On-line following diameter measuring method and device in following grinding

A technology of diameter measurement and grinding, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of V-shaped bodies that cannot be fast and low cost, and achieve the goal of avoiding calculation, manufacturing and inspection Effects of Difficulty, Performance Improvement, Measurement Accuracy and Stability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

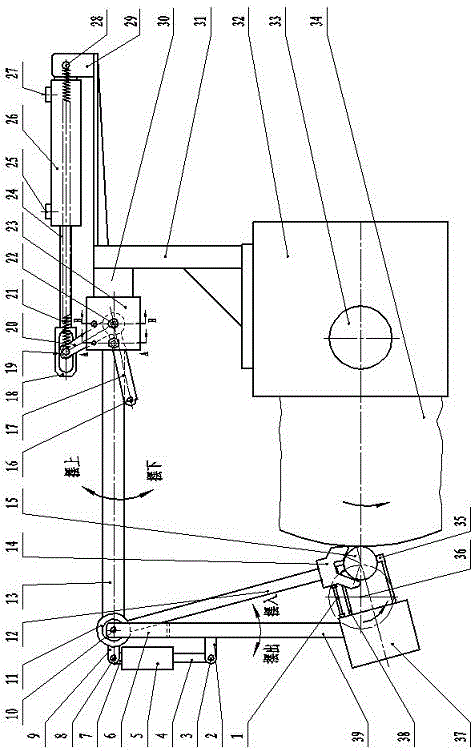

[0040] The invention discloses a method for measuring diameter on-line during follow-up grinding. The method is to make the two jaws of the double-jaw measuring head elastically clamp on the outer diameter of the processed cylinder all the time during the grinding process, and keep the double jaws The freedom of the body of the claw probe to rotate relative to the processed cylinder allows the eccentrically rotated processed cylinder to drive the body of the double-jaw probe to follow the processed cylinder, and is installed on the two jaws respectively The relative two position sensors measure the diameter of the processed cylinder in real time. Therefore, the on-line measurement in the eccentric rotation state is converted into a state similar to the concentric on-line measurement in the grinding of a common cylindrical grinder. The workpieces targeted by the present invention include but are not limited to crankshafts, and the present invention is applicable to all parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com