Airflow spray mouth

A technology of airflow nozzles and nozzles, which is applied in the field of combustion to achieve the effect of uniform fuel film and eliminating sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below will contrast embodiment and appended figure 1 To 7, the present invention is further described.

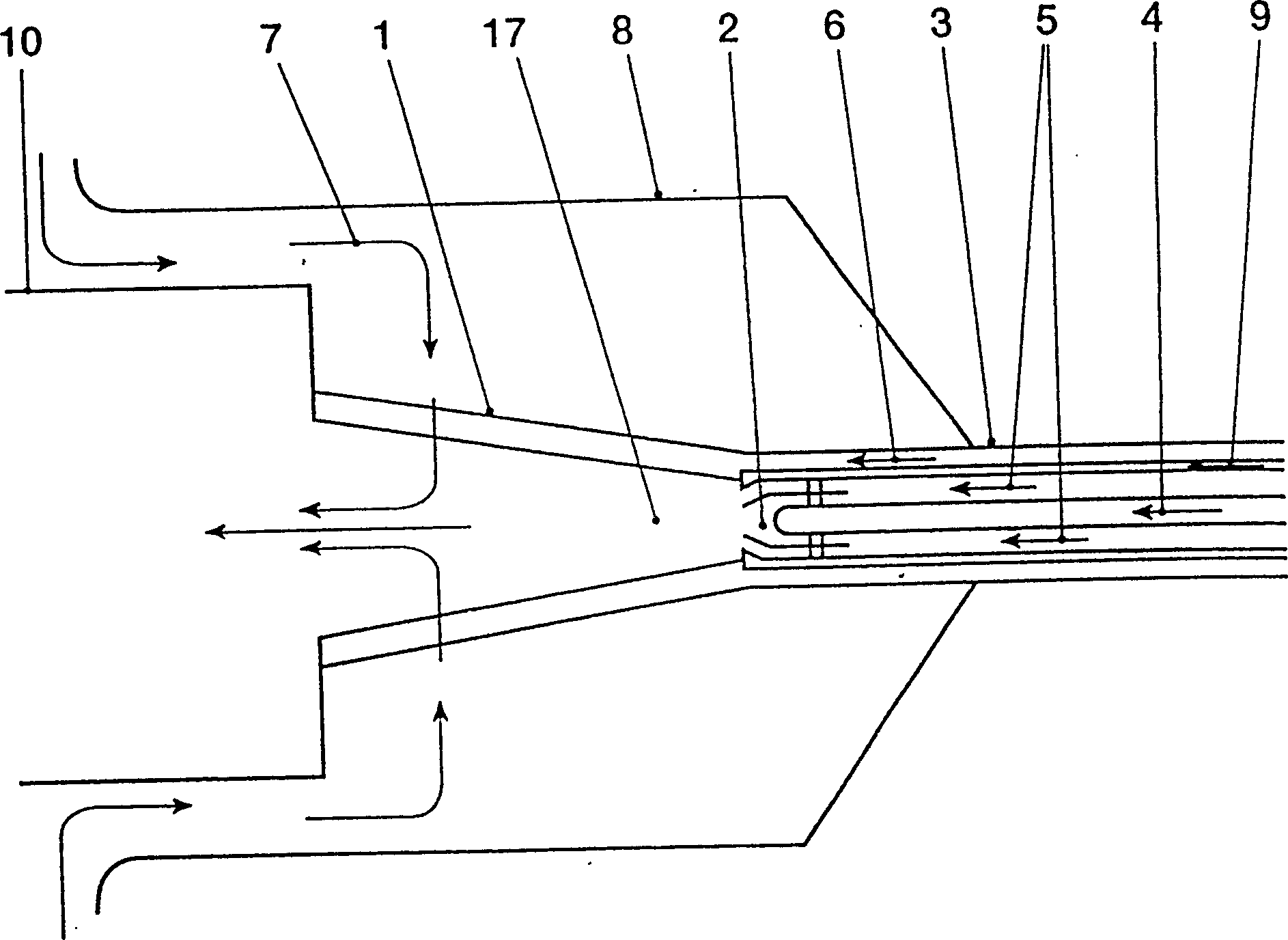

[0031] figure 1 Schematic of the setup for a biconical premixed fuel injector equipped with an airflow nozzle.

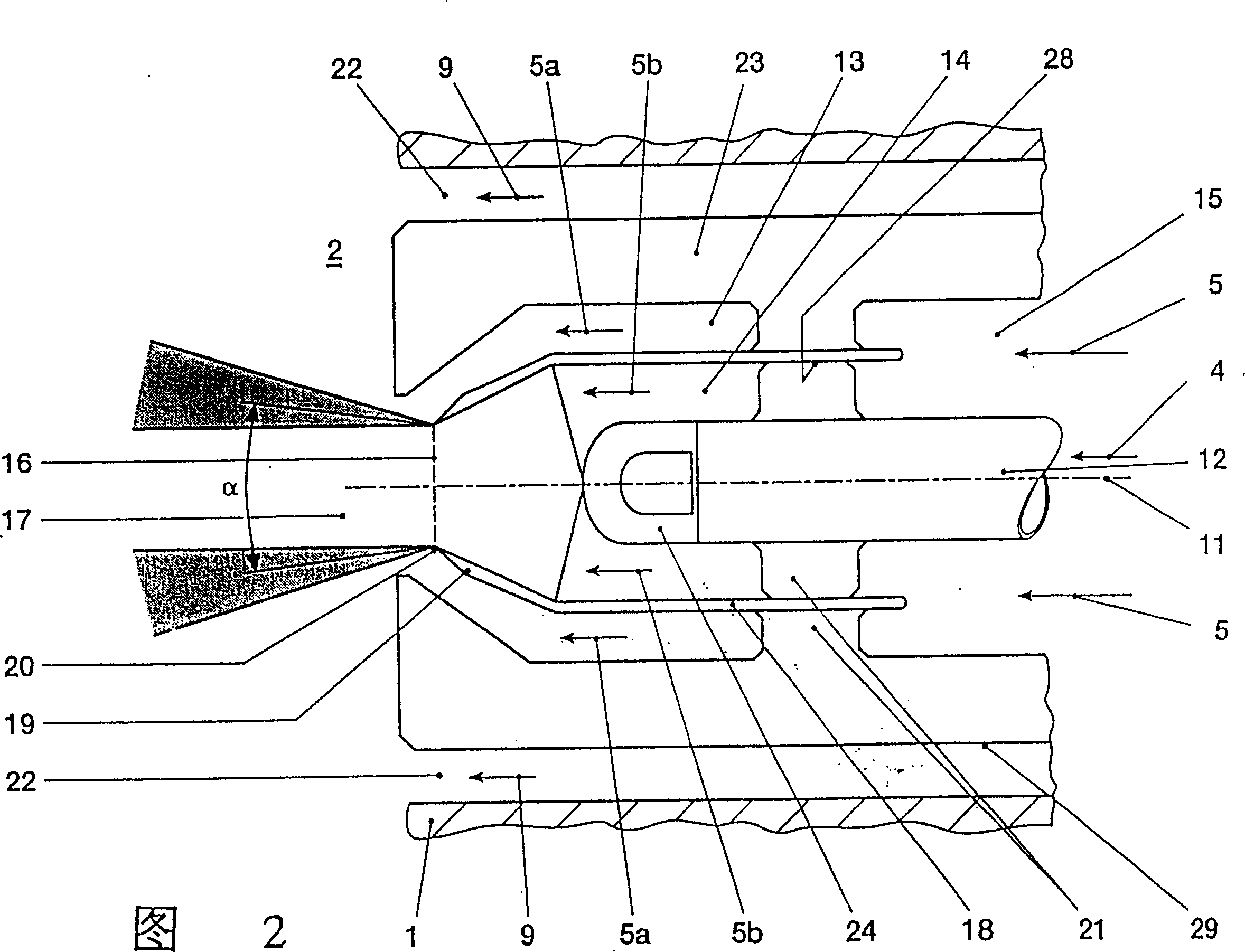

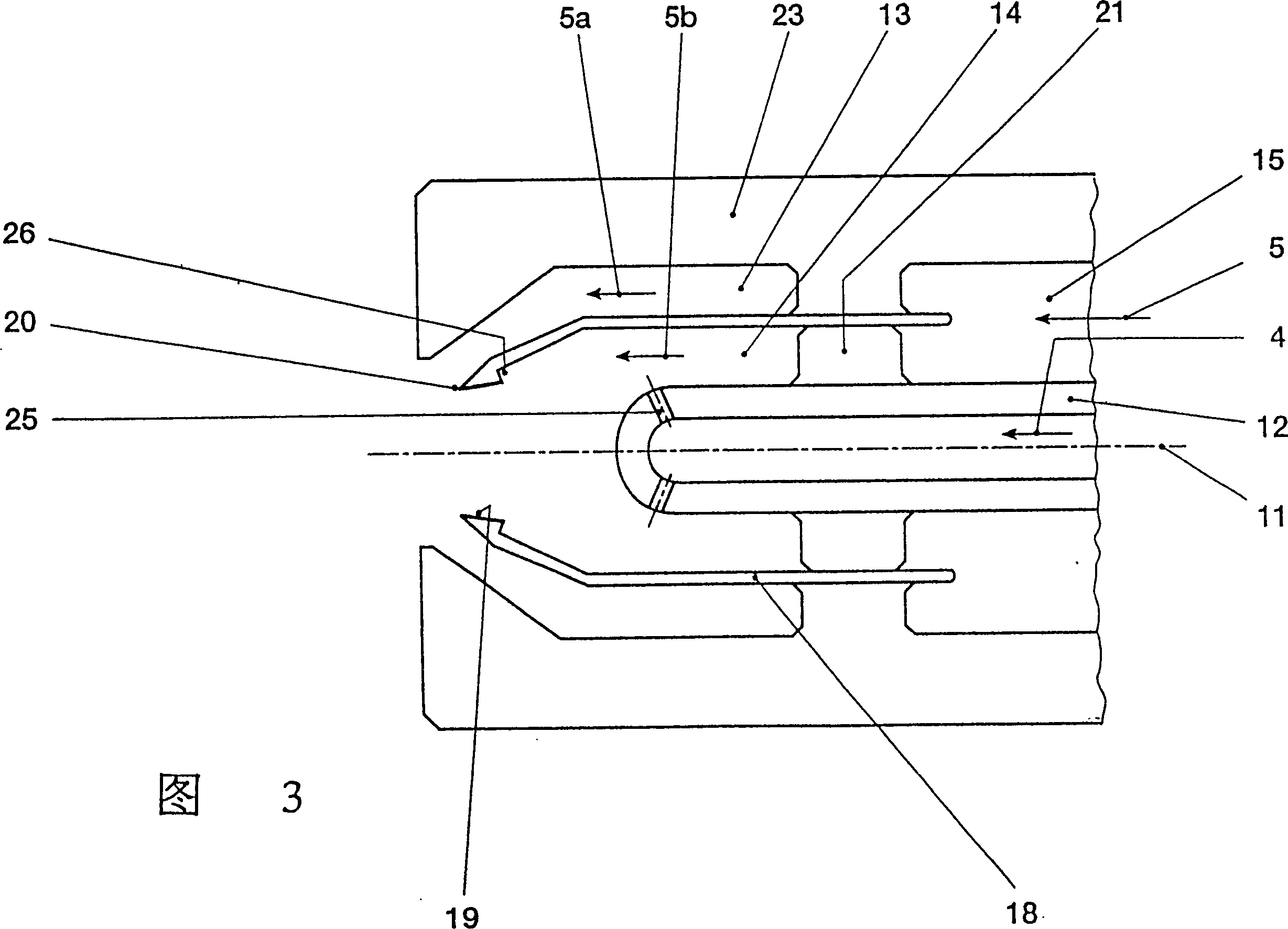

[0032] An air flow nozzle 2 is provided at the upstream end of the burner 1 . The nozzle is supplied with liquid fuel 4 and compressed air 5 via a fuel nozzle 3 connected to the double-cone burner 1 and used for atomizing the fuel 4 . In addition, the fuel nozzle 3 also delivers gaseous fuel 6 to the double-cone fueler 1 , while the gaseous fuel obtains main fueler air 7 from a cavity in the burner housing 8 . The air for the gas flow nozzles 2 can also be supplied by a pressure through system (not shown in the figure) located outside the burner housing 8 . In addition, in this embodiment, additional gaseous fuel (auxiliary gas 9 ) is injected into the burner 1 through the fuel nozzle 3 in order to lubricate the gas near the axis of the nozzle of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com