Ultrafine double-sided adhesive tape die cutting technology

A double-sided tape, die-cutting technology, applied in metal processing and other directions, can solve the problem of inability to complete the ultra-fine product process, achieve the effect of simple and fast waste discharge, reduce manual work, and avoid overflowing glue sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

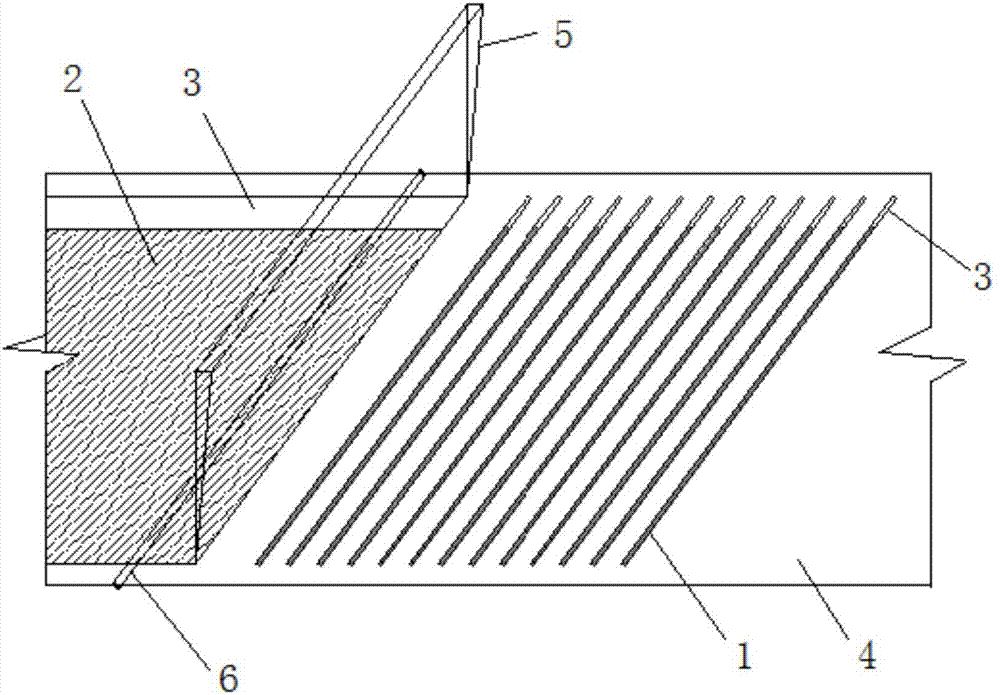

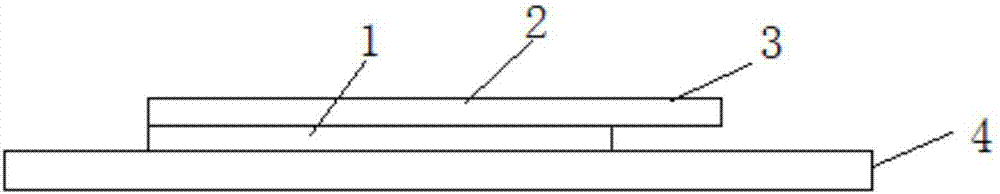

[0020] refer to Figure 1-2 As shown, the present embodiment is an ultrafine double-sided adhesive die-cutting process, comprising the following steps: S1, a double-sided adhesive 1 is provided, the bottom layer of the double-sided adhesive 1 is fitted with a heavy release film 2, and the double-sided adhesive 1 The surface layer is attached with the original release paper, and the double-sided tape is placed in the cutting machine to cut according to the corresponding specifications, and cut into roll-shaped strips.

[0021] S2, Carry out partial roll cutting on the side of the original release paper, cut to the double-sided adhesive 1 position, tear off the double-sided adhesive 1 at the roll cutting position and the original release paper to expose the heavy release film 2 area as the handle part 3 .

[0022] S3, tear off the original release paper bonded by the double-sided tape 1, and replace the light release film 4 whose entire surface is larger than the edge of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com