Deformation interior detector for big deformation

An internal detector and large deformation technology, which is applied in the direction of instruments, measuring devices, surveying and navigation, etc., can solve the problems of low detection accuracy and inability to perform mileage correction of deformed internal detectors, and achieve good passability and deformation adaptability, The effect of reducing the risk of jamming and high detection accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

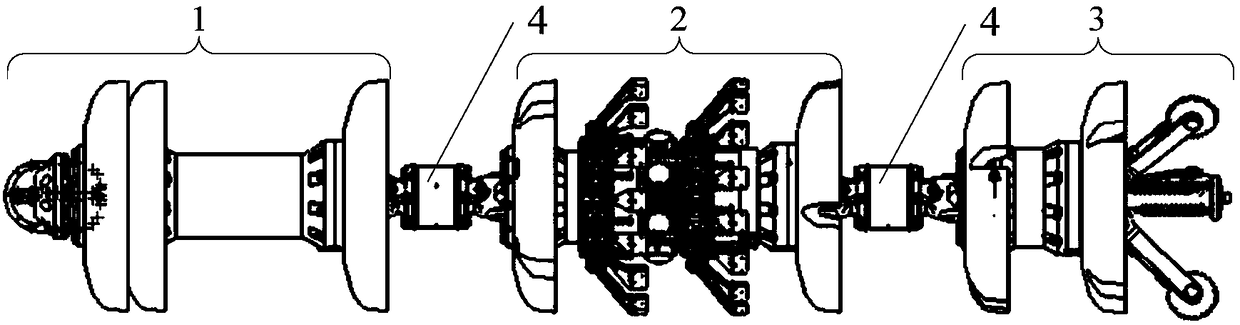

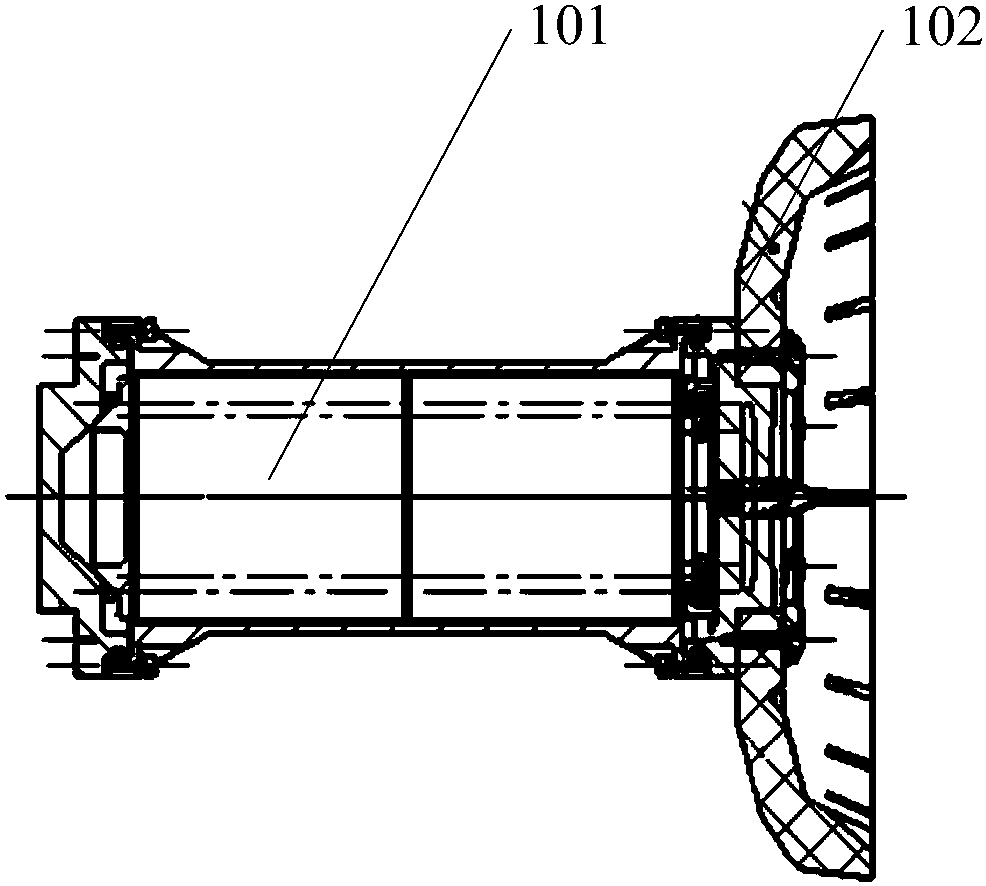

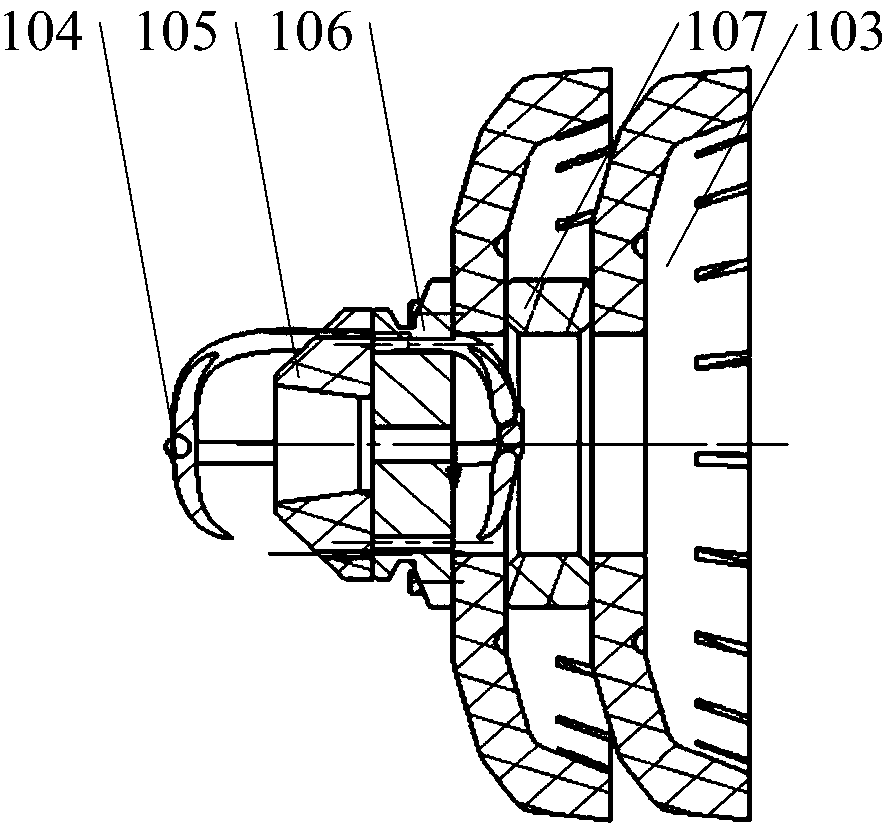

[0035] This embodiment provides a large-deformation in-deformation detector, such as Figure 1 to Figure 9 As shown, it includes an anti-collision power supply mechanism 1, a deformation measurement mechanism 2, and an attitude mileage measurement mechanism 3 that are sequentially connected in rotation. The deformation measurement mechanism 2 includes a central frame 201, an angle sensor 202, a data recording unit 203, and a plurality of The swing arm inductors 204 distributed in the circumferential direction are rotationally connected with the central framework 201, and the ends of the swing arm inductors 204 are always in contact with the inner wall of the pipeline. Among them, the anti-collision power supply mechanism 1 is used to supply power to the angle sensor 202, the data recording unit 203, and the attitude mileage measurement mechanism 3; the angle sensor 202 is used to convert the swing arm displacement collected by the swing arm sensor 204 into angle data, and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com