Single well multiple oil layer plane branch multi-crack fracturing technology

A multi-reservoir, multi-fracture technology, applied in the direction of wellbore/well components, production fluid, drilling composition, etc., can solve the problems of short effective and stable period, increase of artificial fracture density, high performance requirements of fracturing fluid, etc., to achieve Good viscoelasticity and fluid loss control, improving production efficiency and benefit, increasing production and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

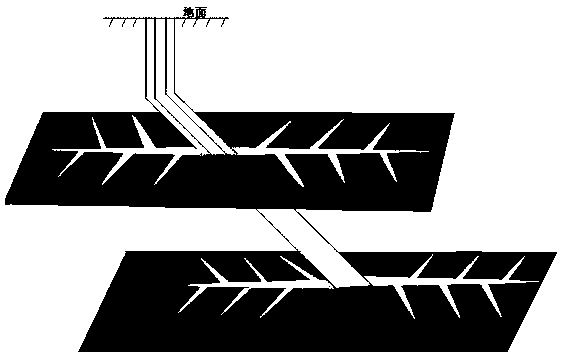

[0024] A single-well multi-reservoir planar branch multi-fracture fracturing process. The process uses high-viscosity pre-fluid and low-viscosity pre-fluid to inject into the formation in two stages. The mixed fluid of fluid loss agent is used to fracture a number of artificial fractures with a half-length greater than or equal to 300m in the formation as the main fractures, and then inject low-viscosity pre-fluid in the second half, and use the low-viscosity pre-fluid in the second half The friction and shear between the fluid and the wall of the main fracture creates multiple branch fractures on the wall of the main fracture, thereby forming a complex artificial fracture area on the entire reservoir; realizing simultaneous fracturing of multiple reservoirs.

Embodiment 2

[0026] A single-well multi-reservoir planar branch multi-fracture fracturing process, the specific implementation includes the following steps:

[0027] Step 1: Configure high-viscosity pre-fluid, high-efficiency fluid loss control agent and low-viscosity pre-fluid according to the ratio;

[0028] The high-viscosity preflux: is made of 1.5% dimethyl didocosyl ammonium chloride, 0.5% sodium 1-amino-4-naphthalenesulfonate, 1.0% potassium chloride and 97% water according to the above quality It is formed by mixing, wherein the chemical structural formula of dimethyl didocosyl ammonium chloride: [(CH 3 ) 2 N(C 22 h 45 ) 2 】 + Cl - ; The viscosity of the high-viscosity preflush at 25°C is 70-80mPa.

[0029] The high-efficiency fluid loss reducer: it is composed of 60% behenyl amidopropyl dimethyl glyceryl ammonium chloride, 15% rosin, and 25% sodium chloride according to the above mass ratio, with a particle size of 100-180 mesh .

[0030] The low-viscosity pre-fluid is pr...

Embodiment 3

[0035] Substantially the same as Example 2, the difference is: the high-viscosity pre-liquid: is made of 2.5% dimethyl docosyl ammonium chloride, 0.8% 1-amino-4-naphthalene sodium sulfonate, 3.0% Potassium Chloride and 93.7% water are mixed according to the above mass ratio, wherein the chemical structural formula of dimethyl didocosyl ammonium chloride: [(CH 3 ) 2 N(C 22 h 45 ) 2 】 + Cl - ; The viscosity of the high-viscosity preflush at 25°C is 70-80mPa.

[0036] The high-efficiency fluid loss reducer: it is composed of 75% behenyl amidopropyl dimethyl glyceryl ammonium chloride, 20% rosin, and 5% sodium chloride according to the above mass ratio, with a particle size of 100-180 mesh .

[0037] The low-viscosity pre-fluid is prepared by diluting the high-viscosity pre-fluid with clear water by 1 time; wherein, the viscosity of the low-viscosity pre-fluid at 25°C is 10-25mPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com