Manufacturing process for energy-saving light electric cable bridge structure

A production process and technology of cable tray, which is applied in the field of production process of energy-saving lightweight cable tray, can solve the problem of not finding patent documents or materials, etc., and achieve the effect of low cost, reduced cost and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

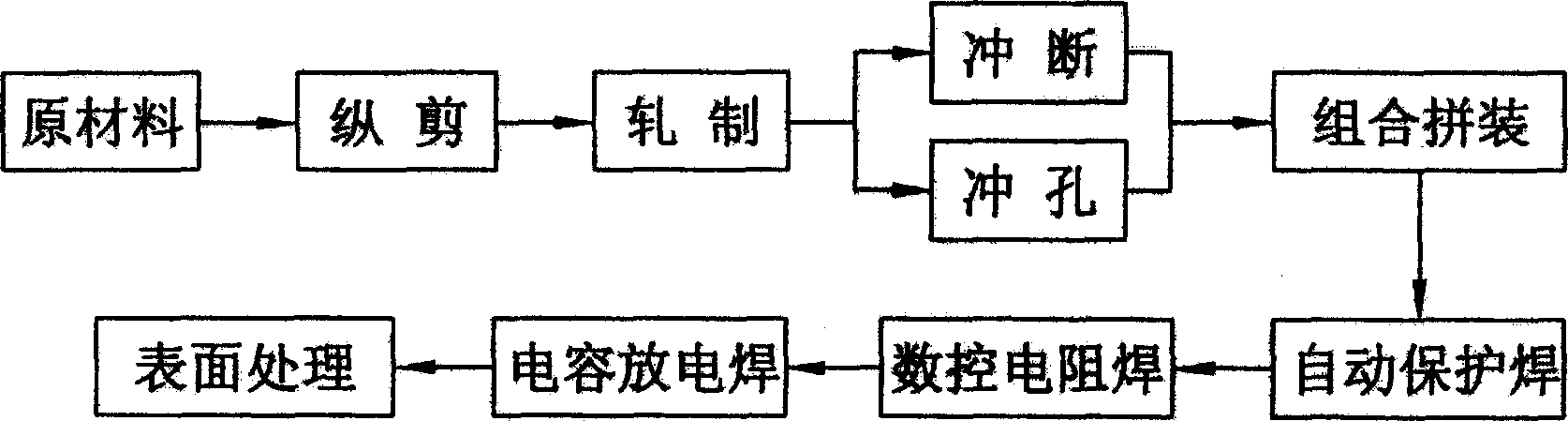

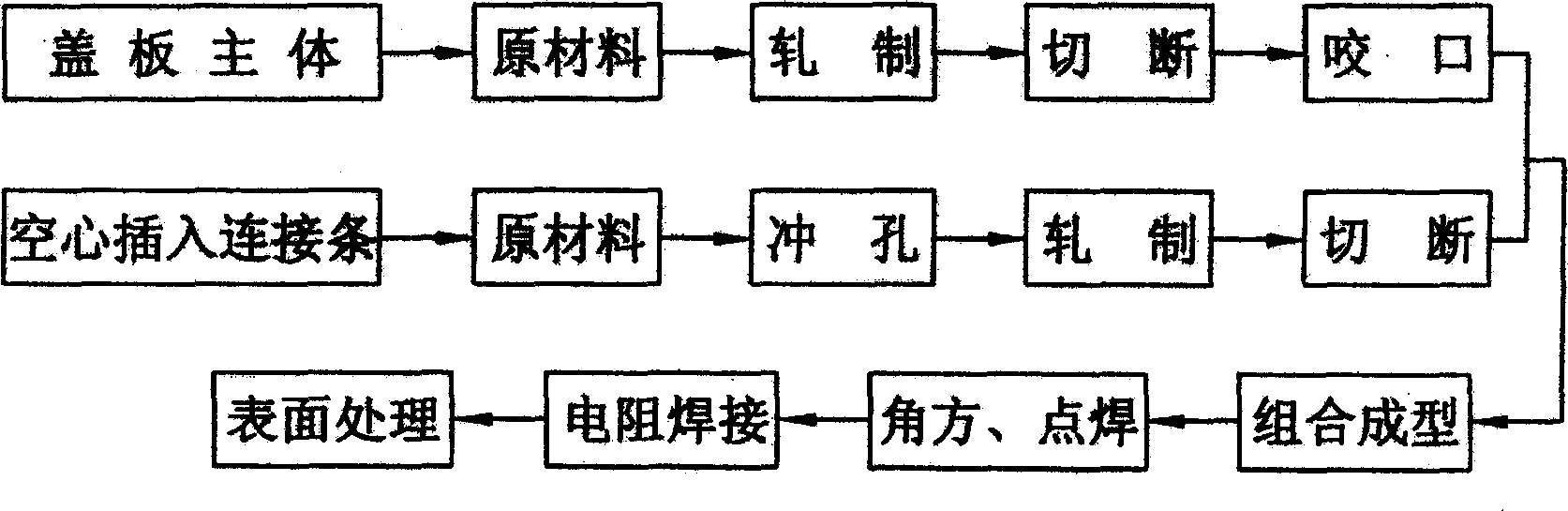

[0060] According to the process flow chart, the entire manufacturing process of energy-saving lightweight cable tray completely abandons the traditional product manufacturing process. The cold-rolled coil is cut into steel strips of fixed specifications by a slitting and slitting machine, and the stretching equipment is used to The steel strip is rolled into concave-convex corrugated bottom plate and U-shaped groove side by multiple rolls. The formed bottom plate is punched into strips according to the width of the bridge product, and the side plate is directly cut by the forming machine into the required bridge frame. The length of the two ends of the side plate and the bottom plate of the tray-type bridge frame are punched into fixed connections and cooling holes by a punching machine. The bottom plate is arranged in sequence and the length of the bridge frame and placed flat on the welding machine track, and the side plate is placed in a standing position. On both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com