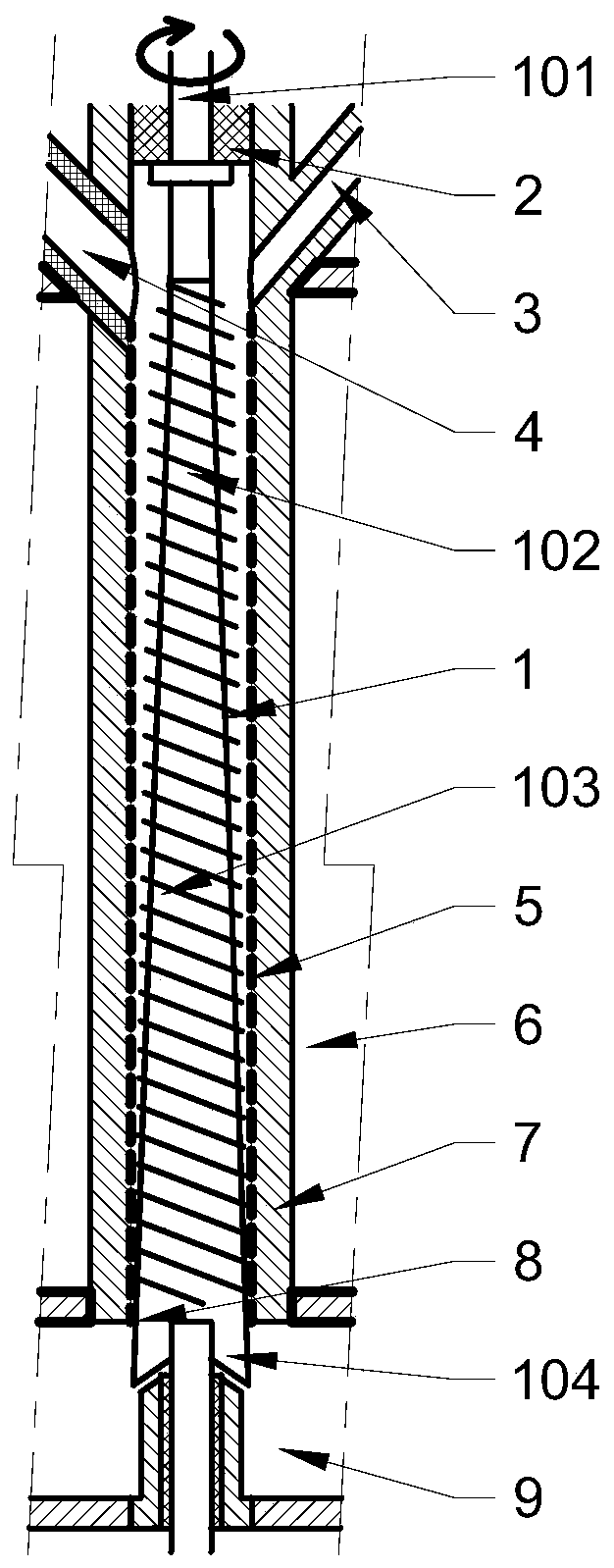

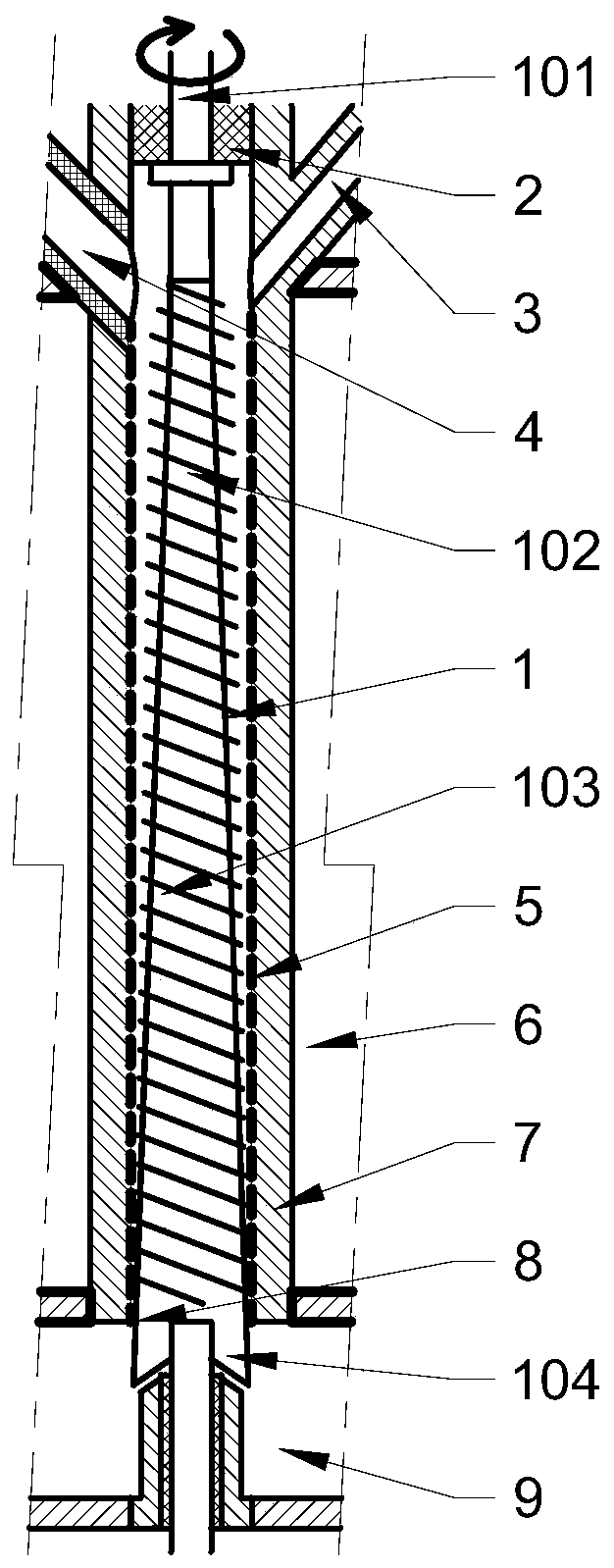

Cone mill roll biomass rapid catalytic pyrolysis reactor and pyrolysis method thereof

A technology of catalytic pyrolysis and conical grinding, which is applied in the direction of biofuel, special dry distillation, liquid hydrocarbon mixture preparation, etc. It can solve the problem that the catalytic pyrolysis product is not as good as the direct catalytic reaction, it is difficult to ensure the catalytic effect of the catalyst, and the condensation of pyrolysis gas Difficulties and other problems, to achieve the effect of compact structure, good catalytic effect, and reduced scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

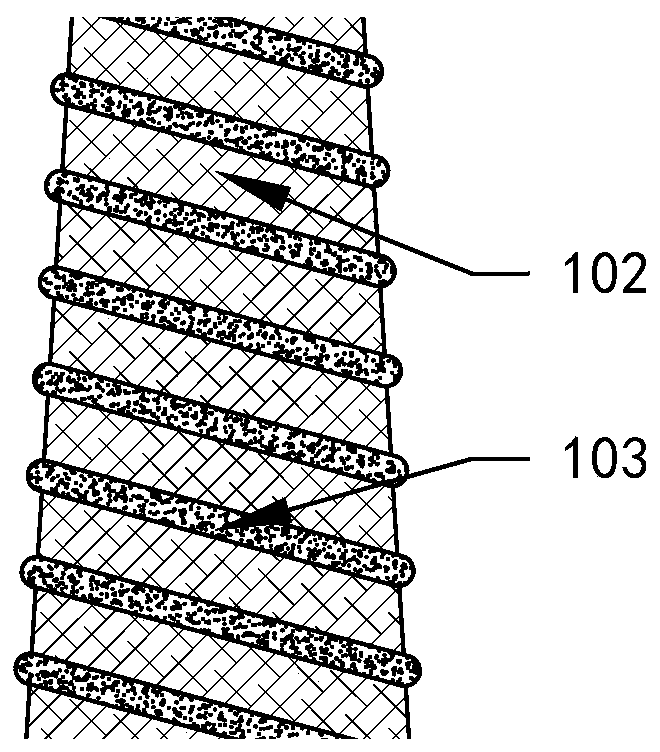

Method used

Image

Examples

Embodiment 1

[0036] Willow with a moisture content of 6wt% is crushed to an average particle size of 10mm, and is fed into the pyrolysis reactor through a screw feed system at a feed rate of 100kg / h; the catalytic tank 102 is only set as a friction layer and filled with friction paint; The speed of the conical grinding roller 1 is 300r / min; the temperature of the hot flue gas in the flue 6 is 670°C, and the measured temperature in the pyrolysis reactor is 500°C; the pyrolysis product is separated and condensed to obtain three Phase pyrolysis products, wherein the yield of coke is 20.1wt%, the yield of bio-oil is 60.3wt%, and the yield of combustible gas is 19.6wt%.

Embodiment 2

[0038] Hazelnut shells with a moisture content of 7wt% are crushed to an average particle size of 10mm; the screw feed system is fed into the feed port 4 with a feed rate of 80kg / h; by adjusting the power of the motor, the conical grinding roller 1 The rotation speed is 150r / min; the catalytic tank only uses the friction coating as the friction layer, and the ZnCl 2 The catalyst is introduced by directly impregnating the raw material during pretreatment, with a load of 16.7wt%; the temperature of the flue gas entering the flue 6 is 480°C, and the temperature in the pyrolysis reactor is guaranteed to be 340°C; the pyrolysis product is gas-solidified After separation and condensation of the pyrolysis gas, three-phase pyrolysis products of coke, bio-oil and combustible gas are obtained, and the respective yields are 49.3wt%, 42.1wt% and 8.6wt%, and the yield of the target product furfural is 7.3wt% .

Embodiment 3

[0040] The rice husks with a water content of 8wt% are crushed to an average particle size of 12mm, and the feed rate is 120kg / h and sent to the feed inlet 4 through a screw feed system; the rotating speed of the conical grinding roller 1 is controlled to maintain 150r / min; No catalyst is introduced, and the entire catalytic tank is set as a friction layer; the temperature of the flue gas entering the flue 6 is 700°C, and the temperature in the pyrolysis reactor is 520°C; The yields of solid, liquid and gas three-phase pyrolysis products are 28.1wt%, 49.7wt% and 22.2w%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com