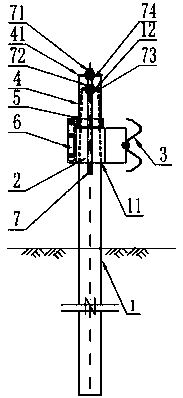

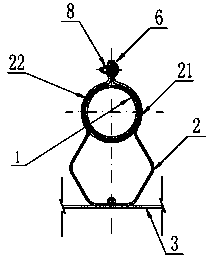

Frustum-shaped height-adjustable guardrail fixing cap and method of use thereof

A fixed cap and frustum-shaped technology, which is applied to bridge parts, roads, bridges, etc., can solve the problems that the height of the guardrail beam cannot be adjusted steplessly, the guardrail is unsafe, and the height of the guardrail beam cannot be adjusted steplessly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

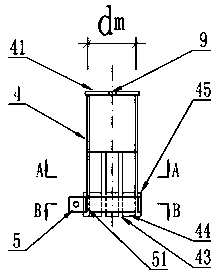

[0211] The frustum-shaped column is made of Q235 steel, and the diameter of the steel pipe is , the wall thickness is 4.5mm, the reserved amount of the conical column is 30cm, and the guardrail beam is a standard wave beam. The hoop of the guardrail beam is 20cm high and 10mm thick. Open wedge type anti-slip ring and fixed cap anti-slip ring thickness 1 ~ 2cm, using vulcanized rubber or neoprene plate: tearing force 5 , Elongation: 280~400%, nominal hardness 60~70IRHD, working temperature -30℃~60℃.

[0212] Dimension table of related components of fixing cap ( )

[0213]

Embodiment 2

[0215] The frustum-shaped column is made of Q235 steel, and the diameter of the steel pipe is , the wall thickness is 4.5mm, the reserved amount of the conical column is 30cm, and the guardrail beam is a standard wave beam. The hoop of the guardrail beam is 20cm high and 6mm thick. Open wedge type anti-slip ring and fixed cap anti-slip ring thickness 1 ~ 2cm, using vulcanized rubber or neoprene plate: tearing force 5 , Elongation: 280~400%, nominal hardness 60~70IRHD, working temperature -30℃~60℃.

[0216] Dimension table of related components of fixing cap ( )

[0217]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com