Structural adhesive for steel bonding

A technology of structural glue and epoxy resin, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve problems such as poor seismic performance, cracking of concrete structures, and insufficient bearing capacity, and achieve strong application and promotion value. The effect of high shear strength and stable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

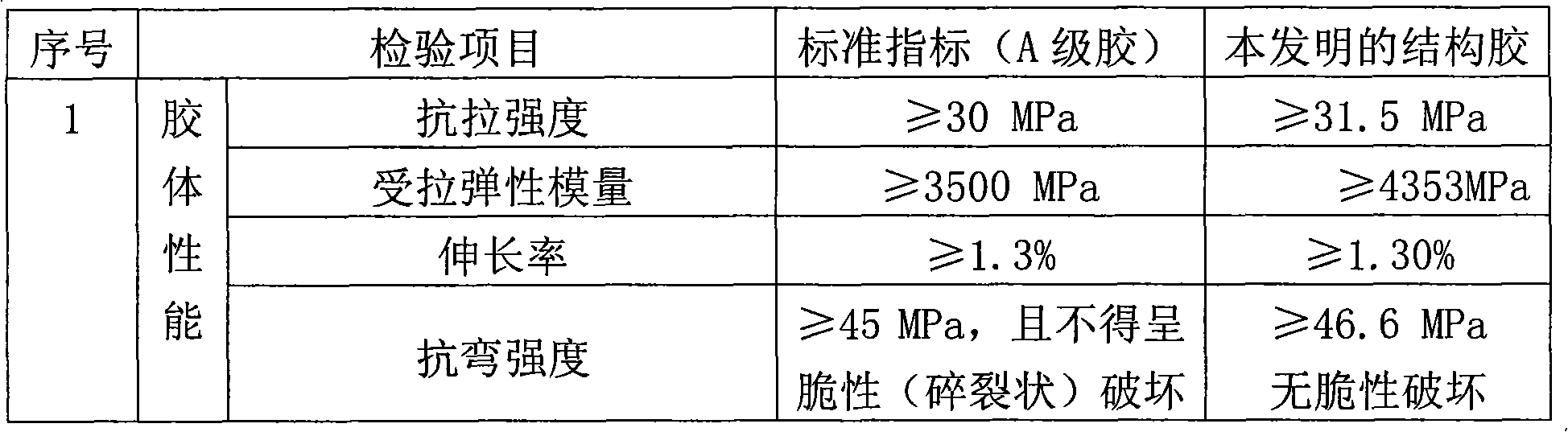

[0064] Embodiment 1, preparation and performance measurement of structural glue

[0065] 1. Preparation of structural adhesive

[0066] It consists of component A (white), component B (black) and quartz sand as filler.

[0067] 1. Preparation of Component A

[0068] Component A is composed of epoxy resin, diluent, plasticizer, toughening agent and coupling agent. Epoxy resin: diluent: plasticizer: toughening agent: coupling agent (mass ratio)=100:16:20:15:2.

[0069] Epoxy resin: temperature-resistant amino epoxy resin and bisphenol A epoxy resin with a mass ratio of 1:2;

[0070] Temperature-resistant amino epoxy resin: VE-3240 epoxy resin purchased from Wuxi Resin Factory;

[0071] Bisphenol A epoxy resin: TDE-85 epoxy resin purchased from Wuxi Resin Factory.

[0072] Diluent (butyl glycidyl ether): Model: 501, purchased from Wuxi Resin Factory.

[0073] Plasticizer (phthalate): dibutyl phthalate, DBP for short, model: yh-lbd-2, purchased from Wuxi Resin Factory.

[0...

Embodiment 2

[0092] Embodiment 2, preparation and performance measurement of structural glue

[0093] 1. Preparation of structural adhesive

[0094] It consists of component A (white), component B (black) and quartz sand as filler.

[0095] 1. Preparation of Component A

[0096] Component A is composed of epoxy resin, diluent, plasticizer, toughening agent and coupling agent. Epoxy resin: diluent: plasticizer: toughening agent: coupling agent (mass ratio) = 100:10:6:10:1.

[0097] Epoxy resin (bisphenol A epoxy resin): TDE-85 epoxy resin, purchased from Wuxi Resin Factory.

[0098] Thinner (propylene glycidyl ether): grade: 500, purchased from Wuxi Resin Factory.

[0099] Plasticizer (phosphate ester): triphenyl phosphate, purchased from Wuxi Resin Factory.

[0100] Toughening agent (nitrile rubber): code name: BNR, purchased from Wuxi Resin Factory.

[0101] Coupling agent (organic carboxylic acid): acetic acid, purchased from Wuxi Resin Factory.

[0102] 2. Preparation of Componen...

Embodiment 3

[0114] Embodiment 3, preparation and performance measurement of structural glue

[0115] 1. Preparation of structural adhesive

[0116] It consists of component A (white), component B (black) and quartz sand as filler.

[0117] 1. Preparation of Component A

[0118] Component A is composed of epoxy resin, diluent, plasticizer, toughening agent and coupling agent. Epoxy resin: diluent: plasticizer: toughening agent: coupling agent (mass ratio)=100:50:40:50:3.

[0119] Epoxy resin (temperature-resistant amino epoxy resin): Model: VE-3240, purchased from Wuxi Resin Factory.

[0120] Thinner (phenyl glycidyl ether): grade: 690, purchased from Wuxi Resin Factory.

[0121] Plasticizer (sebacate): dioctyl sebacate (DOS), purchased from Wuxi Resin Factory.

[0122] Toughening agent (polysulfide rubber): Model: JLY-121, purchased from Wuxi Resin Factory.

[0123] Coupling agent (polyisocyanate): polyisocyanate, brand: JQ-1, purchased from Wuxi Resin Factory.

[0124] 2. Preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com