Double-acting type friction coefficient testing device and method

A friction coefficient and measuring device technology, applied in the field of material processing, can solve problems such as the inability to guarantee the accuracy of the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

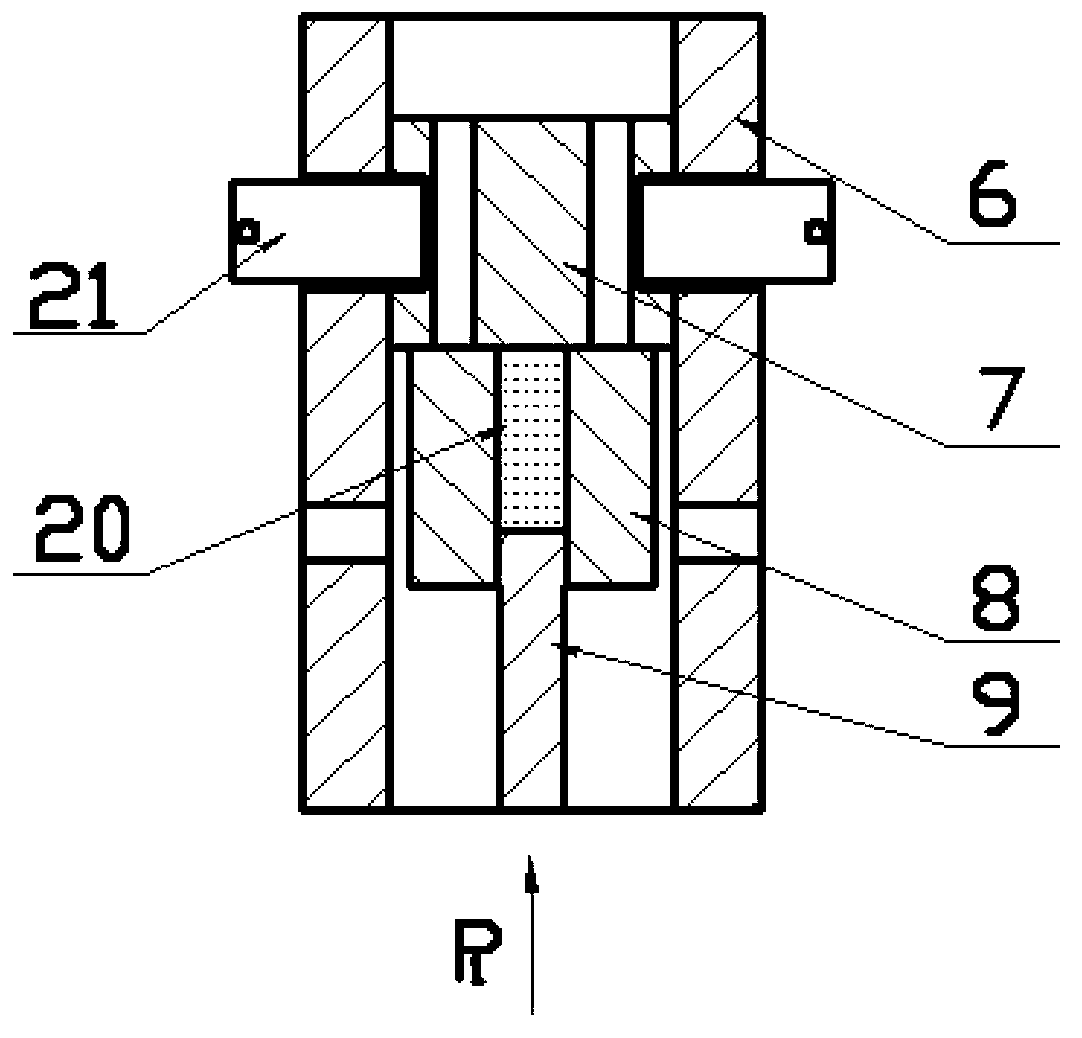

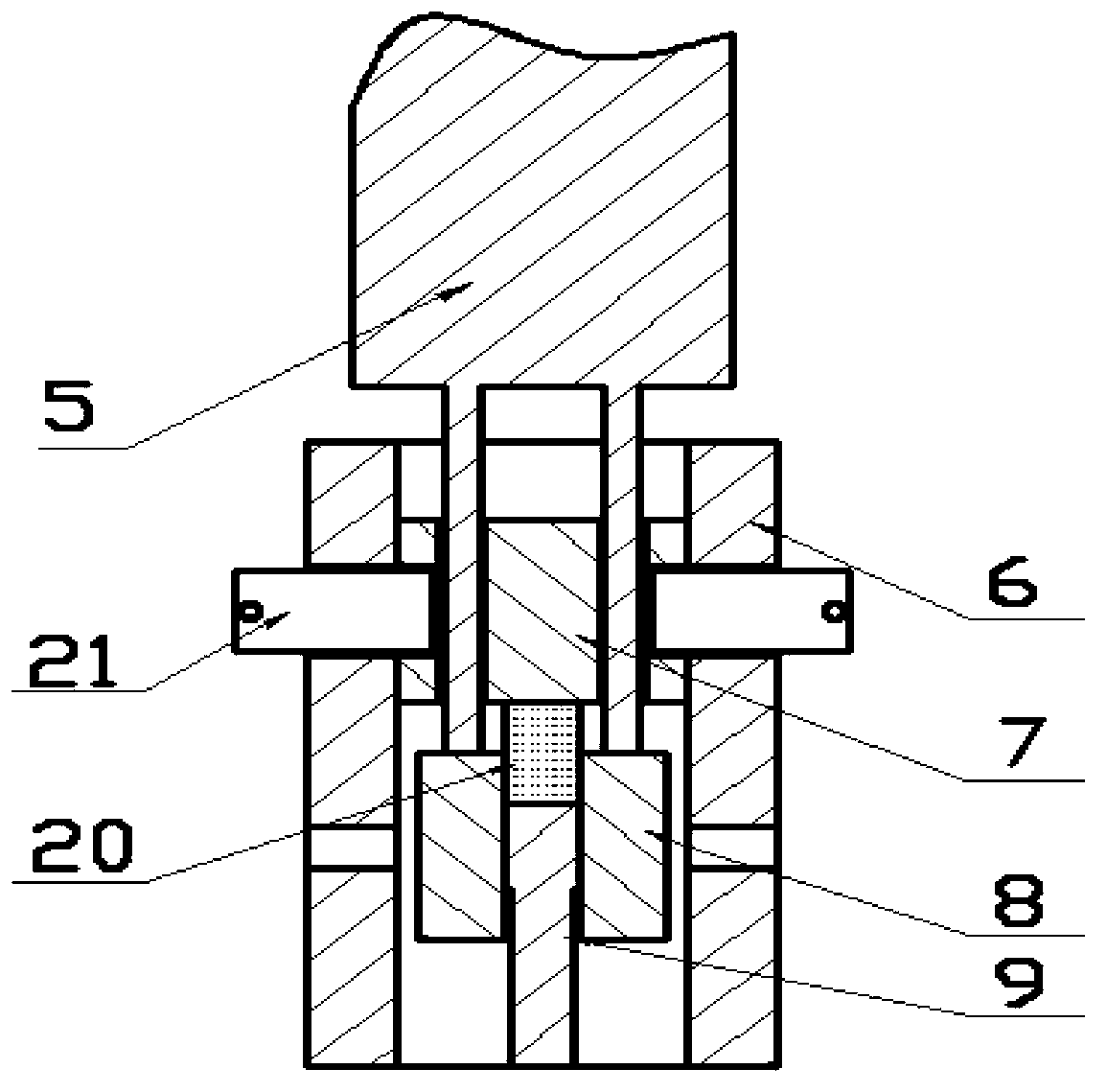

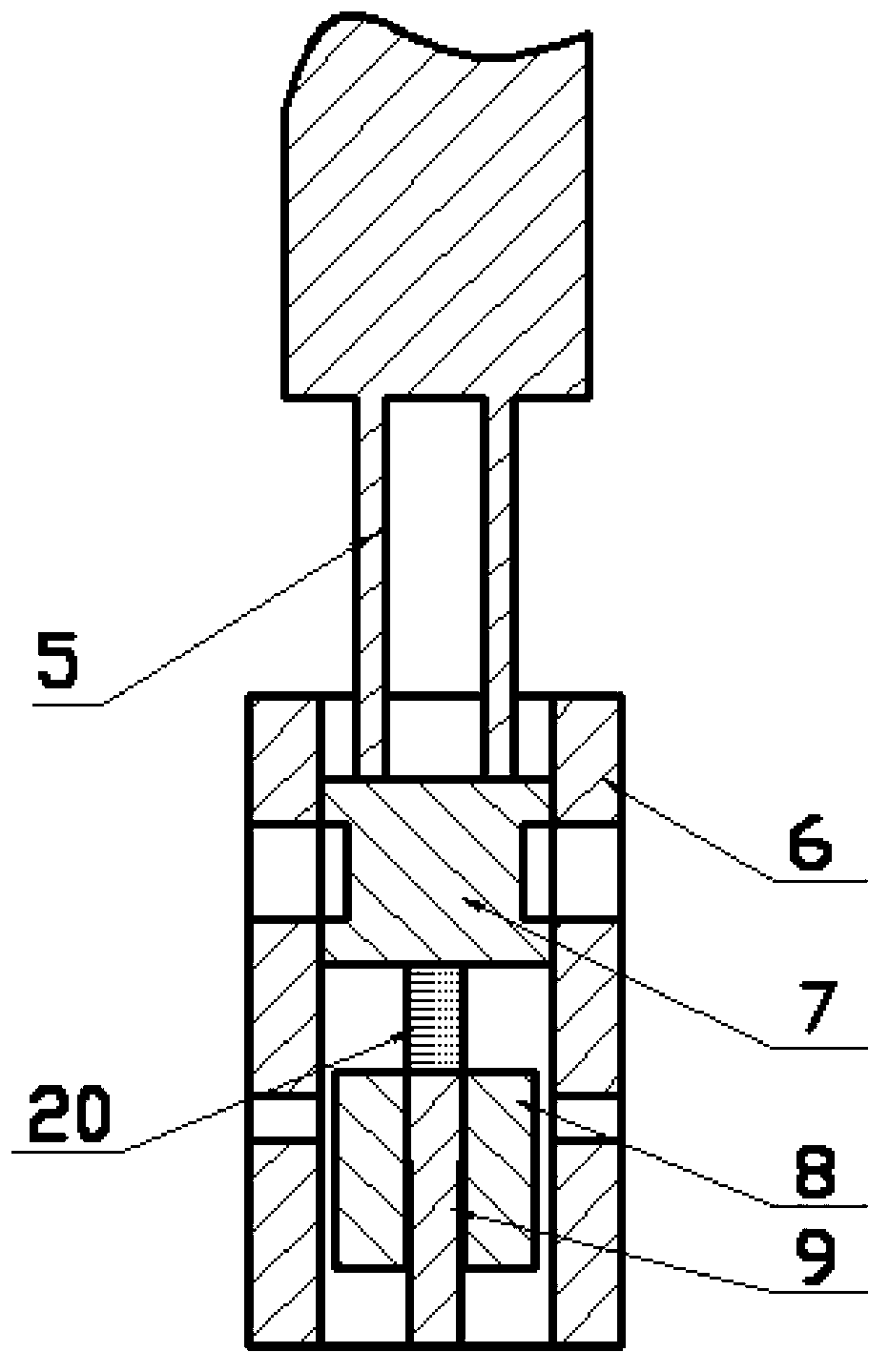

[0026] Figure 4 Shown: A double-action friction coefficient measuring device includes an upper power part, a lower power part, a working part and a supporting part. The upper power part includes a material performance tester 1, a hot gas baffle 2, an upper water cooling device 3 and a connecting screw 4; the lower power part includes a hydraulic cylinder 15, a pressure sensor 14 and a lower water cooling device 13; the working part is placed in a high-temperature heating furnace 22 , the working part includes upper pressing rod 5, upper retaining cylinder (6), upper retaining cylinder top cover 7, extrusion cylinder 8, extrusion rod 9, extrusion rod ejector rod 10, lower retaining cylinder (11), fixed pin 19. Blank 20, detachable column pin 21; the support part includes an upper support plate 12, a lower support plate 16, a support screw 17, and a fastening bolt 18; two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com