Digital full-automatic V-belt wrapping machine

A fully automatic, strapping machine technology, applied to belts, other household appliances, household appliances, etc., can solve the problems of workers with heavy physical labor and poor skills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

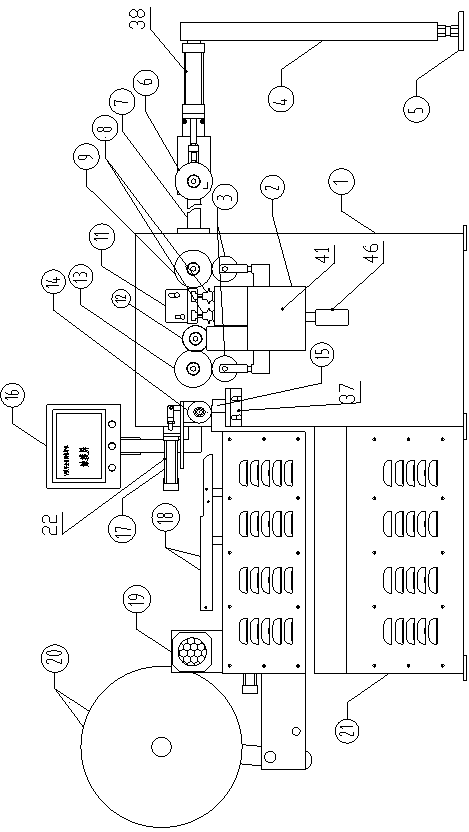

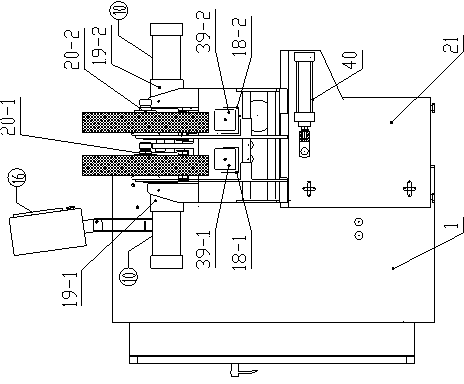

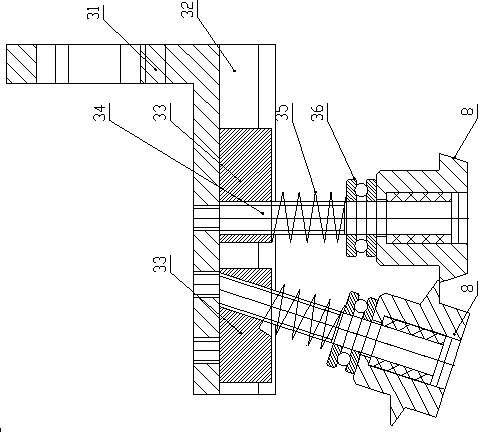

[0031] Such as figure 1 , 2 As shown, the present invention includes a cabinet 1, a feeding box 21, a cloth reel 20, a cloth guiding groove 18, a guiding device 19, a cutting mechanism 22, a bonding assembly 2 and a tensioning assembly. Material cloth reel 20, cloth guide groove 18, automatic cutting assembly 22, bonding assembly 2 are all arranged on the feeding cabinet 1, and tensioning assembly is located at the right side of cabinet 1. Because what the present invention adopts is that two rolls of cloth are fed simultaneously, so the material cloth reel 20, the guiding device 19, and the cloth guide groove 18 are two, and are arranged side by side in parallel. The case 1 is also provided with a touch screen 16 . A roll of material cloth roll is wound on the material cloth reel 20 .

[0032] This machine comprises front drive wheel 13, intermediate drive wheel 9, rear driven wheel 6, nose 11 that are located on the cabinet 1. Front driving wheel 13, middle driving wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com