Steel wire fretting fatigue testing machine and method

A technology of fretting fatigue and testing machine, which is applied in the field of testing machine to achieve the effect of simple structure, easy computer control and measurement, and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

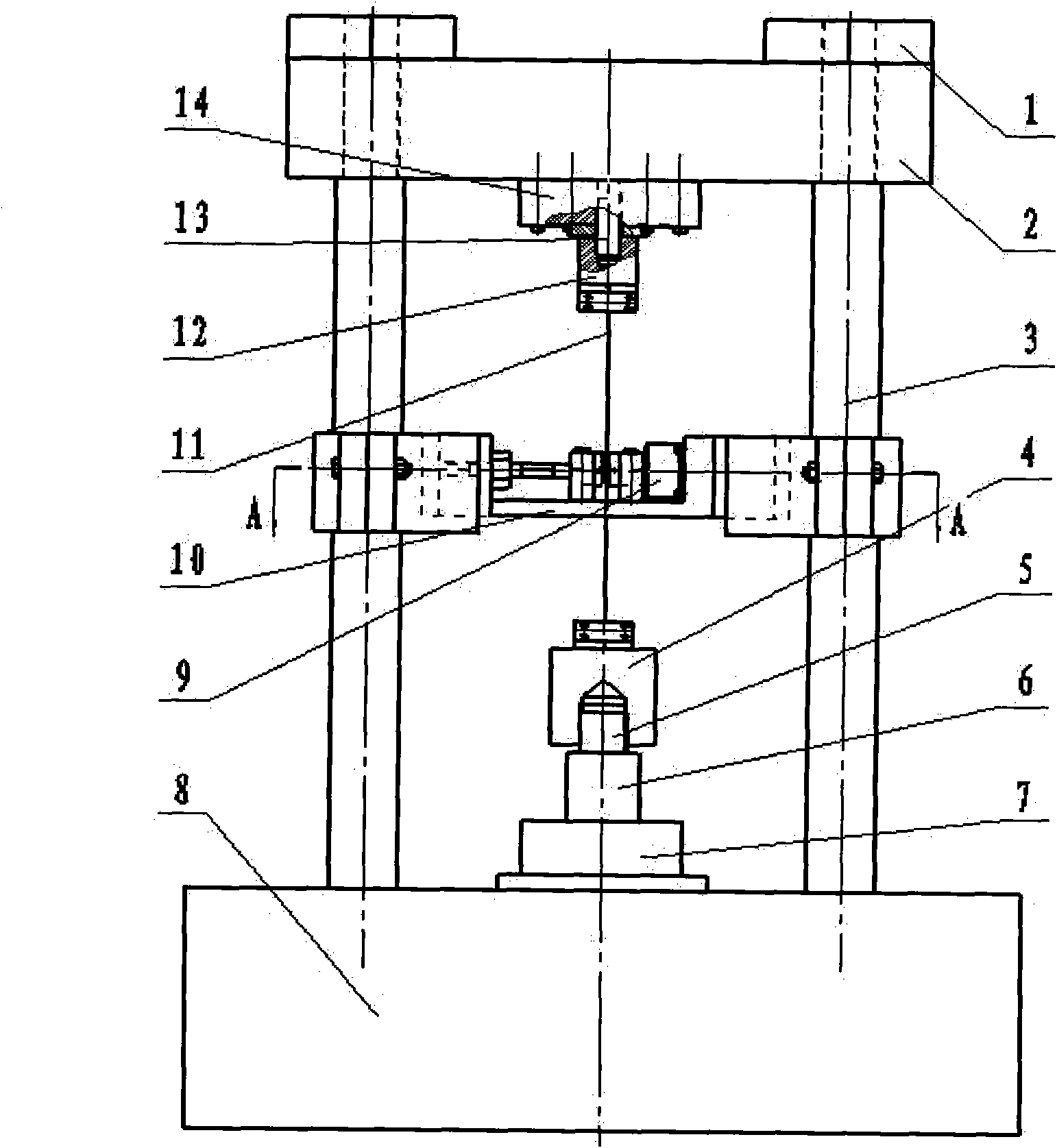

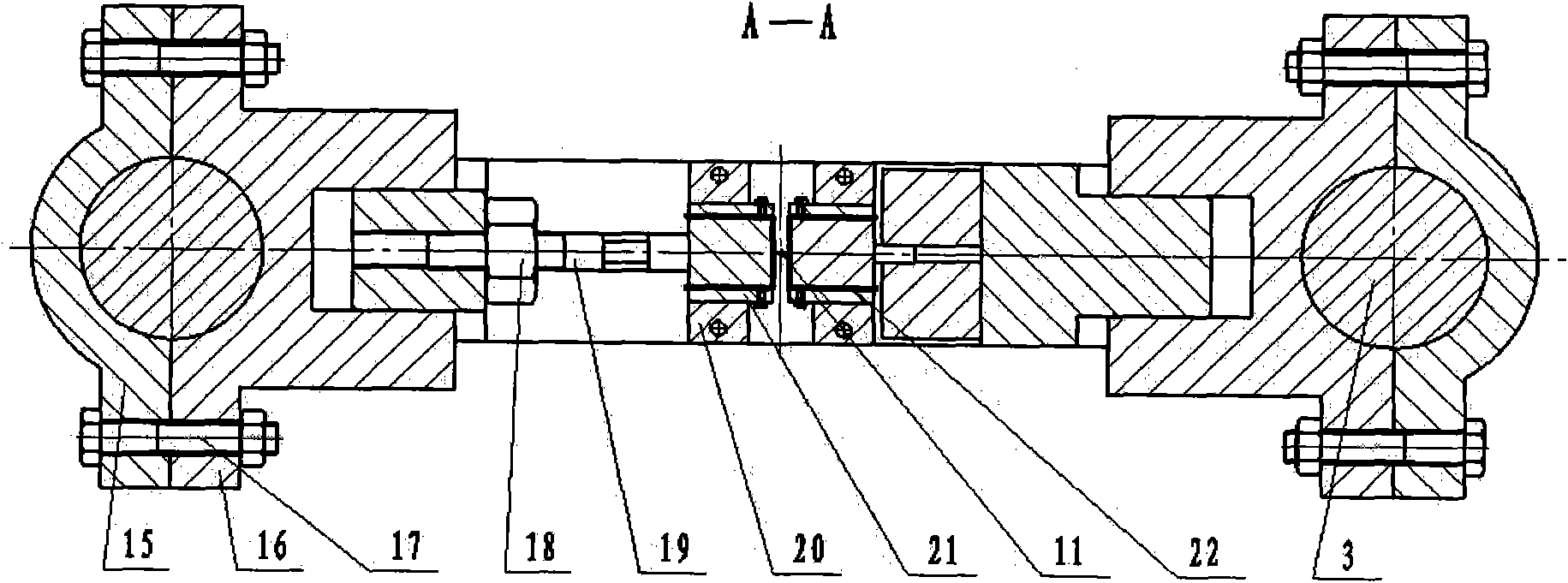

[0020] The steel wire fretting fatigue testing machine of the present invention is mainly composed of a support stand, a horizontal loading device and a fatigue testing device. Support platform is made up of fixed nut 1, upper bearing beam 2, support column 3 and support platform 8, and support column 3 is fixed on the support platform 8, and upper load beam 2 is supported by support column 3, is connected by fixed nut 1. The loading device includes wedge-shaped sliders 21 symmetrically placed on both sides of the axial steel wire. The end face of the wedge-shaped slider 21 is milled with a semicircular groove, and a through hole is punched at the end of the groove. The loading steel wires 22 are respectively placed in the groove, and the The two through holes pass through and are fixed, and two wedge-shaped sliders 21 are respectively placed in guide suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com