Automatic paving control system for paving machine

A paver and central control technology, applied to roads, road repairs, roads, etc., can solve the problems of labor waste, traditional paving misoperation, manual operation inaccuracy, etc., to avoid manual misoperation, reduce labor intensity, The effect of reducing inappropriateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

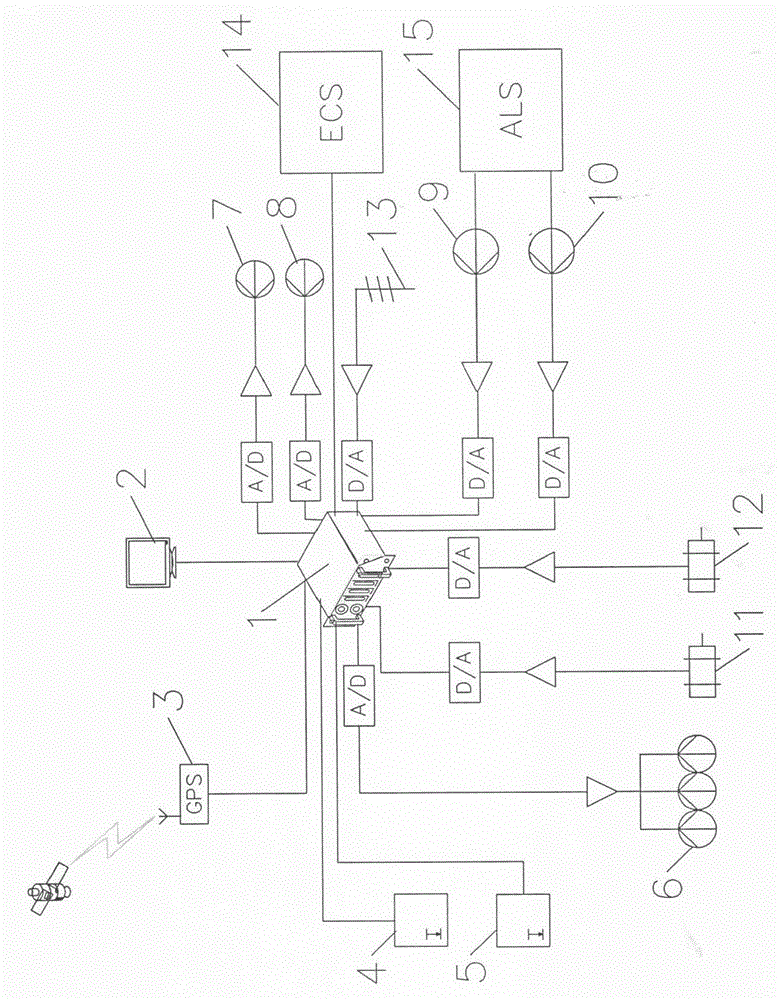

[0008] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, it includes paver automatic leveling system 15, paver electric control system 14, longitudinal slope sensor 9, lateral slope sensor 10, data transmission system, scraper motor 11, screw distributor motor 12, vibrator 13, It also includes central control computer 1, human-computer interaction equipment 2, GPS / Beidou positioning system 3, laser transmitter 4, laser scanner 5, ultrasonic material level sensor 6, speed sensor 7, ultrasonic sensor 8, central control computer 1 and The human-computer interaction equipment 2 is installed in the cab, the GPS / BeiDou positioning system 3 is installed on the top of the paver, the laser transmitter 4 and the laser scanner 5 are also installed on the top of the paver, and the ultrasonic material level sensor 6 is installed in the silo , the ultrasonic sensor 8 is set in the material dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com