Testing machine for mattress durability

A technology for durability testing and mattresses, applied in the field of experimentation and commodity testing, can solve problems such as low efficiency, not a fully automatic testing machine, manual operation, etc., and achieve the effects of accurate measurement, labor saving, and simple operation.

Inactive Publication Date: 2009-06-03

KUNSHAN INNOVATION TESTING INSTR CO LTD

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the current standard QB / T 1952.2-2004 "Upholstered Furniture Spring Mattress" has undergone major changes on the original standard, and the number of durability classification tests has been uniformly stipulated. Most of the traditional testing machines cannot meet the needs. There are the following technical defects or deficiencies in the testing of commodities: 1. Existing durability testing machines mostly use PLC and other output devices for test results, which cannot completely record the inspection items required by the latest standards; 2. Although most of the current durability testing machines Some pneumatic components are also used, but it is still a semi-automatic equipment, not a fully automatic testing machine, and cannot complete automatic transposition, requiring manual operation, which is inefficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

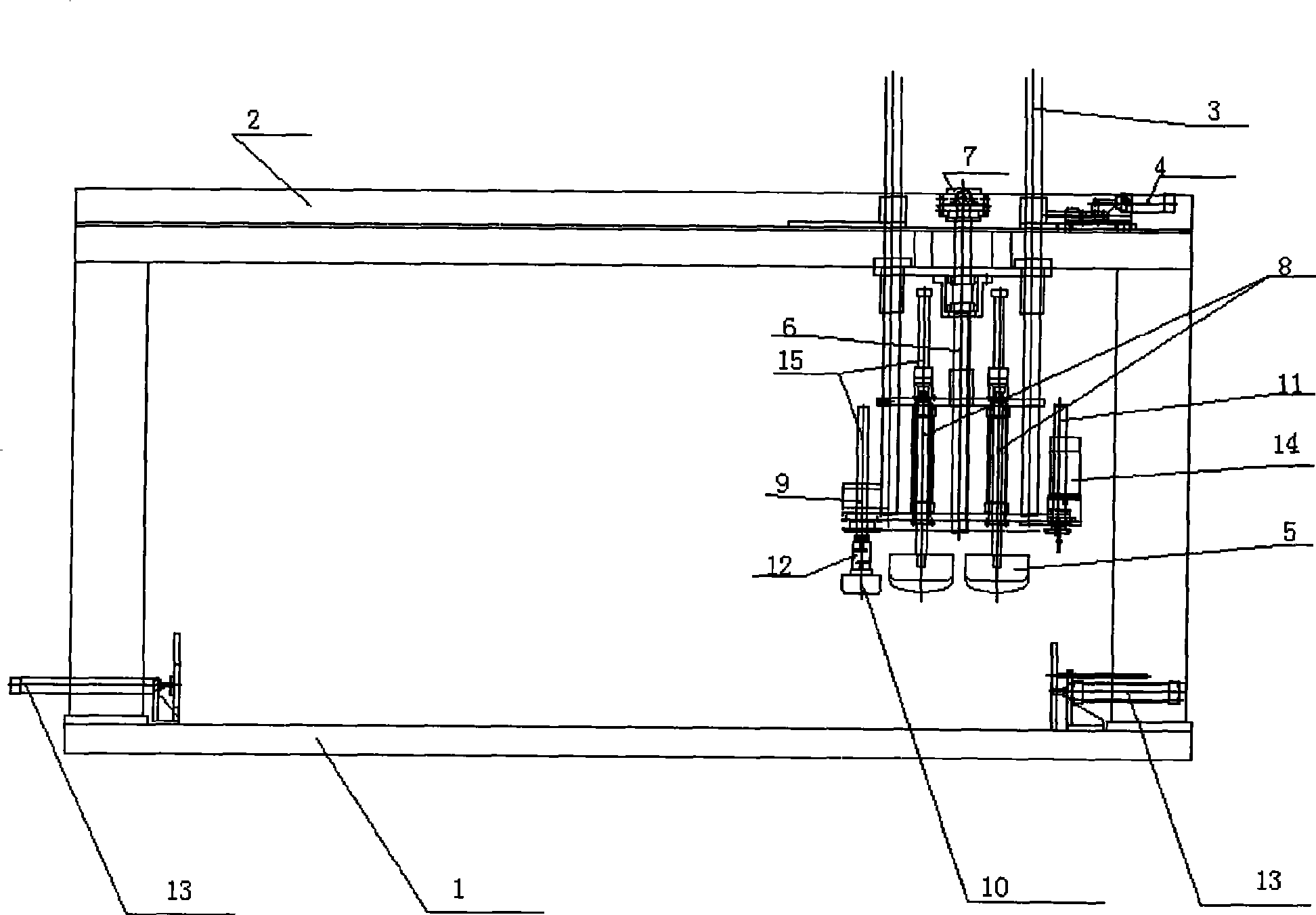

[0010] refer to figure 1 , a mattress durability testing machine, including a control device, a detection platform 1, a loading device, and a detection device, wherein a steel structure beam 2 is erected on the detection platform 1, a loading device is fixed on the beam 2, and the control device is connected to the loading device , the loading device is connected with the detection device.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a testing machine for the durability of a mattress. The machine comprises a test table, a beam, a load device, and an electromagnetic valve, the beam stands on the test table, and the load device is fixed on the beam. The machine is characterized in that the machine further comprises a control device, a test device and a test piece position adjustment cylinder, wherein, the test piece position adjustment cylinder is arranged on the test table, the control device is connected with the load device, and the load device is connected with the test device. The control device controls cylinder working frequency through the electromagnetic valve, so as to adjust the load frequency of load units. The test device is fixed on the ledger plate at the bottom of the load device and in contact with the test piece through a round cushion block. The test device is driven by a motor and pulled by a guide post, the displacement of the test device is measured by a displacement instrument and the applied force is controlled by the strength sensor. The invention is used to test the ability of resisting fatigue stress and surface abrasion of the matters after certain times of to-and-fro pressurizing, has the advantages of simple operation, high efficiency and accurate measure, and belongs to the technical field of product inspection and tests.

Description

technical field [0001] The invention relates to a durability testing machine for testing the long-term repetitive load bearing capacity of a mattress, which belongs to the technical field of product testing and experimentation. Background technique [0002] At present, the commonly used durability testing machine is operated in accordance with the QB / T 1952.2-1999 "soft spring mattress" standard. However, the current standard QB / T 1952.2-2004 "Upholstered Furniture Spring Mattress" has undergone major changes on the original standard, and the number of durability classification tests has been uniformly stipulated. Most of the traditional testing machines cannot meet the needs. There are the following technical defects or deficiencies in the testing of commodities: 1. Existing durability testing machines mostly use PLC and other output devices for test results, which cannot completely record the inspection items required by the latest standards; 2. Although most of the curren...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M5/00

Inventor 陶泽成

Owner KUNSHAN INNOVATION TESTING INSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com