Inserting cutting type variable diameter banana shaft removing and combing cutter self-adaptive to diameter of banana spike rod

An self-adaptive and diameter-variable technology, which is applied in the fields of application, food processing, food science, etc., can solve the problems of low banana processing efficiency, long processing cycle, and inability to comb bananas, etc., to achieve self-adaptive diameter and smooth cross-section of combing , Guarantee the effect of combing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

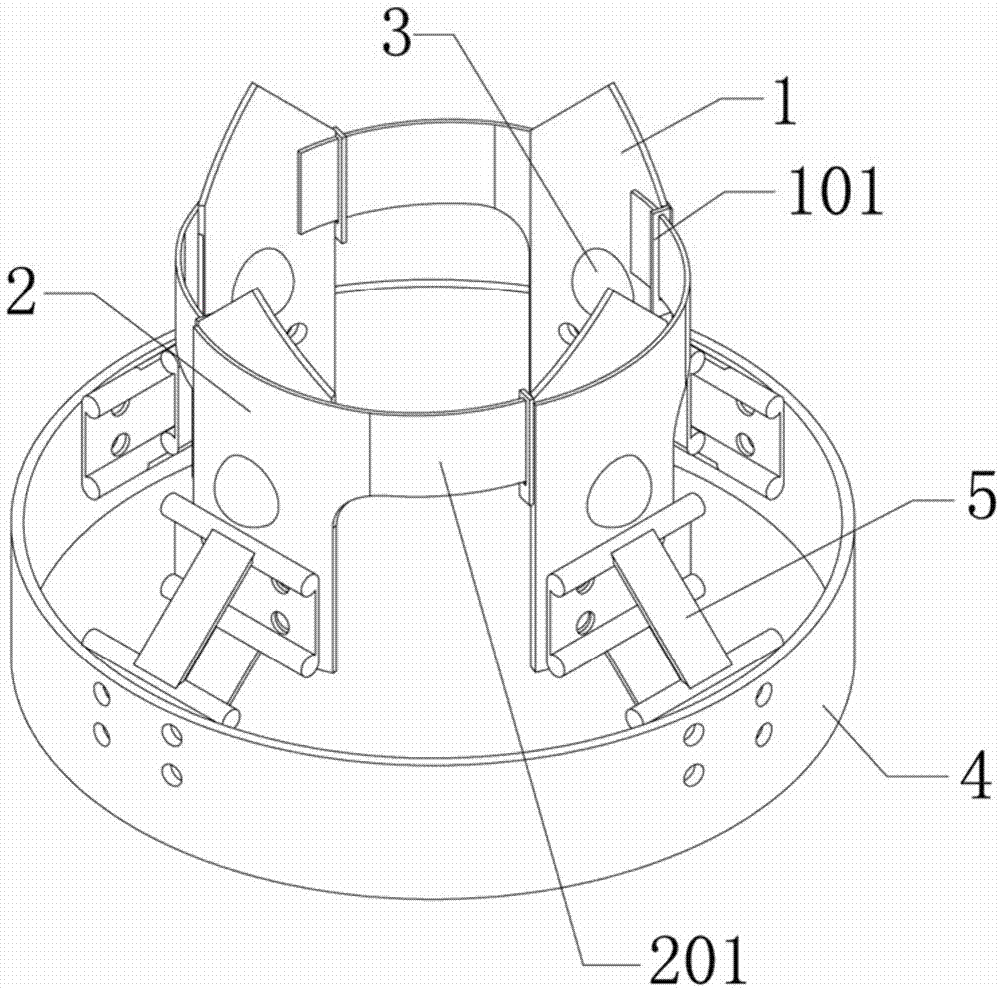

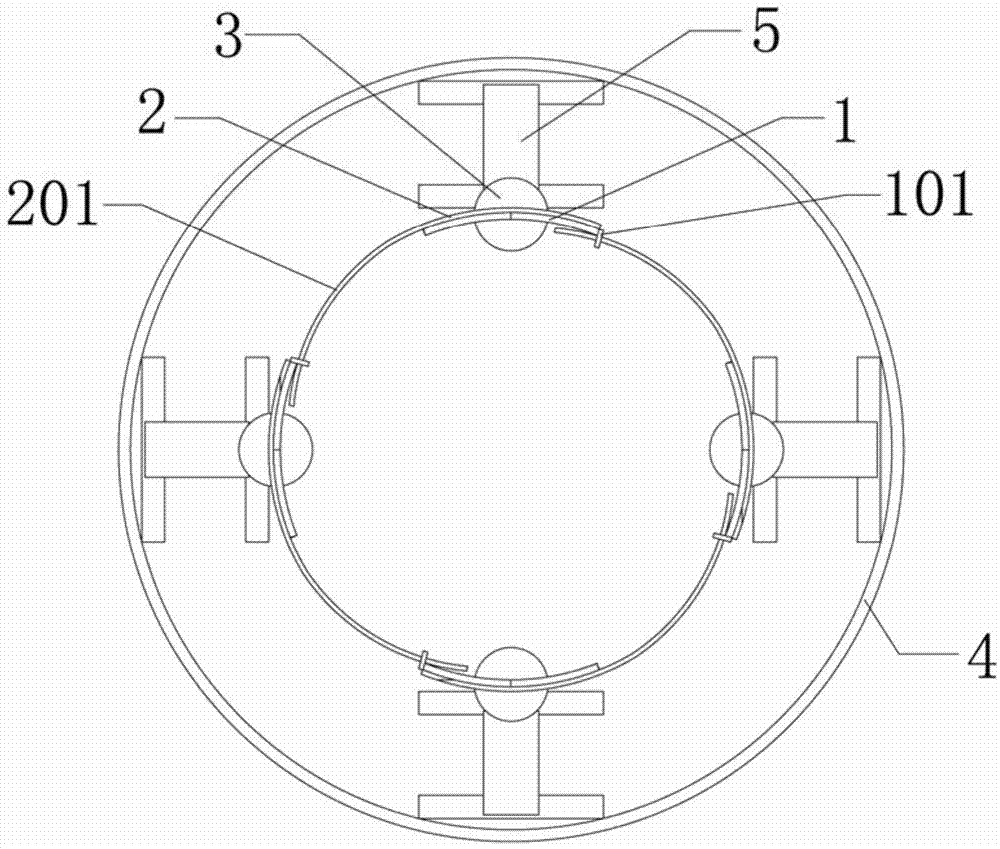

[0023] see figure 1 with figure 2 As shown, the plug-and-cut variable-diameter banana deshafting and combing cutter that can adapt to the diameter of the banana ear stalk described in this embodiment is mainly used for mechanized banana combing, including hard combing blade 1, soft combing Blade 2, universal ball bearing 3 and overall circular frame 4, wherein, the knife arm 201 with a band blade is horizontally extended and formed on the upper side of the knife body of the soft falling comb blade 2, and at the same time, the hard A limit frame 101 through which the knife arm 201 can pass is correspondingly arranged on one side of the upper part of the knife body of the mass-comb blade 1 , and the shape of the limit frame 101 is a rectangle. There are four hard combing blades 1 and 2 of soft combing blades, and the blades of a hard combing blade 1 and a soft combing blade 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com