Tunnel header main driving omnibearing direction adjusting device

A tunnel boring machine and main drive technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as heavy workload, single labor, and keeping the head of the tunnel boring machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

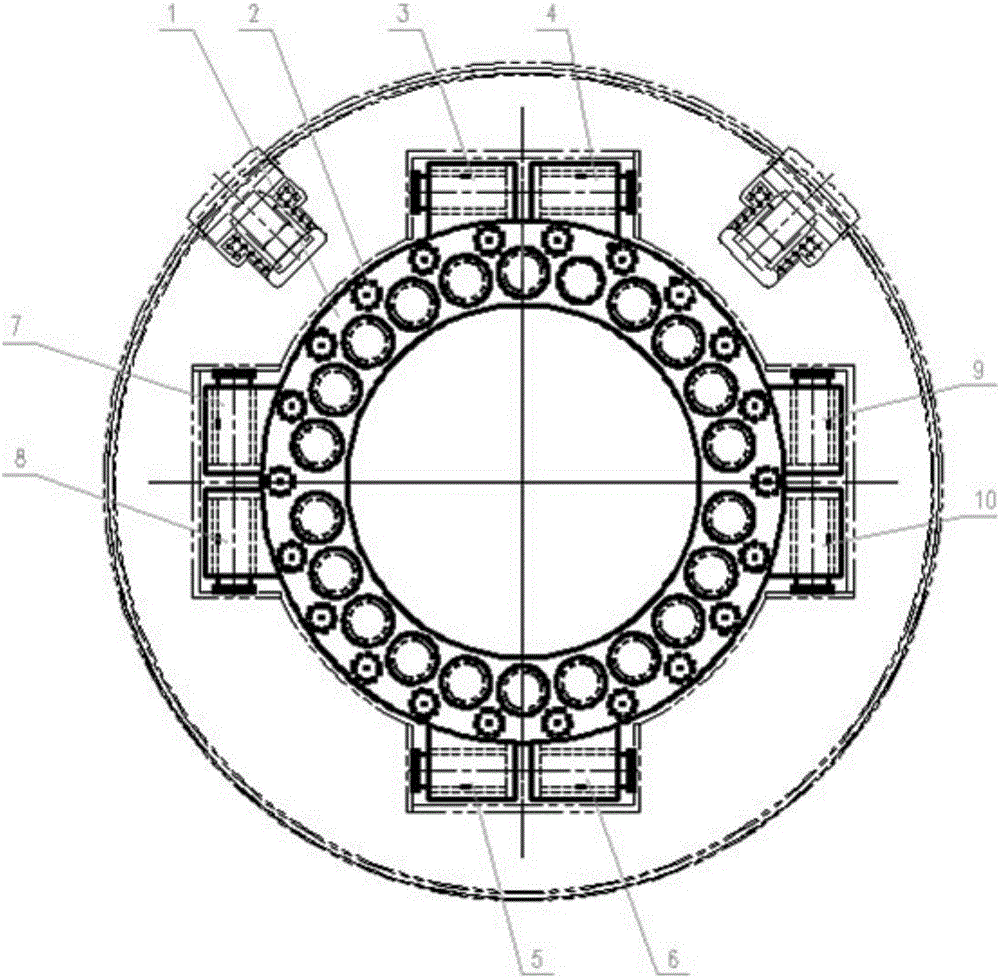

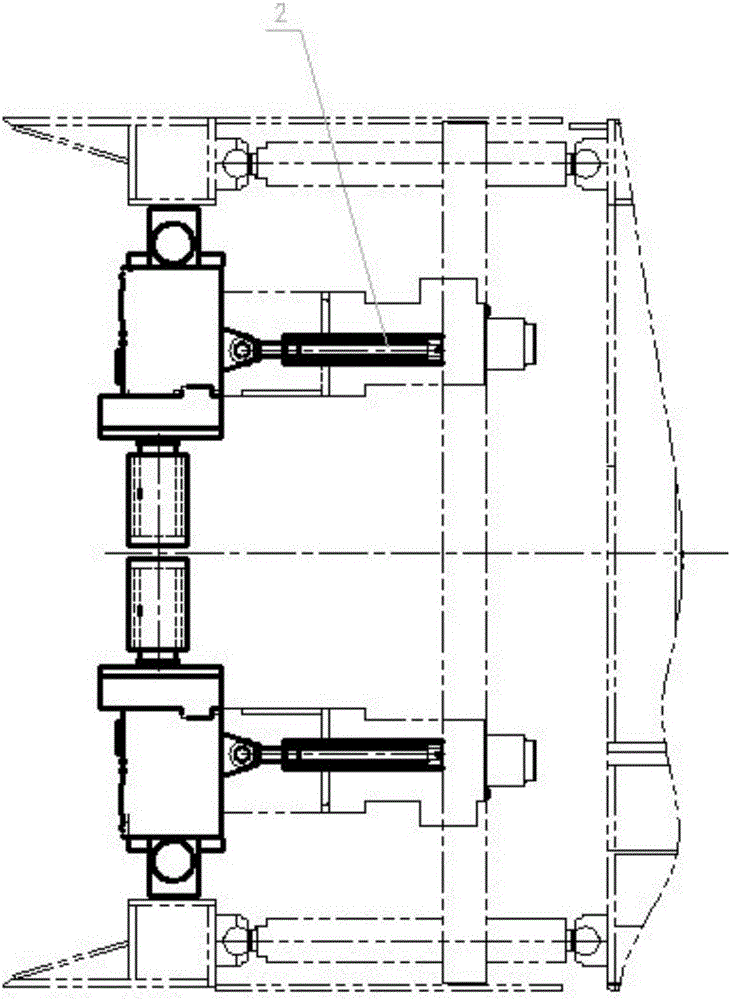

[0011] With reference to the attached drawings, an omnidirectional adjustment device for the main drive of a tunnel boring machine includes a main drive housing 1, a propulsion cylinder 2, an upper left torque cylinder 3, an upper right torque cylinder 4, a bottom left torque cylinder 5, and a bottom Right torque cylinder 6, left upper end torque cylinder 7, left lower end torque cylinder 8, right upper end torque cylinder 9, right lower end torque cylinder 10, the main drive housing 1 is installed inside the front shield housing, and the propulsion cylinder 2 The front end is fixed to the main drive housing 1, the tail is fixedly connected to the bracing shield, the upper left torque cylinder 3, the upper right torque cylinder 4 are fixed on the upper part of the main drive housing 1, the bottom left torque cylinder 5, the bottom right side The torque cylinder 6 is fixed on the lower part of the main drive housing 1, the left upper torque cylinder 7 and the left lower torque cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com