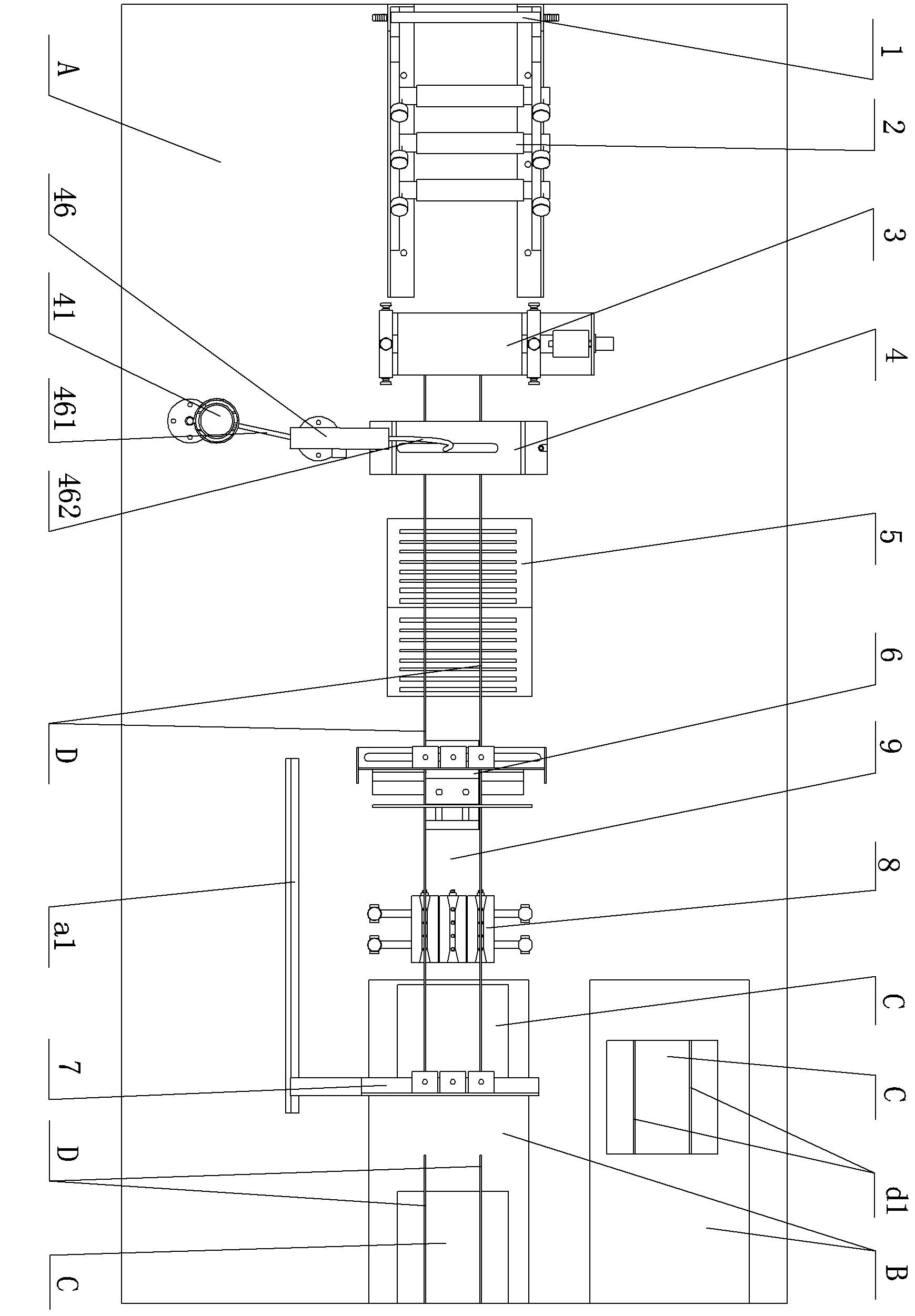

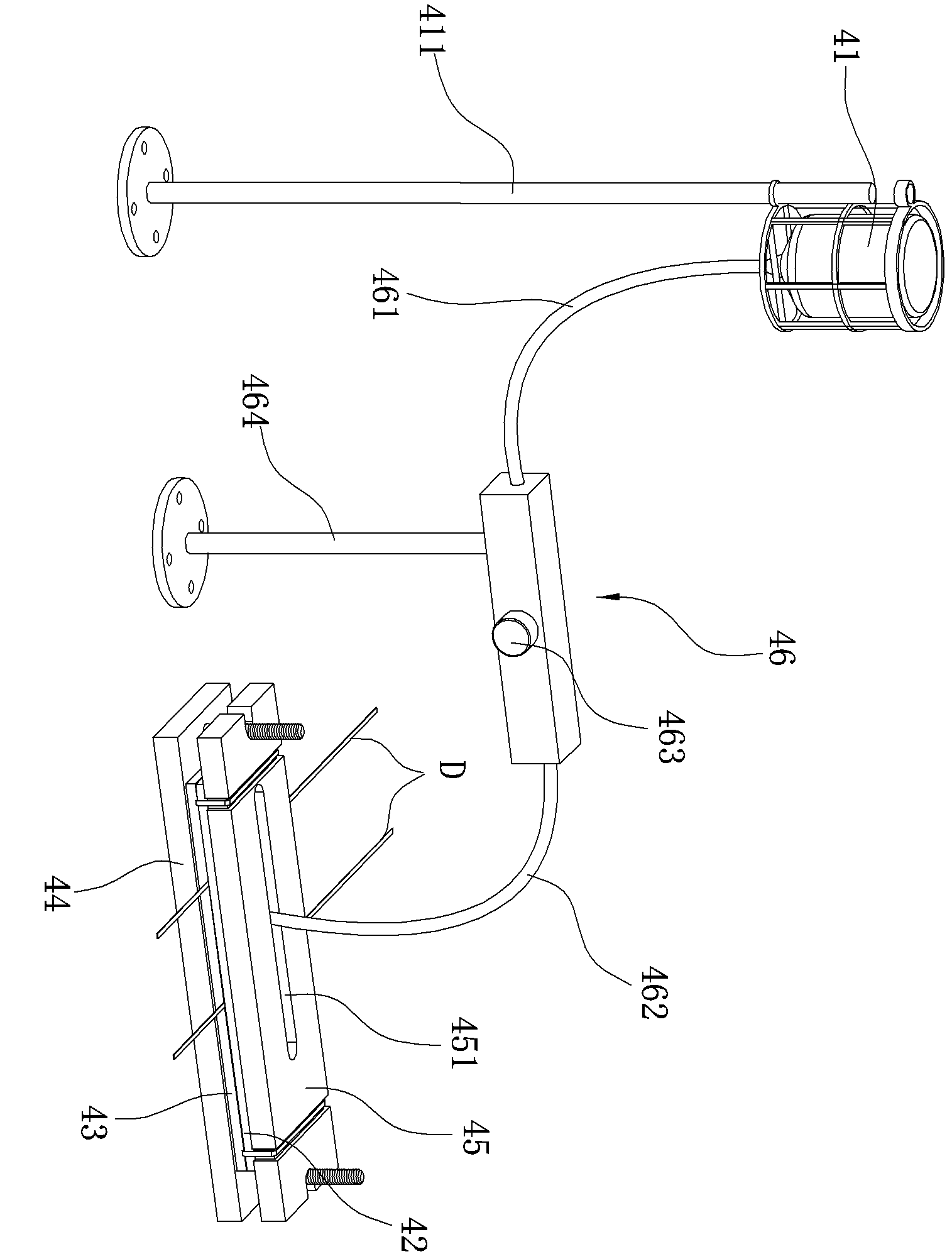

[0037] like Figure 1 to Figure 11As shown, it is a semi-automatic single welding machine for solar cells. The single welding machine in this embodiment realizes automatic conveying and automatic welding of welding tapes through mechanized devices and electrification control, while the picking and placing of solar cells adopts Manual operation, through the combination of manual operation and mechanized operation, semi-automatic single welding of solar cells is realized.

[0038] The single welding machine of this embodiment includes a machine base A, and a welding station is set on the base A. During operation, the solar cell C is placed on the welding station by manual operation. After the welding is completed, the battery is also manually operated. Sheet C is taken out from the welding station; considering that the temperature rises during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com