Vehicle CNG gas cylinder loading and unloading and carrying device and loading and unloading method

A technology for handling devices and gas cylinders, which is applied in the direction of lifting devices, etc., can solve problems such as low efficiency, inconvenient manual efforts, and inconvenient handling, and achieve the effects of improving work efficiency, reducing physical labor, and using safely and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The structure and working mode of the device of the present invention will be further described below in conjunction with the accompanying drawings and examples.

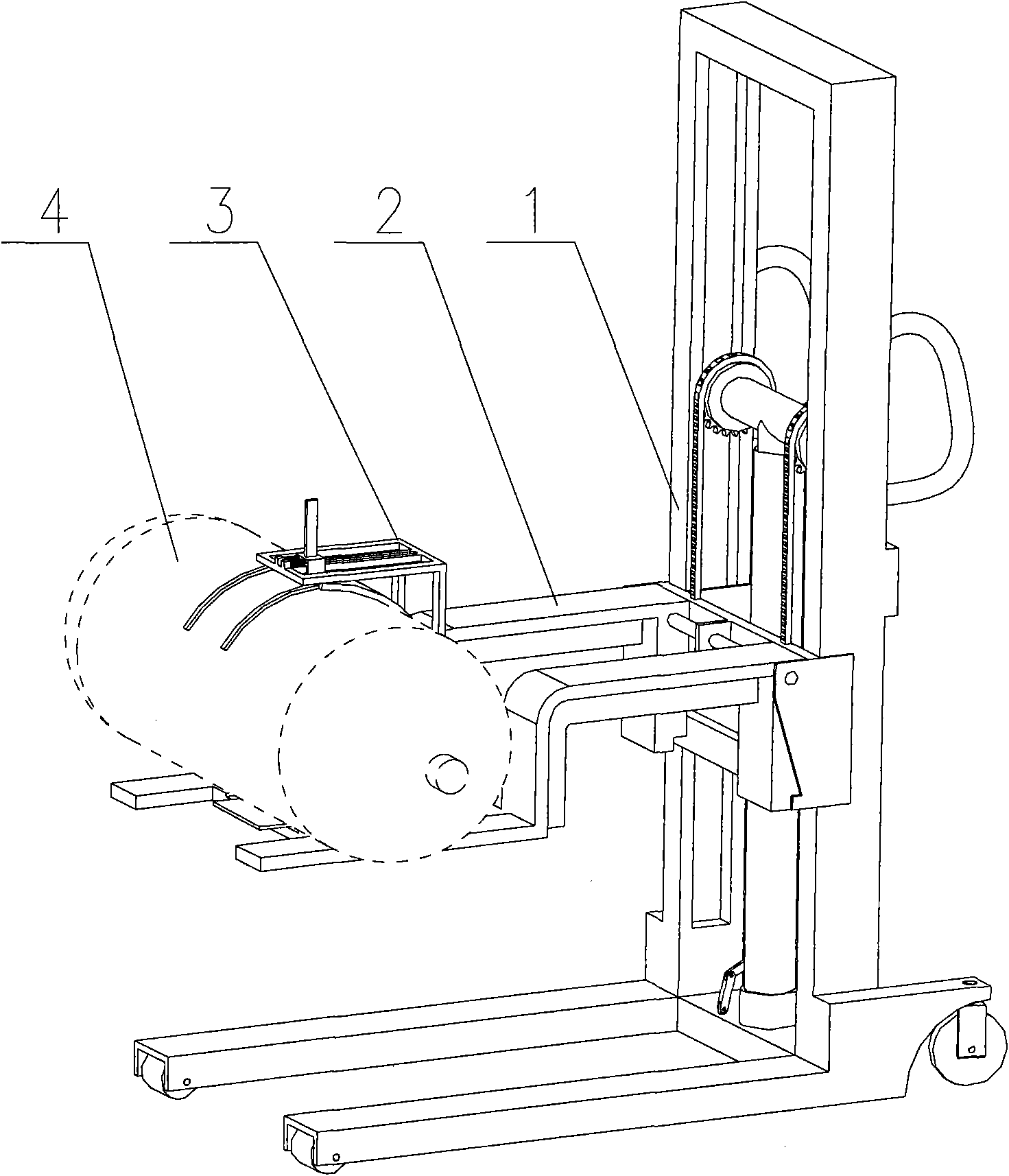

[0067] see figure 1 , The vehicle CNG gas cylinder loading and unloading and handling device is composed of a car body 1, a support arm 2 and a loading and unloading hand 3. The CNG cylinder 4 is the loading and unloading operation object.

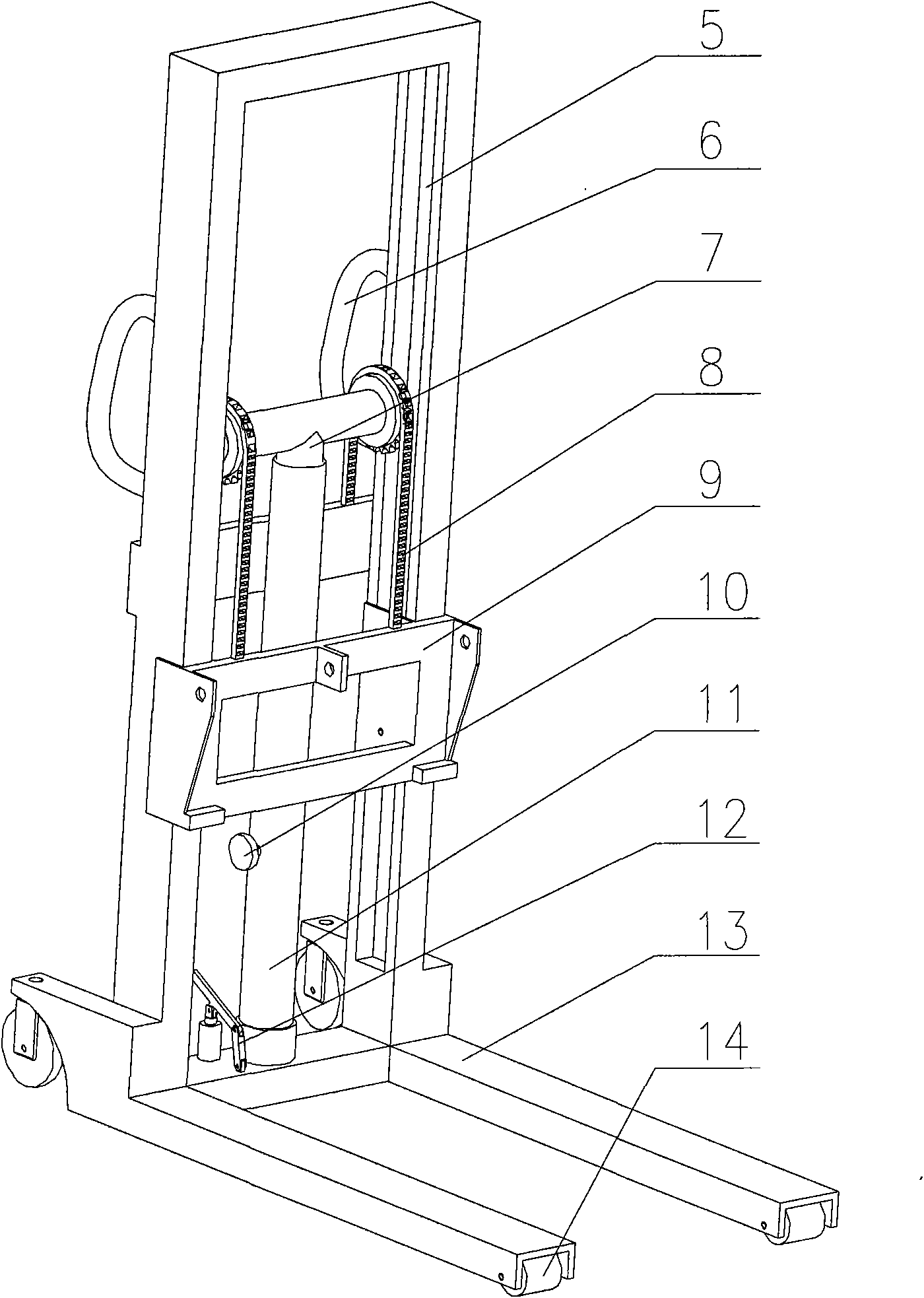

[0068] see figure 2, Car body 1 is made up of vertical sliding groove 5, handlebar 6, elevating rod 7, chain 8, slide plate 9, oil drain valve 10, cylinder barrel 11, operating pedal 12, car body frame 13 and wheel 14. Push the handlebar 6, and the rolling of the wheel 14 drives the car body 1 to advance and retreat horizontally; step on the operating pedal 12, the hydraulic oil enters the cylinder 11 to lift the lifting rod 7, and the oil drain valve 10 is rotated to move the cylinder 11 The hydraulic oil is drained, and the elevating rod 7 can be lowered. Therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com