Ultrasonic-assisted fine blanking process and die

A forming process and forming die technology, applied in the field of fine blanking forming process and its devices, can solve the problems of reducing the life of the die, instability, and the quality of the fine blanking parts, so as to reduce the fine blanking deformation resistance, improve the processing lubrication conditions, The effect of improving fine blanking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An ultrasonic-assisted fine blanking forming process, which comprises the following steps:

[0026] 1) Prepare the ultrasonic-assisted fine blanking forming die:

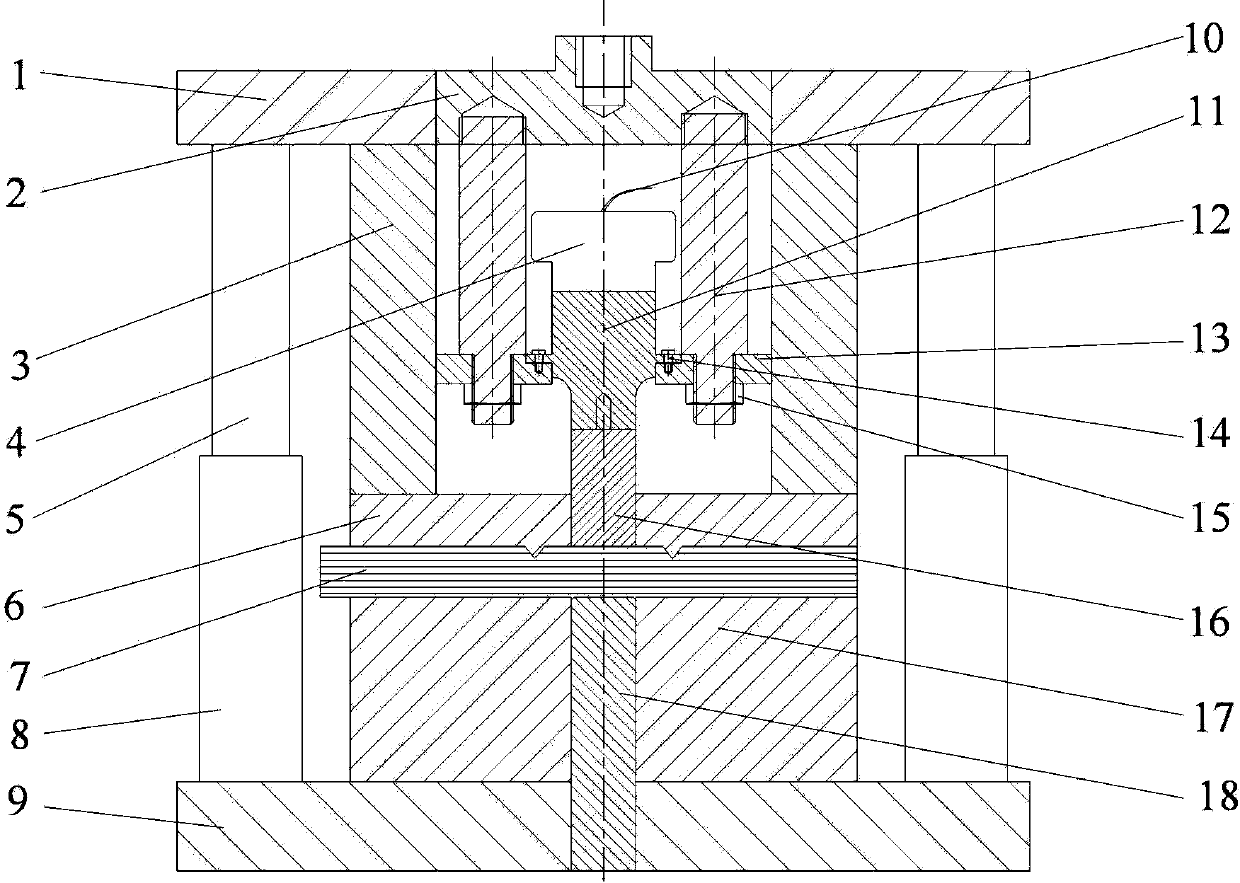

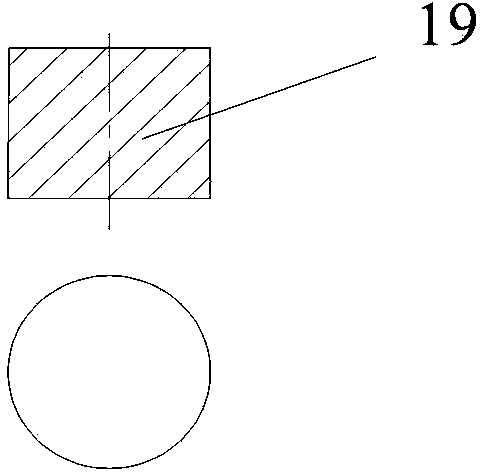

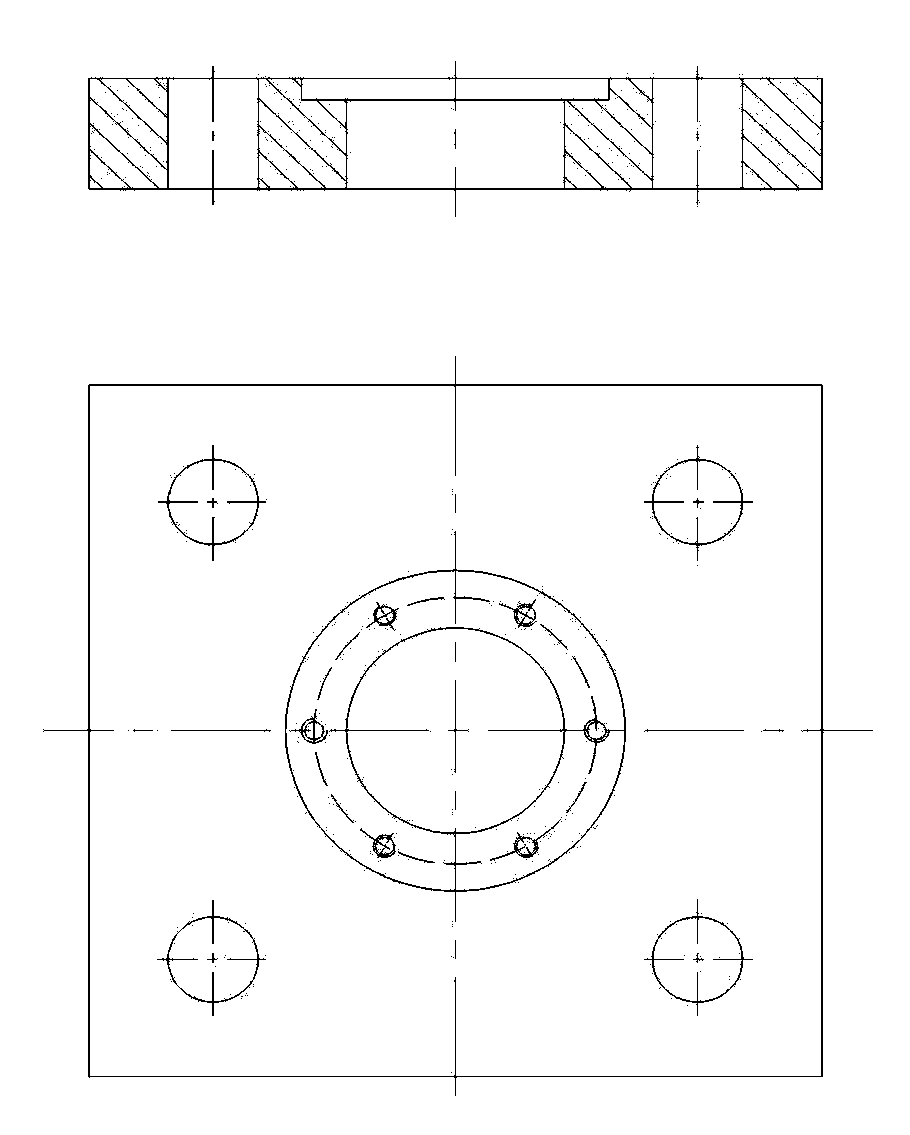

[0027] The ultrasonic-assisted fine blanking forming mold includes an upper template 1, a punch base 2, a pressure backing plate 3, a guide post 5, a V-shaped blank holder 6, a guide sleeve 8, a lower template 9, a punch 16, a die 17, The ejector rod 18; the upper formwork 1 and the lower formwork 9 can move relative to each other (set on the formwork); the pressure backing plate 3 is fixed on the upper formwork 1, and the pressure backing plate 3 is provided with a through hole, and the upper formwork 1 is opened There is a punch seat hole, the punch seat 2 penetrates into the punch seat hole on the upper template 1, the threaded hole at the upper end of the punch seat is connected with the hydraulic plunger on the hydraulic press; the upper end of the guide post 5 is fixed to the upper template 1 , the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com