Slide transverse type symmetrical loading structure

A horizontal and symmetrical technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of inconvenient installation of samples, unstable test process, etc., achieve uniform stress distribution, simplify structure and control system, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

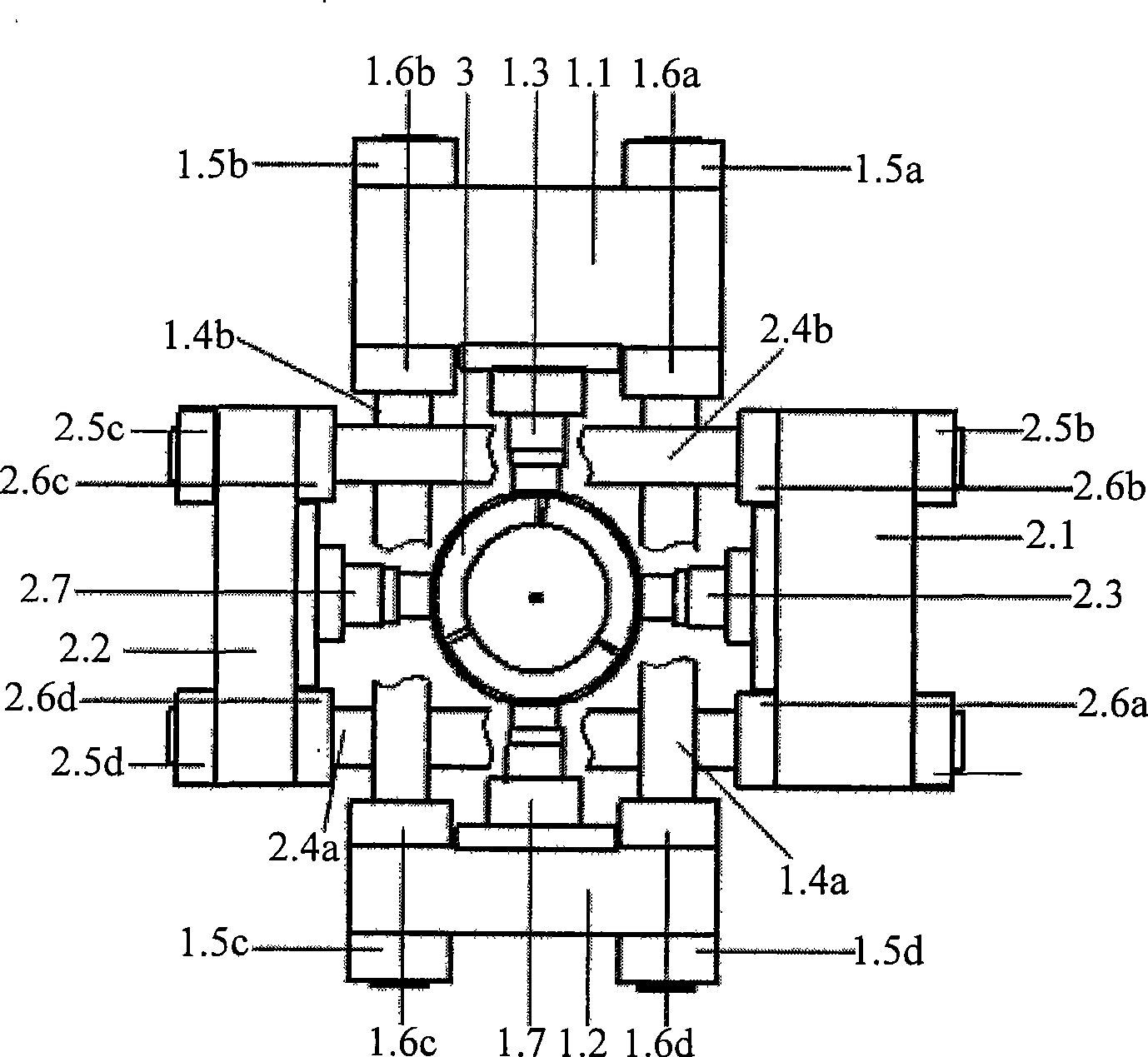

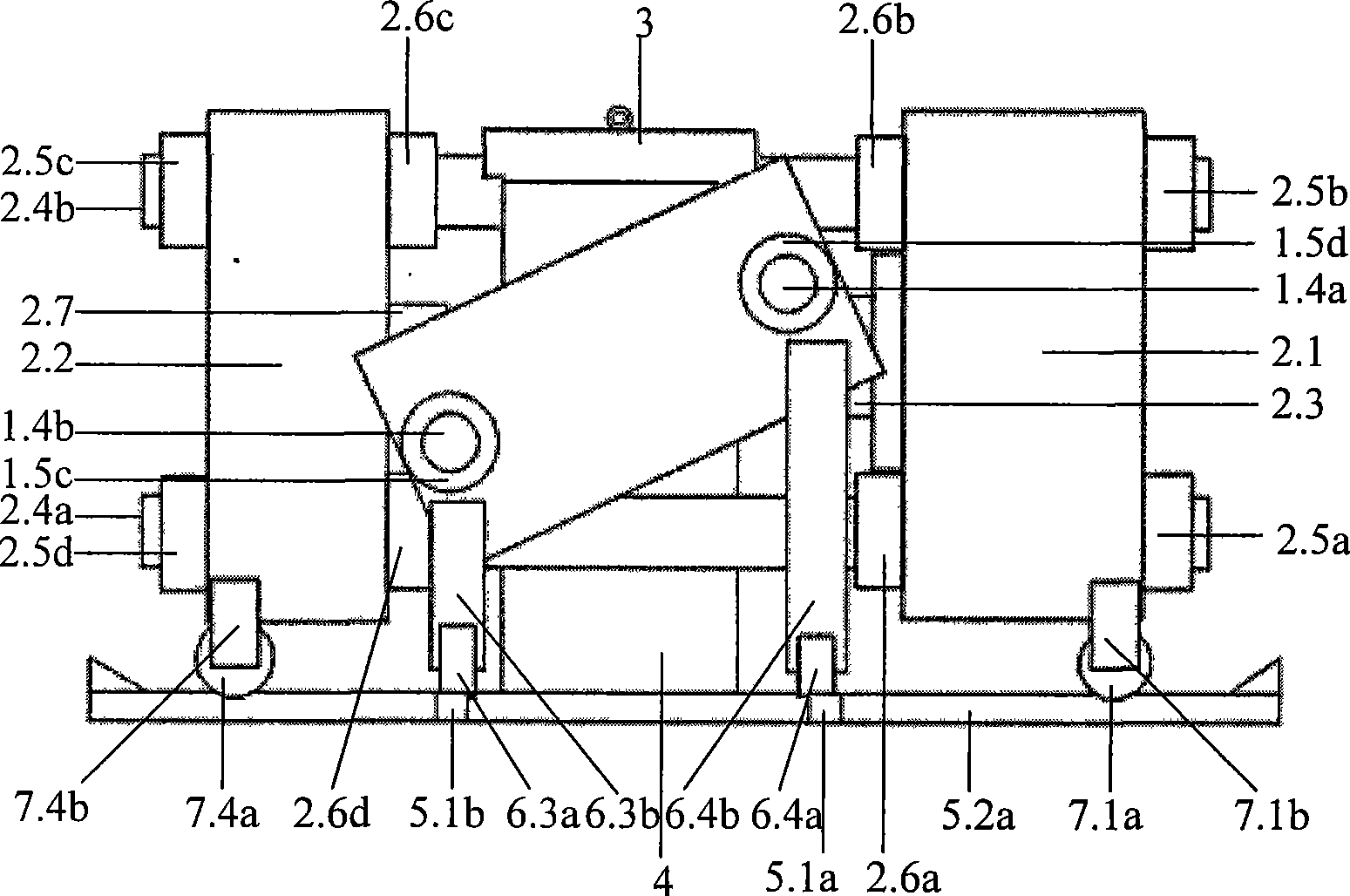

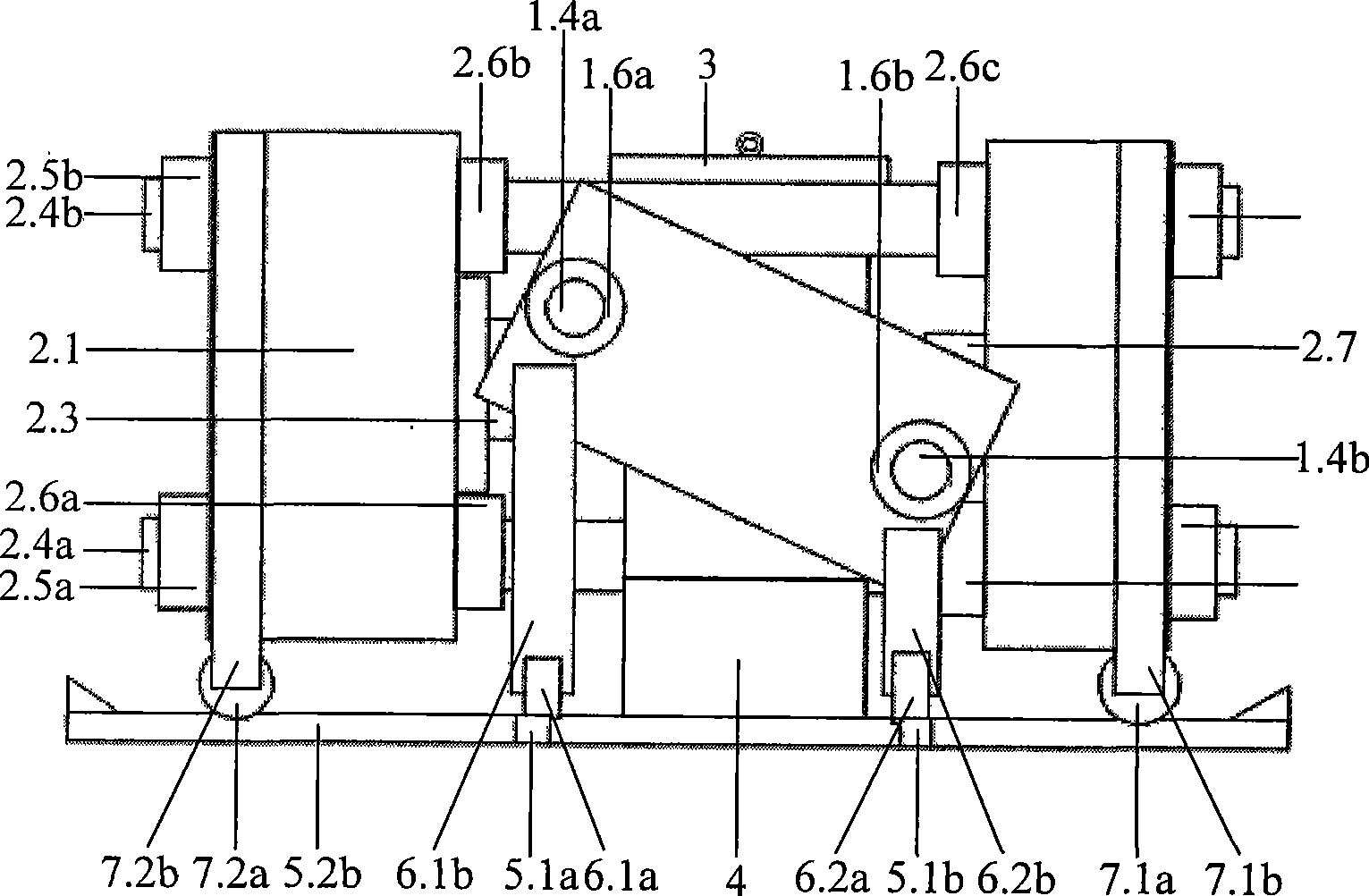

[0032] Such as figure 1 , 2 Shown in and 3, sliding frame one 1 comprises main frame beam 1.1, sub-frame beam 1.2, hydraulic jack 1.3, frame beam 1.4, outer lock nut 1.5, inner lock nut 1.6 and reaction seat 1.7. The frame beam 1.4 is connected with the main frame beam 1.1 and the sub-frame beam 1.2, and the outer lock nut 1.5 and the inner lock nut 1.6 fix the frame beam 1.4, the main frame beam 1.1 and the sub-frame beam 1.2; the hydraulic jack 1.3 and the reaction force Seat 1.7 is respectively placed in the inner side of main frame beam 1.1 and auxiliary frame beam 1.2.

[0033] Such as figure 1 , 2 Shown in and 3, sliding frame two 2 comprises main frame beam 2.1, subframe beam 2.2, hydraulic jack 2.3, frame beam 2.4, outer lock nut 2.5, inner lock nut 2.6 and reaction seat 2.7. The frame beam 2.4 is connected with the main frame beam 2.1 and the sub-frame beam 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com