Pipe pile top friction-shearing type energy consumption connecting device and construction method thereof

A connecting device and shearing type technology, applied in protection devices, sheet pile walls, foundation structure engineering, etc., can solve the problems of large lateral displacement of supports, insufficient vertical isolation capacity, inconvenient maintenance, etc., to avoid brittleness Damage, enhance ductility energy dissipation capacity, reduce the effect of earthquake response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

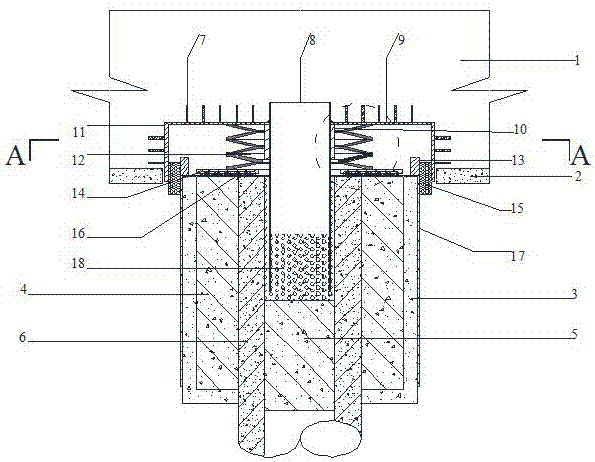

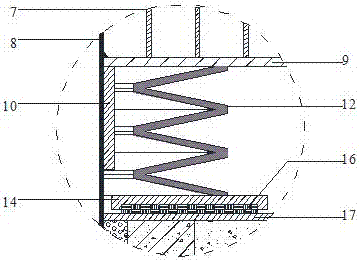

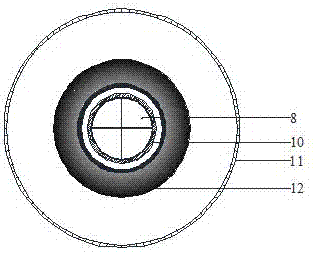

[0033] Such as Figure 1~3 As shown, a pipe pile top friction-shear type energy dissipation connection device, the device includes a soft steel pipe 8, an upper sealing plate 9, a central steel cylinder 10, an outer steel cylinder 11, and an annular disc spring 12 , limit stop ring 13, lower sealing plate 14, soil retaining rubber ring 15, friction ring 16, bottom sleeve 17 and glass ball-graphite mixture 18;

[0034] The upper part of the soft steel pipe 8 is connected to the cap 1, and the lower part is connected to the pipe pile 6;

[0035]The outer side of the soft steel pipe 8 is socketed with the central steel cylinder 10, the top of the central steel cylinder 10 is connected with the upper sealing plate 9, and the outer layer steel cylinder 11 is arranged on the outer side of the upper sealing plate 9, and the central steel cylinder 10, the upper sealing plate 9, The space surrounded by the outer steel cylinder 11 is provided with an annular disc spring 12, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com