Construction steel frame node structure

A node structure and construction steel technology, which is applied in the direction of building structure and construction, can solve the problems of unsatisfactory three-dimensional cross connection, failure to realize circular column connection, complex interface shape requirements, etc., and achieve good transmission, improved safety, The effect of little stress transmission disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

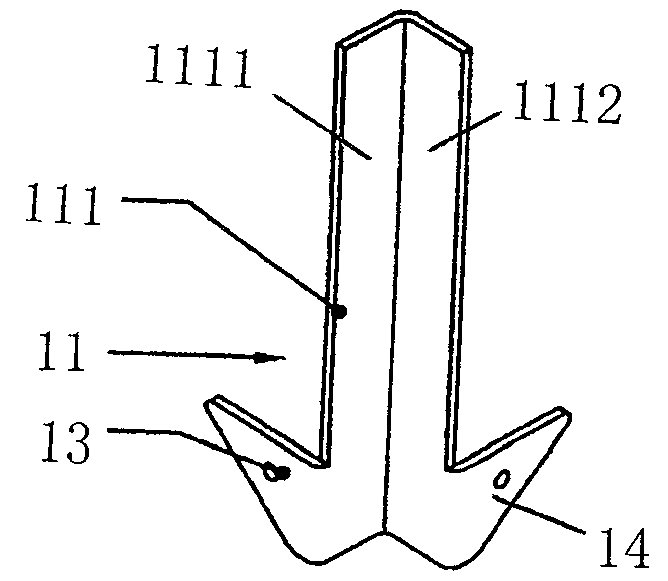

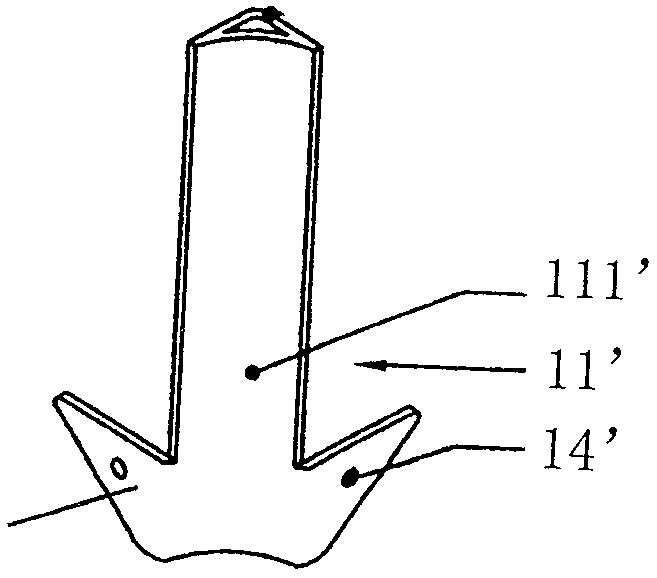

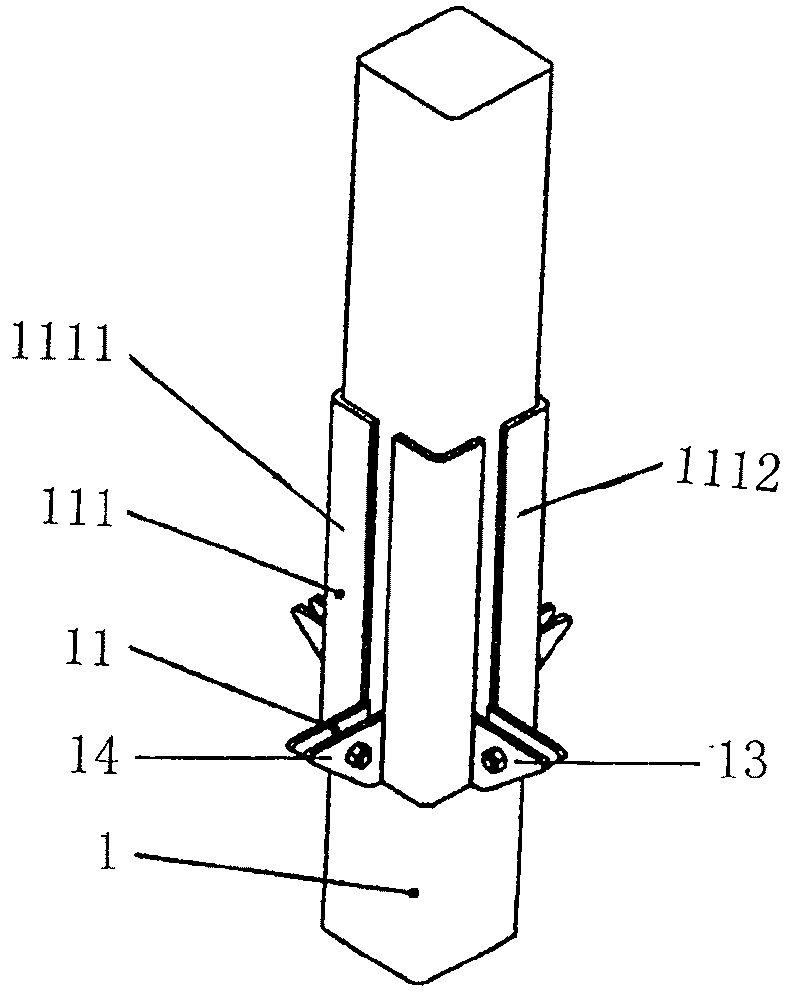

[0028] Such as Figure 5A and Figure 6 Shown is a schematic diagram and a top view of the building steel frame node structure of the present invention, which includes a vertical column 1, a beam 2, a connecting card 3 and four frictional shear plates 11 with a square cross section, combined Figure 4 As shown, the connecting card 3 includes a card main body 4, and two card wings 5 with door-shaped cross sections are respectively arranged at both ends of the card main body 4. The card wings 5 include a bearing plate 7 connected with the card main body 4, and a bearing plate 7 The opposite pre-tightening plate 6 and the self-locking fastening plate 9 connecting the bearing plate 7 and the pre-tightening plate 6 have at least two through holes on the self-locking fastening plate 9, and at least one through hole on the pre-tightening plate 6 Through holes, the card main body 4 is located on two opposite sides of the vertical column 1, the pre-tightening plates 6 of the card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com