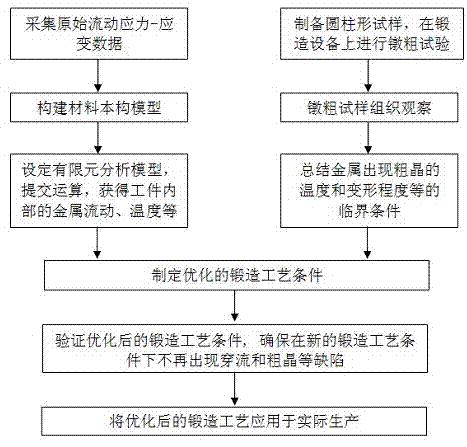

Method for analyzing and preventing forging through flow and coarse-grain defects

A preventive method, coarse-grained technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of relying on human factors, wasting materials and energy, etc., to improve efficiency, avoid recurrence, save materials and energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The key to the implementation of the present invention is to accurately obtain the original stress-strain data of the material, construct the material constitutive equation with as high precision as possible, and reasonably set the boundary conditions of the finite element model of the forging process; in the physical simulation test, it is required to obtain as much as possible Upsetting samples close to the actual forging environment.

[0017] Taking the forging process optimization of a 7B04 aluminum alloy forging as an example, the specific method is as follows:

[0018] (1) On the Gleeble-3500 dynamic thermal simulation test machine, the size is Φ The 10×12mm 7B04 aluminum alloy sample is subjected to isothermal constant strain rate compression test, the reduction is about 60%, the equipment automatically controls temperature, displacement and displacement speed, etc., and can automatically collect or calculate load, flow stress-strain and other related data ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com