Piezoelectric cantilever beam generator for wind driven generator blade monitoring system

A technology for wind turbines and monitoring systems, applied in the directions of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem that micro-miniature power generation devices cannot meet the self-power supply requirements of monitoring systems , low power generation efficiency and other problems, to achieve the effect of novel structure, strong power generation capacity, effective speed and bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

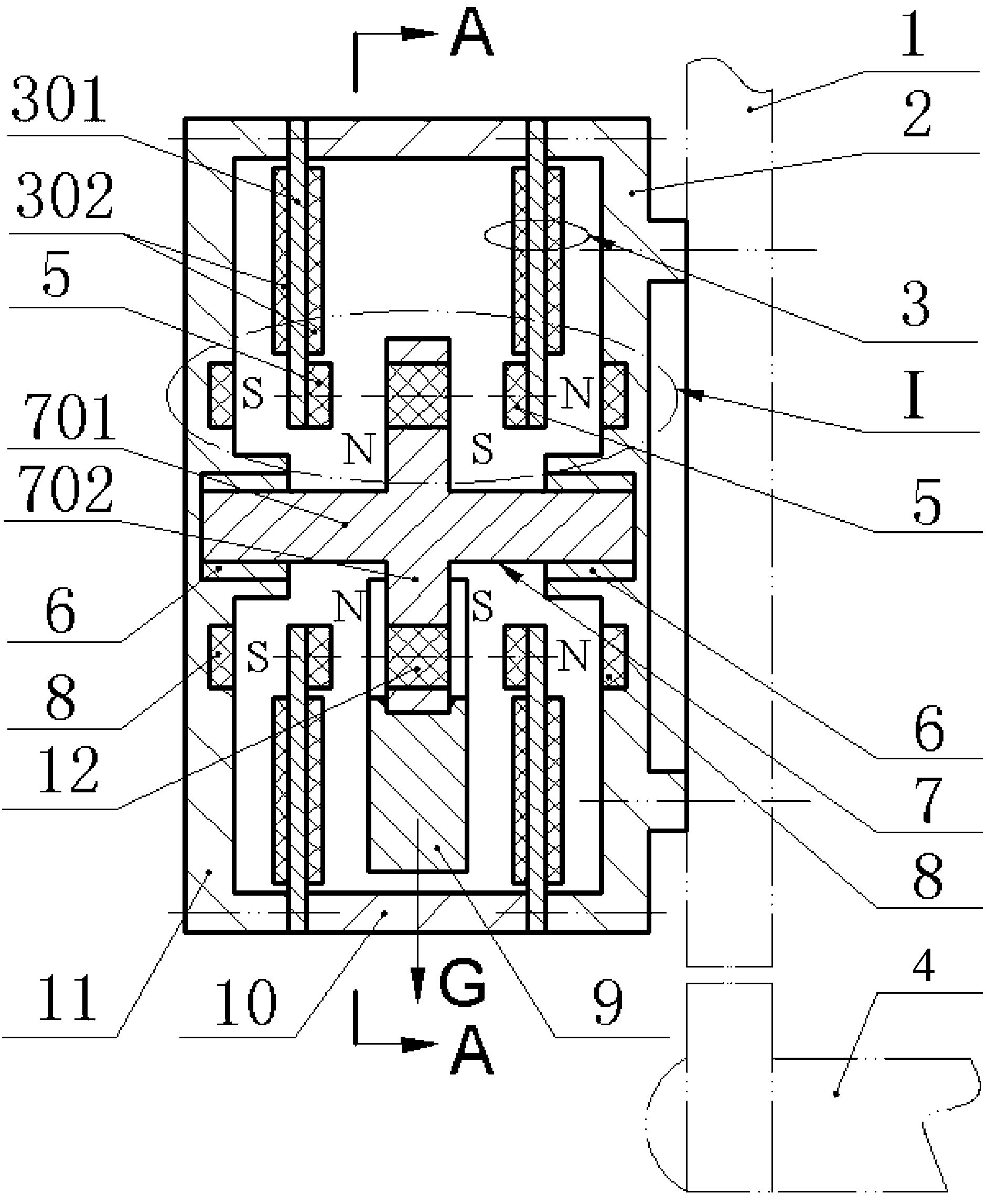

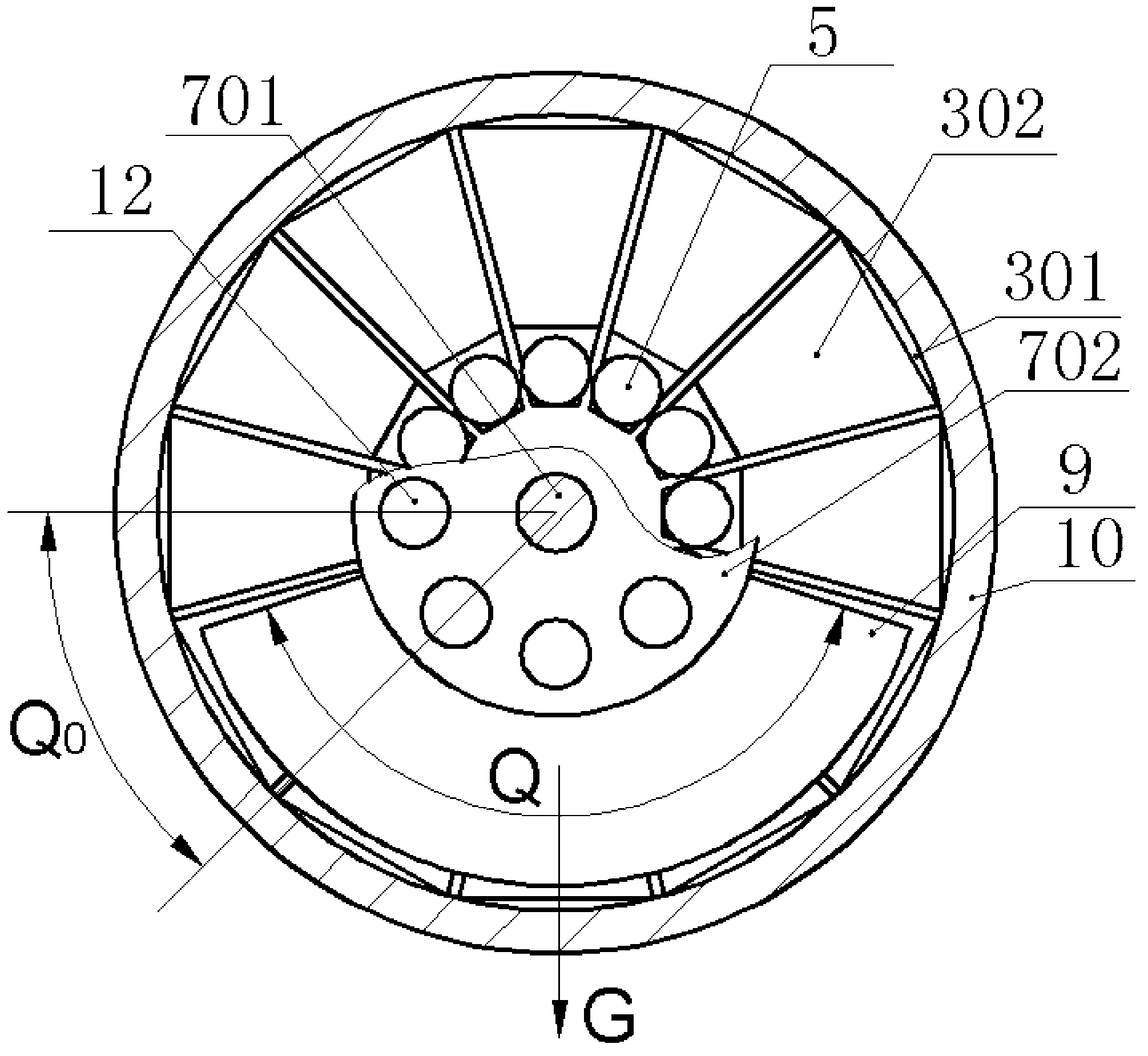

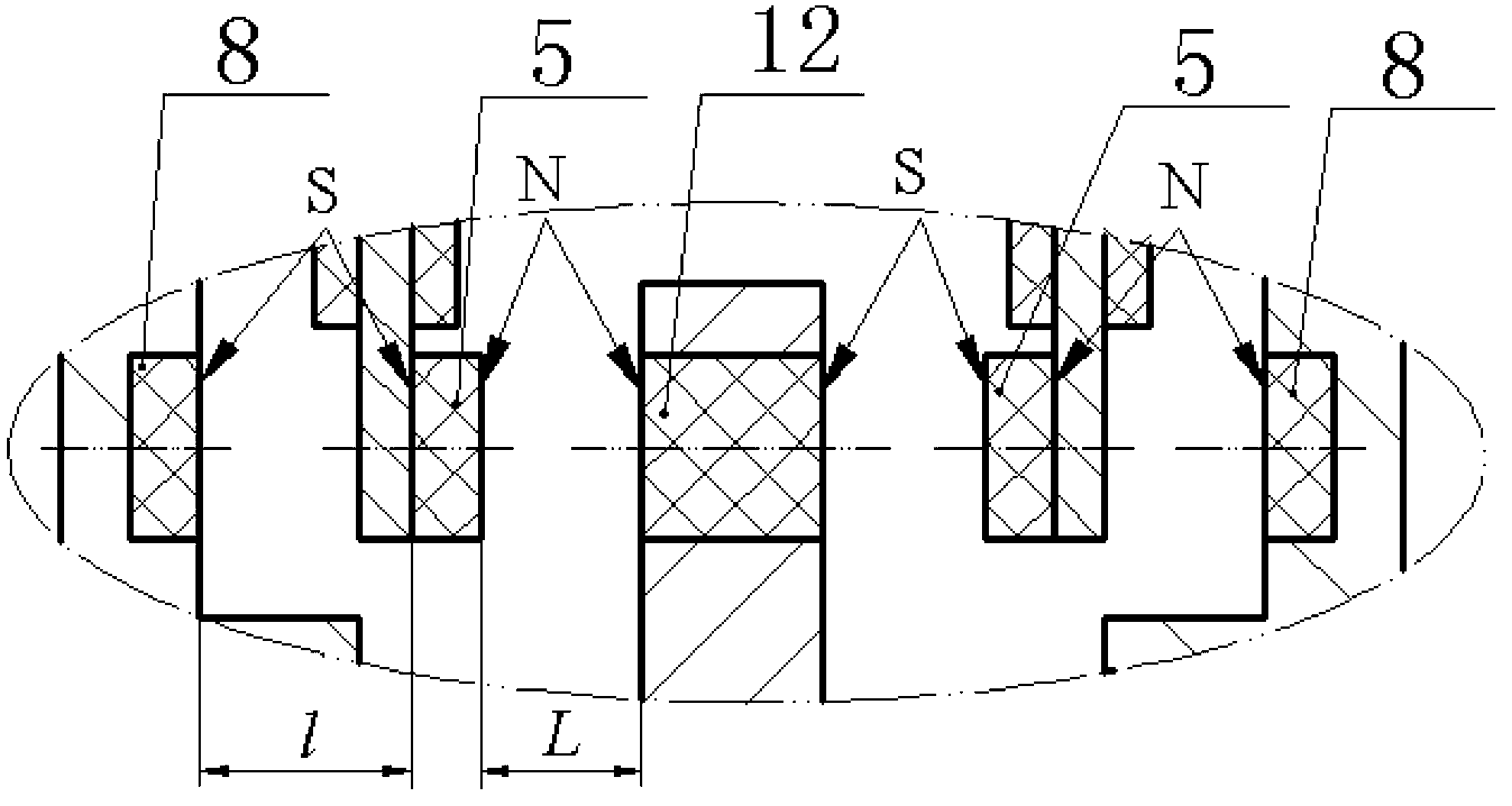

[0016] The left end cover 11 and the right end cover 2 are respectively installed on the two ends of the housing 10 by screws, and the inner side of the bottom of the left end cover 11 and the right end cover 2 are respectively inlaid with a first magnet 8 and a shaft sleeve 6; A metal substrate 301 is crimped between the right end cover 2 and the housing 10, the metal substrate 301 and the piezoelectric chips 302 bonded on both sides together form a fan-shaped cantilever beam piezoelectric vibrator 3, the piezoelectric The free end of the vibrator 3 is installed with a second magnet 5 through a screw, and the second magnet 5 coincides with the center line of the first magnet 8 installed on the inner side of the bottom of the left end cover 11 and the right end cover 2; In the hole of the sleeve 6 embedded in the bottom of the left end cover 11 and the right end cover 2, the rotating shaft 701 is hinged with the inner hole of the sleeve 6; the outer edge of the disc body 702 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com