Double-outrigger type cable beam anchoring structure of bridge steel box girder

A cable-girder anchoring and steel box technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of large force, static strength and fatigue strength are not easy to meet design requirements, etc., to overcome stress concentration, improve stress safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

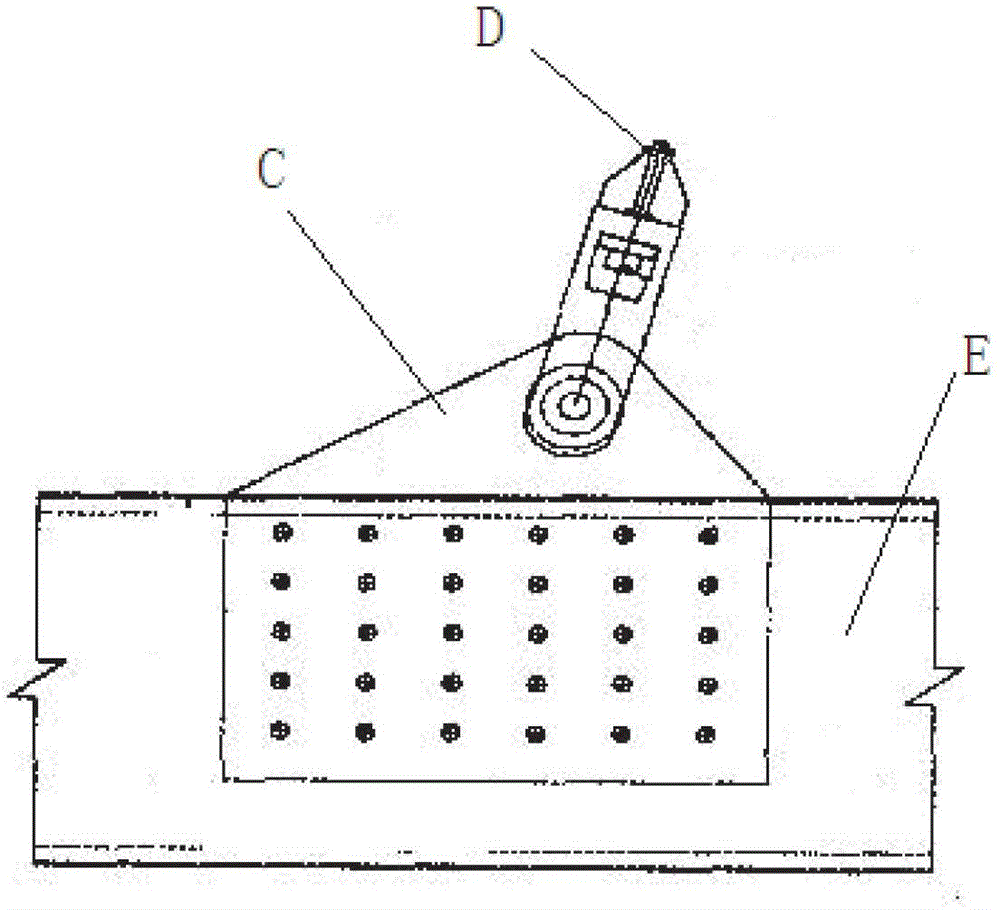

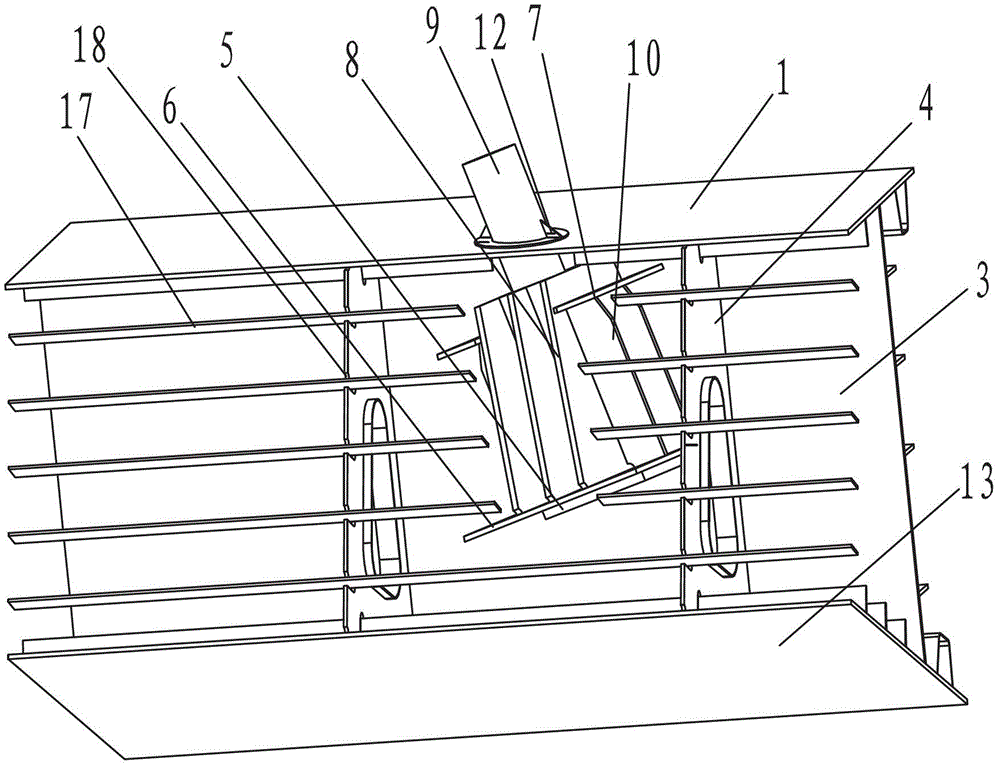

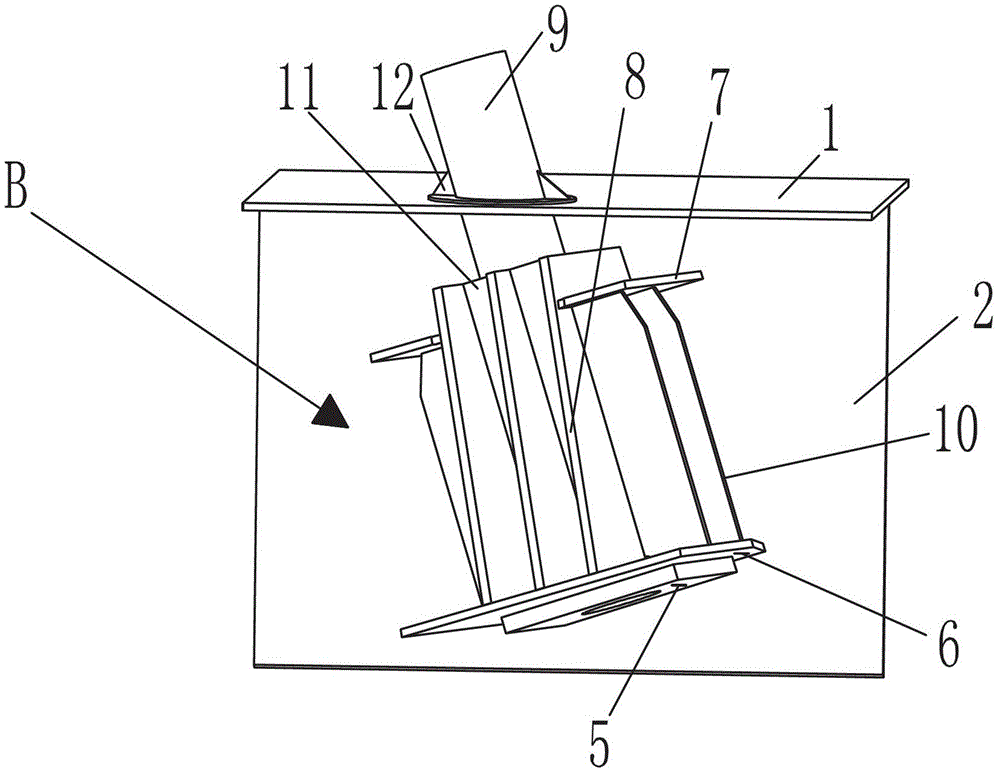

[0032] Such as Figure 2~6 The shown bridge steel box main girder double-slung cable beam anchorage structure includes a steel box main girder A mainly composed of a top plate 1, a side plate 2, a side longitudinal web 3, a bottom plate 13 and a diaphragm 4, and it also includes The anchor box B is used to transmit the force of the stay cables to the steel box girder A. The cable sleeve 9 of the anchor box B runs through the roof 1. The box body of the anchor box B is located in the steel box girder A, and the anchor Both sides of the box body of box B are welded with the side plate 2 and the side longitudinal web 3 respectively.

[0033] In the above technical solution, the anchor box B includes an anchor plate 5, a pressure bearing plate 6, a transverse support plate 7, a plurality of longitudinal support plates 8, and a cable sleeve 9 passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com