Full-automatic drill boom for anchor rod drill carriage

A bolter rig, fully automatic technology, applied in the direction of installation of bolts, earthwork drilling, drilling equipment, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

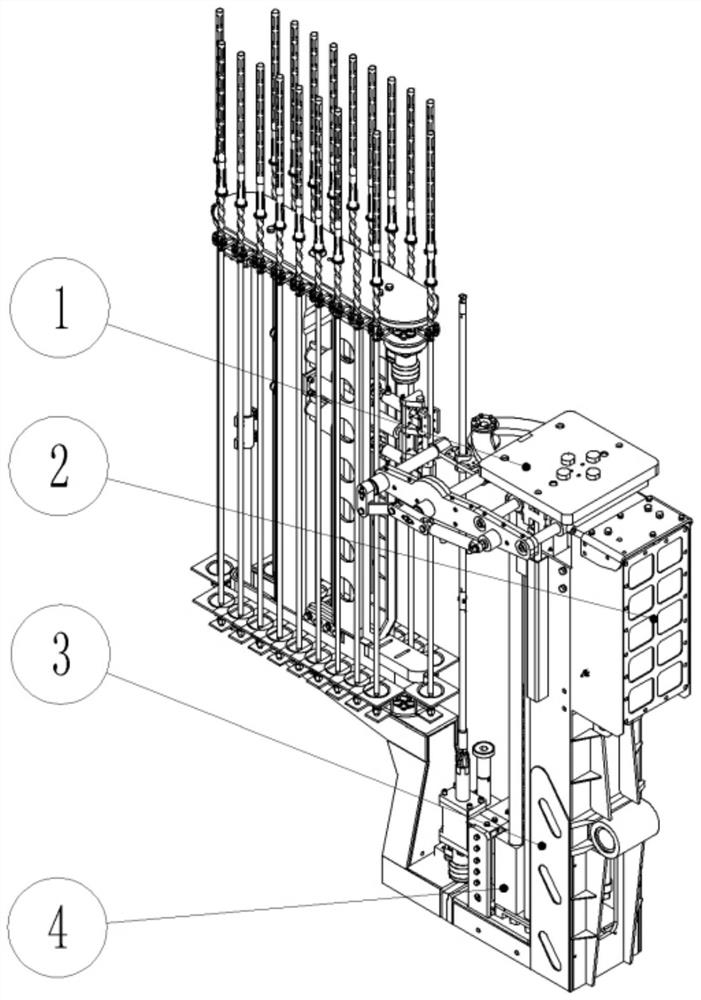

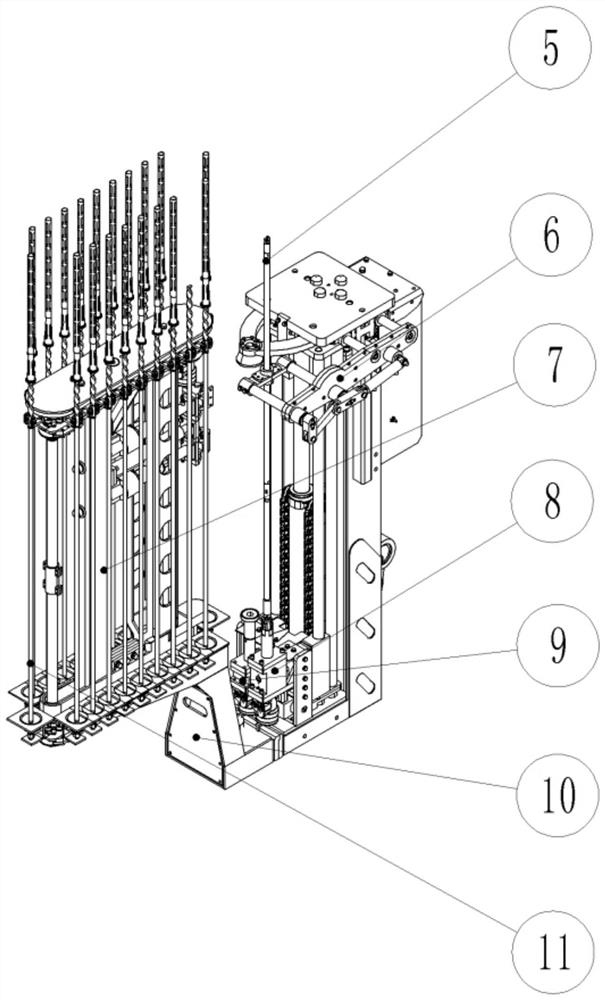

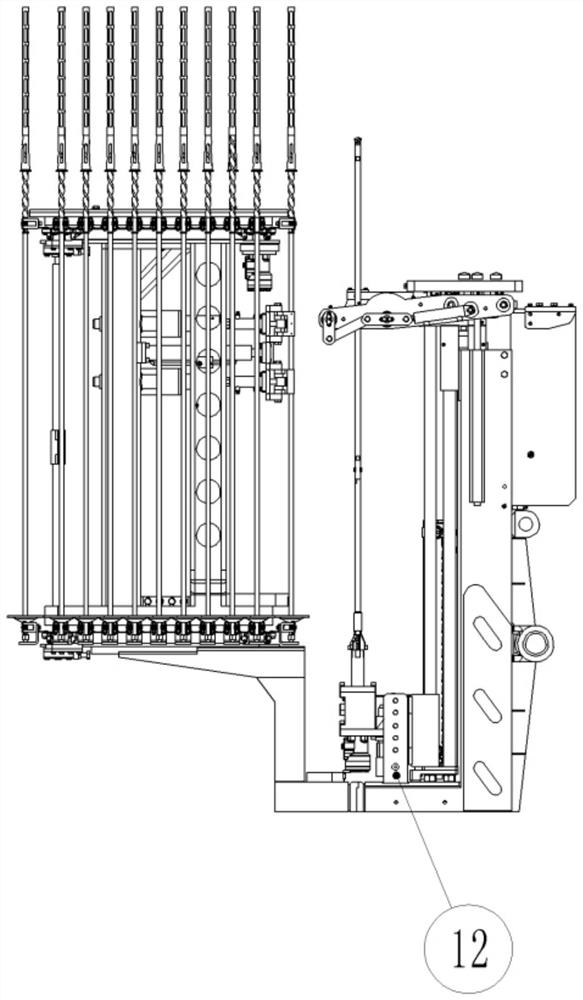

[0038]SeeFigure 1 to Figure 3, The present invention provides a fully automatic drill boom structure for a rock bolt drill carriage, which includes a top support 1, an electro-hydraulic control box 2, a frame 3, a double-speed feed mechanism 4, a drill rod 5, a drill rod holder 6, an anchor Rod bin 7, drill rod box 8, anchor rod mounting drill box 9, rear frame 10, anchor rod 11, drill box shifter 12, and top support cylinder. The top support 1, the electro-hydraulic control box 2 and the double-speed feed mechanism are mounted on the frame 3. The top support 1 is driven by the top support cylinder to slide relative to the frame 3, and the drill rod holder 6 is mounted on the top On the support 1, together with the top support 1, provide a stable support for the drill rod 5 and the anchor rod 11. The drill rod drill box 8 and the anchor rod installation drill box 9 are installed on the double-speed emergency mechanism 4. The double-speed feed mechanism 4 drives the drill rod drill b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com