Electric dry shaver

A dry-type, operating device technology, applied in metal processing and other directions, can solve the problem of limited maximum swing range, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

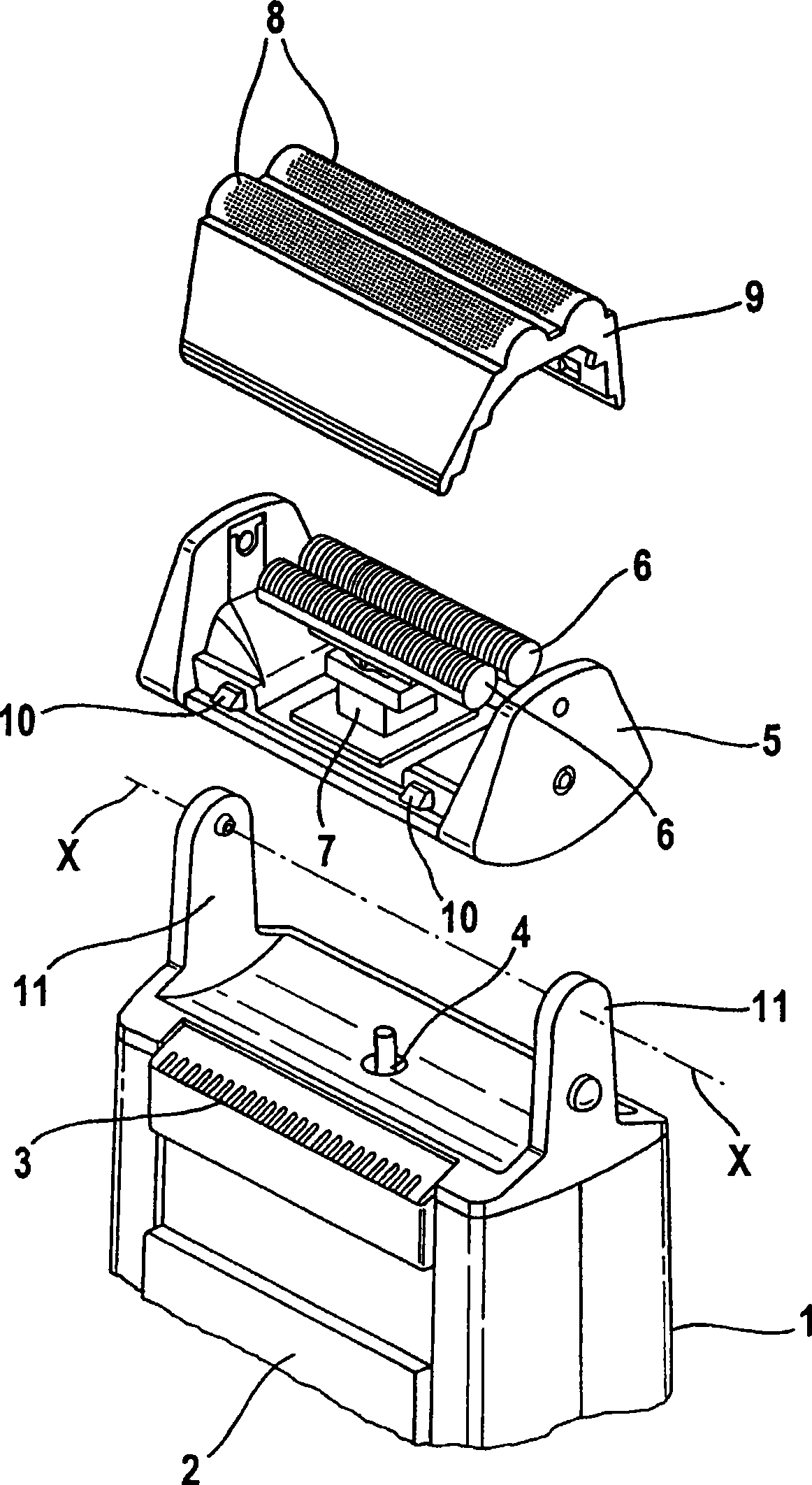

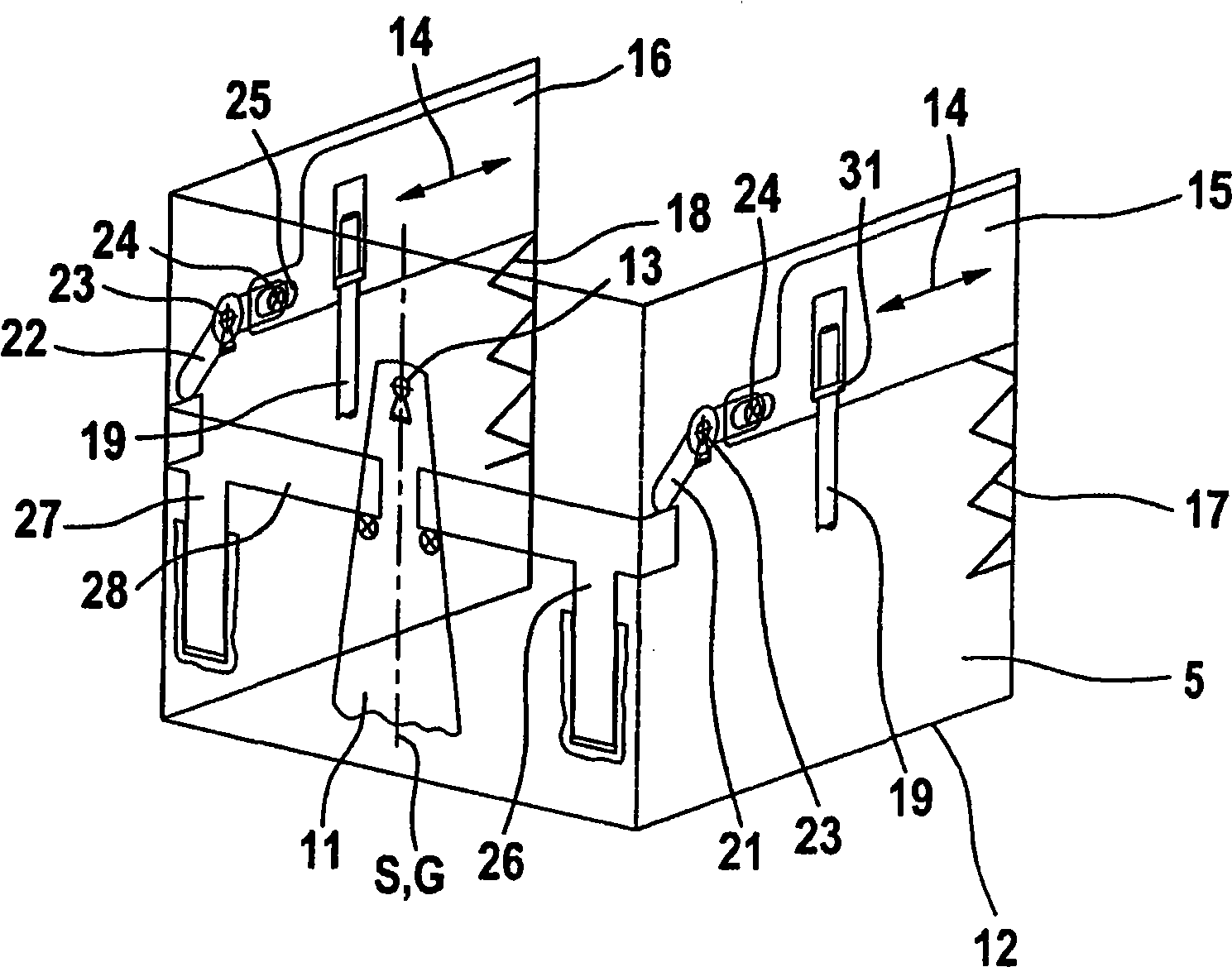

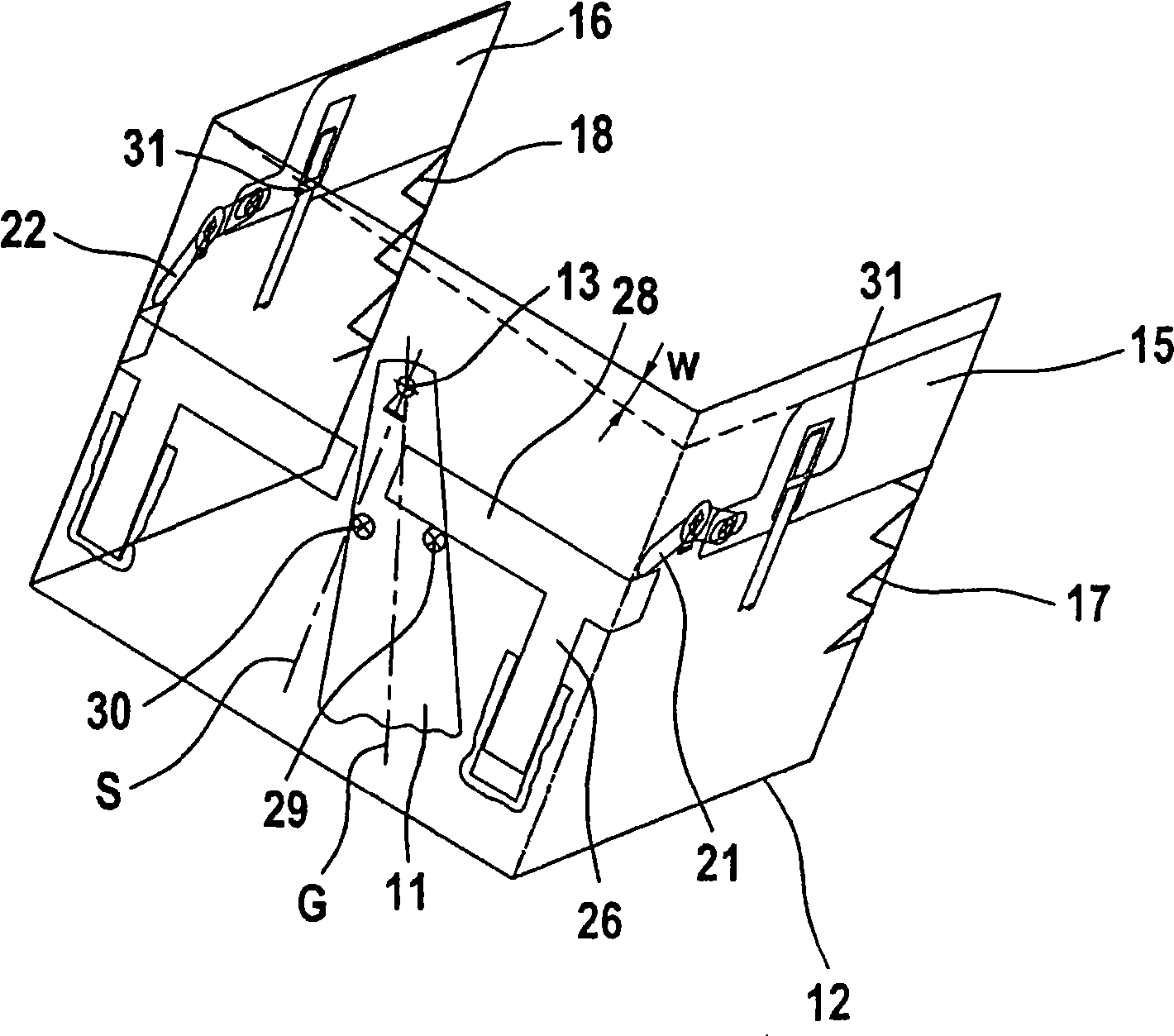

[0019] exist figure 1 The basic structure of a dry shaver with a pivotable trimming head is shown in perspective in the middle, which consists of a housing 1 which accommodates the electric drive and optionally a battery pack, accumulator or the like. On the housing 1 are arranged an on / off device 2 and a trimmer 3 for shortening longer hairs if necessary. At the upper end of the housing, the drive element 4 , which is connected to the electric motor, protrudes from the housing 1 . The pruning head housing 5 accommodates a lower cutter 6 which is formed as a cutter group with a plurality of blades distributed transversely to the direction of oscillation. The lower knife 6 is held by a coupling element 7 which is again connected to the drive element 4 . The upper blade, which is designed as a perforated pruning blade 8 , is held in a frame 9 , which can be connected to the pruning head housing, for example, via latching elements 11 . The trimmer head housing 5 is again suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com