Method for removing transition metal impurities in silicon wafer or silicon device in sucking mode at indoor temperature

A technology of transition metals and silicon wafers, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as destroying device structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

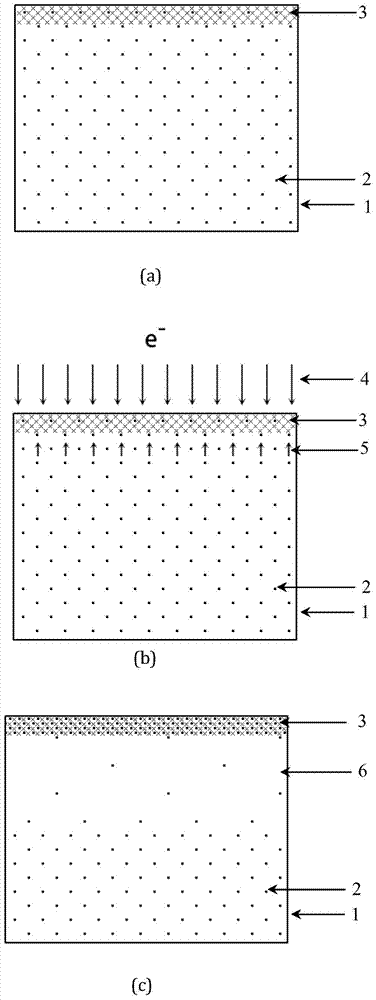

Method used

Image

Examples

Embodiment 1

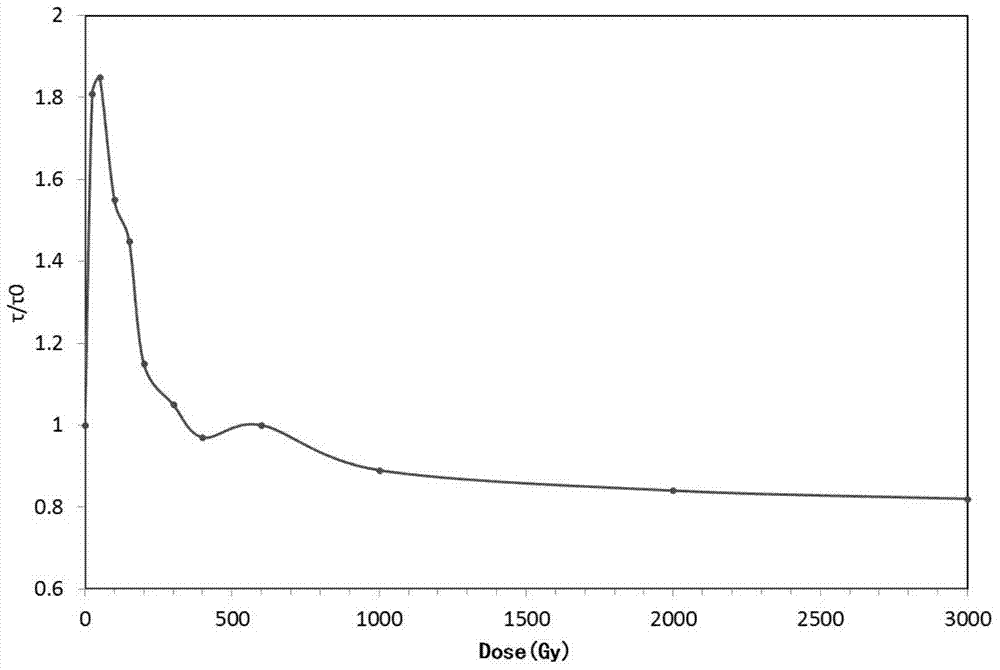

[0020] Gold is injected into the polished silicon single wafer sample, and the transition metal impurity gold in the silicon wafer is removed by electron irradiation gettering method, and the effect of electron irradiation gettering is measured. Specifically, the ion implantation method is used to implant gold, the implantation energy is 550KeV, and the surface density is 1×10 12 cm -2, A silicon single wafer containing transition metal impurity gold was obtained for gettering experiments. Before gettering, use ICP (inductively coupled plasma) equipment to process the silicon single wafer for 2 minutes at a power of 250W, and introduce new defect regions with a depth of no more than 20 nanometers on the front surface of the silicon single wafer. Then use an electron accelerator to irradiate the front side of the silicon wafer at an energy of 3-5 MeV, and the radiation dose rate is about 8Gy / s, τ / τ 0 as a function of radiation dose figure 2 shown. When the irradiation dose...

Embodiment 2

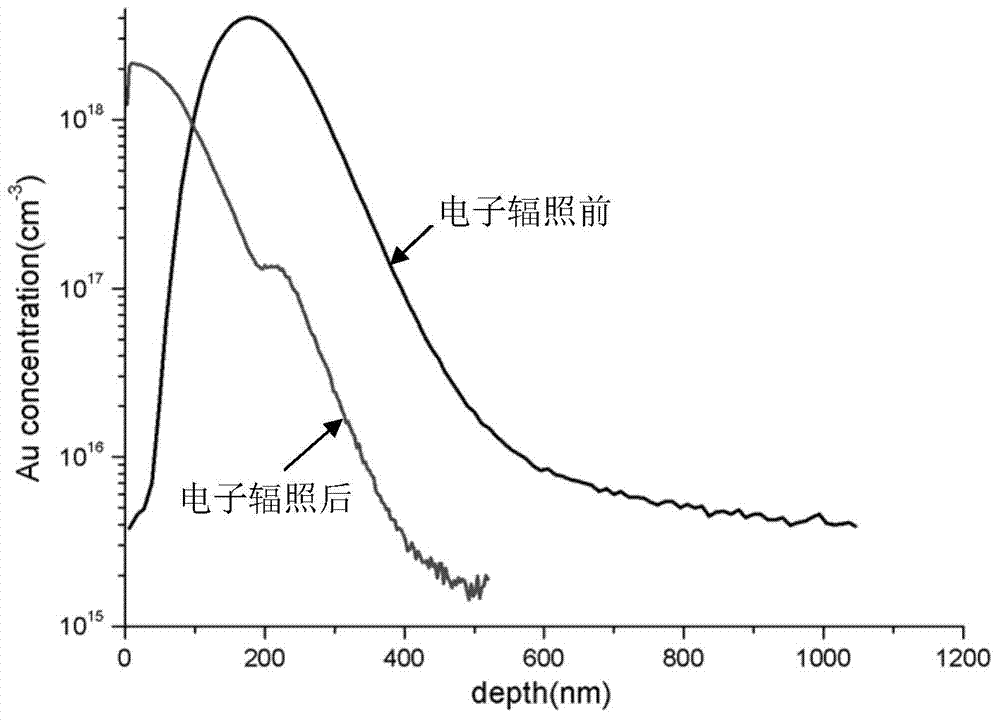

[0022] Gold is injected into the polished silicon single wafer sample, and the gold implanted in the silicon wafer is removed by electron radiation gettering method to detect the effect of electron radiation gettering. Specifically, the ion implantation method is used to implant gold, the implantation energy is 550KeV, and the surface density is 7×10 13 cm -2 . Using the gettering method and condition parameters in the above-mentioned embodiment 1, SIMS (secondary ion mass spectrometry) measures the distribution of gold on the silicon single wafer before and after electron irradiation, and the distribution peak of the impurity gold that was originally in the area to be cleaned is obviously towards the silicon wafer. The gettering defect region on the surface moves, such as image 3 shown. The gettering effect of the transition metal impurity Au diffusing to the gettering defect region and being trapped under electron irradiation was confirmed.

Embodiment 3

[0024] Transition metal impurity gold is injected into the polished silicon single wafer sample, and the effect of absorbing gold in the silicon wafer by room temperature electron irradiation is tested. Specifically, gold is implanted with ions, the energy is 550KeV, and the implantation dose is 1×10 12 cm -2 . Use ICP (Inductively Coupled Plasma) equipment to process the silicon single wafer for 2 minutes at a power of 250W, and introduce a gettering defect region with a depth of no more than 20 nanometers on the front surface. Then use an electron accelerator to irradiate the front of the wafer with an energy of 3-5 MeV, the radiation dose rate is 50Gy / s, and the radiation dose is 200Gy, and measure the ratio τ / τ of the minority carrier lifetime of the sample before and after electron irradiation 0 is 1.96, that is, the minority carrier lifetime is nearly doubled after electron irradiation, reflecting the decrease in the concentration of transition metal gold as a recombin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com