Two-dimensional floating mechanism used for pipeline detection

A floating mechanism and pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of inability to adapt to large deformation pipeline detection, poor adaptability and passability, etc., and reduce the risk of jamming , realize self-adaptation, improve passability and the best effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

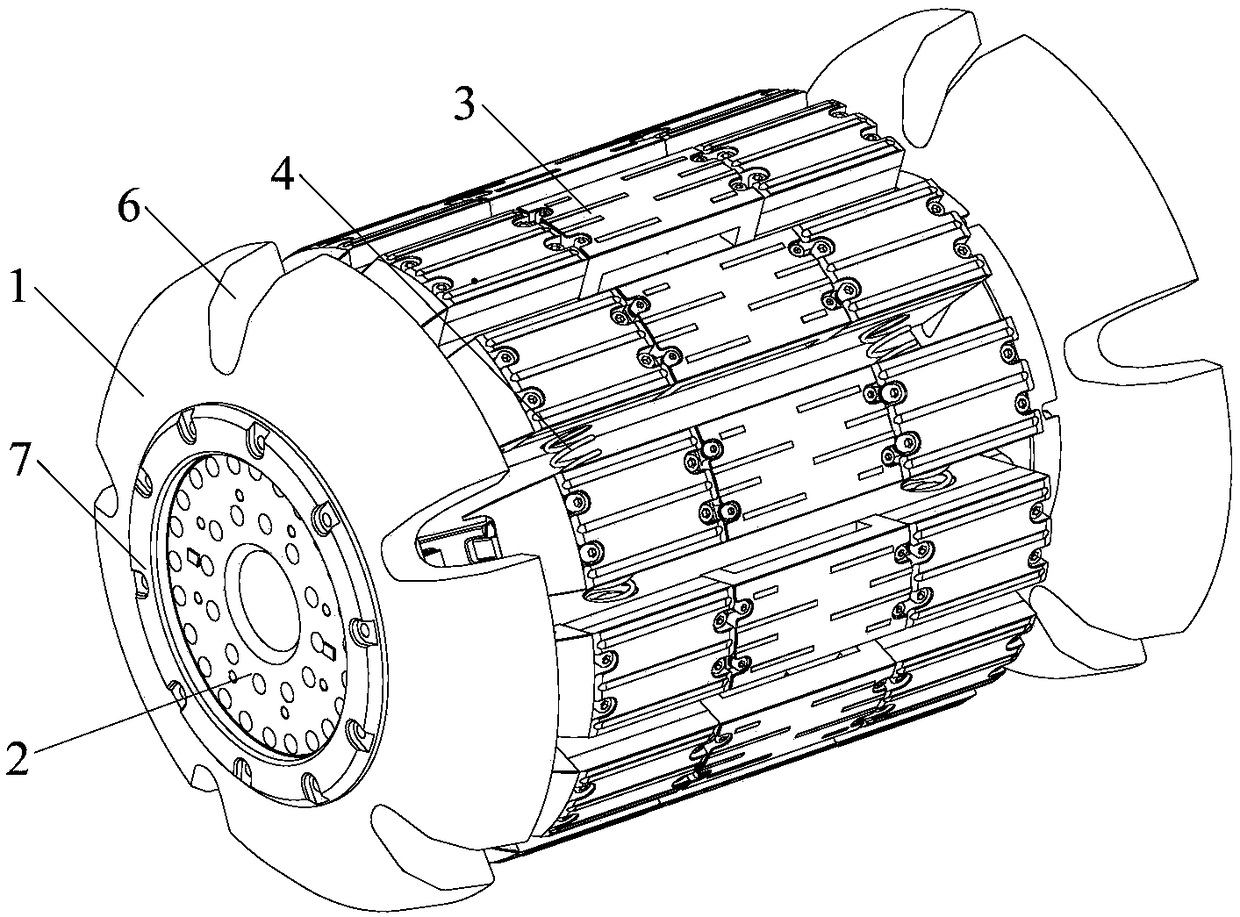

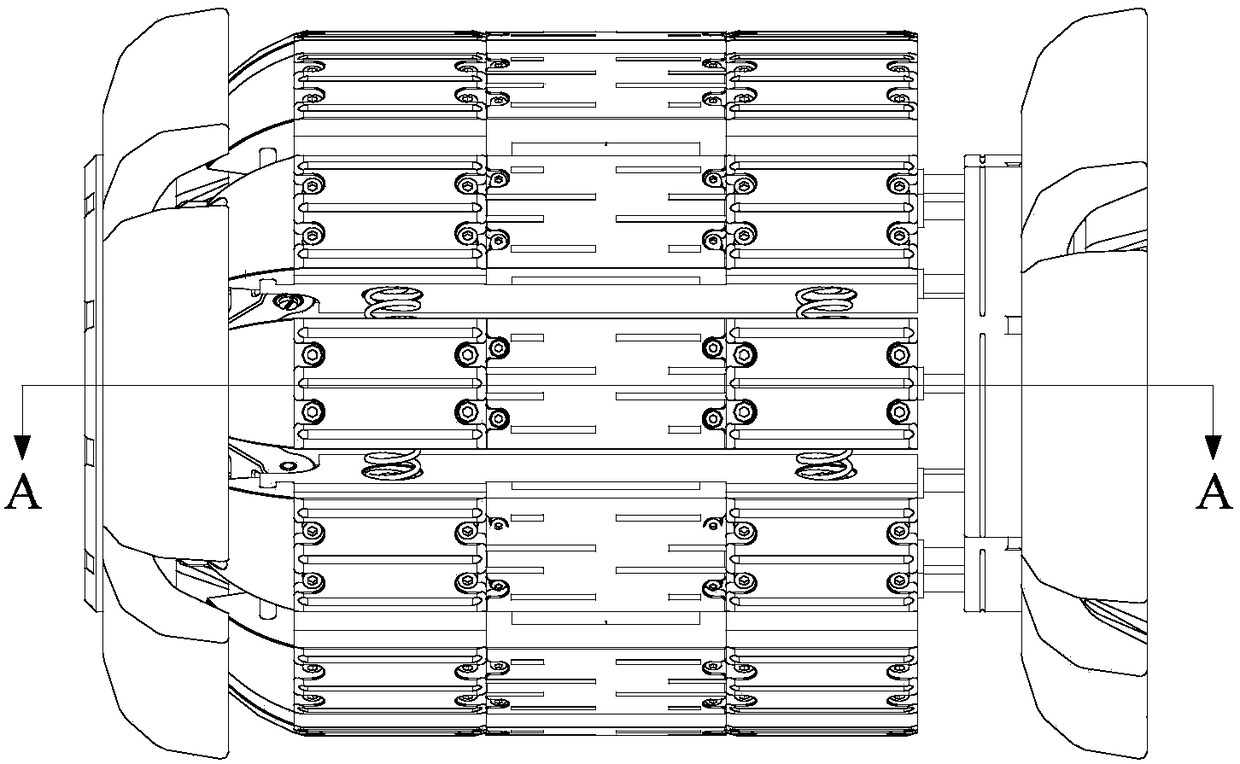

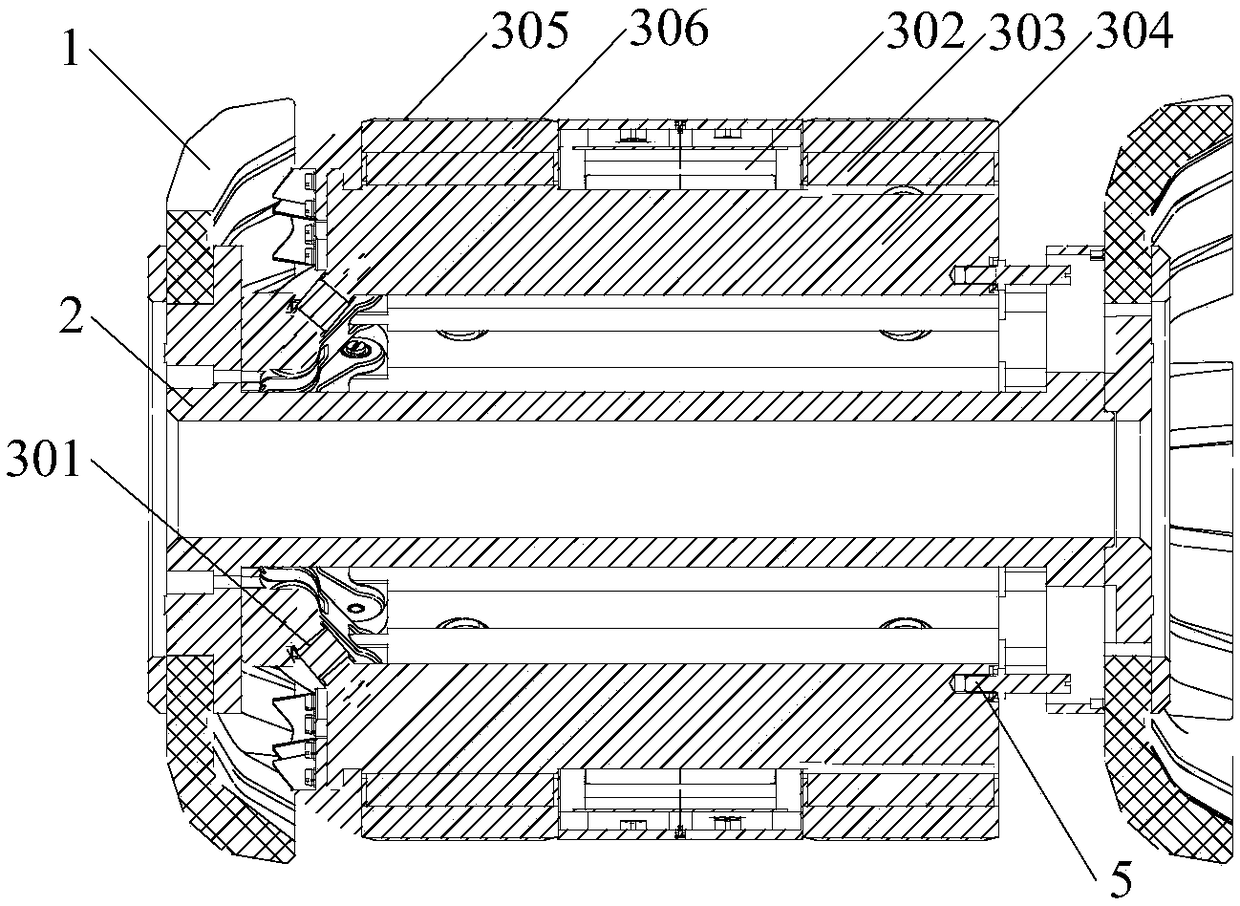

[0028] This embodiment provides a two-dimensional floating mechanism for internal detection of pipeline magnetic flux leakage, which can adapt to changes in the inner diameter of pipelines within a certain range, such as Figure 1 to Figure 3 As shown, it includes: a supporting cup 1 , a magnetic circuit module 3 and a central frame 2 . Among them, the magnetic circuit module 3 is sleeved on the outer edge of the central frame 2, and the magnetic circuit module 3 can float two-dimensionally relative to the central frame 2 (moving along the axial and radial directions of the central frame 2), and the magnetic circuit module 3 is always in contact with the central frame 2. The inner wall of the pipe is attached, the magnetic circuit module 3 generates a magnetic field, and generates a magnetic flux leakage signal to the defective pipe; the supporting cup 1 is sleeved on both ends of the central frame 2 in a forward direction, and the edge of the supporting cup 1 is always in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com