Acceleration test verification method for strength of center of supercharger turbine

A supercharger turbine, accelerated test technology, applied in the testing of machine/structural parts, mechanical parts testing, instruments, etc., can solve the problems of infeasibility, long design life of supercharger turbine, etc., to shorten the test time, The effect of reducing the test cost and improving the efficiency of test verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

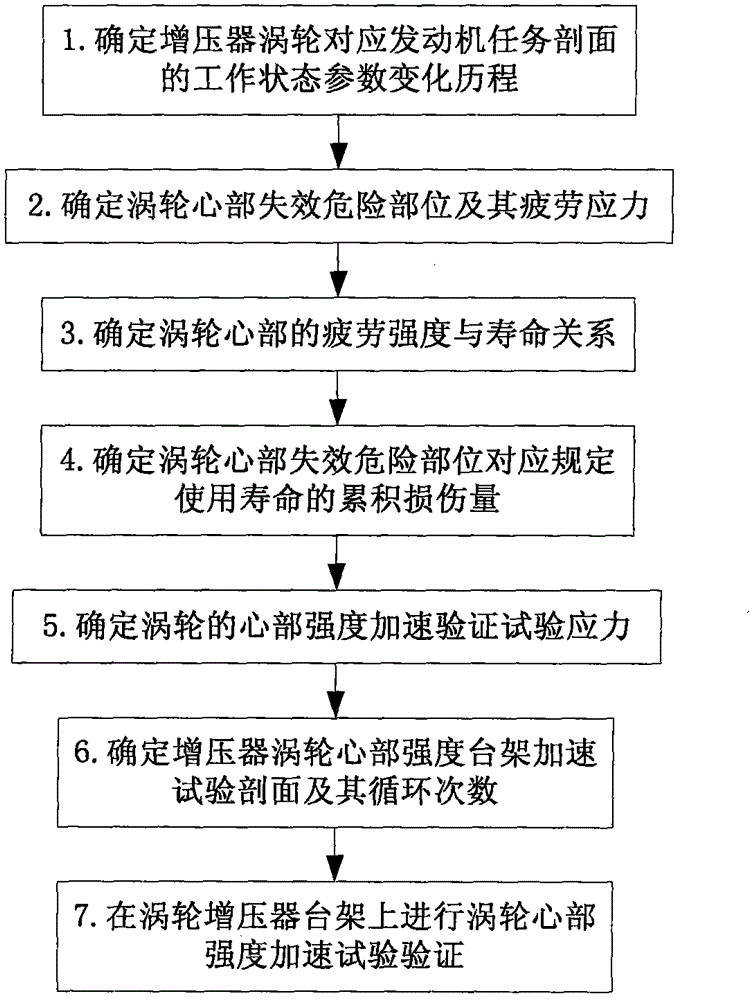

[0028] A turbocharger turbine core strength acceleration test verification method, comprising the following steps:

[0029] a. Determine the working state parameter change history of the turbocharger turbine corresponding to the engine task profile: combined with the engine task profile, through the test method or by using the simulation calculation method according to the performance matching relationship between the turbocharger and the engine, determine the turbocharger turbine corresponding The change history of the working state parameters of the engine's one task profile cycle, including the change history of the turbine speed, the change history of the inlet temperature, the change history of the outlet temperature, the change history of the inlet pressure, the change history of the outlet pressure and the change history of the gas flow;

[0030] b. Determining the dangerous parts of the turbine core failure and their fatigue stress: According to the change history of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com