Wedge main friction plate made of high-temperature-resistant high-polymer composite and production method of wedge main friction plate

A composite material and high-temperature-resistant technology, which is applied in the direction of layered products, chemical instruments and methods, and synthetic resin layered products, can solve problems such as thermal recession, and the decrease and decrease of the friction coefficient of the main friction plate of the wedge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A high-temperature-resistant polymer composite oblique wedge main friction plate, the production method of which is as follows:

[0053] (1) Resin copolymerization reaction:

[0054] The raw materials were weighed according to the following components by weight: 1.6 Kg of 4,4-diphenylmethane bismaleimide, and 0.9 Kg of diallyl bisphenol A.

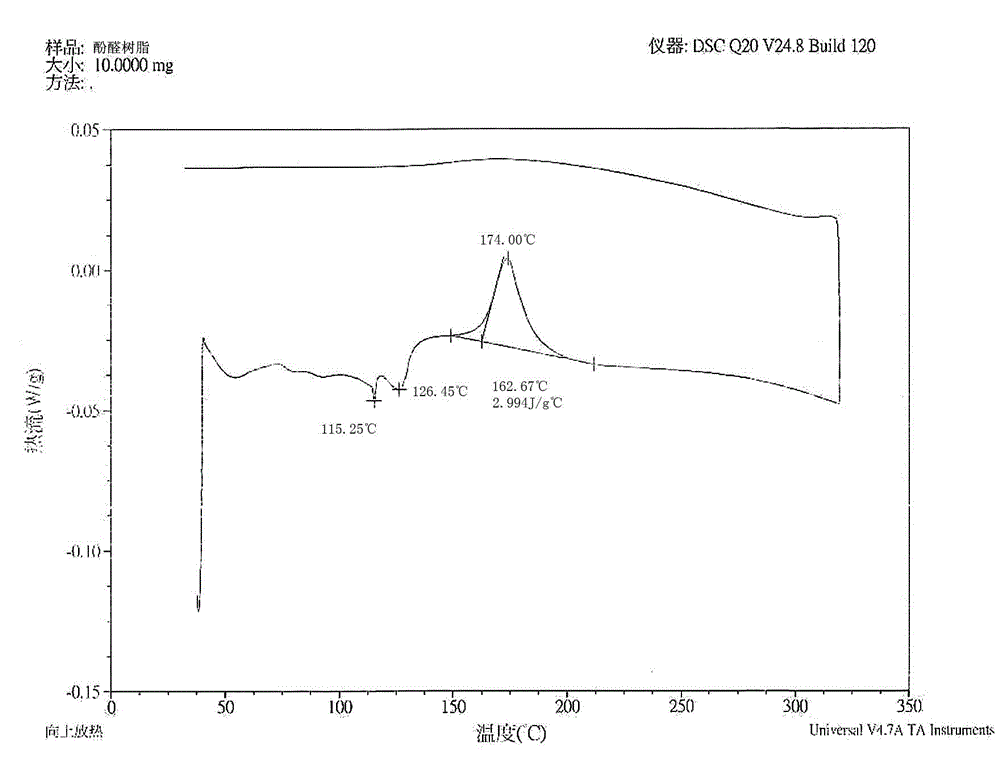

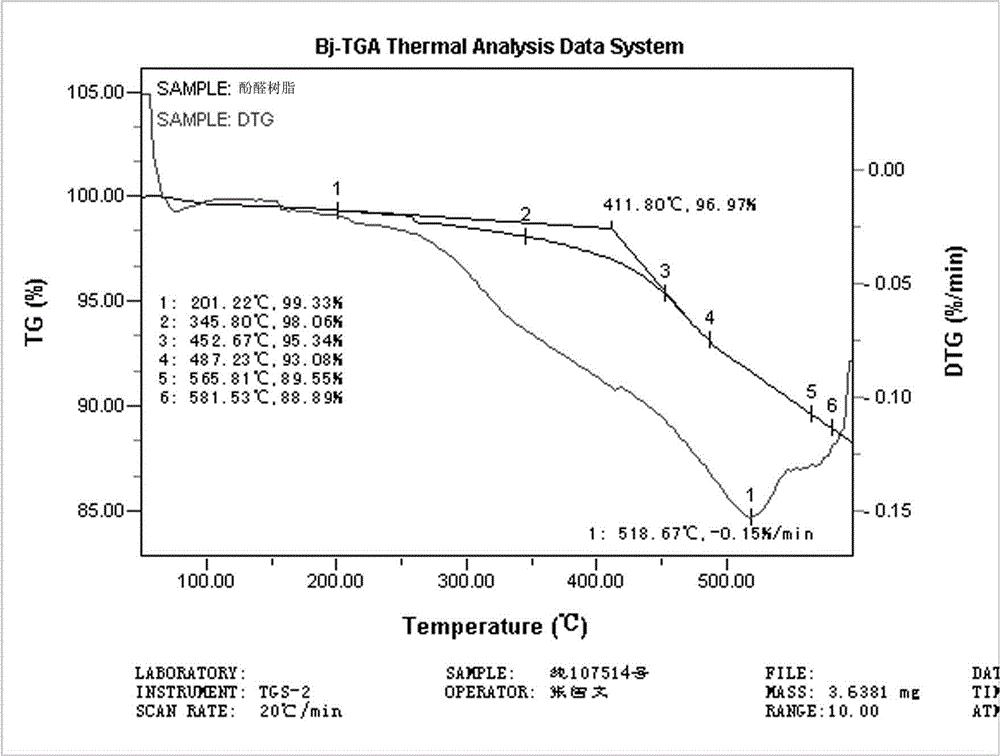

[0055] Add 4,4-diphenylmethane bismaleimide, diallyl bisphenol A and catalyst in proportion to a three-necked flask equipped with a stirrer, thermometer and reflux condensation, heat to 125°C to melt prepolymerization, and control The reaction temperature is 125~130°C, and the prepolymerization time is 3.5~4 hours to obtain a solid copolymerized modified resin. It is pulverized and sieved with 100 meshes to obtain the desired copolymerized modified resin powder. Wherein, the catalyst adopts n-butylamine, and its consumption is the consumption of catalyst in general chemical reaction, with 3‰~20% of the weight of 4,4-diphenylmethan...

Embodiment 2

[0073] A high-temperature-resistant polymer composite oblique wedge main friction plate, the production method of which is as follows:

[0074] (1) Resin copolymerization reaction:

[0075] The raw materials were weighed according to the following components by weight: 1.0 Kg of 4,4-diphenylmethane bismaleimide, and 1.2 Kg of diallyl bisphenol A.

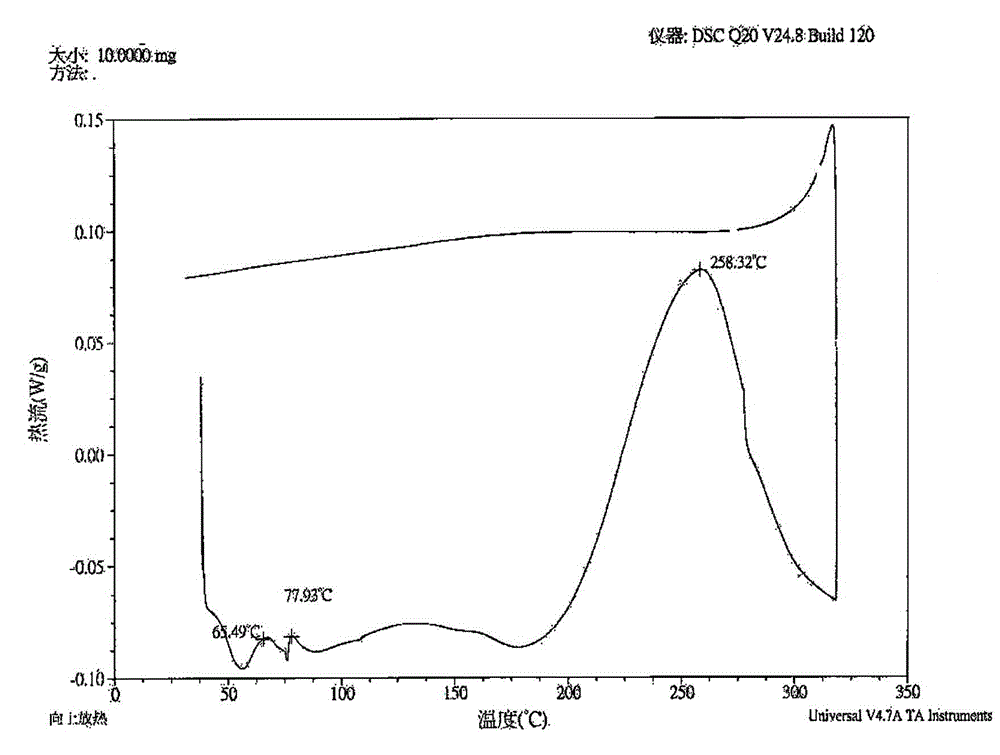

[0076] Add 4,4-diphenylmethane bismaleimide, diallyl bisphenol A and a catalyst in a three-necked flask equipped with a stirrer, a thermometer and reflux condensation according to the proportion, heat to a certain temperature to melt the prepolymerization, and control The reaction temperature is 125~130°C, and the prepolymerization time is 3.5~4 hours to obtain a solid copolymerized modified resin. It is pulverized and sieved with 100 meshes to obtain the desired copolymerized modified resin powder. Wherein, the catalyst adopts n-butylamine, and its consumption is the consumption of catalyst in general chemical reaction, with 3‰~2...

Embodiment 3

[0093] A high-temperature-resistant polymer composite oblique wedge main friction plate, the production method of which is as follows:

[0094] (1) Resin copolymerization reaction:

[0095] The raw materials were weighed according to the following components by weight: 1.7 Kg of 4,4-diphenylmethane bismaleimide, and 0.6 Kg of diallyl bisphenol A.

[0096] Add 4,4-diphenylmethane bismaleimide, diallyl bisphenol A and a catalyst in a three-neck flask equipped with a stirrer, a thermometer and reflux condensation according to the proportion, heat to a certain temperature to melt the prepolymerization, and control The reaction temperature is 125~130°C, and the prepolymerization time is 3.5~4 hours to obtain a solid copolymerized modified resin. It is pulverized and sieved with 100 meshes to obtain the desired copolymerized modified resin powder. Wherein, the catalyst adopts n-butylamine, and its dosage is the dosage of catalysts in general chemical reactions, preferably 3‰~20‰. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com