Molten steel casting device for investment casting

A technology of investment casting and molten steel, which is applied in the field of molten steel casting devices for investment casting, can solve the problems of sparks and high-temperature metal particle processing personnel injury, interference, and damage to protective clothing, so as to improve operation convenience and production efficiency, save Elimination of filter disassembly process, the effect of reducing the degree of splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

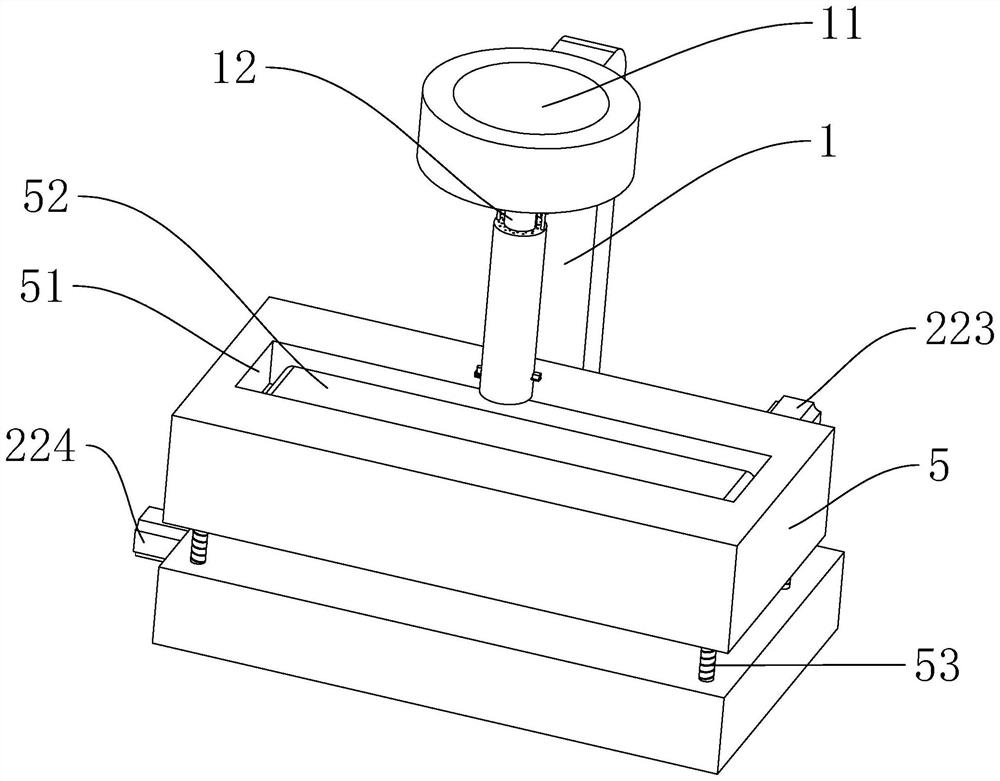

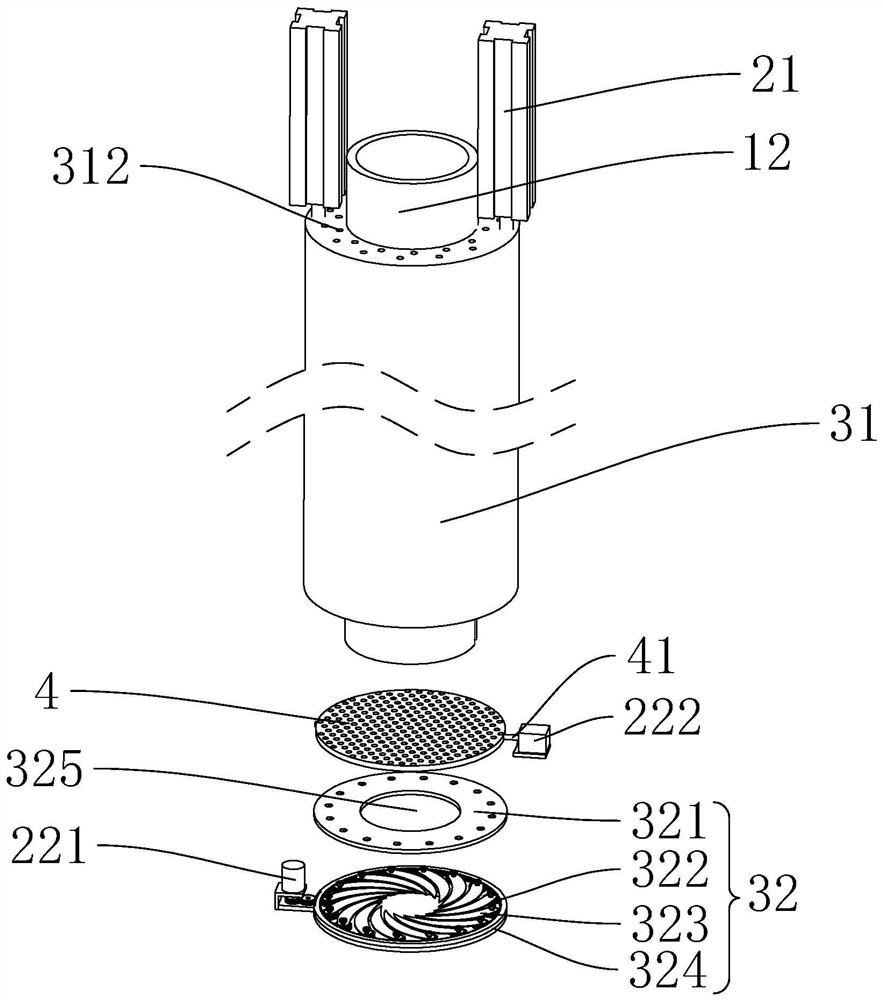

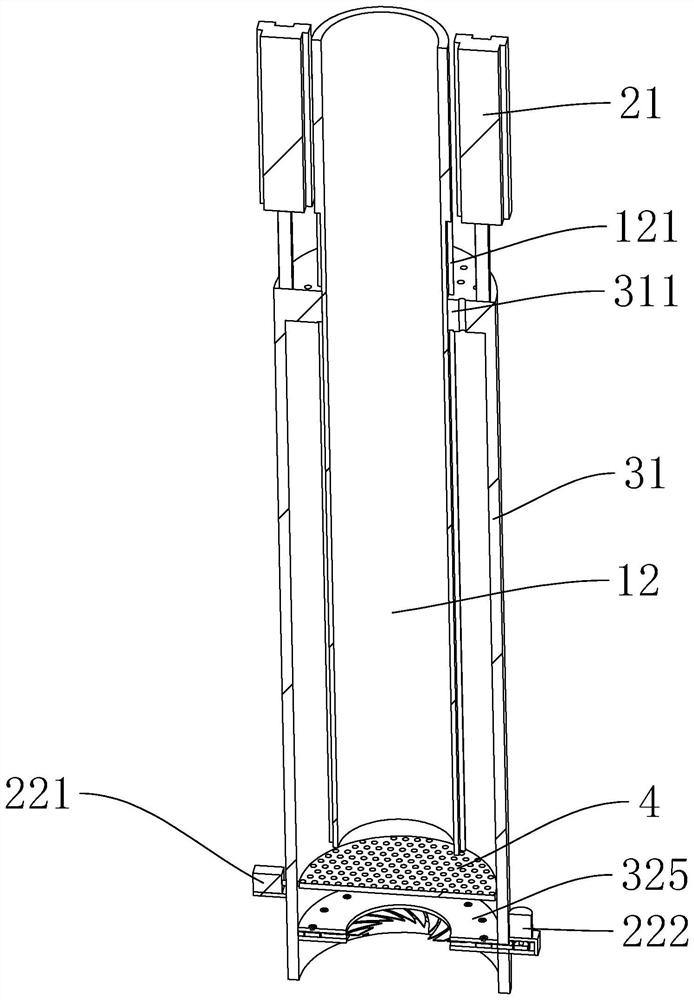

[0037] Attached to the following Figure 1-4 This application will be described in further detail.

[0038] The embodiment of the present application discloses a molten steel casting device for investment casting. refer to figure 1 and figure 2 , the molten steel casting device for investment casting includes a frame 1, a drive assembly, a partition assembly and an operating table 5. The frame 1 is placed vertically, and the top of the frame 1 is fixedly installed with a holding pool 11. The pool wall of the holding pool 11 is in the shape of a Arc-shaped, the accommodating pool 11 is used to hold molten steel, and the bottom of the accommodating pool 11 is connected with a guide pipe 12, and the guide pipe 12 is used to send the molten steel in the accommodating pool 11 from the pouring riser into the mold shell; The assembly includes a protective sleeve 31, the protective sleeve 31 is sleeved and installed outside the guide pipe 12, and the protective sleeve 31 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com