Preparation method of epoxy asphalt road surface materials

A technology for epoxy asphalt and pavement materials, which is applied in building insulation materials, roads, roads, etc., can solve the problems of high cost, unexplained water stability, poor water stability, etc., and achieves good deformation ability and durability, shortening Traffic closed time, excellent effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

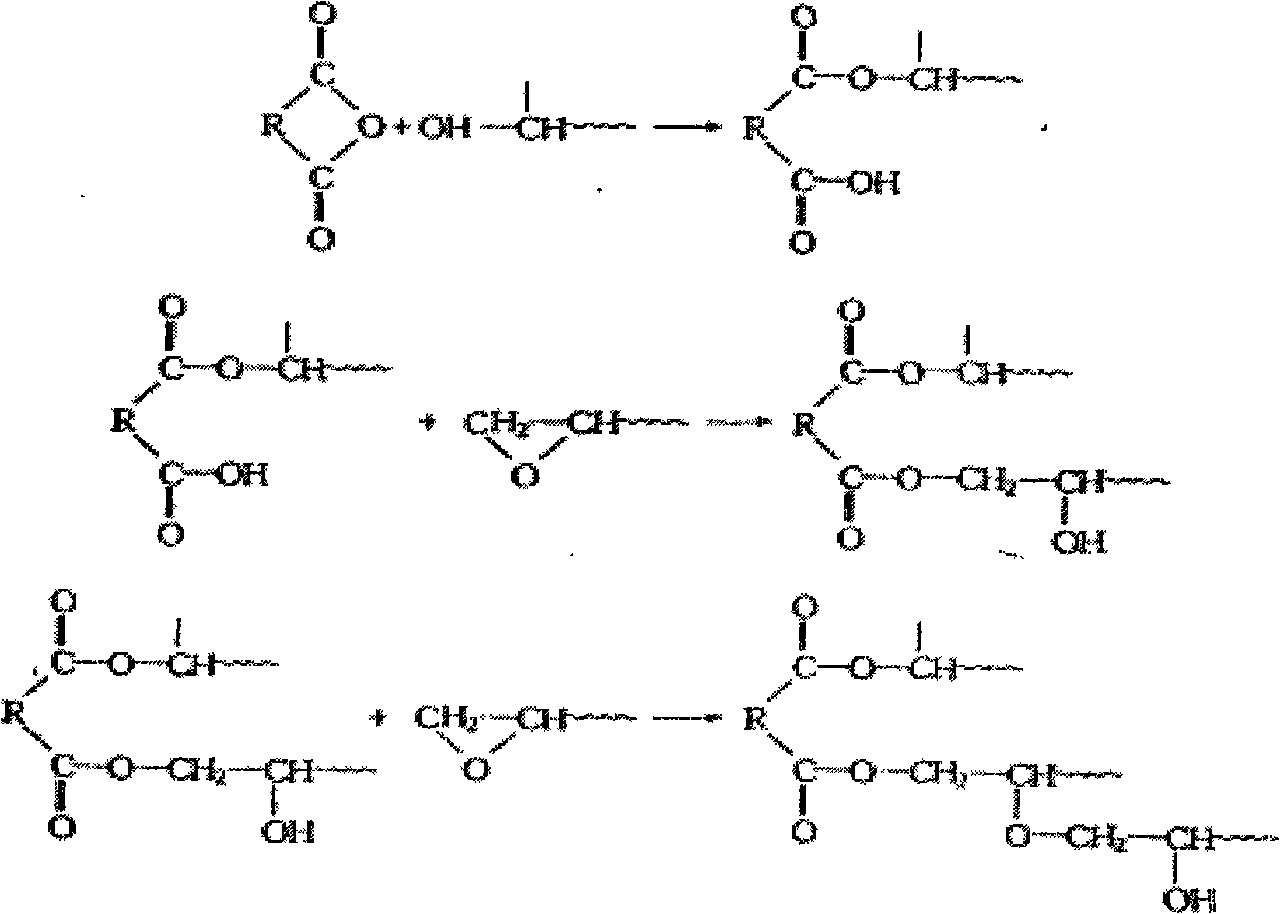

Method used

Image

Examples

Embodiment 1

[0020] The steps of the preparation method of the present embodiment epoxy asphalt pavement material are as follows:

[0021] A) putting 25 parts by weight of petroleum pitch (U.S. Shell) into a reactor and heating it to 120° C. to melt it;

[0022] B) tetrahydrophthalic anhydride (Jintan Weidelong Chemical Co., Ltd.) of 1.2 weight parts, the hexahydrophthalic anhydride (Jintan Weidelong Chemical Co., Ltd.) of 1.3 parts by weight and 16 Phenyl glycidyl ether (Shanghai Bangcheng Chemical Co., Ltd.) in parts by weight was added to the melted petroleum asphalt for high-speed shearing and stirring for 25 minutes to obtain component A, and heated to 150 ° C;

[0023] C) with 15 parts by weight of bisphenol A epoxy resin (Zhenjiang Danbao Resin Co., Ltd., E-44) as component B, heated to 150 ° C,

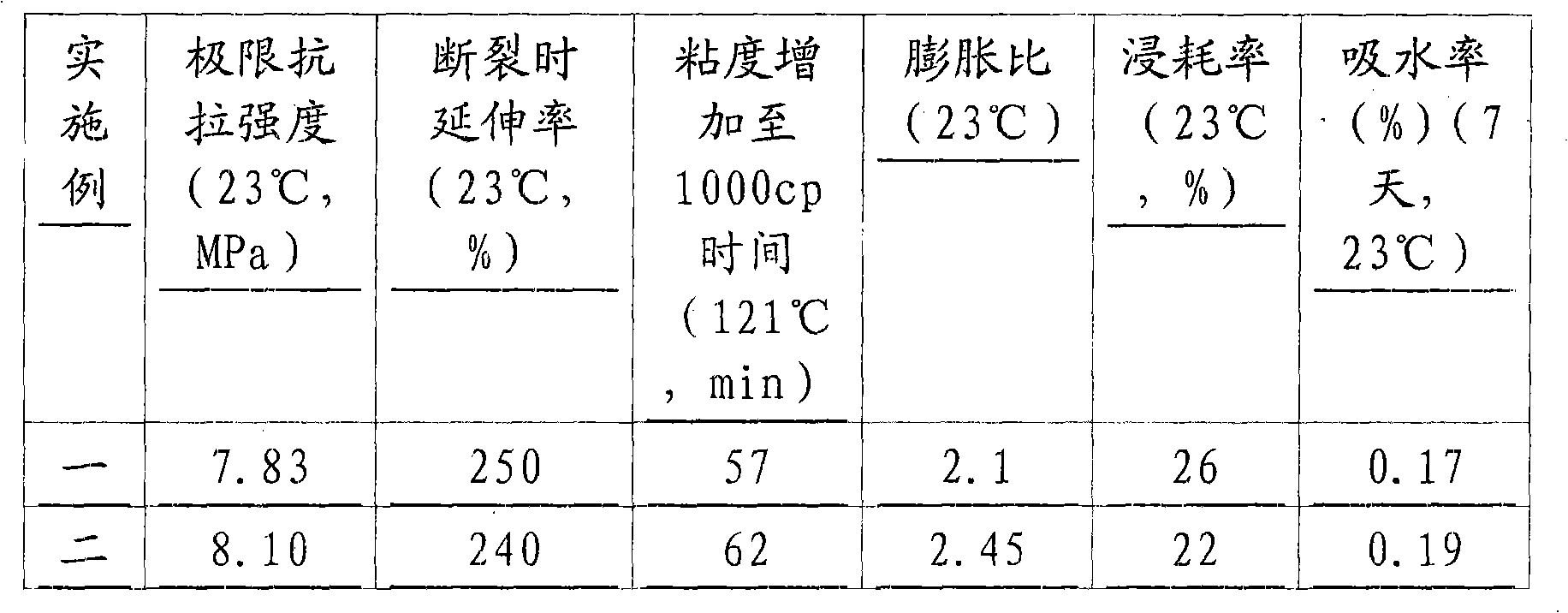

[0024] D) Mix the above component A with component B, the ratio of parts by weight is 2.9:1, after stirring at 130°C, keep warm for 2 hours and then cool to obtain epoxy asphalt pavement ...

Embodiment 2

[0026] The steps of the preparation method of the present embodiment epoxy asphalt pavement material are as follows:

[0027] A) 50 parts by weight of oxidized bitumen (U.S. Shell) is put into a reactor and heated to 120° C. to melt it;

[0028] B) adding 6 parts by weight of trimellitic anhydride (Jintan Weidelong Chemical Co., Ltd.) and 30 parts by weight of cresol glycidyl ether (Guangzhou Cangliqi Chemical Materials Co., Ltd.) into the melted oxidized asphalt High-speed shearing and stirring for 22 minutes to obtain component A, and heating to 140°C;

[0029] C) using 40 parts by weight of bisphenol A epoxy resin (Shanghai Xinhua Resin Factory, E-51) as component B, heated to 140 ° C;

[0030] D) Mix component A and component B, the ratio of parts by weight is 2.15:1, stir at 110°C, keep warm for 1.5 hours and then cool to get epoxy asphalt pavement material, which can be used as pavement The bonding layer is used, and its properties are shown in Table 1.

Embodiment 3

[0032] The steps of the preparation method of the present embodiment epoxy asphalt pavement material are as follows:

[0033] A) putting 60 parts by weight of coal tar pitch (Jingmen Petrochemical) into a reactor and heating to 120°C to melt it;

[0034] B) adding 9 parts by weight of tetrahydrophthalic anhydride (Jintan Weidelong Chemical Co., Ltd.) and 35 parts by weight of phenol (Nanjing Zhongxu Chemical Co., Ltd.) into the melted coal tar pitch for high-speed shearing Stir for 15 minutes to obtain component A, and heat to 130°C;

[0035] C) the total epoxy resin of 33 parts by weight of the bisphenol F epoxy resin (Shanghai Xinhua Resin Factory, trade mark 6420) and the resorcinol epoxy resin (Shanghai Xinhua Resin Factory) of 17 parts by weight as group Part B, heated to 130°C;

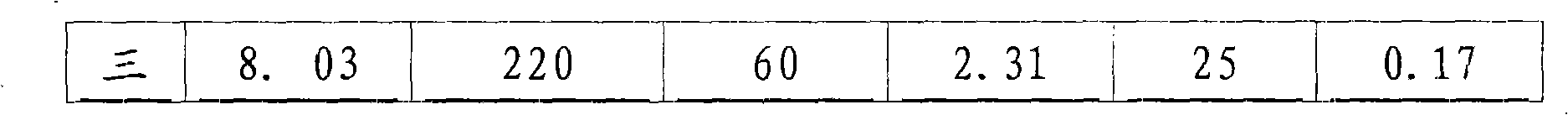

[0036] D) Mix component A and component B, the ratio of parts by weight is 3.15:1, stir at 140°C, keep warm for 2.5 hours and then cool to get epoxy asphalt pavement material, which can be use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com