Planetary rubbing type pea peeling machine

A peeling machine, pea technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of affecting the quality of starch, reducing the quality of vermicelli, troublesome deslagging process, etc., and achieves convenient operation, simple structure, and increased Effects on Farmers' Income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

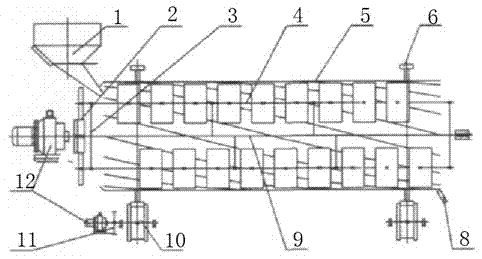

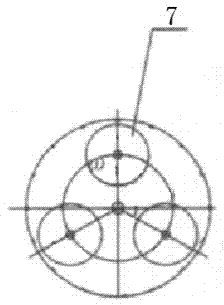

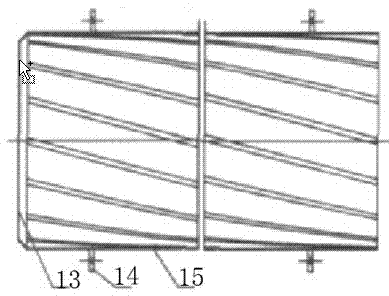

[0017] exist figure 1 .2, including feed hopper, planetary transmission, planetary carrier, planetary shaft, drum, roller, kneading roller, discharge port, main shaft, idler, chain transmission, driving device, in which the high-power geared motor drives the main shaft (9) and two planetary carriers (3), and drive the planetary shaft (4) and the kneading roller (7) to revolve at the same time, the planetary shaft and the kneading roller also do and revolve under the action of the meshing force of the planetary gear and the fixed sun gear Turn to the same rotation. The drum (5) rotates in the direction opposite to that of the planet carrier under the drive of a small-power reduction motor through the chain drive (11). After the soaked wet peas enter the inner cavity of the drum through the hopper, they are lifted up by the drum due to the friction between the inner wall of the drum and the centrifugal force of the material itself. Because the rotation direction of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com