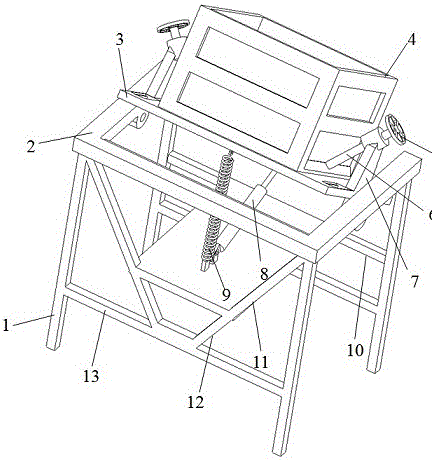

Coarse barium slag dumping overturning platform device

A technology of turning over tables and countertops, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of large dust volume and unadjustable efficiency, and achieve the advantages of less dust volume, shortening production cycle, and maintaining a clean working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

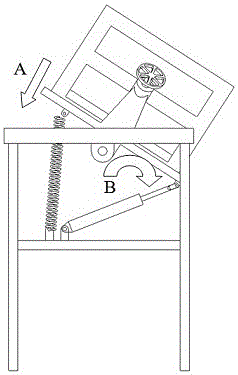

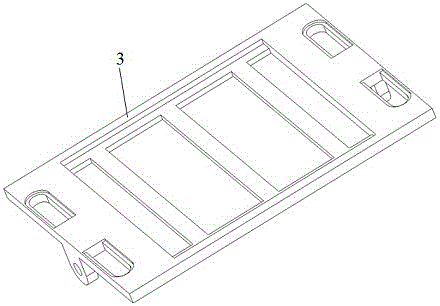

[0018] Such as figure 1 As shown in -3, due to the harsh working environment, before the device works, it is necessary to focus on checking the connection of the overturning hydraulic cylinder 8 and the return spring 9, and at the same time ensure that the parts are reliably connected to avoid safety accidents, and then put the material The box 4 is placed on the overturning platform 3, the material box 4 is fixed by rotating the compression handwheel 5 and the compression screw rod 6, and the overturning hydraulic cylinder 8 is started for trial operation, and the action of the return spring 9 and the overturning platform 3 is observed to be normal, and finally the Turning platform 3 is in horizontal state, and rotates compression handwheel 5 simultaneously to make the far-end of compression screw rod 6 close to fastening frame 7, thereby avoids material box 4 when it is placed and interferes with it, so far the device completes the preparation work.

[0019] After the calcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com