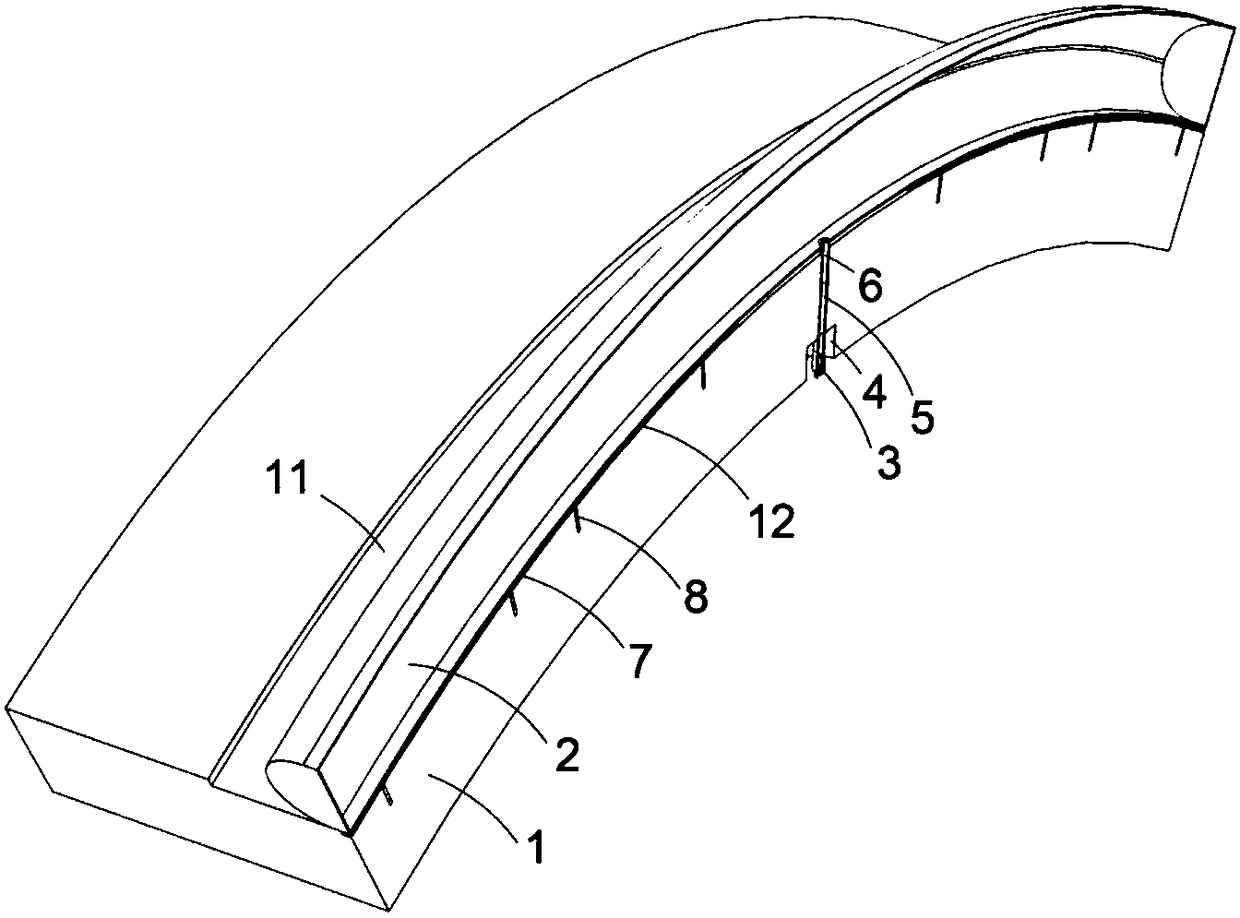

Patents

Literature

62results about How to "Reduced jam risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

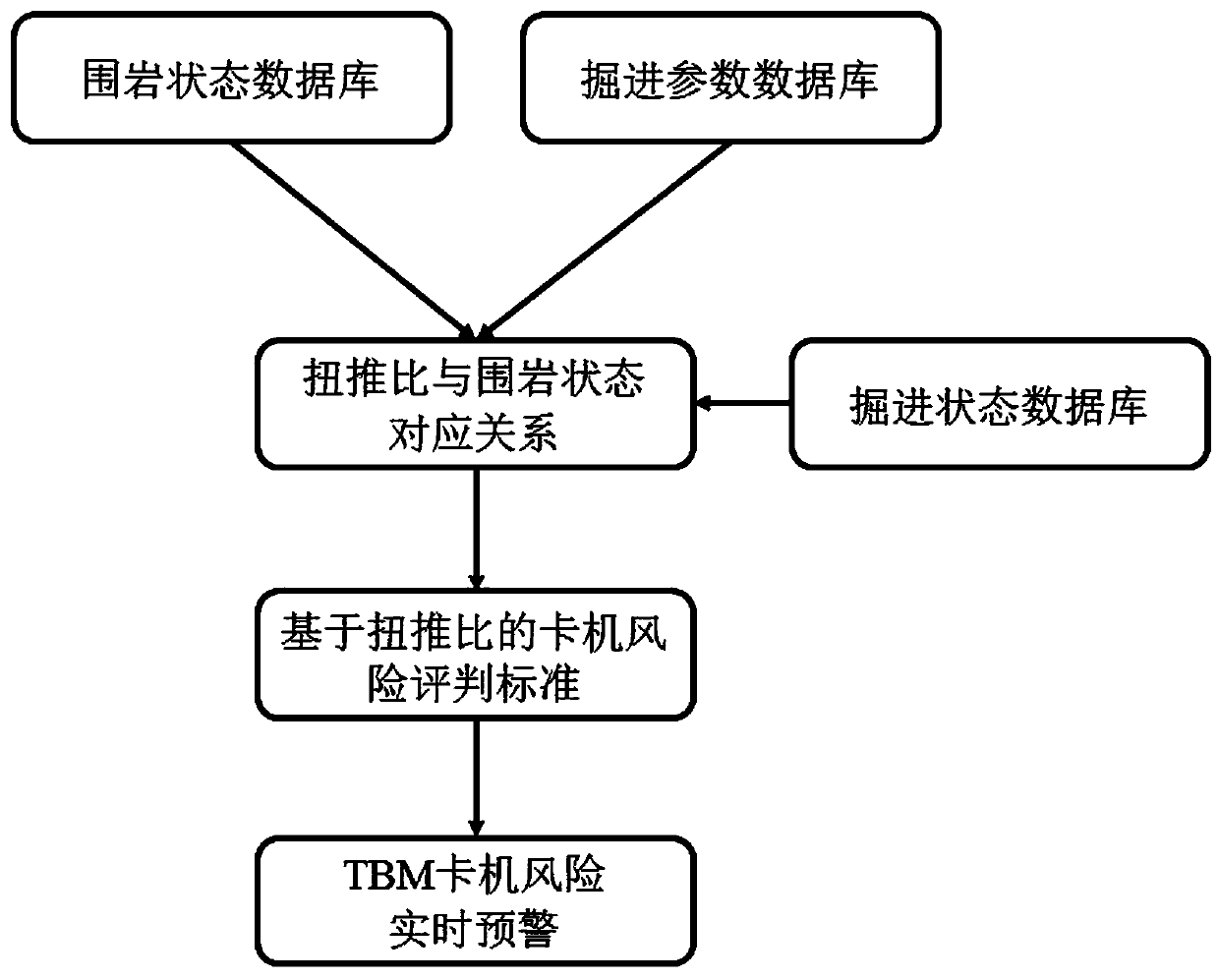

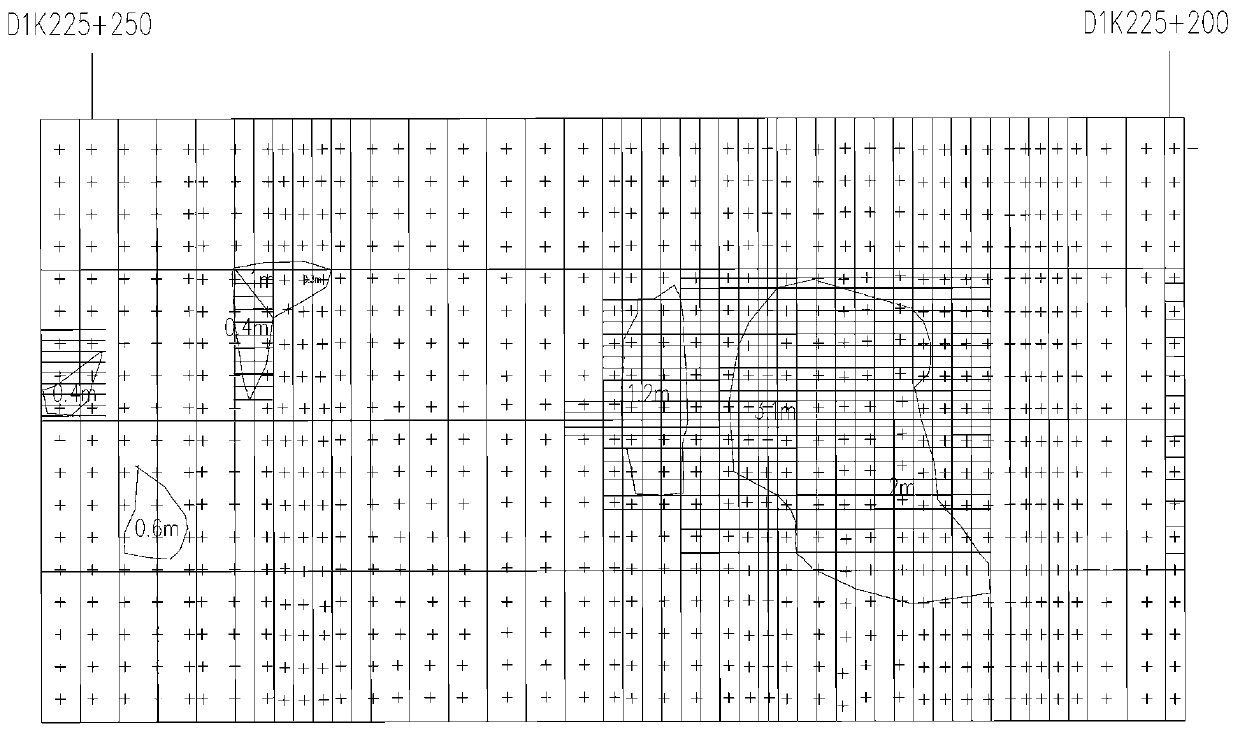

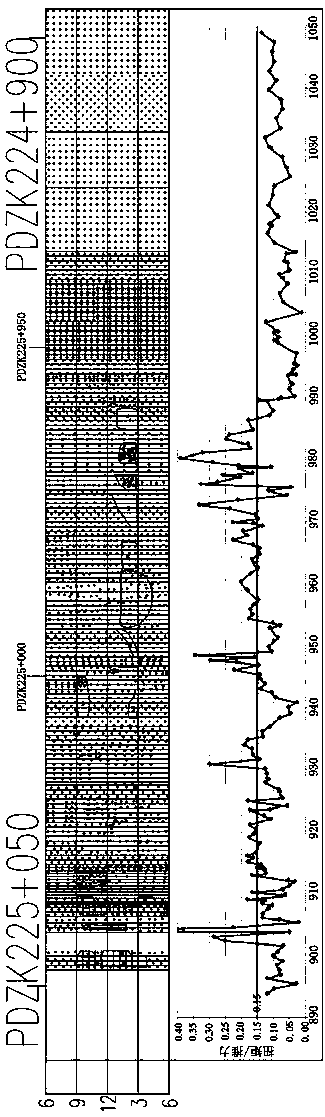

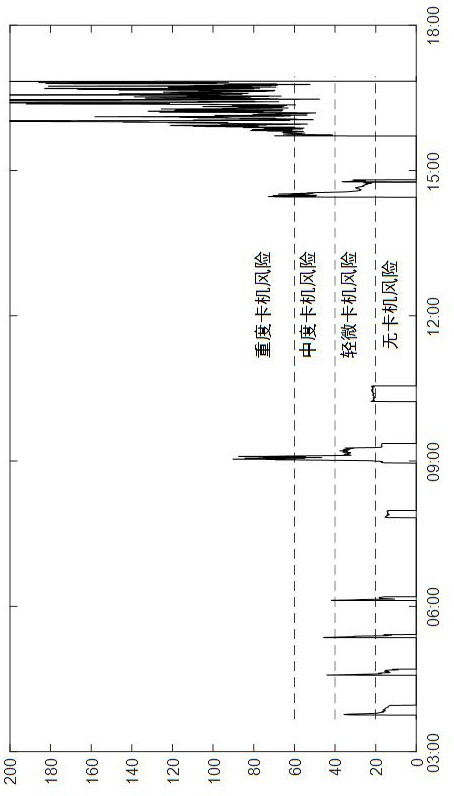

Broken stratum TBM jamming risk early warning method based on torque-to-push ratio

ActiveCN110675092AAvoid machine jamsTimely and effective grasp of machine card riskMining devicesResourcesData acquisitionStructural engineering

The invention discloses a broken stratum TBM jamming risk early warning method based on a torque-to-push ratio, and the method comprises the following steps of S1, collecting the surrounding rock state data through exposing a shield surrounding rock geological sketch; S2, acquiring the TBM tunneling parameter data through a TBM data acquisition system; S3, establishing a corresponding relation between the torque-to-push ratio and the surrounding rock state; S4, acquiring the tunneling state data through a TBM tunneling report recorded by a main driver; S5, establishing a jamming risk evaluation standard based on the torque-to-push ratio; and S6, through the TBM real-time tunneling parameters, according to the judgment standard, judging the TBM jamming risk, and carrying out the real-time early warning. According to the present invention, the tunnel surrounding rock state, the tunneling state of the TBM and the possible jamming risk of TBM tunneling can be effectively mastered in time,so that the constructors can master the information at all aspects in time and take the TBM jamming prevention measures in time, the jamming risk of the TBM can be effectively reduced, and the construction efficiency of the TBM is improved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

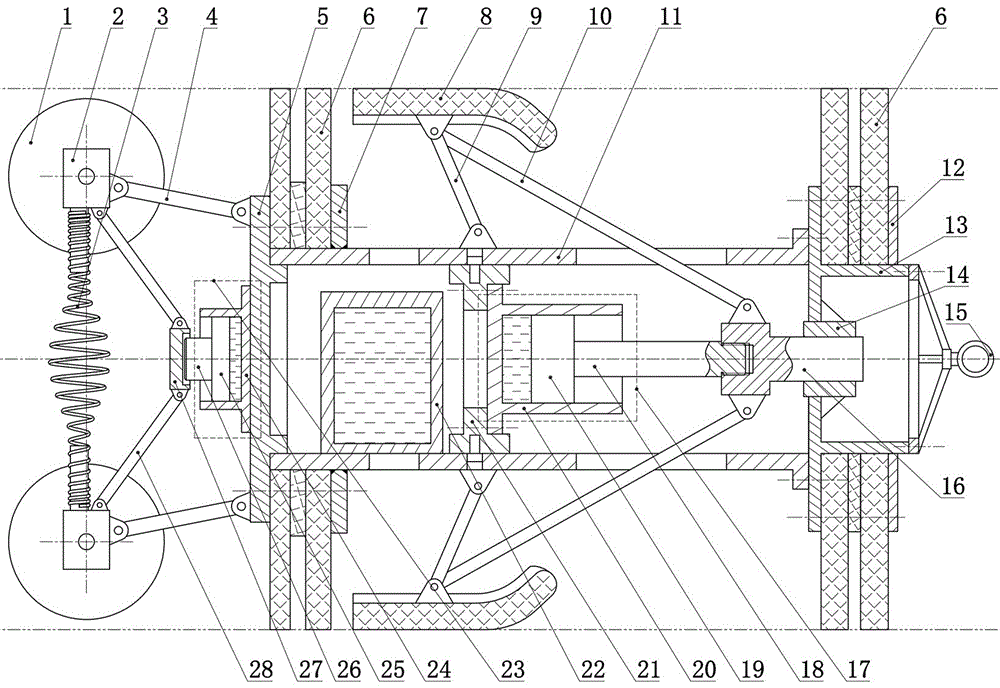

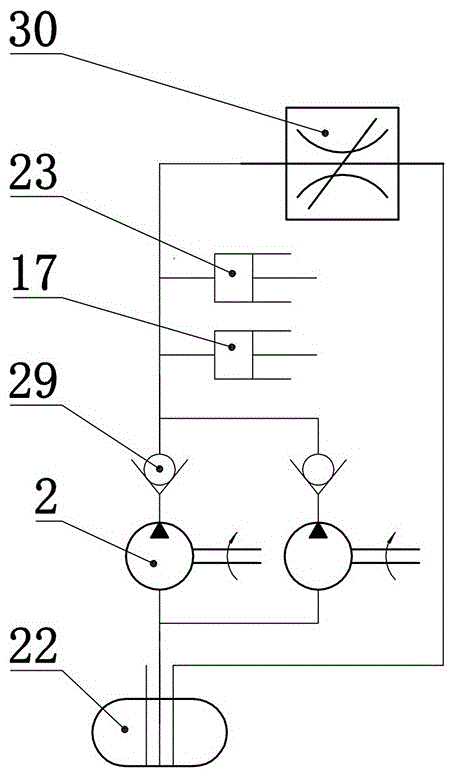

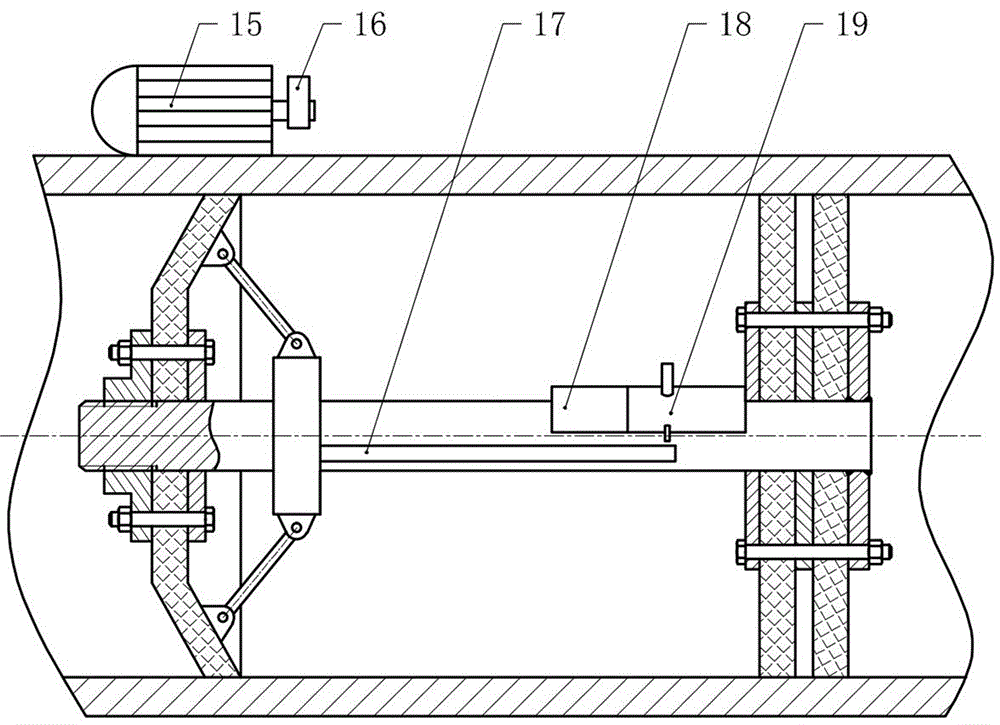

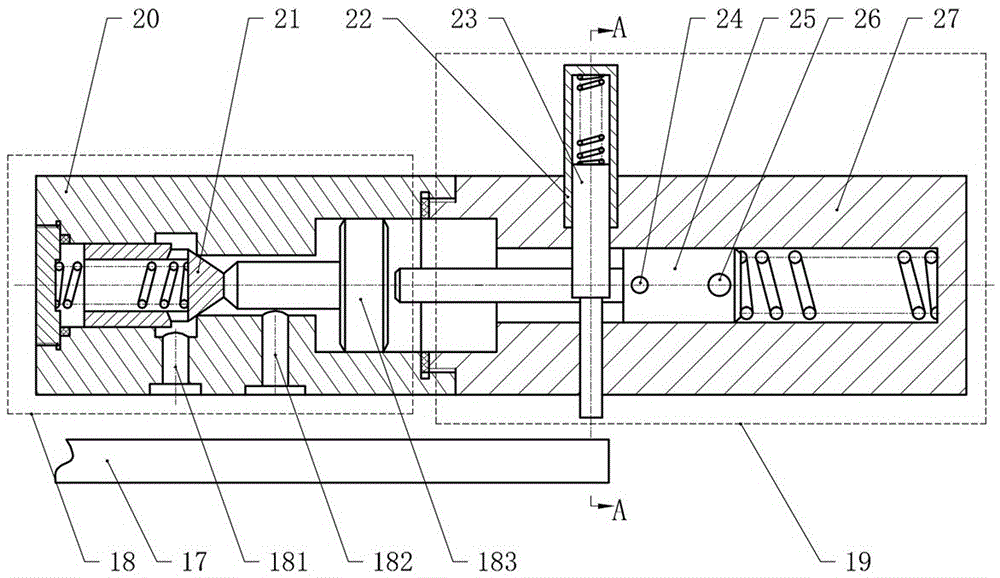

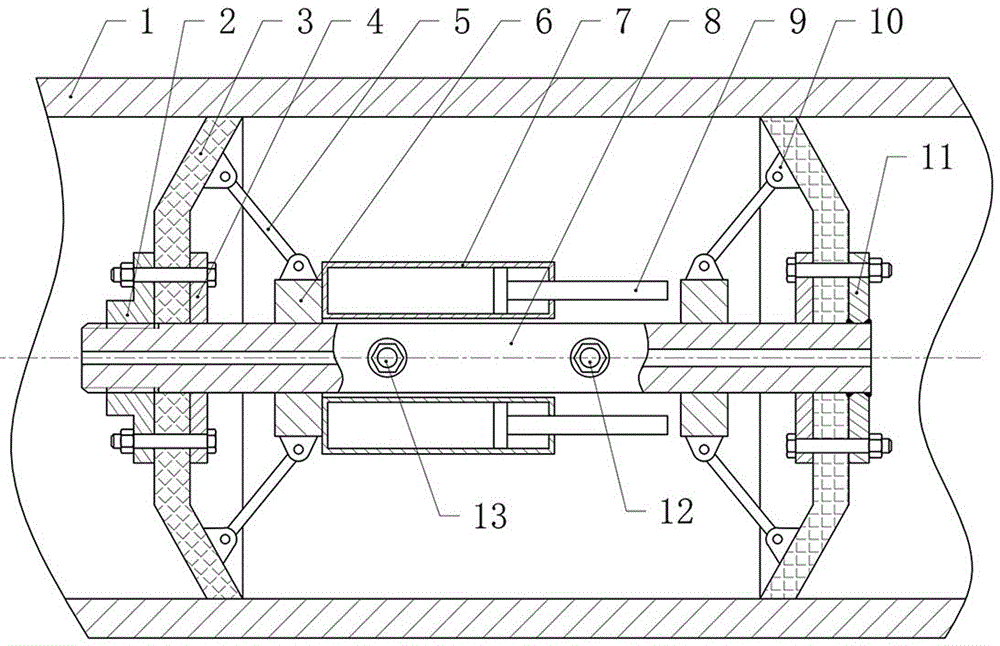

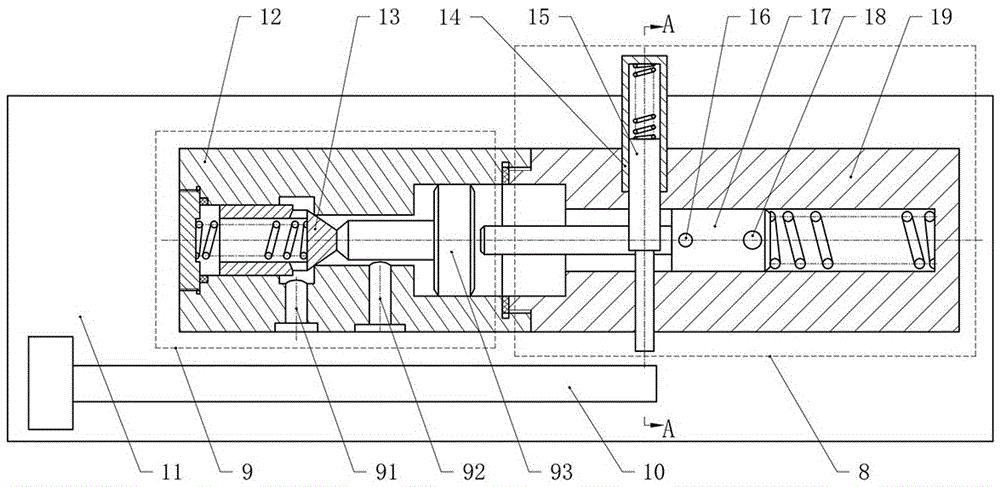

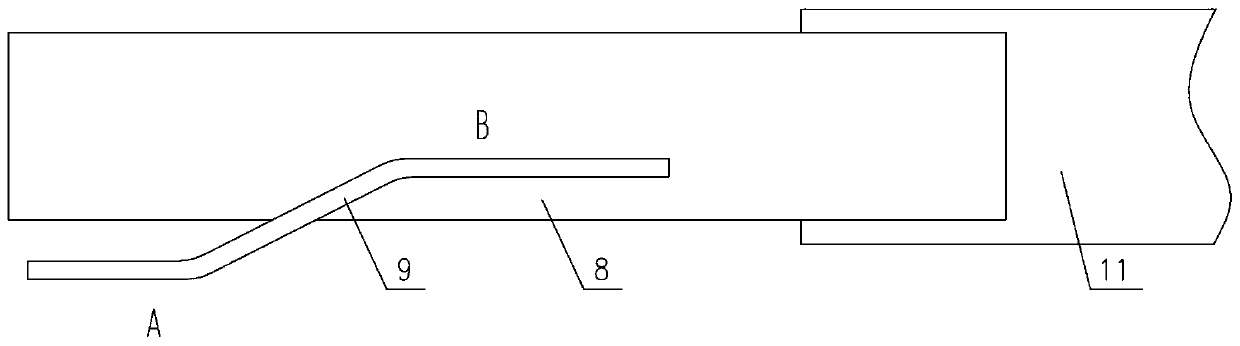

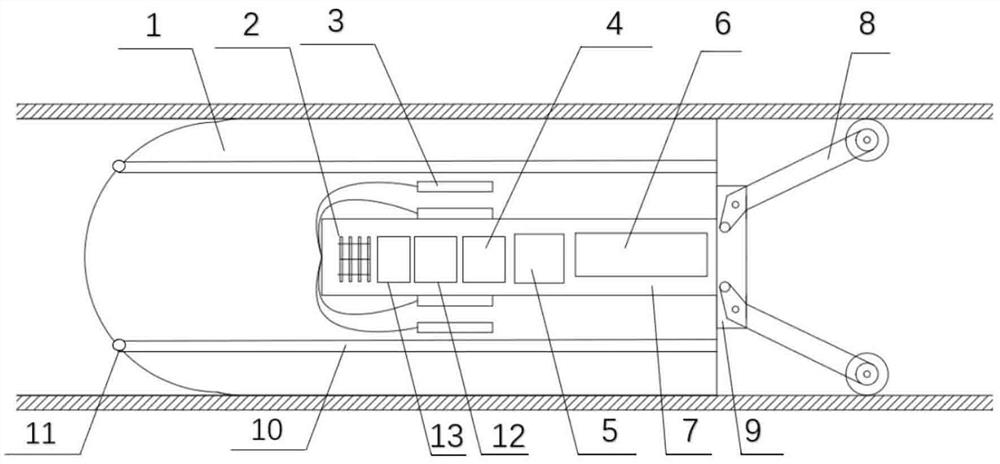

Pipe cleaning device with automatic brake device

InactiveCN106424032AOverall size is largeReduced jam riskHollow article cleaningVelocity controllerFuel tank

The invention relates to a pipe cleaning device with an automatic brake device. The pipe cleaning device is used for pipe cleaning work. The defect that an existing speed adjusting pipe cleaning device is poor in generality in a pipe is overcome. According to the technical scheme, leather bowls are arranged at the two ends of a cylinder, one end of a connecting rod B is hinged to a brake piece, the other end of the connecting rod B is hinged to the cylinder, one end of a connecting rod C is hinged to the brake piece, the other end of the connecting rod C penetrates a groove hole of the cylinder and is hinged to a mandrel, a brake oil cylinder is arranged in the cylinder, a piston rod of the brake oil cylinder is connected with the mandrel, rollers are mounted on input shafts of hydraulic pumps, a supporting spring is arranged between the two hydraulic pumps which are arranged at the rear end of the cylinder, an oil tank is arranged in the cylinder, oil suction openings of the hydraulic pumps are connected to the oil tank, oil outlets of the hydraulic pumps are connected to a throttling valve, an oil returning opening of the throttling valve is connected to the oil tank, and the front end of the throttling valve is connected with the brake oil cylinder. A pipe cleaning device speed controller is free of an electric appliance element, safety and reliability are achieved, and the device has the high generality in the pipe.

Owner:SOUTHWEST PETROLEUM UNIV

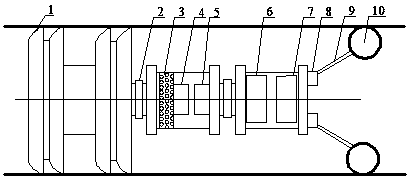

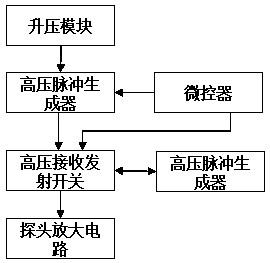

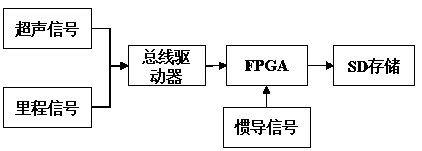

Ultrasonic detection device for oil pipeline defect

PendingCN110045024AImplement detectionReduce the amount of defective dataAnalysing solids using sonic/ultrasonic/infrasonic wavesPipeline systemsElectrical batteryUniversal joint

The invention relates to an ultrasonic detection device for an oil pipeline defect. The ultrasonic detection device comprises a pipeline clean section, a defect detection section, and a power supply section, wherein the pipeline clean section and the defect detection section as well as the defect detection section and the power supply section are separately connected through universal joints, thepipeline clean section mainly comprises two pairs of petal-shaped leather cups that are staggered and overlaid, and is supported by spaced leather cups, when the leather cups are driven by pressure difference, the detection device advances towards the oil transfer direction; the defect detection section comprises three columns of ultrasonic sensors uniformly distributed in a circumferential direction, a probe signal processing system and an inertial navigation system; and the power supply section comprises a data storage system and a battery, the data storage system stores an ultrasonic signal, an inertial navigation signal and a mileage signal, and the battery powers a probe, inertial navigation and a mileage wheel. The ultrasonic detection device for the oil pipeline defect adopts an array probe, and analyzes primary echo by using an ultrasonic reflection single-pulse distance detection method so as to detect defects, thereby comprehensively detecting inner wall defects of the pipeline and effectively reducing defect data processing amount.

Owner:SOUTHWEST PETROLEUM UNIV

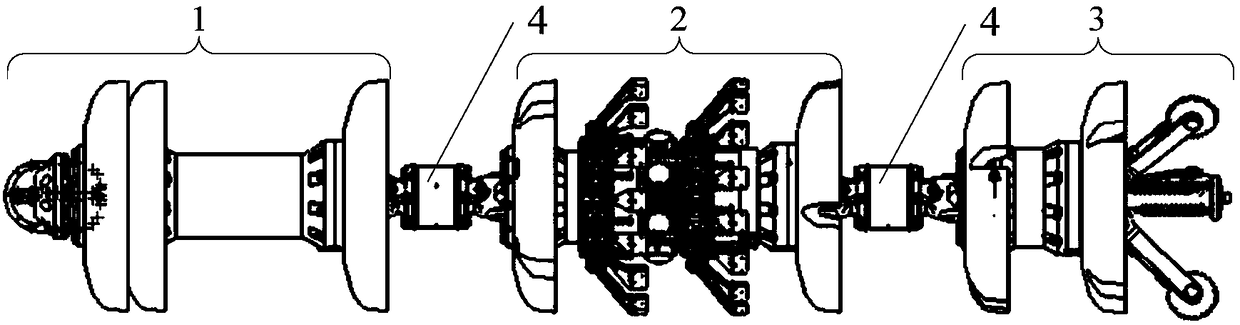

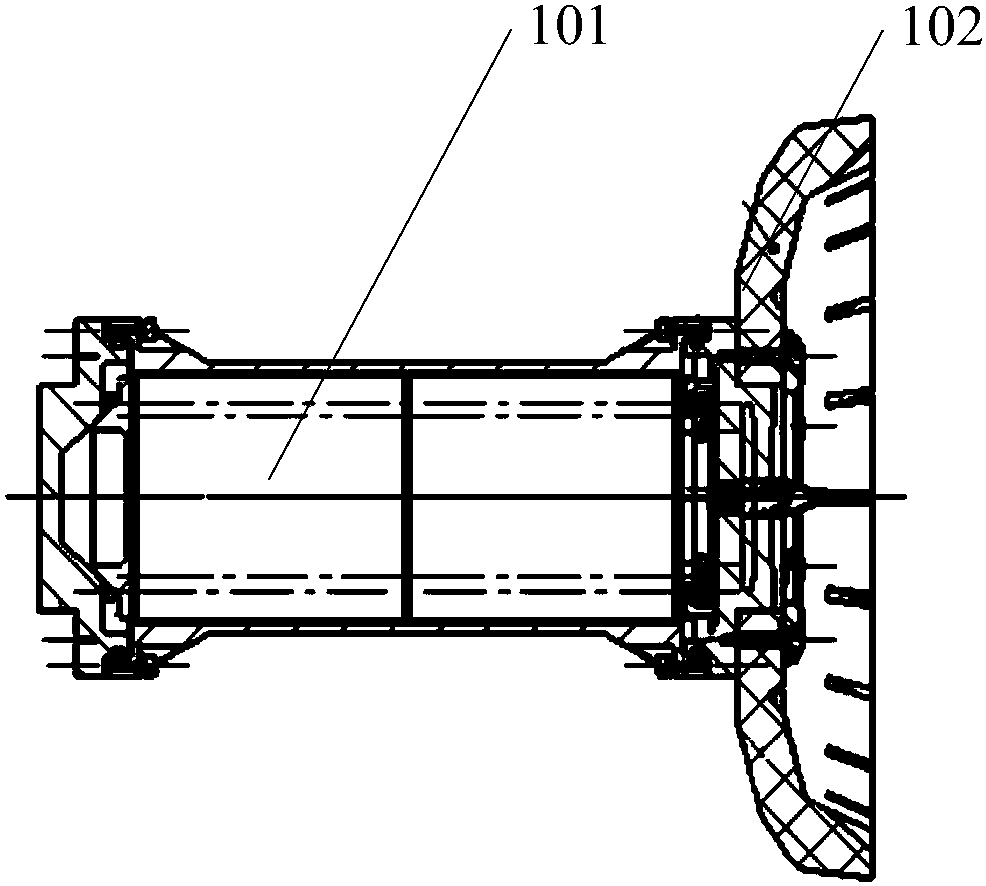

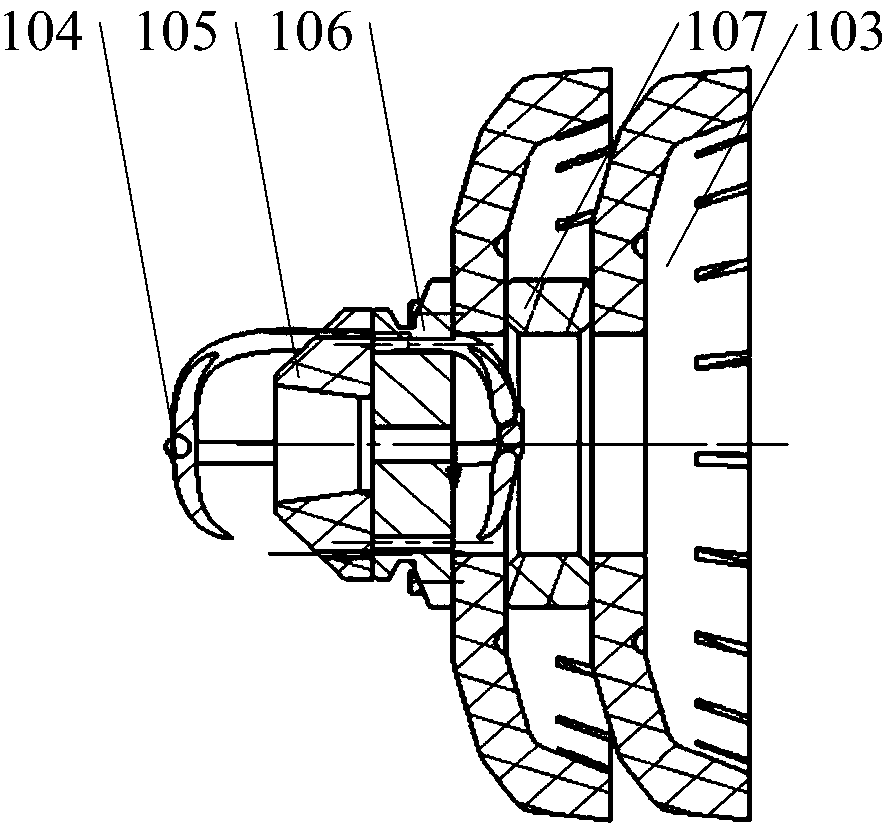

Deformation interior detector for big deformation

InactiveCN108180883AImprove passabilityImprove adaptabilityNavigation instrumentsInductorData recording

The invention discloses a deformation interior detector for big deformation, belongs to the technical field of pipe interior detectors, and solves problems that a deformation interior detector in theprior art is low in detection precision and cannot correct the mileage. The detector comprises an anti-collision power supply mechanism, a deformation measurement mechanism and a posture mileage measurement mechanism, wherein the anti-collision power supply mechanism, the deformation measurement mechanism and the posture mileage measurement mechanism are sequentially connected in a rotating manner. The deformation measurement mechanism comprises a central skeleton, an angle sensor, a data recording unit, and a plurality of swinging arm inductors which are distributed in the peripheral direction of the central skeleton. The swinging arm inductors are in rotating connection with the central skeleton, and the end parts of the swinging arm inductors make contact with the inner wall of a pipe.The detector provided by the invention can be used for detecting the deformation of the inner wall of the pipe.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

Drilling fluid for drilling of fractured igneous rock formation and preparation method of drilling fluid

The invention relates to a drilling fluid for drilling of a fractured igneous rock formation and a preparation method of the drilling fluid in the field of petroleum drilling. The drilling fluid is prepared from components in parts by weight as follows: 1,000 parts of water, 3-4 parts of drilling fluid bentonite, 2-3 parts of sodium carbonate, 2-3 parts of a polymer coating agent, 2-3 parts of potassium polyacrylate or a metal cation polymer, 5-10 parts of an organic amine inhibitor, 20-30 parts of an anti-sloughing reinforced wall fixation agent, 20-30 parts of sulfonated phenol formaldehyderesin, 5-10 parts of a sulfonate copolymer filtrate reducer, 20-30 parts of walchowite, 10-20 parts of an anti-salt and temperature-resistant fluid loss agent, 20-40 parts of superfine calcium carbonate, 50-70 parts of potassium chloride, 0-10 parts of an organic anti-friction compound and 10-20 parts of a nano-micro blocking agent, and the weight is increased to 1.30-1.85 g / cm<3> with a density weighting agent. The drilling fluid has good temperature resistance and lubricating property and excellent inhibition property and anti-sloughing wall fixation property and can effectively prevent thefractured igneous rock formation from collapsing; the rock carrying capability of the drilling fluid can be substantially improved, repeated grinding of larger falling blocks nearby a drill bit is prevented, the frictional resistance is reduced, the mechanical drilling speed is increased, and underground safety is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pipeline plugging device with resonance switch

The invention relates to a pipeline plugging device with a resonance switch, and the pipeline plugging device is used for plugging a pipeline cut-off part during welding operation of a pipeline in use. According to the technical scheme adopted by the invention, a front end cover and a rear end cover are mounted at the end parts of a mandrel; a front leather cup is fixed to the front end cover; a rear leather cup is fixed to the rear end cover; a sliding sleeve is arranged in the middle of the mandrel in a sleeved manner; the side edge of the front leather cup and the sliding sleeve are connected by a supporting rod; an air cylinder is arranged between the sliding sleeve and the rear end cover; a vibrating rod is fixedly arranged on the sliding sleeve; a controllable one-way valve and a vibrating switch are mounted at the end parts of the vibrating rod. The pipeline plugging device is taken back in a hole shrinkage mode, so that resistance generated in a taking-back process can be reduced; the plugging device only comprises a mechanical system and an air pressure system, and does not have an electric control part, so that the use security on an oil-gas pipeline is higher.

Owner:SOUTHWEST PETROLEUM UNIV

Paper currency form detection method, paper currency form detection device, and self-service depositing and withdrawing equipment

PendingCN107845188AComprehensive forecastImprove accuracyCoin/currency accepting devicesPulp and paper industrySelf-service

Owner:SHENZHEN YIHUA COMP +2

Leather cup type pipeline plugging device

InactiveCN105864558AReduced jam riskImprove the safety of usePipe elementsEngineeringAtmospheric pressure

The invention relates to a leather cup type pipeline plugging device which is used for the welding operation of an in-service pipeline. The invention adopts the technical scheme that a front end cover and a rear end cover are mounted at the end part of a core shaft; a leather cup is fixed on each of the front end cover and the rear end cover; sliding sleeves sleeve the middle positions of the core shaft; the edges of the cups and the sliding sleeves are connected by supporting rods; an air cylinder is arranged between the two sliding sleeves. The leather cup type pipeline plugging device provided by the invention adopts a mechanical and pneumatic system and is free from an electric control part and higher in the use safety of an oil and gas pipeline; through necking recovery, the resistance in the recovery process is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

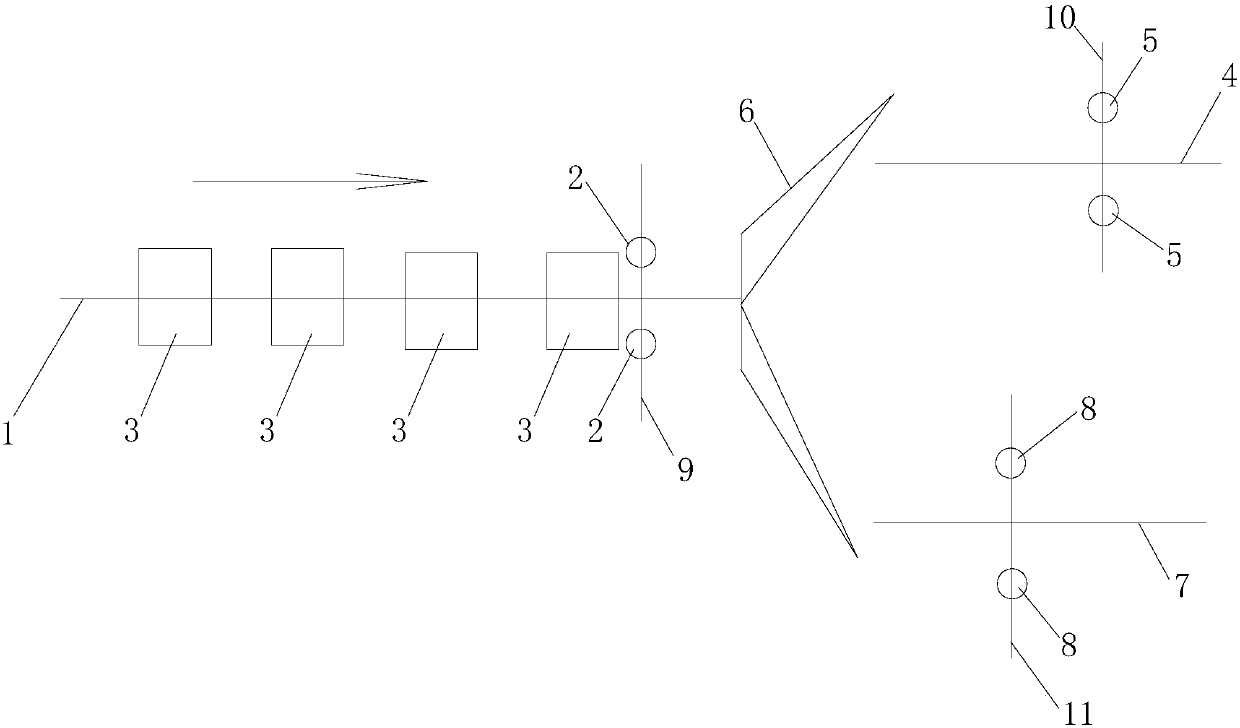

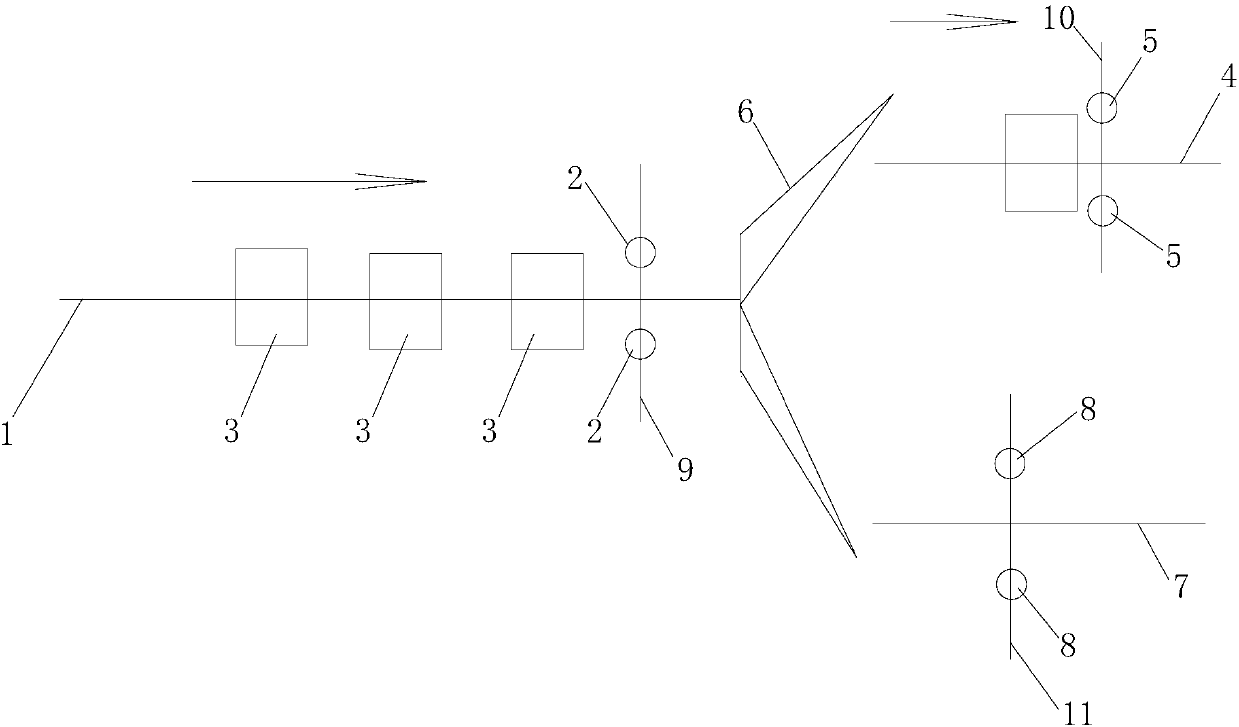

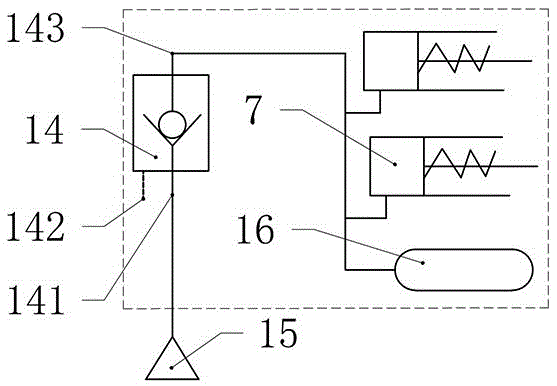

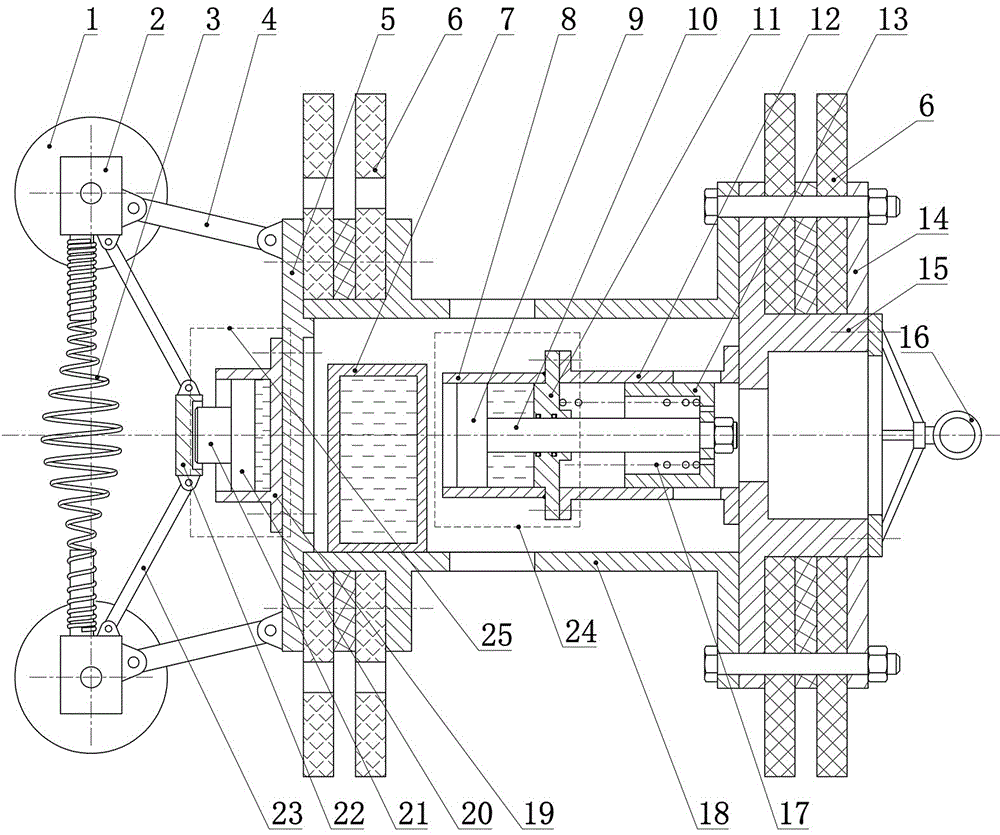

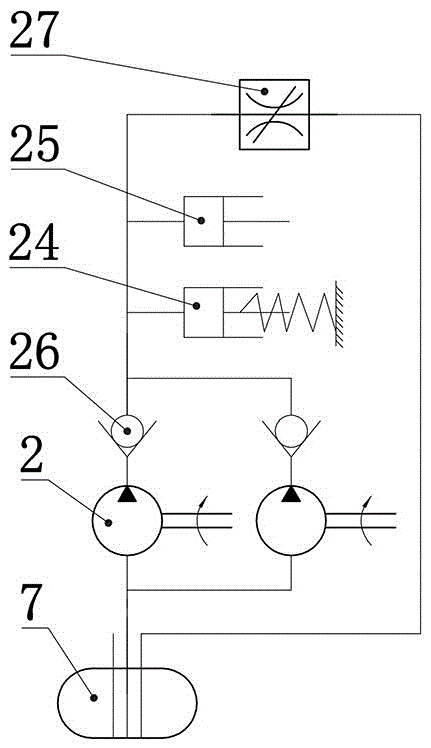

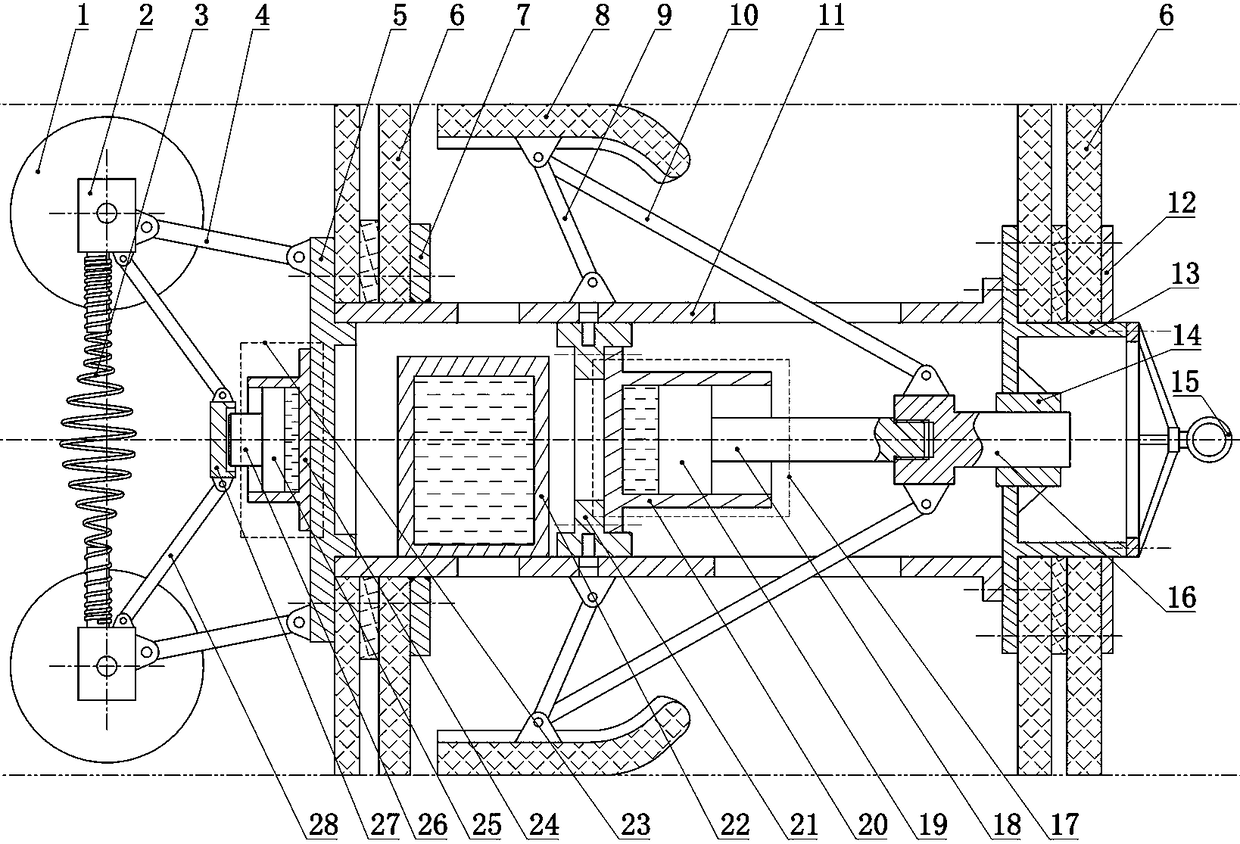

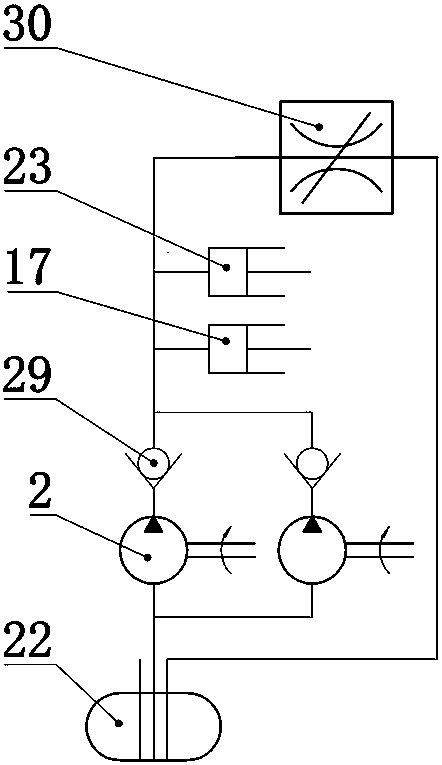

Hydraulic control bypass valve type speed governing pipe cleaning device

The invention relates to a hydraulic control bypass valve type speed governing pipe cleaning device which is used for pipe cleaning operation. The shortcoming that the passing ability of an existing speed governing pipe cleaning device pipe in a pipe is not high is overcome. According to the technical scheme, a front end cover and a back end cover are arranged on the two sides of a barrel, a cup is arranged on the barrel, a center cylinder is arranged in the barrel, a valve cylinder is arranged in the center cylinder, a speed governing oil cylinder is installed at the end of the center cylinder, and a piston rod of the speed governing oil cylinder is connected with the valve element; a roller is installed on a hydraulic pump input shaft, a supporting spring is arranged between two hydraulic pumps, and the hydraulic pumps are arranged on the outer side of the back end cover; and an oil tank is arranged in the barrel, hydraulic pump oil sucking ports are connected to the oil tank, hydraulic pump oil outlets are connected to a throttle valve, a throttle valve oil return port is connected to the oil tank, and the front end of the throttle valve is connected with the speed governing oil cylinder. By means of the cleaning device, a speed controller is free of electrical apparatus elements, and safety and reliability are achieved; the bypass valve structure is relatively large, and blockage is not likely to occur; and the passing ability of the device in the pipe is high.

Owner:SOUTHWEST PETROLEUM UNIV

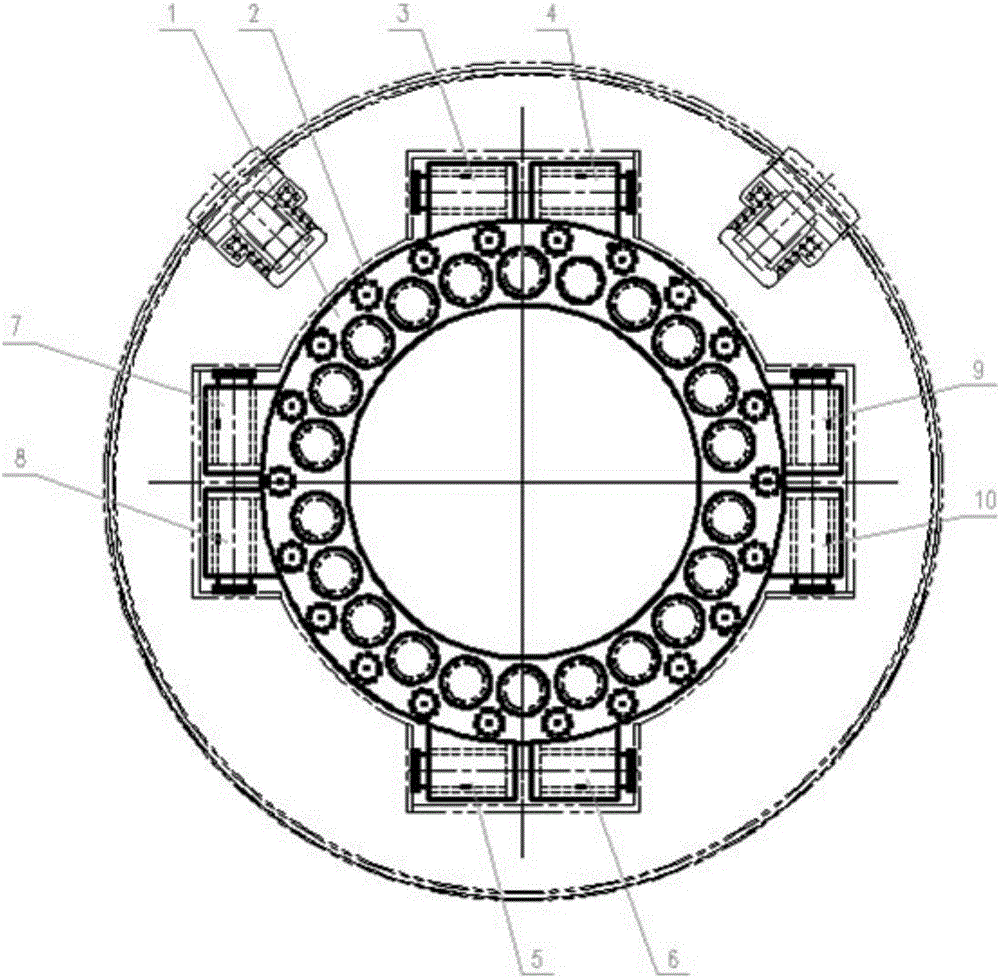

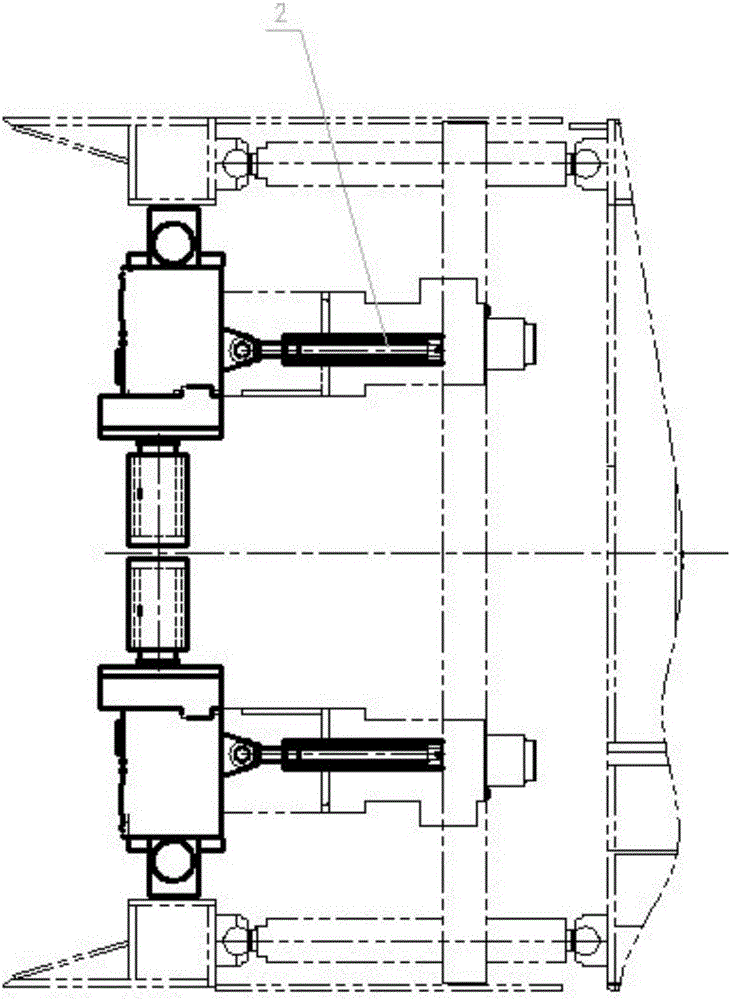

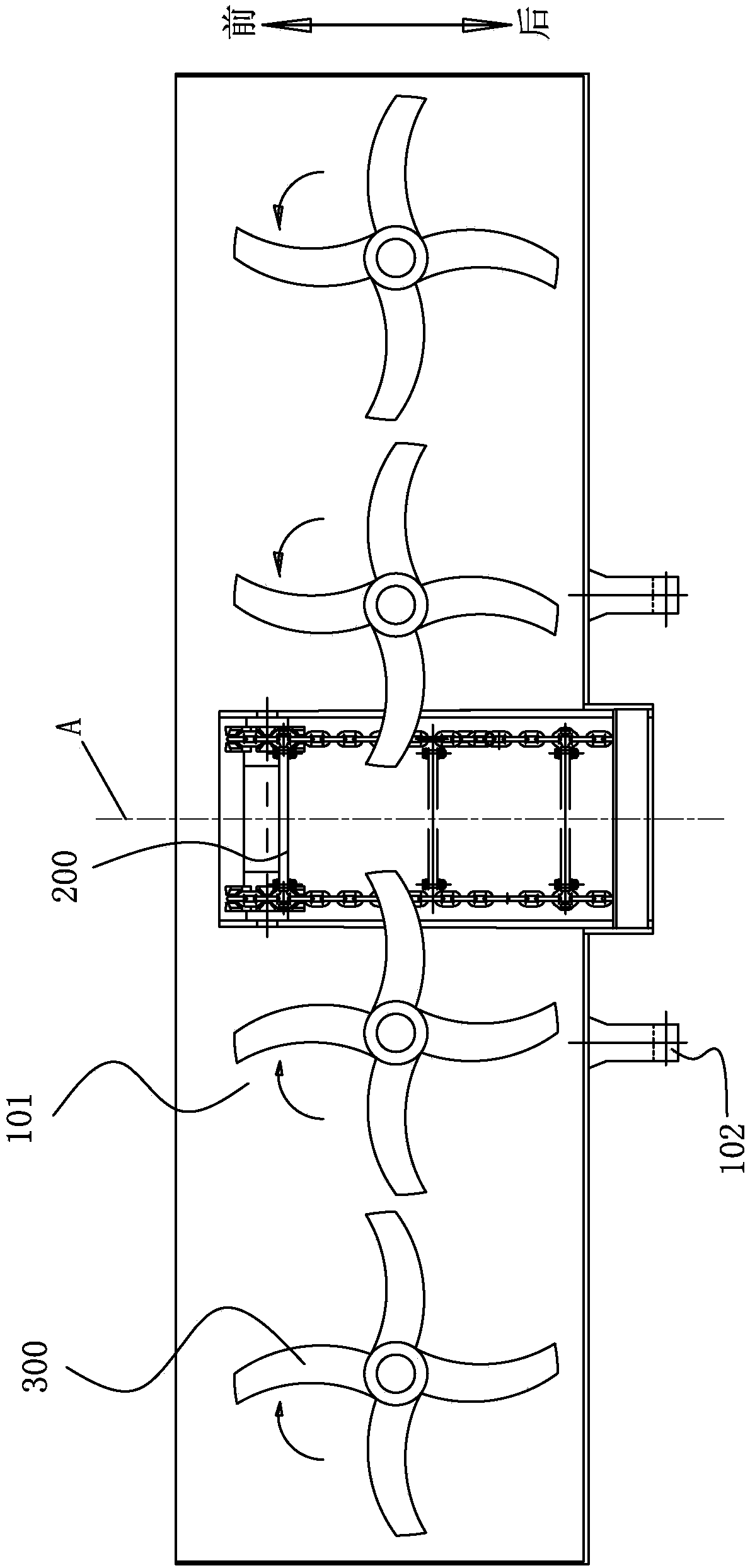

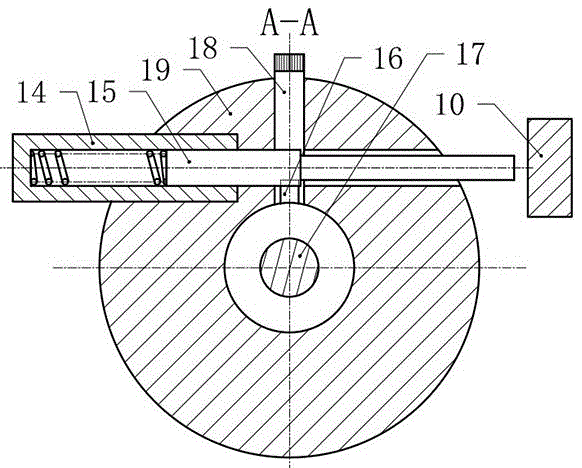

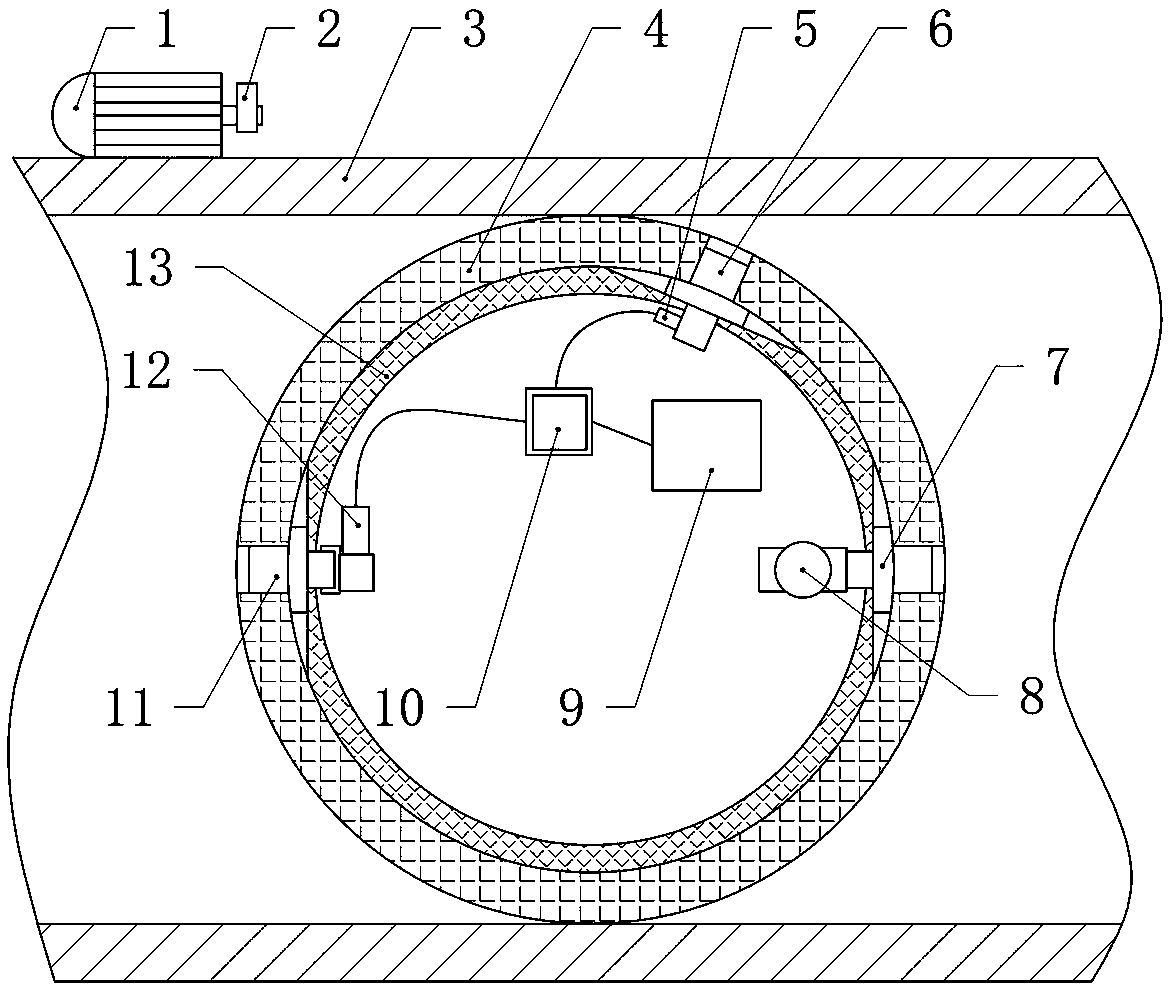

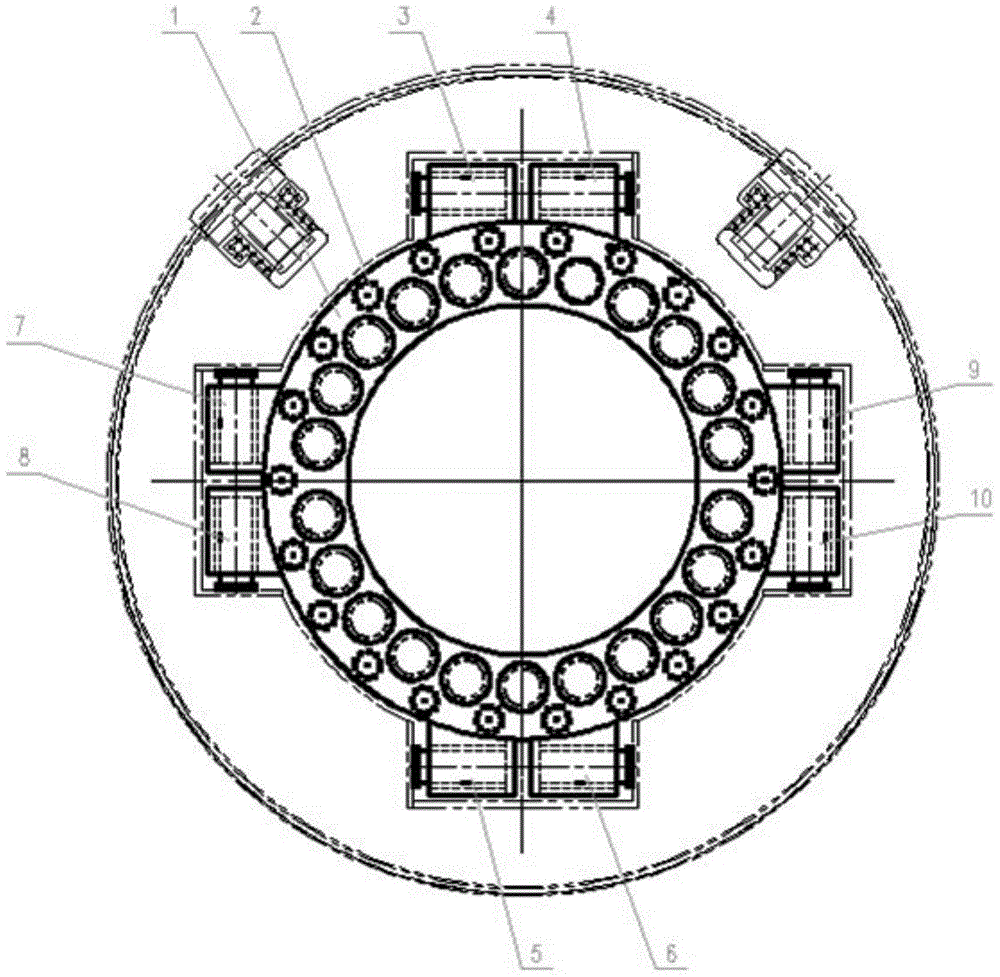

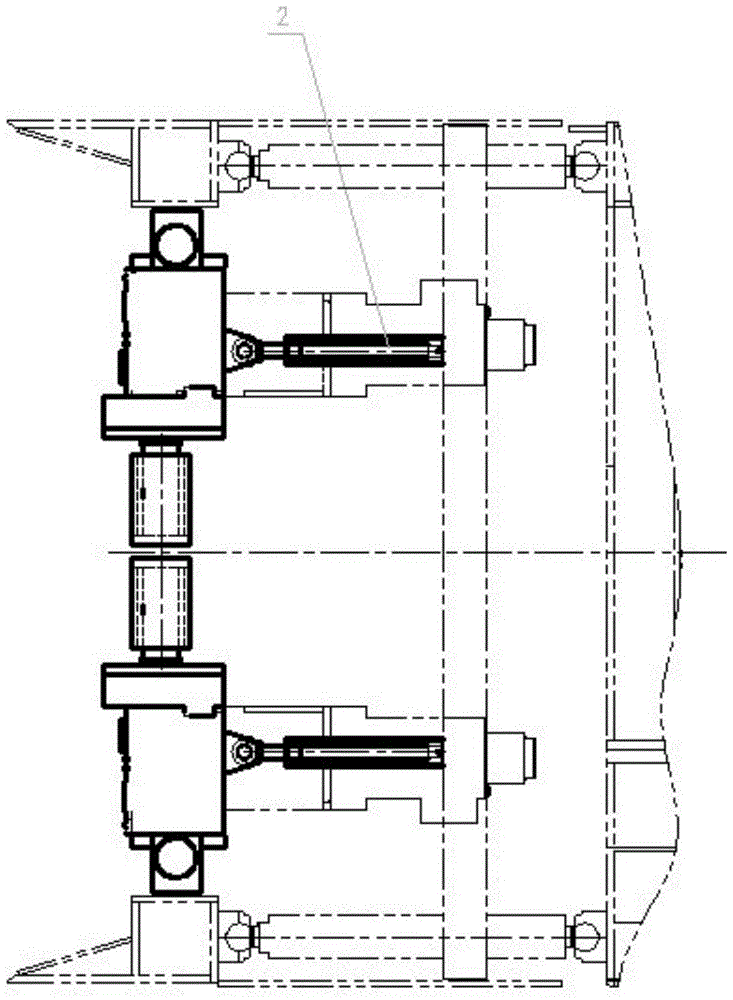

Tunnel header main driving omnibearing direction adjusting device

A tunnel header main driving omnibearing direction adjusting device used in the field of tunnel headers comprises a main driving shell body, a pushing oil cylinder, an upper left side torque oil cylinder, an upper right side torque oil cylinder, a bottom left side torque oil cylinder, a bottom right side torque oil cylinder, a left side upper end torque oil cylinder, a left side lower end torque oil cylinder, a right side upper end torque oil cylinder and a right side lower end torque oil cylinder. The main driving shell body is arranged in a front shield shell body. The front end of the pushing oil cylinder and the main driving shell body are fixed. The tail is fixedly connected with a supporting shield. The upper left side torque oil cylinder and the upper right side torque oil cylinder are fixed on the upper portion of the main driving shell body. The bottom left side torque oil cylinder and the bottom right side torque oil cylinder are fixed on the lower portion of the main driving shell body. A telescopic end is supported on the front shield shell body. The device is novel in structure and high in practicability, during a tunnel header construction process, header blocking risks can be lowered, direction adjusting is convenient, and the fact that a header carries out upward heading at any time can be kept at any time.

Owner:NORTHERN HEAVY IND GRP CO LTD

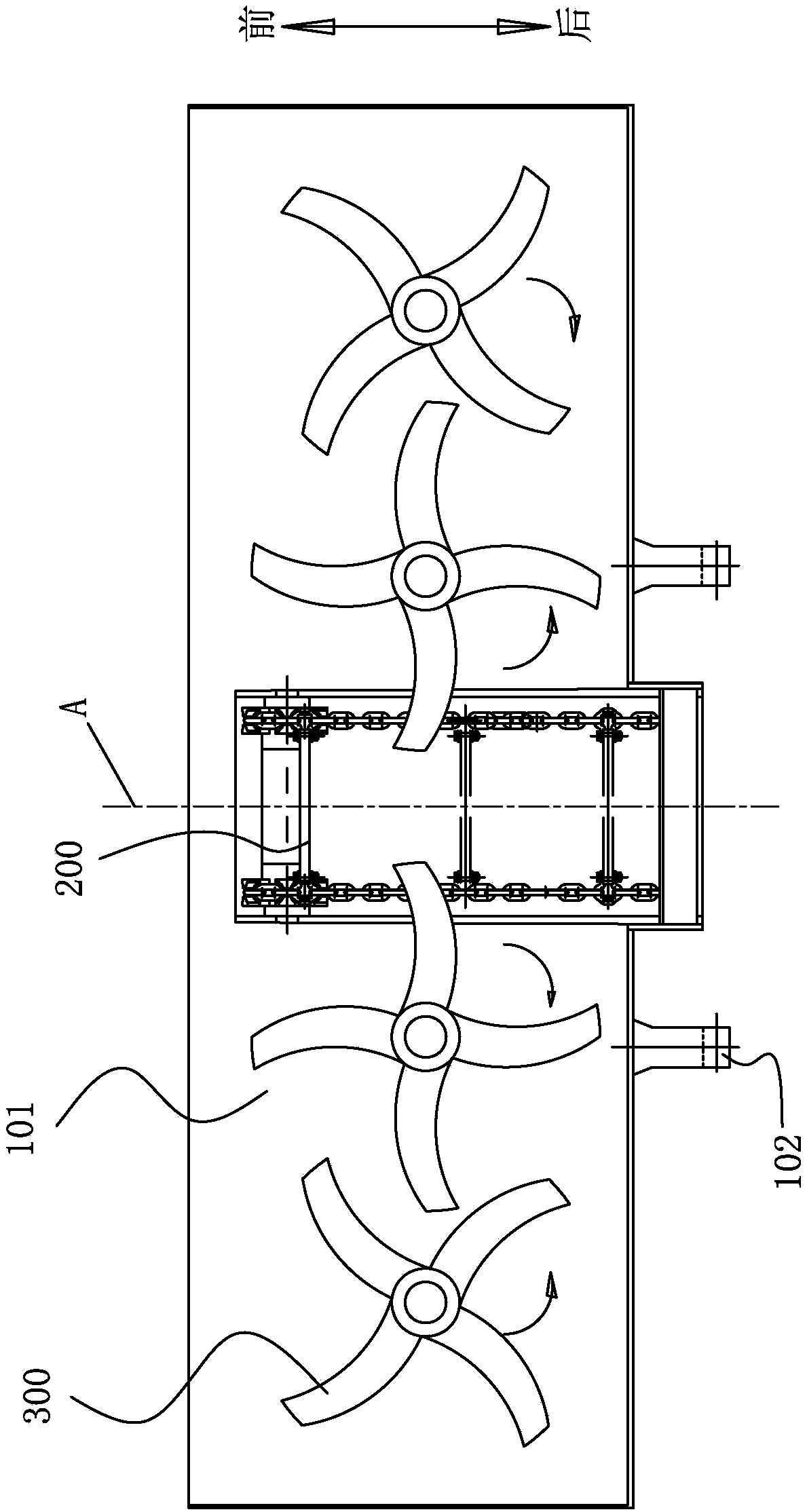

Cantilever-type heading machine

The invention discloses a cantilever-type heading machine. The machine comprises a chassis, a cantilever-type cutting part, a loading shovel plate, a scraping plate conveyor and star wheels or rakingclaws; the scraping plate conveyor is arranged between double crawler-type walking parts, and the conveyor tail of the scraping plate conveyor is arranged on the loading shovel plate; the star wheelsor raking claws are rotatably installed on the loading shovel plate and distributed at the two sides of the vertical center line of a chute at the conveyor tail of the scraping plate conveyor; three or more star wheels or raking claws are installed on the loading shovel plate, two or more star wheels or raking claws are distributed at one side of the scraping plate conveyor, one or more star wheels or raking claws are distributed at the other side of the scraping plate conveyor, and the adjacent star wheels or raking claws at the same side of the scraping plate conveyor are distributed left and right. According to the cantilever-type heading machine, when the loading width is increased, a loading device and the cantilever-type cutting part cannot interfere each other, and accordingly structural optimization of equipment is facilitated.

Owner:日照市上普重型装备股份有限公司

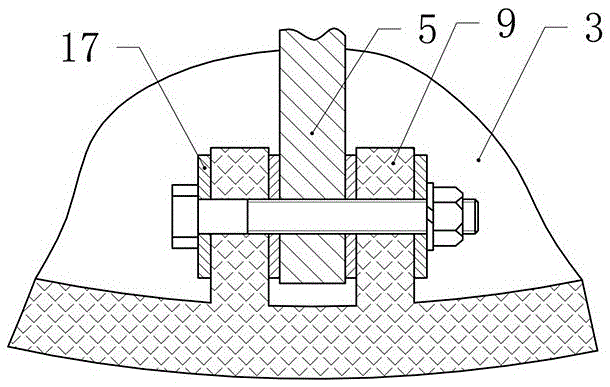

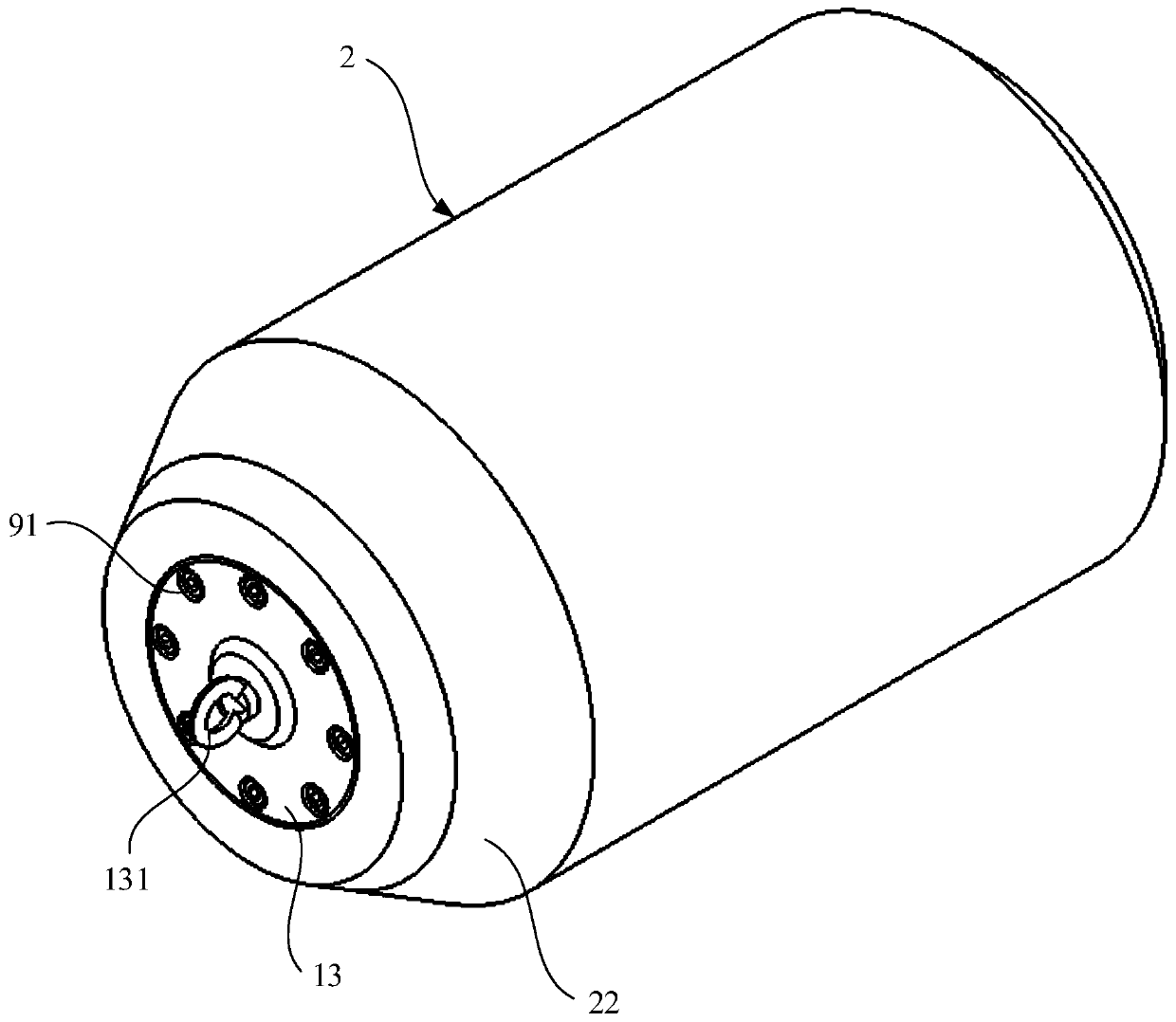

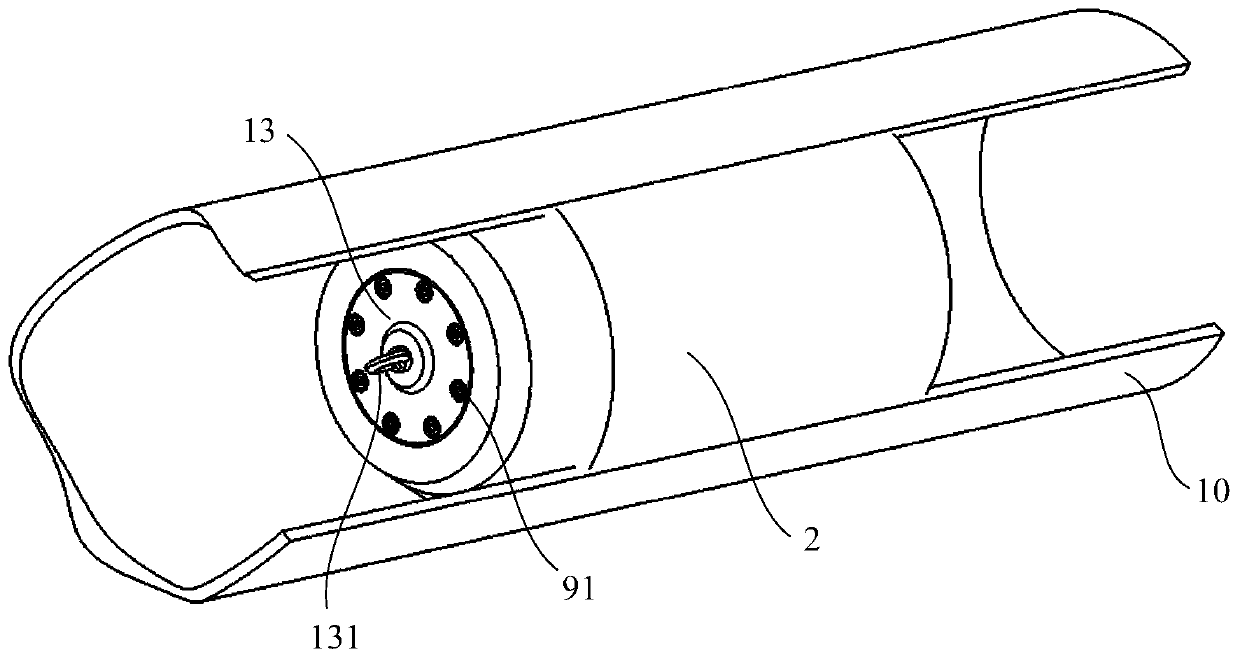

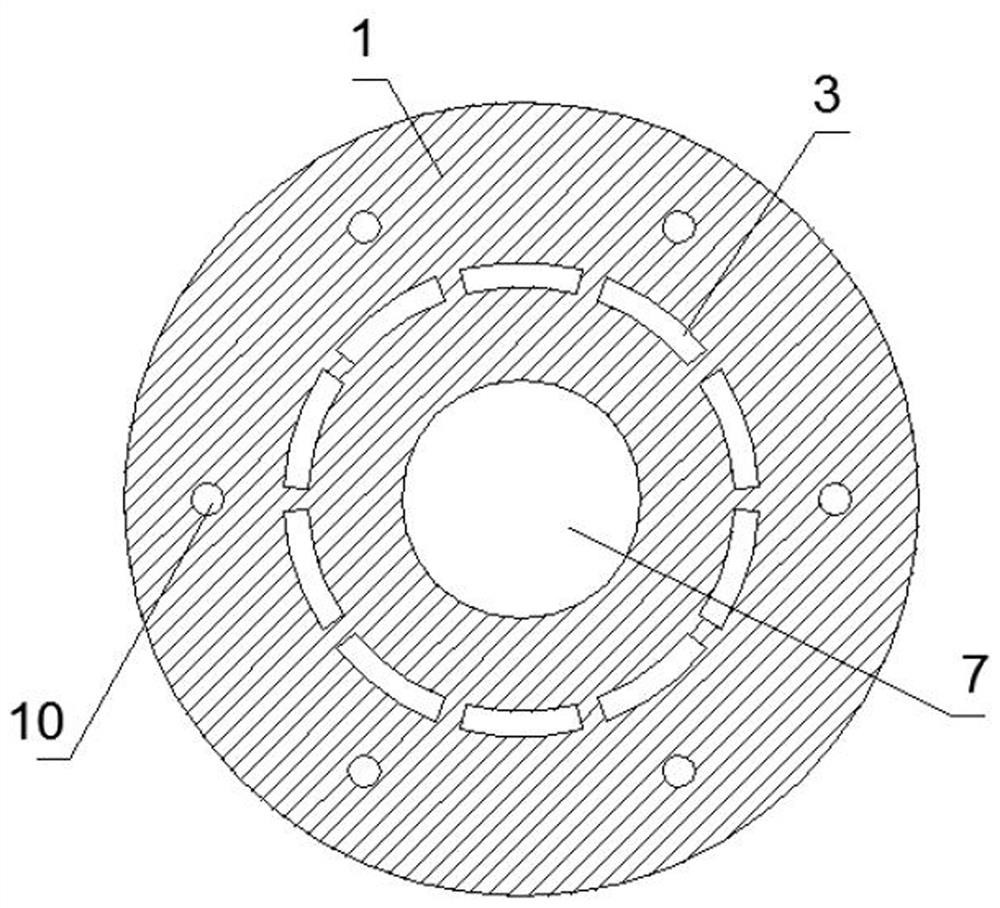

Variable-diameter spherical pipe cleaner

InactiveCN105953019AControl shrink recoveryReduced jam riskPipe elementsMicrocontrollerSolenoid valve

The invention relates to a variable-diameter spherical pipe cleaner which is used for welding operation of an inservice pipeline. According to the technical scheme, an inner shell is a rubber spherical shell, an injection connector and a liquid discharge connector are arranged outside the inner shell, a gas discharge hole is formed above the mounting position of the inner shell; a check valve is arranged at the inner side of the injection connector, a solenoid valve is arranged at the inner side of the liquid discharge connector, and a vibration sensor is arranged at the inner side of the gas discharge hole; a microcontroller and a battery are arranged in the inner shell, and the microcontroller is connected with the solenoid valve and the sensor; and an eccentric block is arranged on a motor output shaft, and a motor is arranged outside a pipeline corresponding to the mounting position of the pipe cleaner. According to the pipe cleaner disclosed by the invention, reducing recovery is adopted, so that resistance in recovery can be reduced; and the discharge reducing of the spherical shell is controlled by only adopting a vibrating signal, thus being reliable in control.

Owner:SOUTHWEST PETROLEUM UNIV

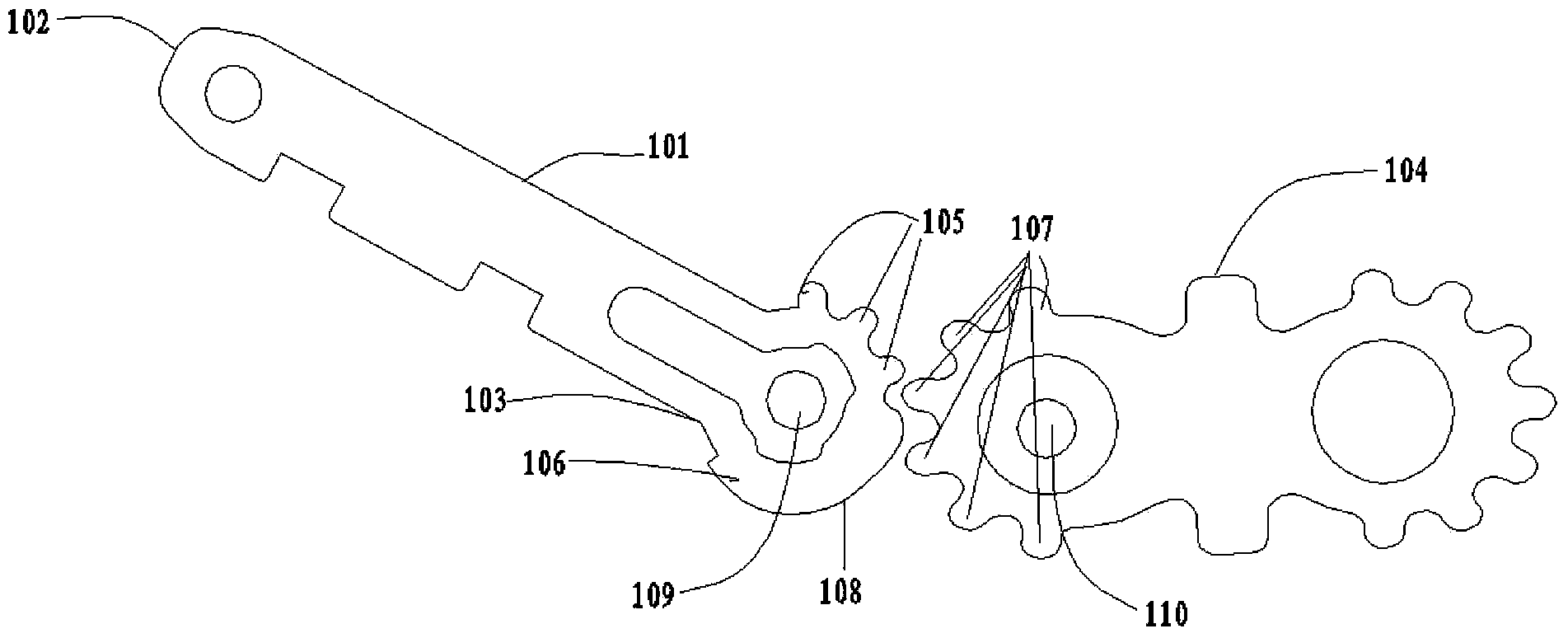

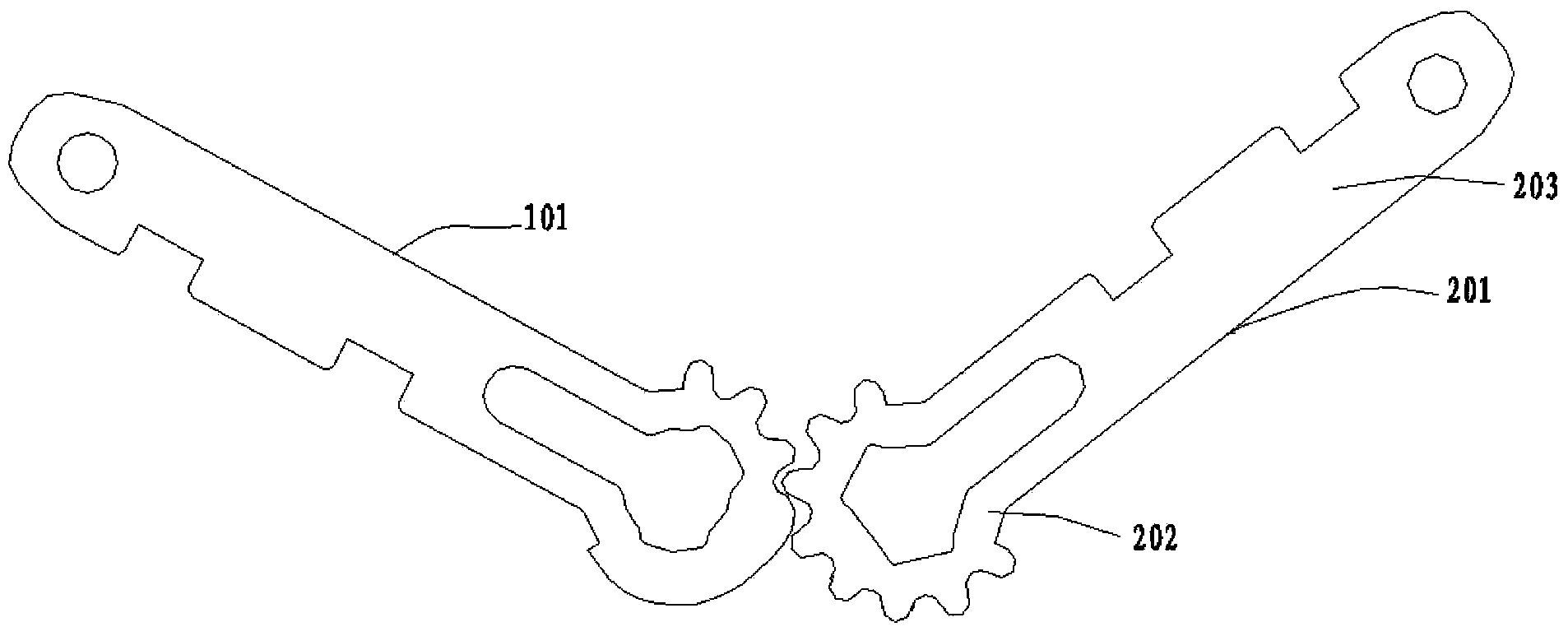

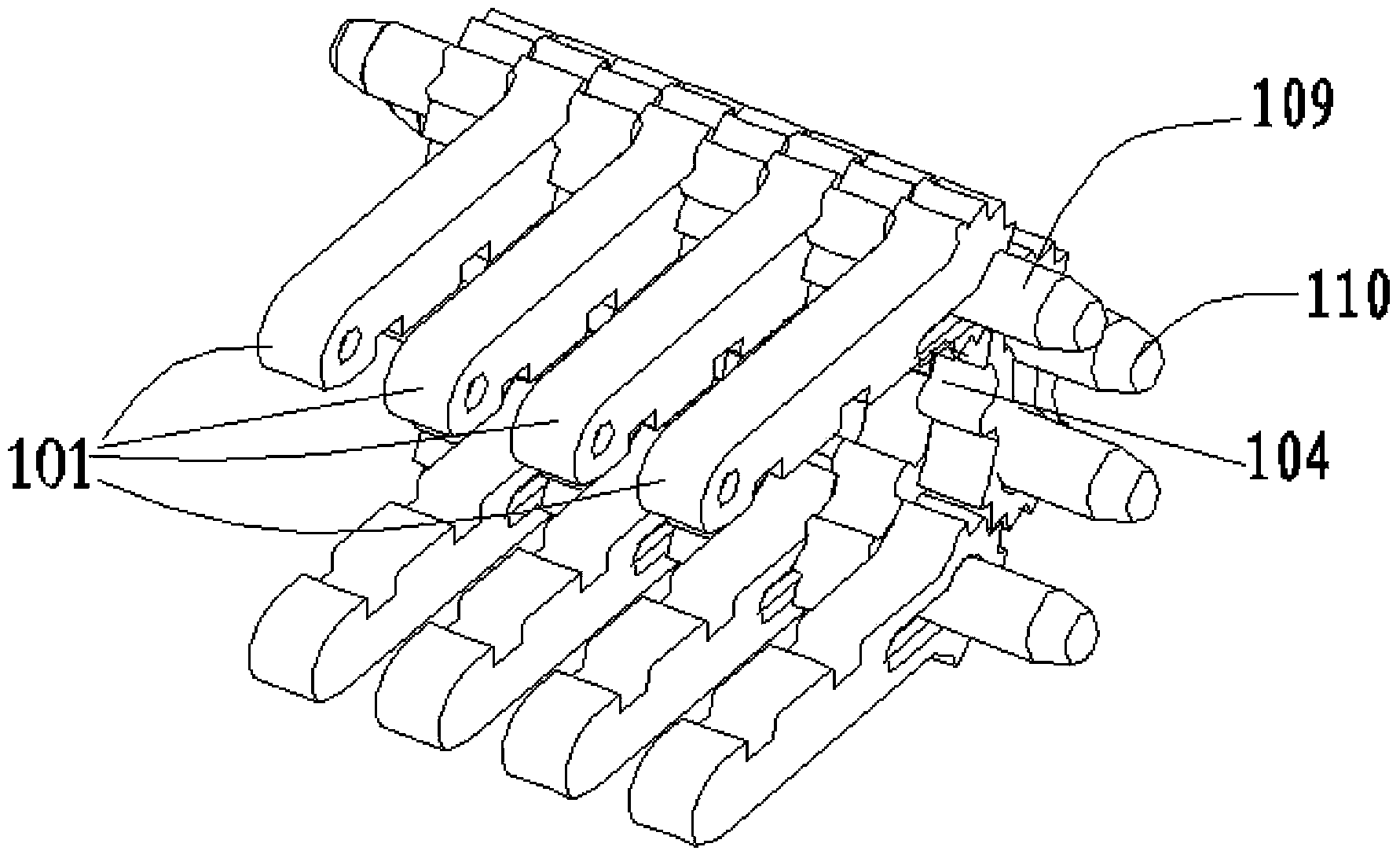

Rotating shaft and electronic device

ActiveCN104343813AArbitrarily control the maximum opening angleSolve the design costDigital data processing detailsPivotal connectionsTablet computerEngineering

The invention discloses a rotating shaft and an electronic device. The rotating shaft comprises a first support, a tooth piece and a first limiting structure. The first support comprises a first fixed end and a first meshing end; the tooth piece is meshed with the first meshing end; the first fixed end is fixed to a first body; the first meshing end comprises M first teeth which are arranged in parallel and used for being meshed with the tooth piece so as to enable the tooth piece to rotate relative to the first support; the M is a natural number; the first limiting structure is arranged on one sides of the M teeth and is used for preventing the tooth piece from continuing to rotating when second teeth on the tooth piece are in contact with the first limiting structure. The rotating shaft and the electronic device are used for solving the technical problems that in the prior art, according to a tablet computer which can be opened in a 360-degree turn-over mode and a common notebook computer, different rotating shafts need to be designed and produced, and the design cost and the production cost are wasted. The technical effects that the rotating shafts of the tablet computer which can be opened in the 360-degree turn-over mode and the common notebook computer can be generally used, and the design cost and the production cost are saved are achieved.

Owner:LENOVO (BEIJING) CO LTD

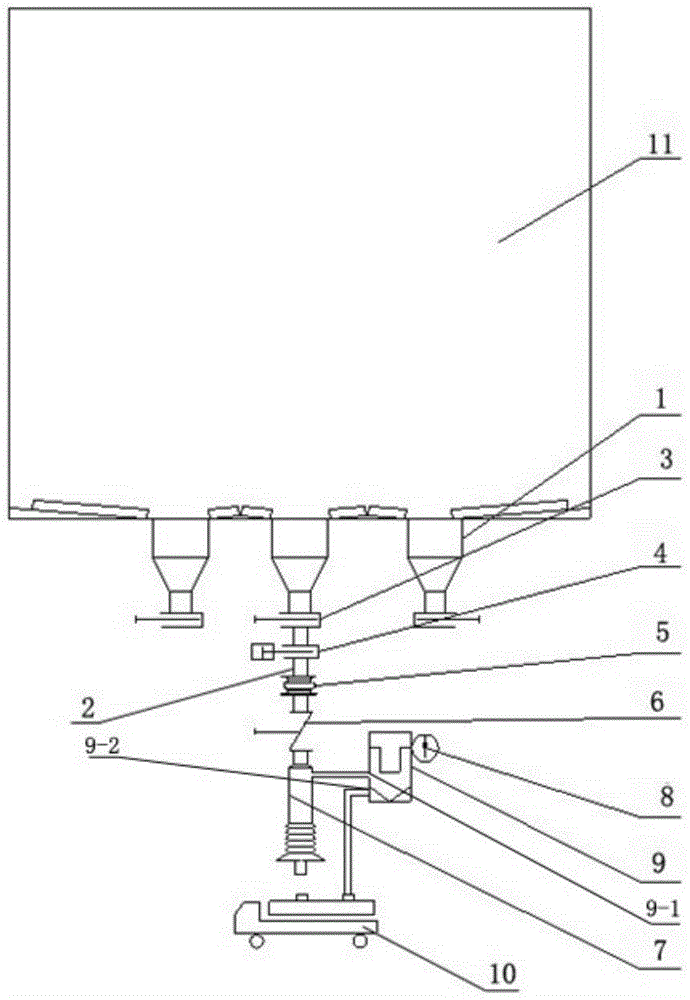

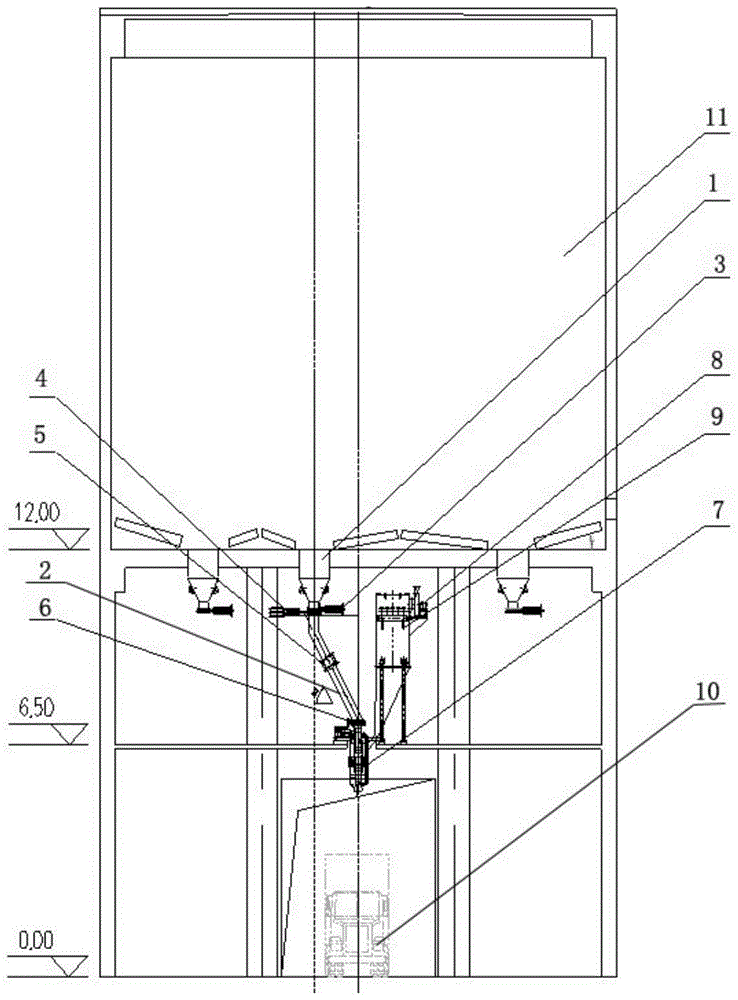

A dry ash loading device for coal-fired power plants

ActiveCN103466349BReduce flyingAvoid direct contactLarge containersLoading/unloadingBottom ashCoal plant

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

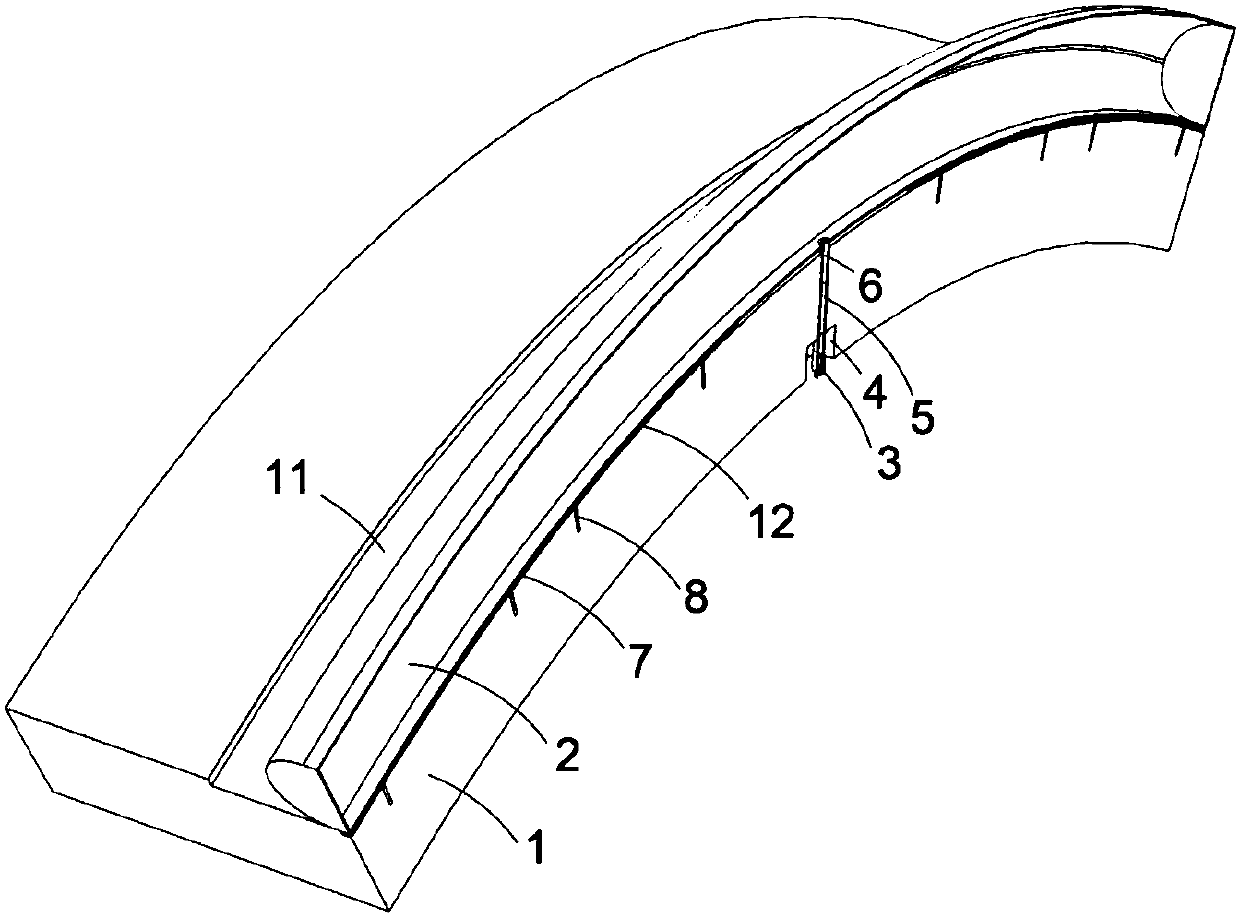

Backfill grouting expansion type sealing device of shield type tunnel boring machine (TBM) segment and construction method

ActiveCN107587883AEfficient supportEfficient closureUnderground chambersTunnel liningTunnel boring machineEngineering

The invention discloses a backfill grouting expansion type sealing device of a shield type tunnel boring machine (TBM) segment and a construction method. The sealing device involves a rubber capsule and a fixed facility thereof, an air filling and exhaust port, a rubber capsule installation groove structure and construction steps, wherein the rubber capsule is fixed to the interior of a rubber capsule installation groove by virtue of a rubber capsule fixing strip, and the size and length of the rubber capsule can be adjusted as required; a segment filling tube hole, a segment valve hole, the rubber capsule installation groove and a rubber capsule fixing strip installation groove can be prefabricated or formed at a later stage, and the sizes can be adjusted according the size between the segment and surrounding rocks; and the construction steps comprise forming of the segment filling tube hole, the segment valve hole, the rubber capsule installation groove and the rubber capsule fixingstrip installation groove, installation, air exhaust and filling of the rubber capsule and the like. According to the backfill grouting expansion type sealing device, gaps between the shield type TBMsegment and the surrounding rocks can be quickly and effectively sealed, so that the blocking and sealing requirements of backfill grouting are satisfied.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Box positioning mechanism and financial equipment

ActiveCN107438869AEffective positioningHigh precisionCoin/currency accepting devicesStructural engineeringControl theory

Owner:SHENZHEN YIHUA COMP

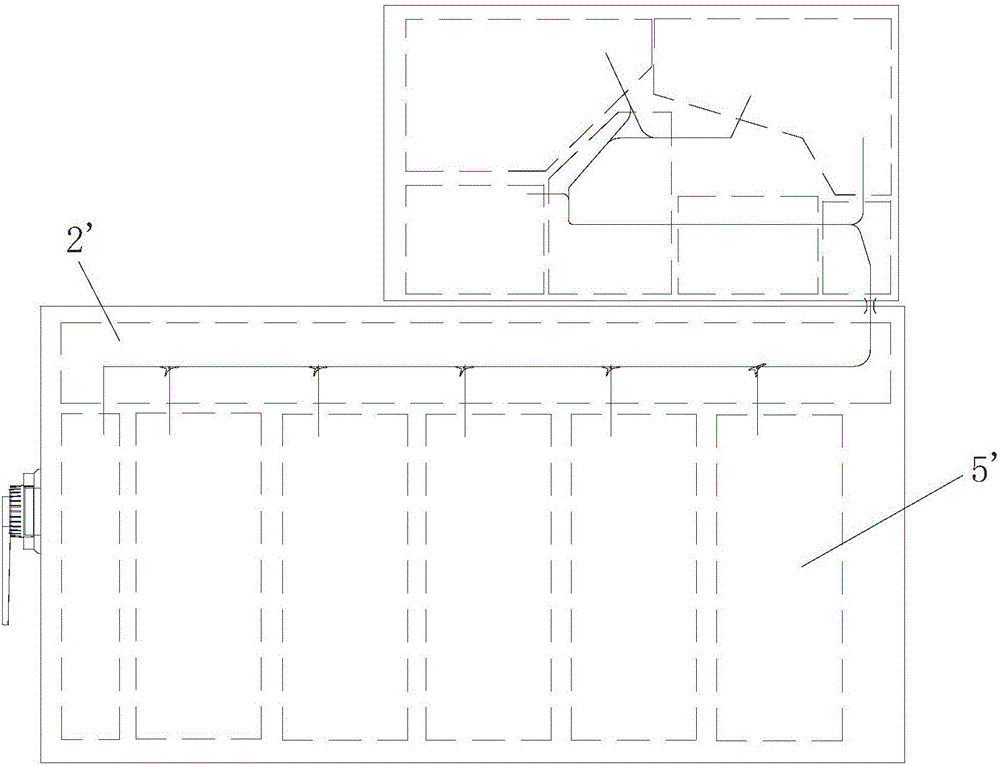

Pipeline detection pipe cleaner with multiple layers of foaming bodies

PendingCN111375607AImprove passabilityReduced jam riskHollow article cleaningInterference fitProcess engineering

The invention provides a pipeline detection pipe cleaner with multiple layers of foaming bodies. The pipeline detection pipe cleaner comprises a pipe cleaner body and a foaming body assembly arrangedon the outer side of the pipe cleaner body, wherein the foaming body assembly comprises at least two layers of foaming bodies which are sequentially arranged in a sleeved mode, and at least one layerof foaming body is different from other foaming bodies in material and / or density, so that the foaming bodies of the foaming body assembly are different in hardness and flexibility, the passing ability of the pipeline detection pipe cleaner is improved, some pipelines with large bending degrees can be passed through more easily, and the risk that the pipeline detection pipe cleaner is blocked is reduced; and moreover, the outermost foaming body is in interference fit with a to-be-detected pipeline, so that a certain of differential pressure exists and maintains in the front and rear ends of the pipeline detection pipe cleaner, and the pipeline detection pipe cleaner can operate stably.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

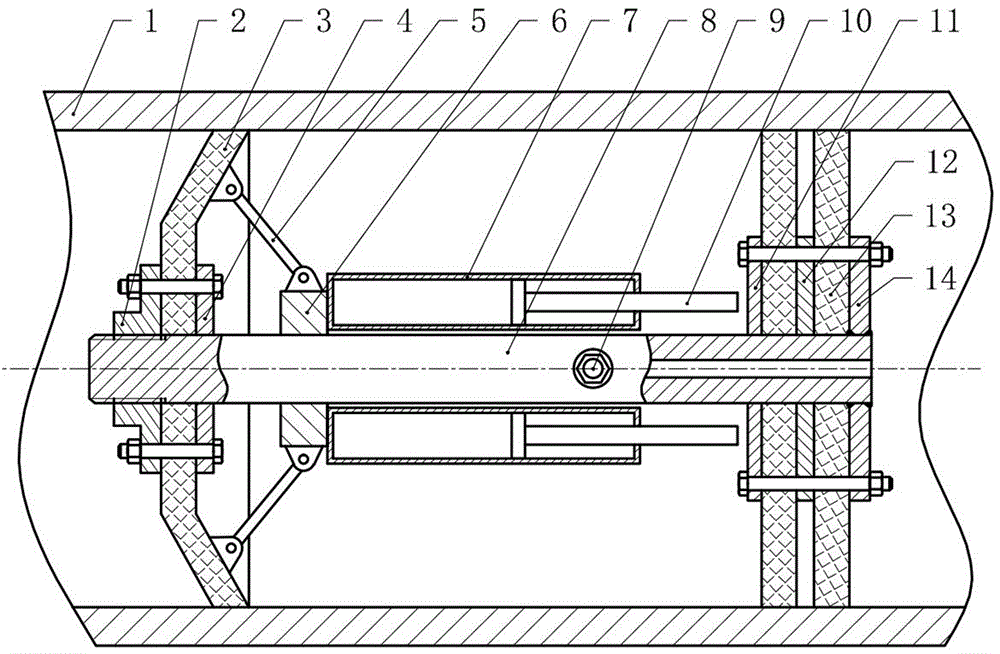

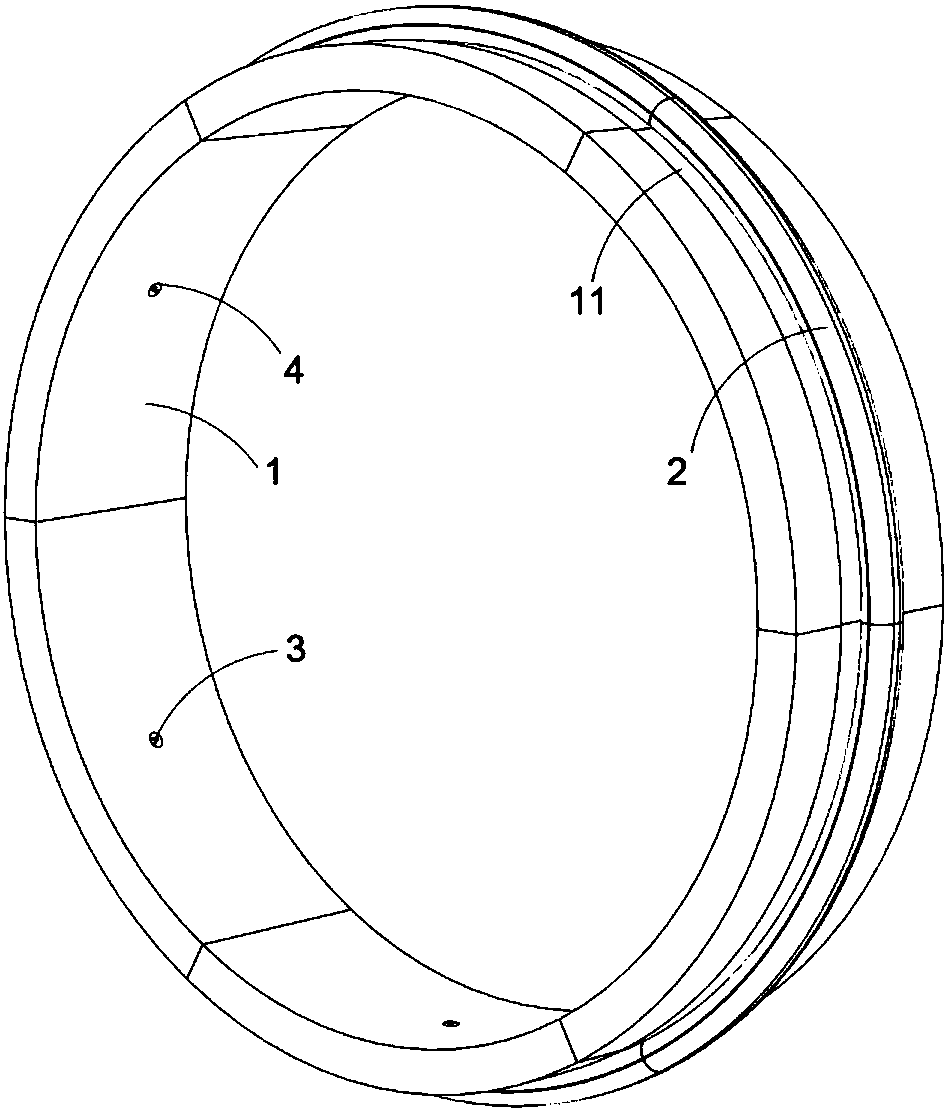

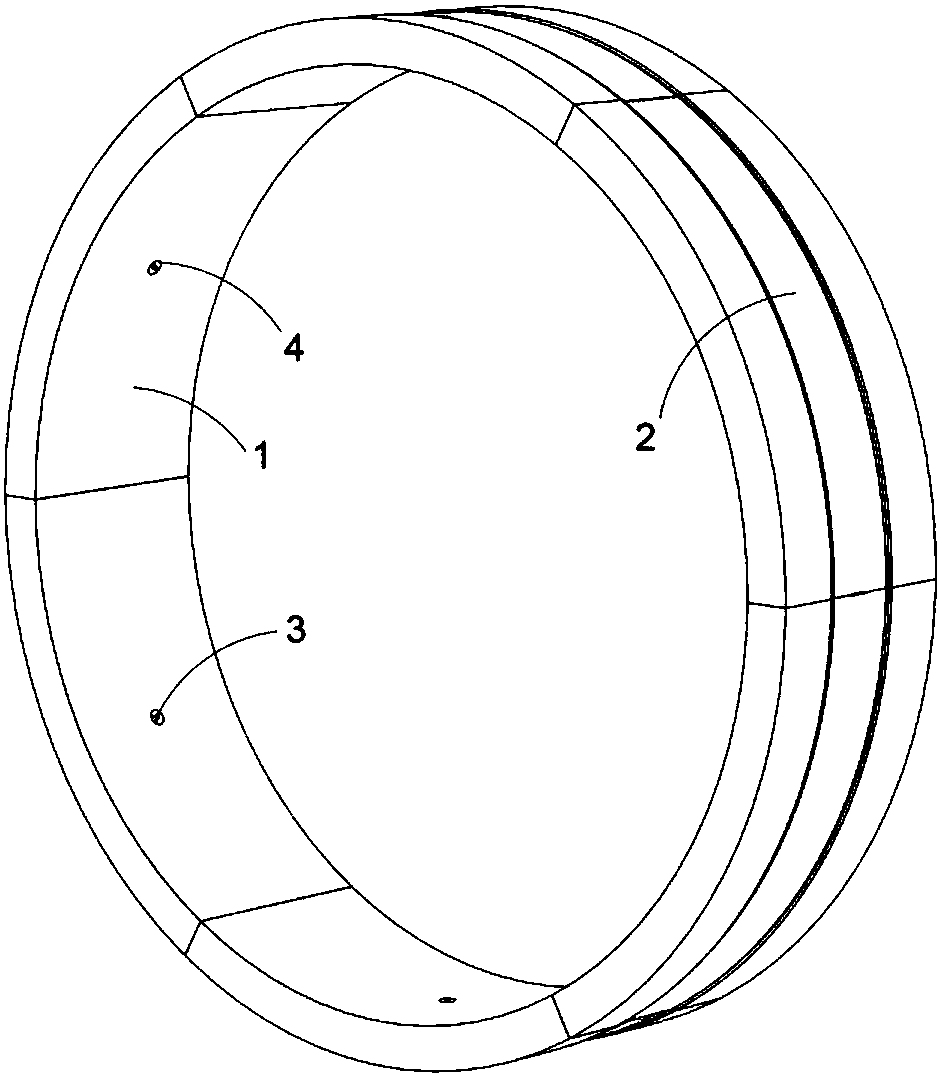

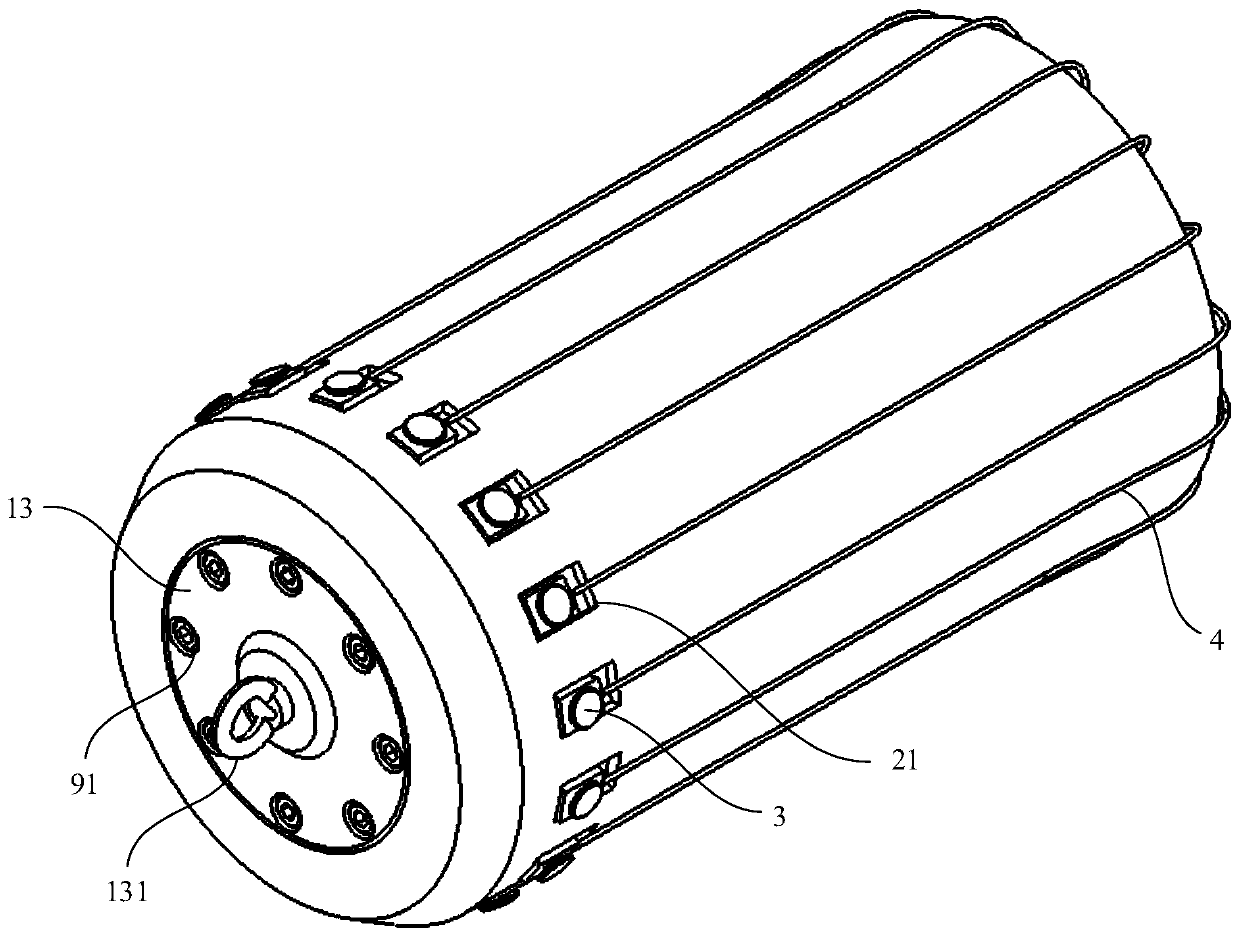

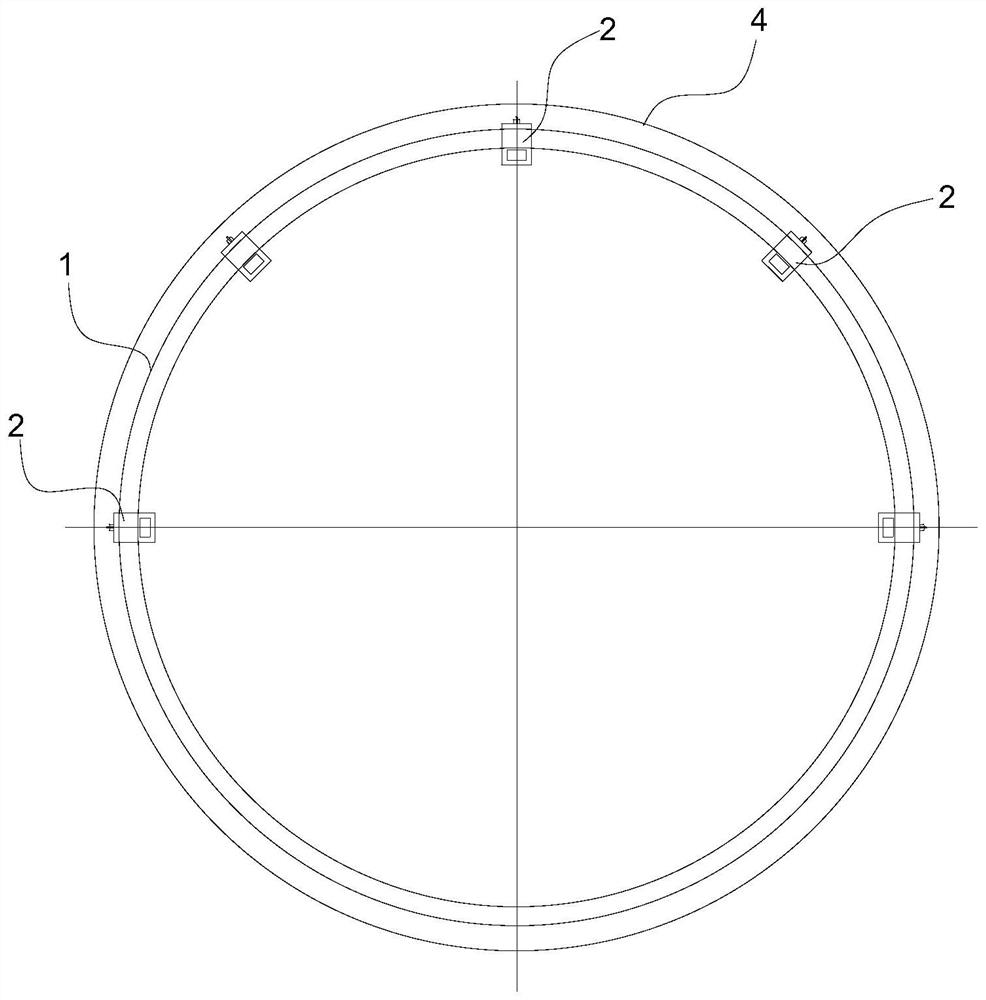

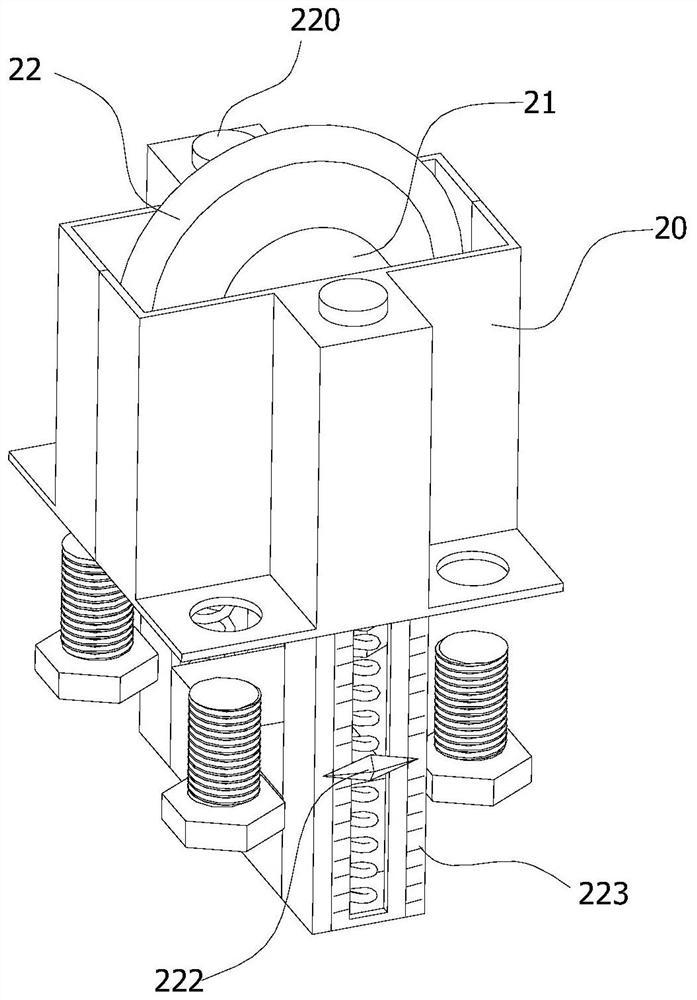

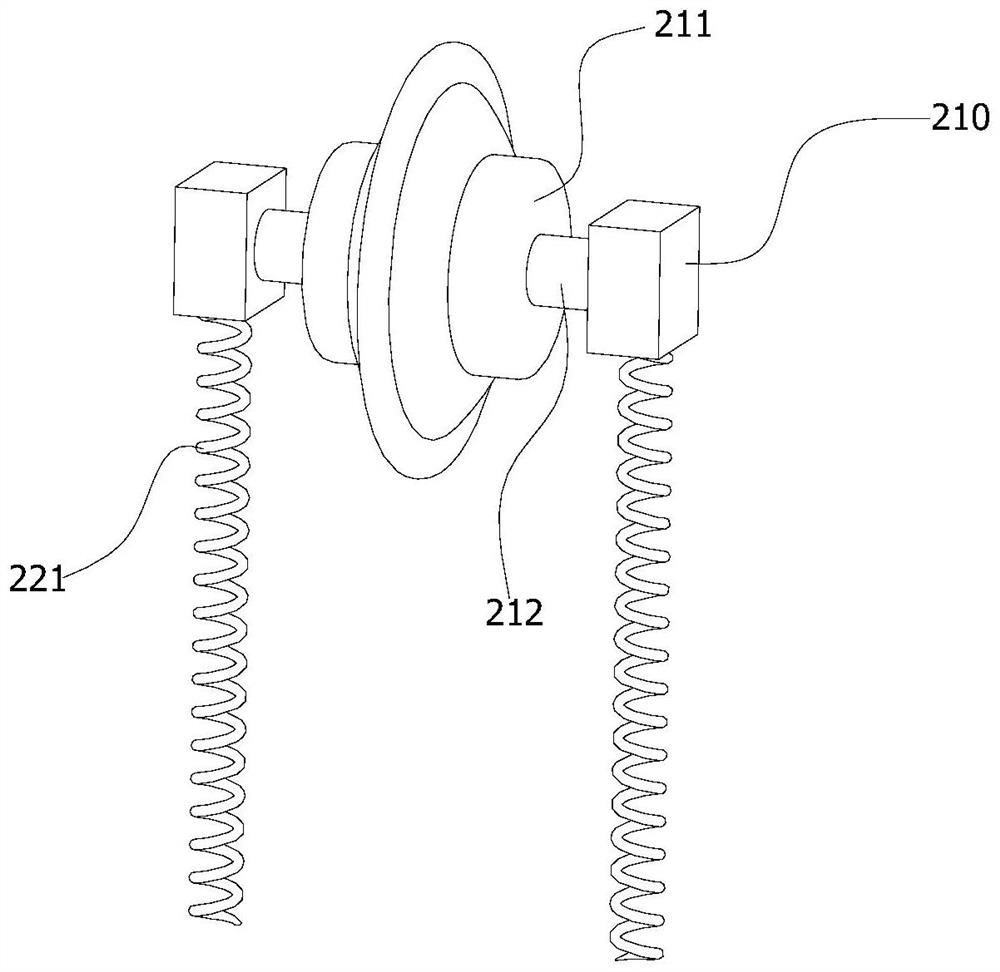

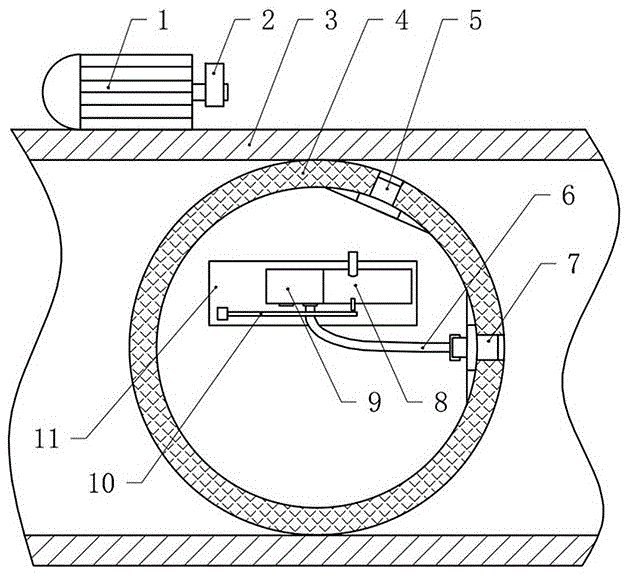

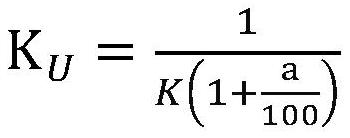

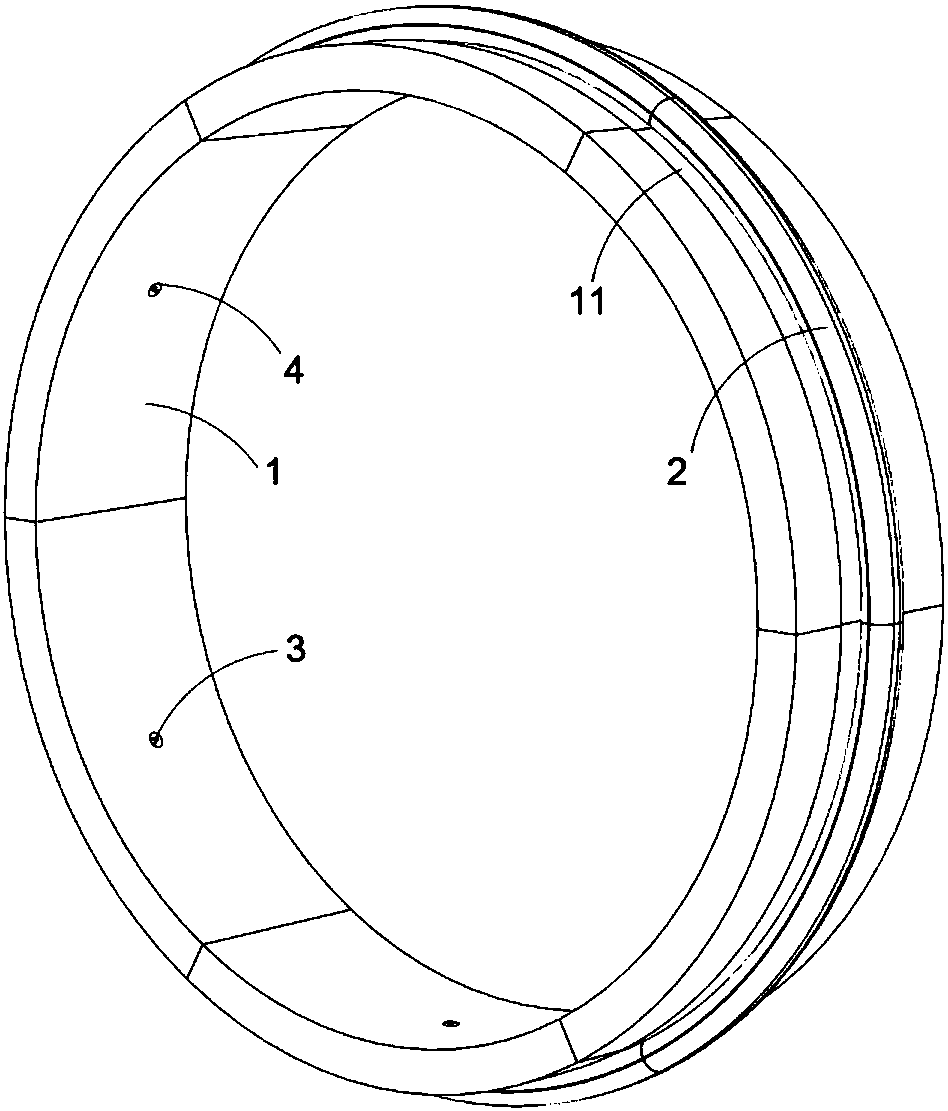

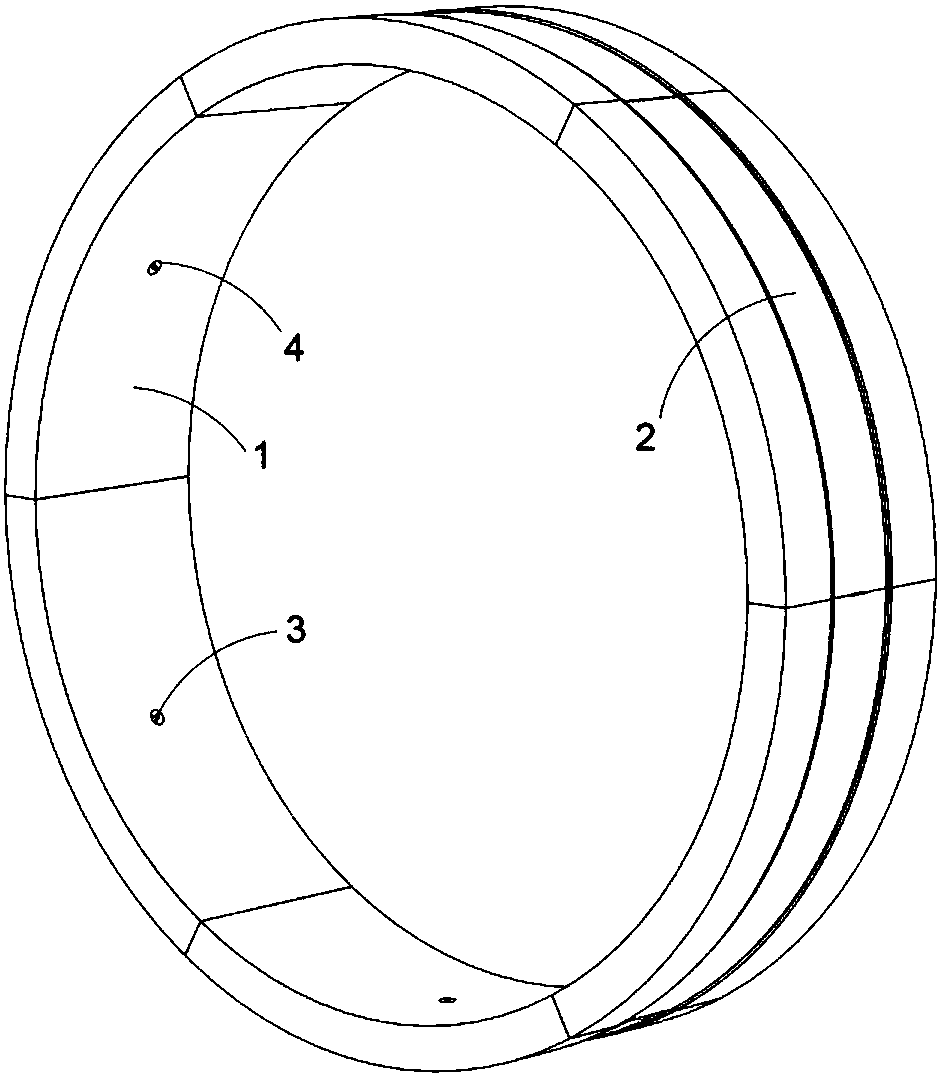

Shield machine jamming monitoring and preventing device based on measurement of expanding excavation gap

PendingCN114109397ASolve monitoring difficultiesReduced jam riskMechanical clearance measurementsApparatus for force/torque/work measurementStructural engineeringShield tunneling

The invention discloses a shield machine jamming monitoring and preventing device based on measurement of an expanding excavation gap. The shield machine jamming monitoring and preventing device comprises a monitoring mechanism and a preventing mechanism, wherein the monitoring mechanism is arranged in a shield shell of a shield and used for monitoring change pairs of the expanding excavation gap, and the preventing mechanism is arranged in the shield shell of the shield and used for preventing the shield machine jamming; the monitoring mechanism comprises a shell and a monitoring assembly arranged in the shell through a rolling assembly, and a metal probe of the monitoring assembly extends out of the outer side of the shield shell of the shield and makes contact with surrounding rock. The device is a monitoring device which reflects the change of the expanding excavation gap according to the compression amount of the spring, and can also measure the soil pressure on the surface of the shield shell through a soil pressure sensor arranged on the device; shield tunneling can be manually suspended through the supporting assembly at the shield tail of the shield tunneling machine, the size of the expanding excavation gap around a tunnel is kept, it is guaranteed that bin opening and tool changing work has enough time, operation is reliable, and use is convenient and fast.

Owner:SHENZHEN METRO CONSTR GRP CO LTD +1

Reducing spherical plugging device

InactiveCN106392386AImprove the safety of useReduced jam riskWelding/cutting auxillary devicesAuxillary welding devicesElectric controlOil and gas pipelines

The present invention relates to a reducing spherical plugging device for the welding operation for an in-service pipeline. A technical solution for the reducing spherical plugging device is as follows: the plugging device is provided with a spherical rubber shell in which an injection connection and an exhaust vent are mounted; a controllable one-way valve and a vibrating switch are disposed within the housing; the vibrating switch is disposed at a cantilever end of the vibrating rod; and an eccentric block is mounted on an output shaft of a motor that is disposed outside a pipeline corresponding to a mounting position of the plugging device of the present invention. The plugging device of the present invention is retrieved by the way of reducing, such that resistance in the retrieval process can be reduced; and without an electric control part, the plugging device has higher use safety for oil and gas pipelines.

Owner:SOUTHWEST PETROLEUM UNIV

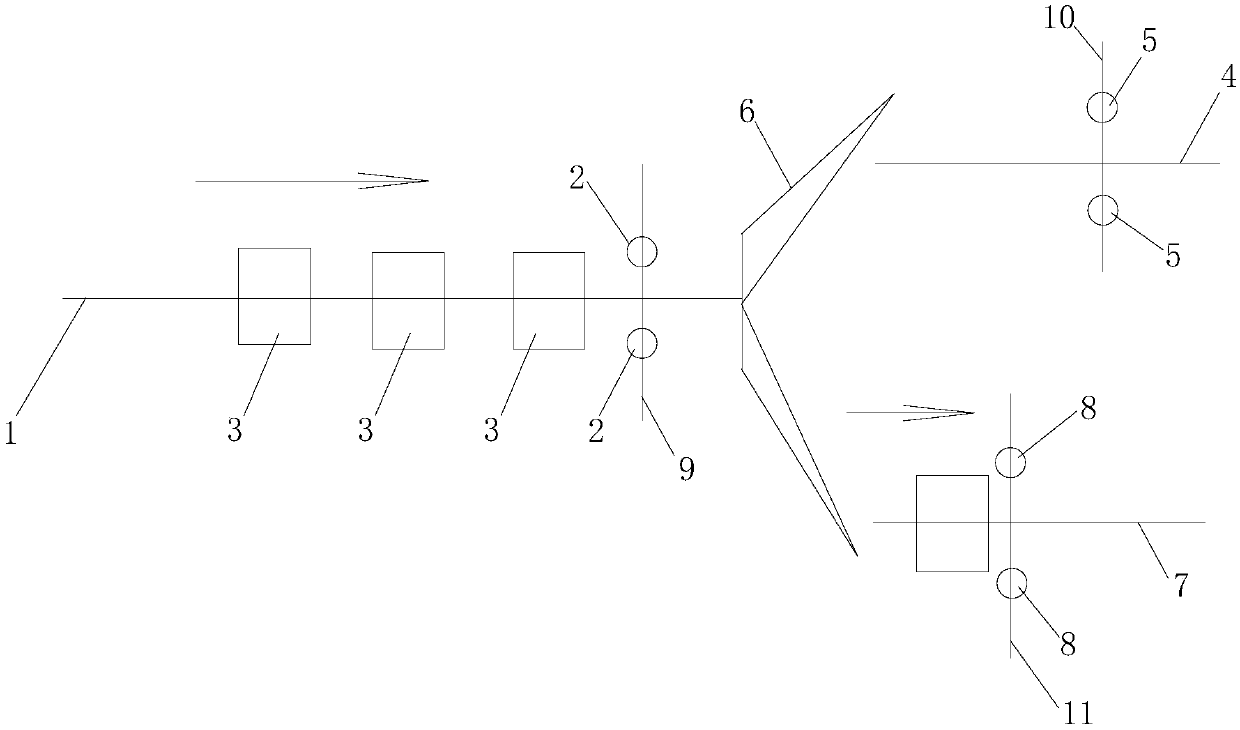

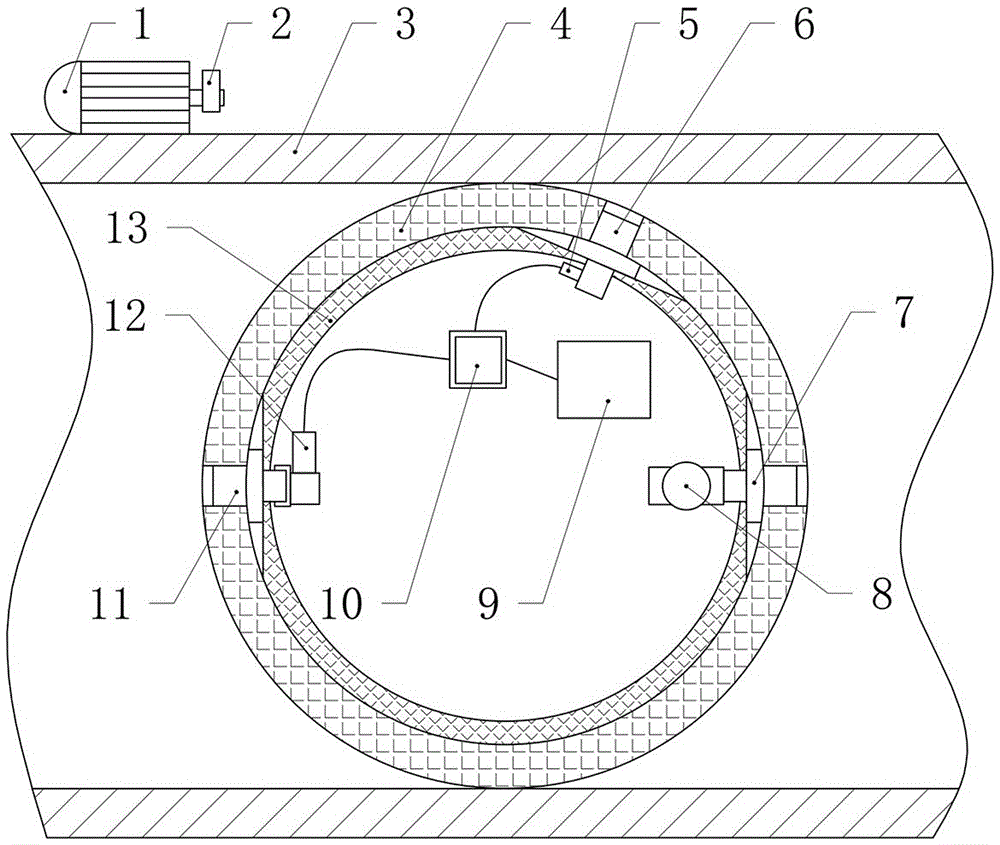

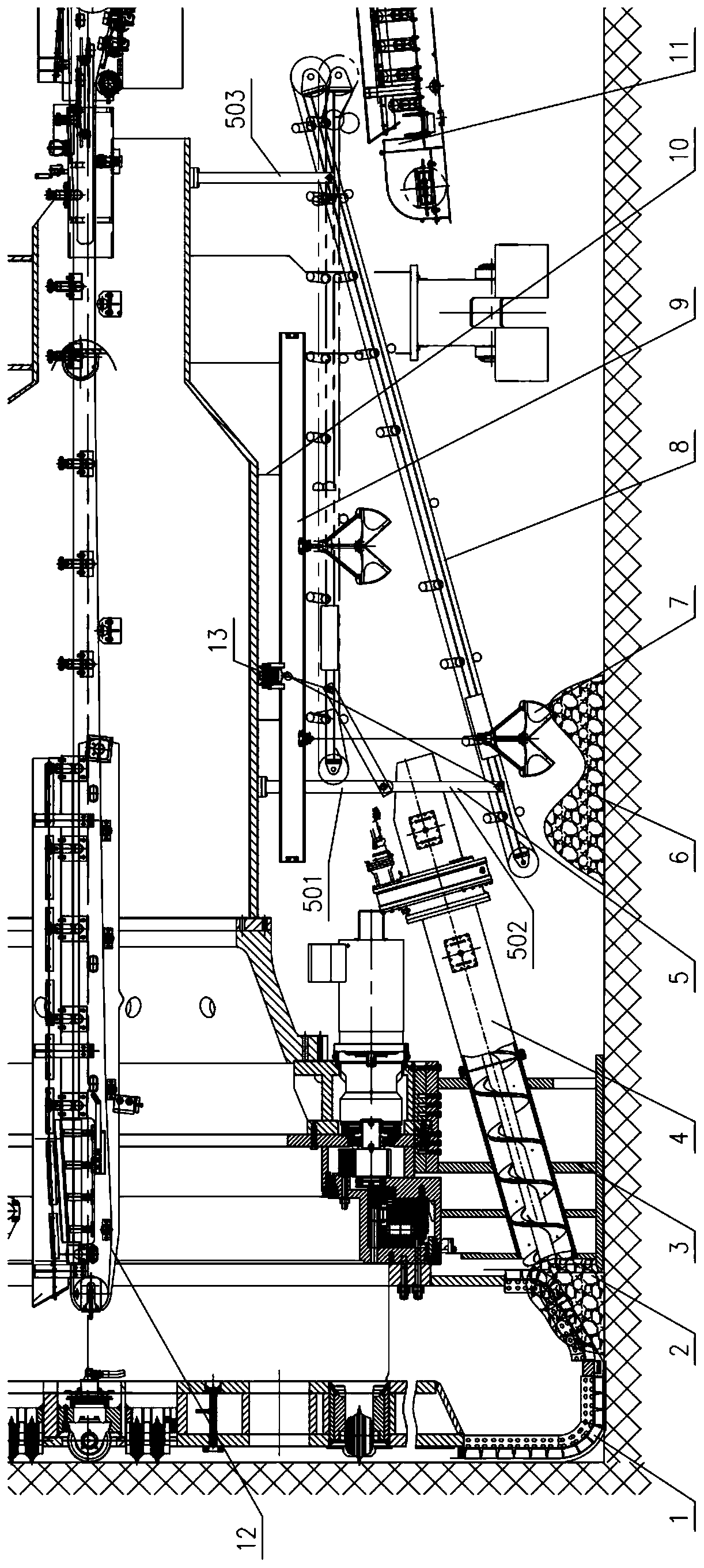

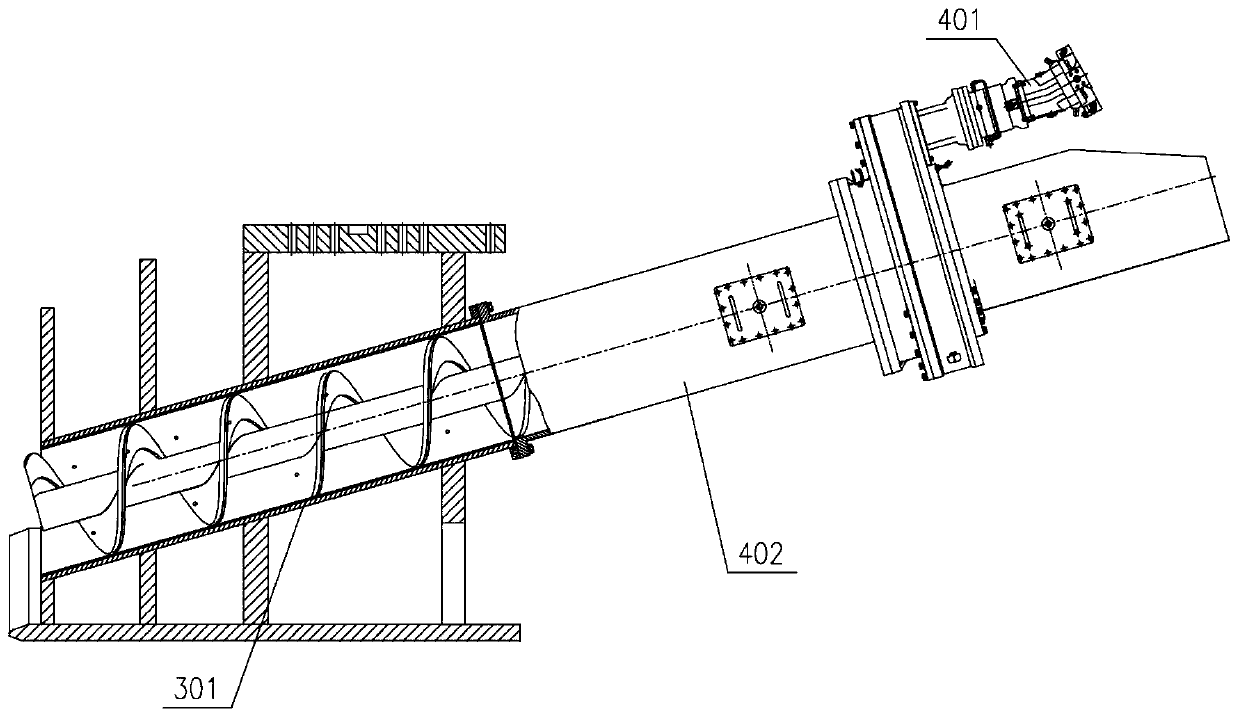

TBM and continuous deslagging device thereof

The invention discloses a TBM and a continuous deslagging device thereof. The continuous deslagging device comprises a screw conveyer, a first conveyor, a grab bucket and a second conveyor. The firstend of the screw conveyer is arranged on a slag accumulating area at the bottom of a cutterhead. The second end of the screw conveyer is arranged above a slag accumulating area at the bottom of a mainbeam. The first end of the first conveyor is located between the second end of the screw conveyor and the slag accumulating area at the bottom of the main beam. The grab bucket is used for grabbing accumulated slag located on the slag accumulating area at the bottom of the main beam and grabbing the accumulated slag to the first conveyor. The second conveyor is arranged below the second end of the first conveyor, so that the second conveyor receives the accumulated slag conveyed by the first conveyor and the accumulated slag grabbed by the grab bucket. According to the continuous delsagging device, the accumulated slag at the bottom of the cutterhead and the bottom of the main beam can be fast removed, so that the phenomenon that when the TBM passes through a crushed zone or other unfavorable geologies, due to the fact that a large amount of slag is accumulated at the bottom of the cutterhead, the cutterhead is blocked; and meanwhile the bottom deslagging efficiency of the open main beam of the TBM is improved, and it is guaranteed that the TBM fast passes through the surrounding rock crushed zone and other unfavorable geologies.

Owner:CHINA RAILWAY CONSTR HEAVY IND

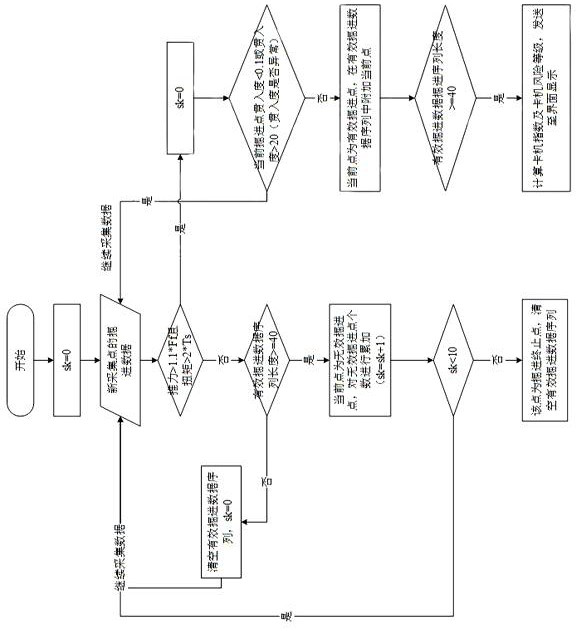

TBM real-time tunneling jamming risk early warning method

ActiveCN111915193AReduce economic lossEnsure safetyMining devicesResourcesEngineeringComputational physics

The invention discloses a TBM (Tunnel Boring Machine) real-time tunneling jamming risk early warning method which comprises the following steps: setting a tunneling termination length judgment value and an effective tunneling length judgment value, and setting an effective tunneling data sequence to be empty; collecting tunneling data; carrying out effective tunneling state judgment on TBM tunneling according to the collected tunneling data; when TBM tunneling is in an effective tunneling state, making effective tunneling point judgment on tunneling points of tunneling data; when TBM tunnelingis in an invalid tunneling state, judging invalid tunneling points; adding and storing the tunneling data of the tunneling point into an effective tunneling data sequence, and calculating the lengthof the effective tunneling data sequence; comparing the length of the effective tunneling data sequence with an effective tunneling length judgment value if the tunneling point is the effective tunneling point; calculating a stuck machine index final value according to tunneling data in the effective tunneling data sequence; and judging and displaying the risk degree of the card machine. The jamming risk in tunneling is effectively identified, the jamming risk is alarmed in real time, the economic loss caused by jamming is reduced, and the construction safety is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

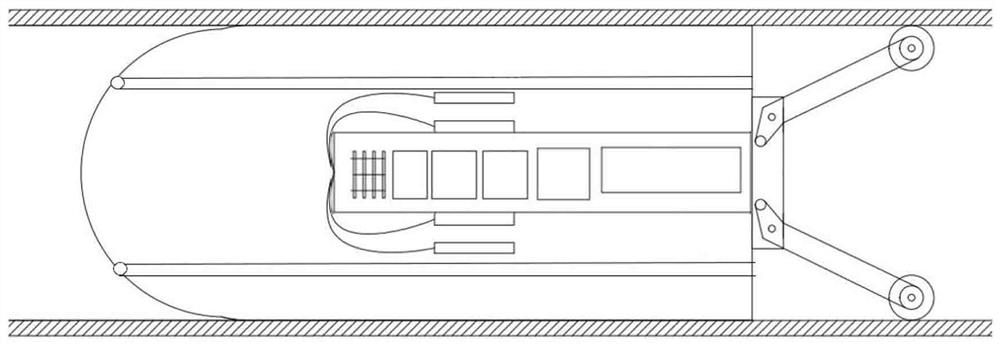

High-trafficability pipeline reducing detection and positioning device

ActiveCN114646250AReduced jam riskReduce pigging timesHollow article cleaningMechanical diameter measurementsJet flowStructural engineering

The invention discloses a high-trafficability pipeline reducing detection and positioning device which comprises a shell and an inner cavity, one end, facing the advancing direction, of the shell is arranged to be a round head, and the other end of the shell is arranged to be a flat head. The outer circumferential side face of the shell makes contact with the inner wall of the pipeline. An inner cavity is formed in the shell, an intelligent analysis control mechanism, a positioning mechanism, a signal transmitter, an inertia measurement mechanism, a power supply system and an information acquisition and storage mechanism are arranged in the inner cavity, and the functions of detecting and positioning the reducing condition of the pipeline along the way are achieved. The device is made of an all-polyurethane foaming material, has high passing performance and low requirements on a pipe inlet environment, and utilizes the jet pipe and the high-pressure combined fan-shaped nozzle to wash dirt on the inner wall of the pipeline, so that the blocking risk is greatly reduced, and the safety of pipeline detection is ensured.

Owner:NORTHEASTERN UNIV

A variable-diameter spherical pipe cleaner

InactiveCN105953019BControl shrink recoveryReduced jam riskPipe elementsMicrocontrollerSolenoid valve

The invention relates to a variable-diameter spherical pipe cleaner which is used for welding operation of an inservice pipeline. According to the technical scheme, an inner shell is a rubber spherical shell, an injection connector and a liquid discharge connector are arranged outside the inner shell, a gas discharge hole is formed above the mounting position of the inner shell; a check valve is arranged at the inner side of the injection connector, a solenoid valve is arranged at the inner side of the liquid discharge connector, and a vibration sensor is arranged at the inner side of the gas discharge hole; a microcontroller and a battery are arranged in the inner shell, and the microcontroller is connected with the solenoid valve and the sensor; and an eccentric block is arranged on a motor output shaft, and a motor is arranged outside a pipeline corresponding to the mounting position of the pipe cleaner. According to the pipe cleaner disclosed by the invention, reducing recovery is adopted, so that resistance in recovery can be reduced; and the discharge reducing of the spherical shell is controlled by only adopting a vibrating signal, thus being reliable in control.

Owner:SOUTHWEST PETROLEUM UNIV

An all-round direction adjustment device for the main drive of a tunnel boring machine

A tunnel boring machine main drive all-round direction adjustment device applied in the field of tunnel boring machines, including a main drive housing, a propulsion cylinder, an upper left torque cylinder, an upper right torque cylinder, a bottom left torque cylinder, a bottom right Side torque oil cylinder, left upper end torque oil cylinder, left lower end torque oil cylinder, right upper end torque oil cylinder, right lower end torque oil cylinder, the main drive shell is installed inside the front shield shell, and the front end of the propulsion cylinder is fixed to the main drive shell. The tail part is fixedly connected with the tension shield, the upper left torque cylinder and the upper right torque cylinder are fixed on the upper part of the main drive shell, the bottom left torque cylinder and the bottom right torque cylinder are fixed on the lower part of the main drive shell, and the telescopic end Supported on the front shield shell. The invention has a novel structure and strong practicability, can reduce the risk of the boring machine jamming during the construction process of the tunnel boring machine, is convenient for direction adjustment, and can keep the boring machine driving upward at any time.

Owner:NORTHERN HEAVY IND GRP CO LTD

A pipe cleaner with automatic braking device

The invention relates to a pipe cleaning device with an automatic brake device. The pipe cleaning device is used for pipe cleaning work. The defect that an existing speed adjusting pipe cleaning device is poor in generality in a pipe is overcome. According to the technical scheme, leather bowls are arranged at the two ends of a cylinder, one end of a connecting rod B is hinged to a brake piece, the other end of the connecting rod B is hinged to the cylinder, one end of a connecting rod C is hinged to the brake piece, the other end of the connecting rod C penetrates a groove hole of the cylinder and is hinged to a mandrel, a brake oil cylinder is arranged in the cylinder, a piston rod of the brake oil cylinder is connected with the mandrel, rollers are mounted on input shafts of hydraulic pumps, a supporting spring is arranged between the two hydraulic pumps which are arranged at the rear end of the cylinder, an oil tank is arranged in the cylinder, oil suction openings of the hydraulic pumps are connected to the oil tank, oil outlets of the hydraulic pumps are connected to a throttling valve, an oil returning opening of the throttling valve is connected to the oil tank, and the front end of the throttling valve is connected with the brake oil cylinder. A pipe cleaning device speed controller is free of an electric appliance element, safety and reliability are achieved, and the device has the high generality in the pipe.

Owner:SOUTHWEST PETROLEUM UNIV

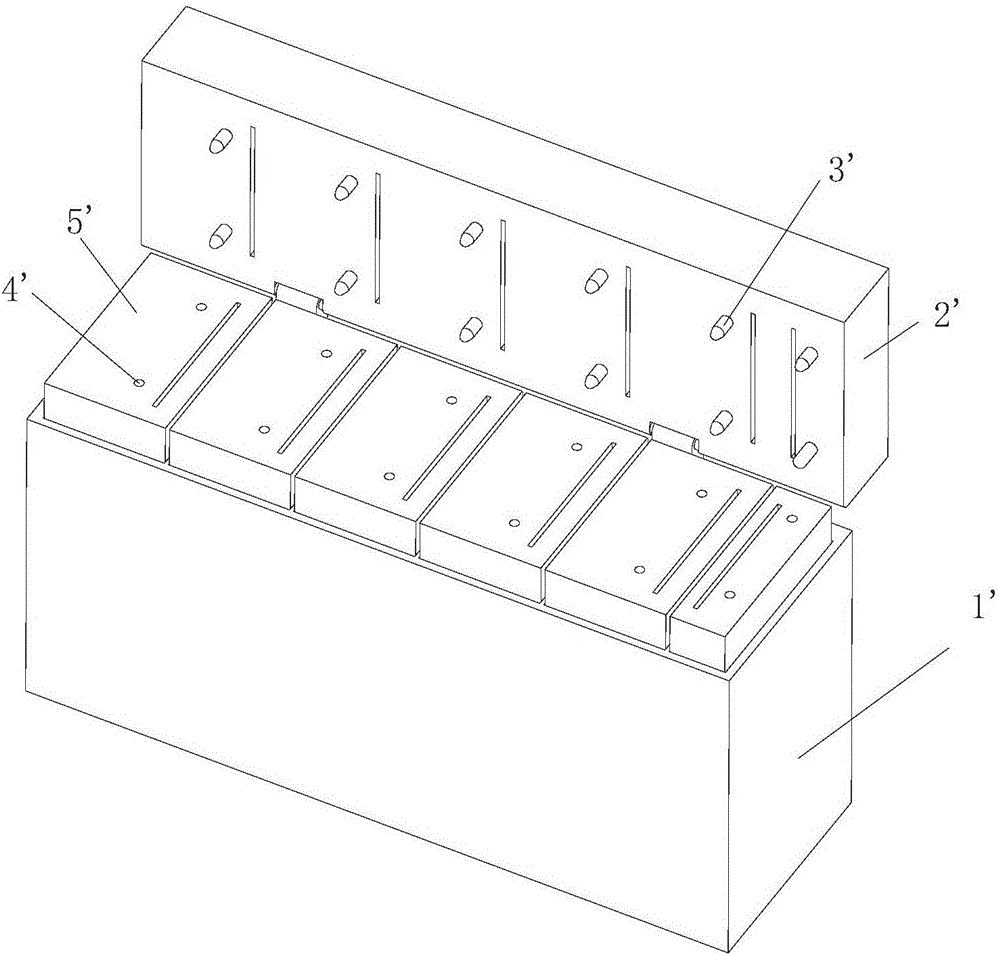

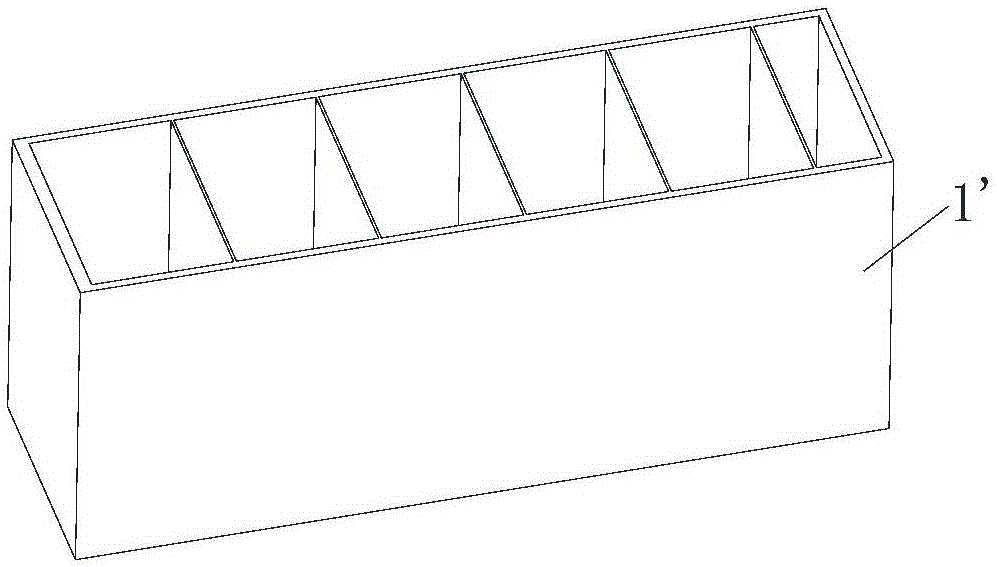

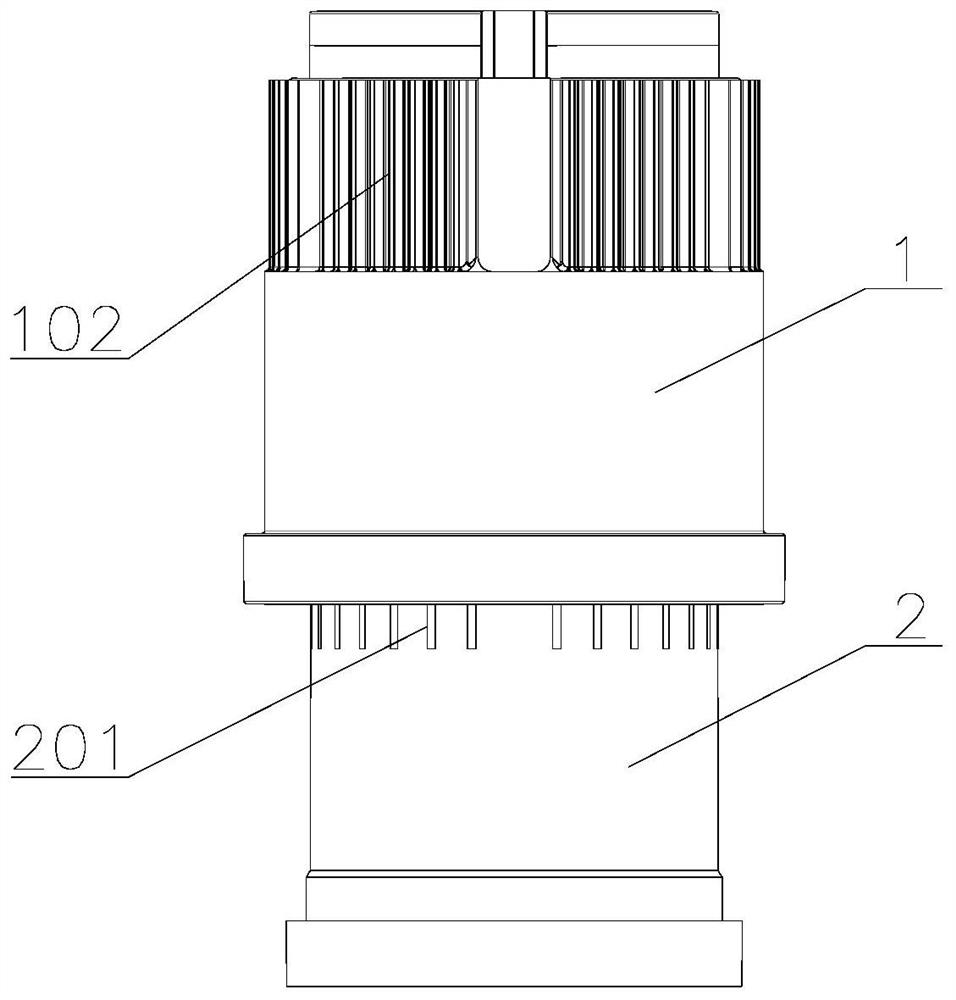

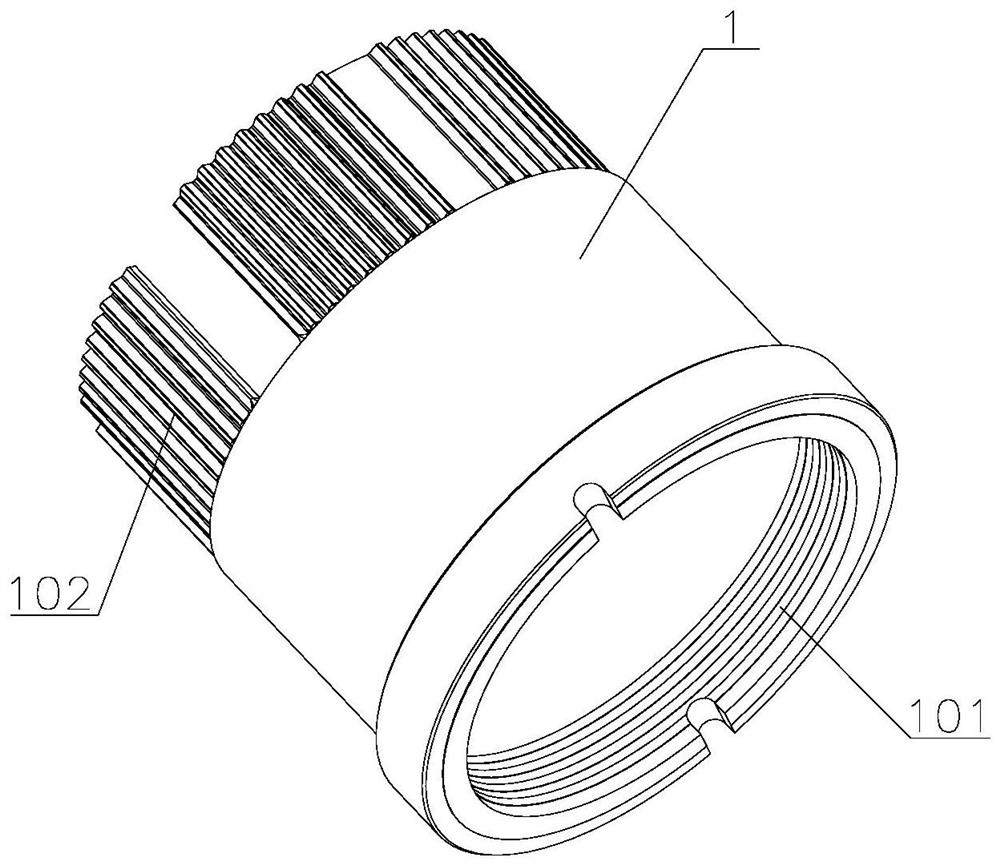

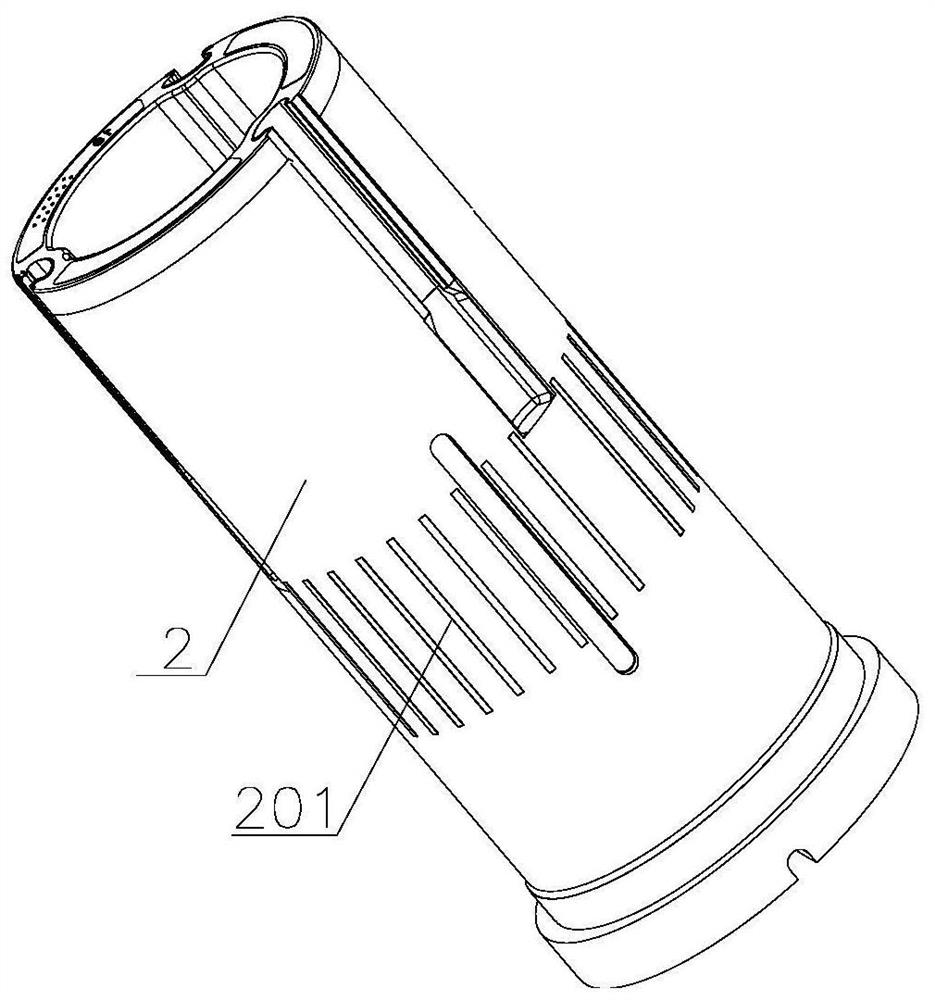

Powder metallurgy gear hub forming die

The invention provides a powder metallurgy gear hub forming die. The powder metallurgy gear hub forming die comprises an upper punching die and a lower punching die, each of the upper punching die and the lower punching die comprises an outer punching part and a middle punching part, the outer punching parts are arranged on the outer sides of the middle punching parts in a sleeving mode, a plurality of positioning rings arranged in the circumferential direction are arranged on the rear sides of the inner wall surfaces of the outer punching parts, and a plurality of positioning keys matched with the positioning rings are arranged on the outer wall surfaces of the middle punching parts in the circumferential direction at intervals. According to the powder metallurgy gear hub forming die, the stability in the die production process is improved, the die clamping risk is reduced, and the service life of the die is prolonged; the quality stability in the part production process is improved; the jumping precision of the external tooth end surface of the part is improved, and external tooth end surface machining is omitted.

Owner:江苏智造新材有限公司

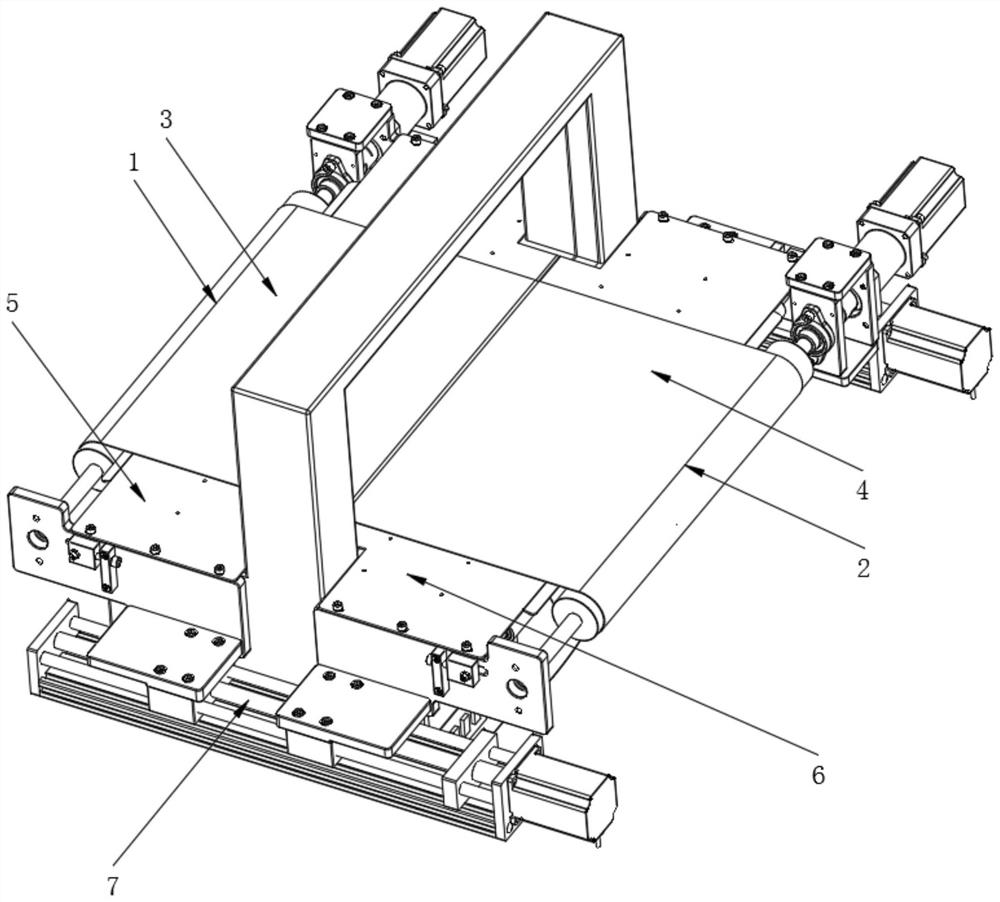

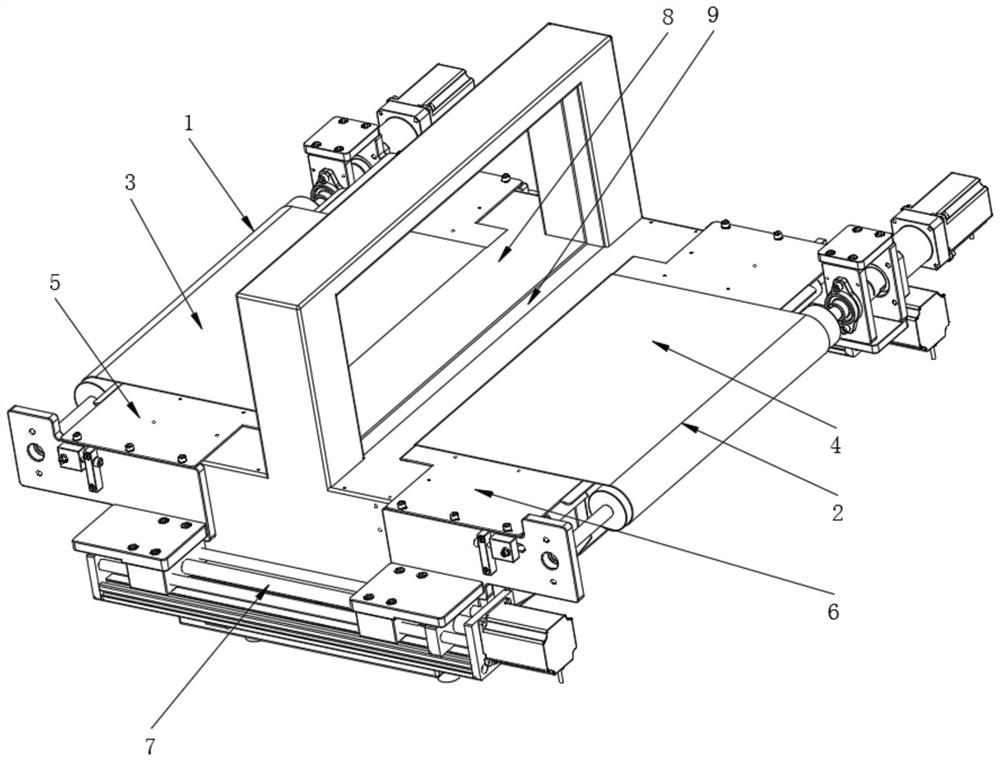

Movable platform for banding machine, banding device and banding method

PendingCN113619840AReduce the risk of jammingReduced jam riskPaper article packagingBinding material applicationEngineeringStructural engineering

The invention discloses a movable platform for a banding machine, a banding device and a banding method The movable platform comprises a front panel and a rear panel, the front panel and the rear panel are horizontally arranged, the end portion of the front panel and the end portion of the rear panel are oppositely arranged, and the front panel or / and the rear panel can move in the front-back direction. The panels capable of moving in the front-back direction are arranged on the banding machine, the front panel and the rear panel firstly move to a closed state before sheet materials are conveyed to the position above a belt groove of the banding machine, the belt groove of the banding machine is shielded by the closed panels, and the risk that the sheet materials cannot cross the belt groove and are clamped in the belt groove is avoided; and during banding, the front panel is separated from the rear panel, and the belt groove is exposed to ensure that banding is completed smoothly. Therefore, the material clamping risk of the sheet materials on the belt groove of the banding machine is greatly reduced.

Owner:四川卡库机器人科技有限公司

A method for unsealing the sealed package container of extraterrestrial celestial body samples

ActiveCN106276743BAvoid pollutionLess affectedBottle/container closurePower operated devicesCelestial bodyGas cylinder

The invention discloses a method for unsealing an extraterrestrial celestial body sample sealing packaging container and belongs to the technical field of vacuum. The device comprises a transition bin, an operation bin, an unsealing bin, a gas circulation purifying device, a gas cylinder and a vacuum pump. The unsealing bin is composed of an upper-end rigid section, a middle flexible section and a lower-end rigid section. The flexible section is detachably connected with the lower-end rigid section. When the flexible section is connected with the lower-end rigid section, an airtight space is formed by the unsealing bin. The transition bin is connected with the operation bin through a gate valve and communicates with the operation bin through a pipeline. The transition bin is connected with the vacuum pump through a pipeline. The gas circulation device communicates with the operation bin and the gas cylinder through pipelines. The upper-end rigid bin and the lower-end rigid bin of the unsealing bin are fixedly connected with the operation bin through a through hole in the upper surface of the operation bin and a through hole in the lower surface of the operation bin correspondingly, and the lower-end rigid section is connected with the vacuum pump through a pipeline. The unsealing bin communicates with the operation bin through a pipeline.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

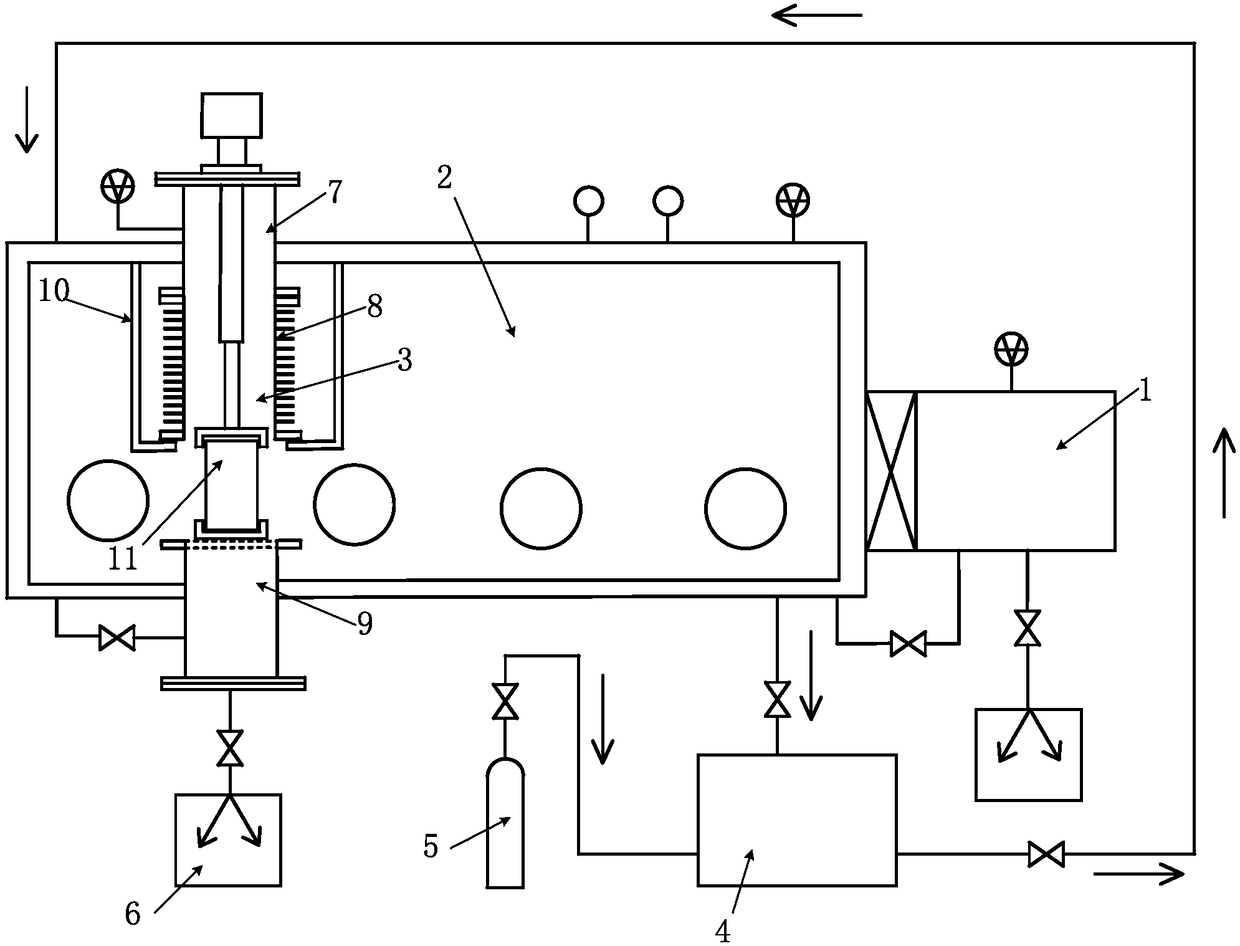

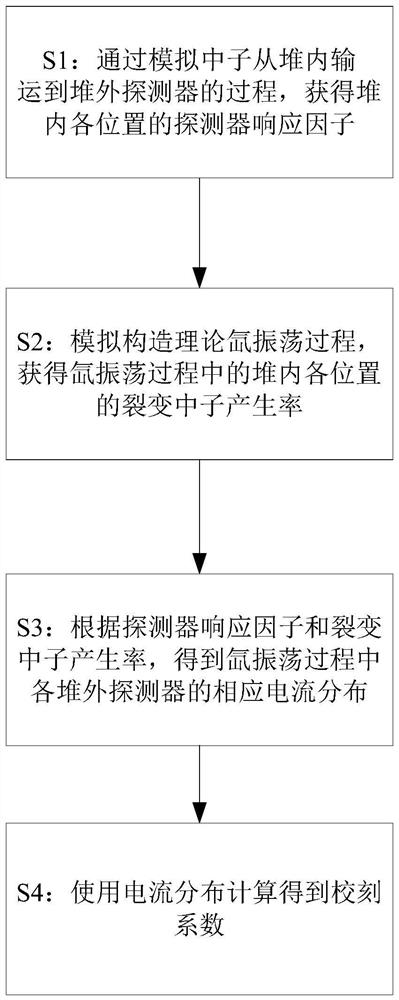

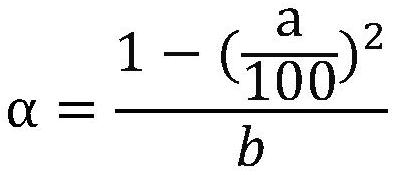

Ex-pile detector calibration method, computer equipment and storage medium

PendingCN114446501AReduce disturbanceRelieve pressureNuclear energy generationNuclear monitoringNuclear engineeringCurrent distribution

The invention relates to an out-of-pile detector calibration method, which comprises the following steps of: S1, acquiring detector response factors at all positions in a pile by simulating a process of transporting neutrons from the inside of the pile to an out-of-pile detector; s2, a theoretical xenon oscillation process is simulated and constructed, and fission neutron generation rates of all positions in the reactor in the xenon oscillation process are obtained; s3, according to the detector response factors and the fission neutron generation rate, response current distribution of all the out-of-pile detectors in the xenon oscillation process is obtained; and S4, calculating the calibration coefficient by using the current distribution. According to the invention, while the implementation of a field xenon oscillation test is cancelled, a set of complete calibration coefficient with enough precision can still be provided, the disturbance to a reactor core is reduced, and the control difficulty of the reactor (especially at the end of the service life) is reduced, so that the pressure of operators is also reduced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

A shield type TBM segment backfill grouting expansion type sealing device and construction method

ActiveCN107587883BEfficient supportEfficient closureUnderground chambersTunnel liningTunnel boring machineEngineering

The invention discloses a backfill grouting expansion type sealing device of a shield type tunnel boring machine (TBM) segment and a construction method. The sealing device involves a rubber capsule and a fixed facility thereof, an air filling and exhaust port, a rubber capsule installation groove structure and construction steps, wherein the rubber capsule is fixed to the interior of a rubber capsule installation groove by virtue of a rubber capsule fixing strip, and the size and length of the rubber capsule can be adjusted as required; a segment filling tube hole, a segment valve hole, the rubber capsule installation groove and a rubber capsule fixing strip installation groove can be prefabricated or formed at a later stage, and the sizes can be adjusted according the size between the segment and surrounding rocks; and the construction steps comprise forming of the segment filling tube hole, the segment valve hole, the rubber capsule installation groove and the rubber capsule fixingstrip installation groove, installation, air exhaust and filling of the rubber capsule and the like. According to the backfill grouting expansion type sealing device, gaps between the shield type TBMsegment and the surrounding rocks can be quickly and effectively sealed, so that the blocking and sealing requirements of backfill grouting are satisfied.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com