Device and method for testing structural fatigue of H-shaped vertical shaft wind turbine blade

A technology for wind turbine blades and fatigue testing, which is applied in the testing of machine/structural components, measuring devices, and testing of mechanical components. Adaptability, accurate and reliable results, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

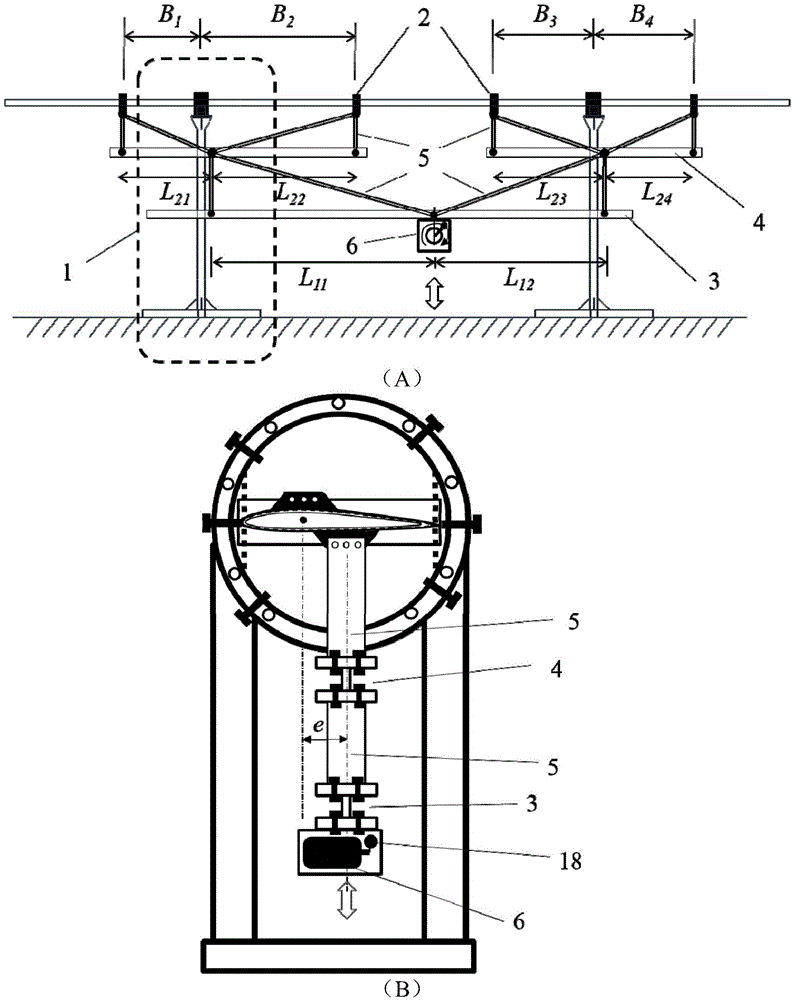

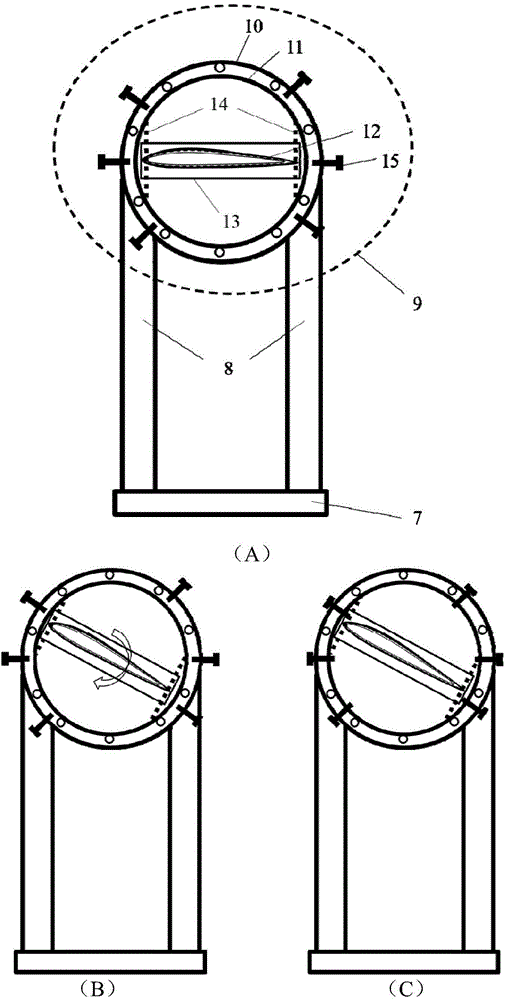

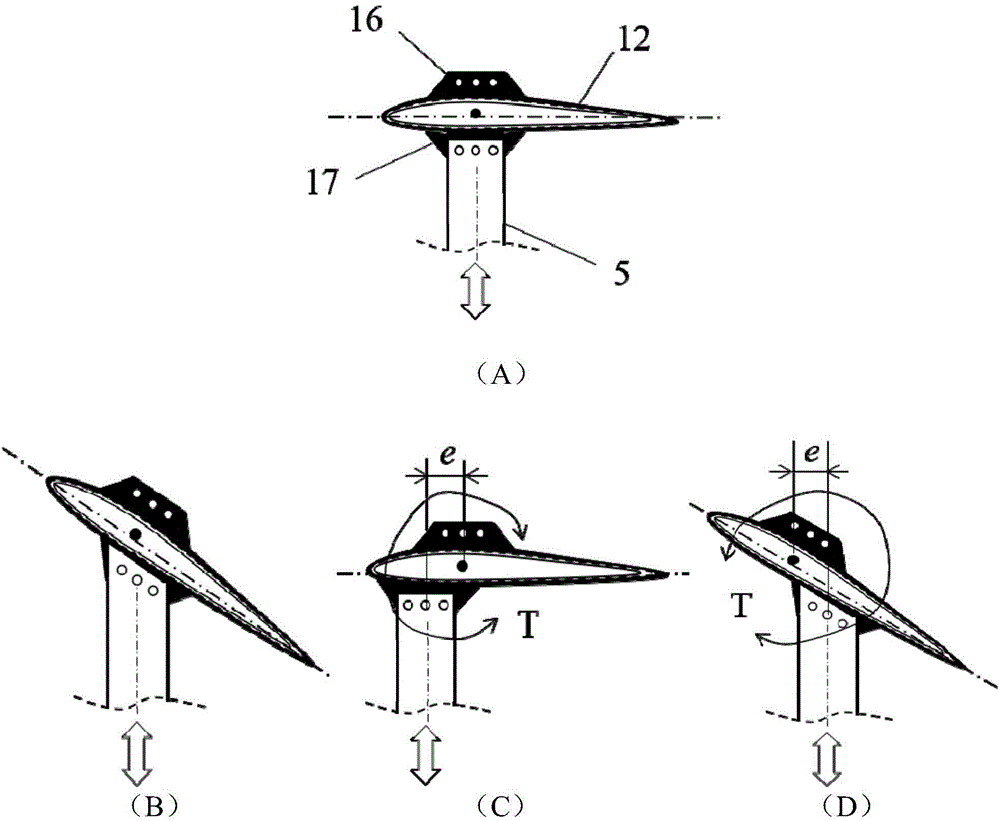

[0025] Take the double-bearing blade as an example, such as figure 1 As shown, the H-shaped vertical axis wind turbine blade structure fatigue test device of the present invention includes a support component 1, a loading hoop 2, a primary distribution beam 3, a secondary distribution beam 4, a supporting link 5, and an eccentric motor 6. . The first-level distribution beam 3, the second-level distribution beam 4, the loading hoop 2 and the support connecting rod 5 are bolted to form the entire load distribution system, which is used to transmit and distribute the fatigue load acting up and down; in the middle of the first-level distribution beam 3 An eccentric motor 6 is provided, and the eccentric motor 6 is used to provide fatigue loads acting u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com