Masonry anchor device

a technology of anchor device and masonry, which is applied in the direction of threaded fasteners, screws, fastening means, etc., can solve the problems of brittle failure, premature failure, and failure of masonry tapping fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]While the invention may be susceptible to embodiment in different forms, there is shown in the drawings, and herein will be described in detail, a specific embodiment with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention, and is not intended to limit the invention to that as illustrated and described herein.

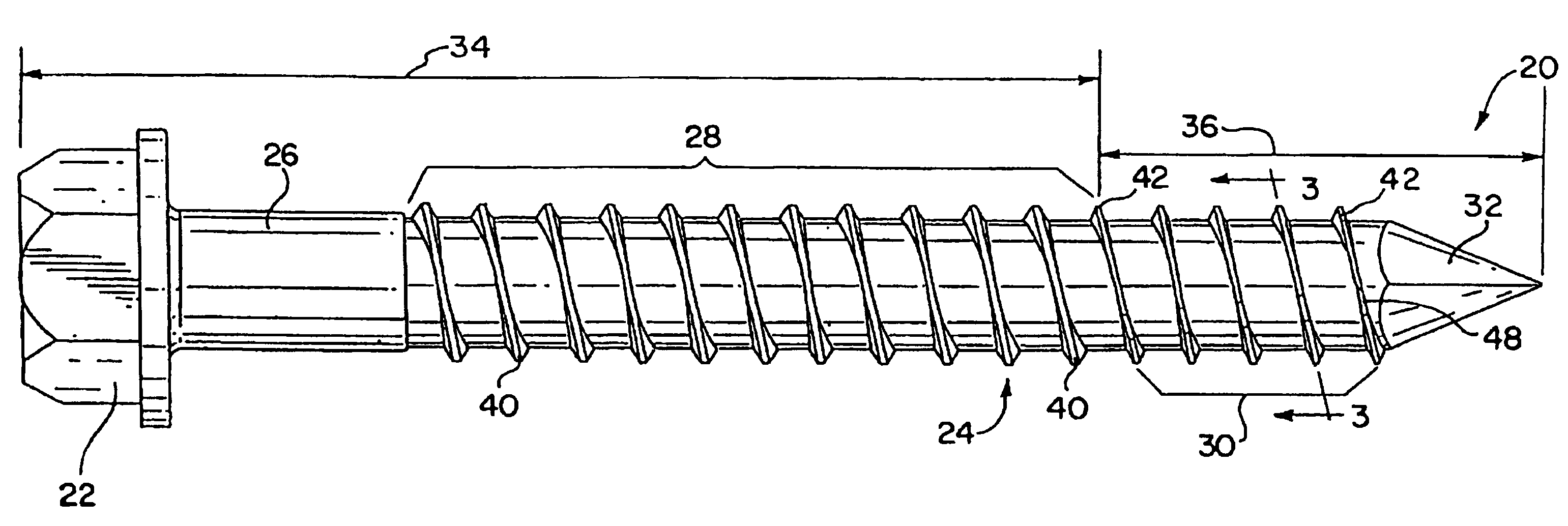

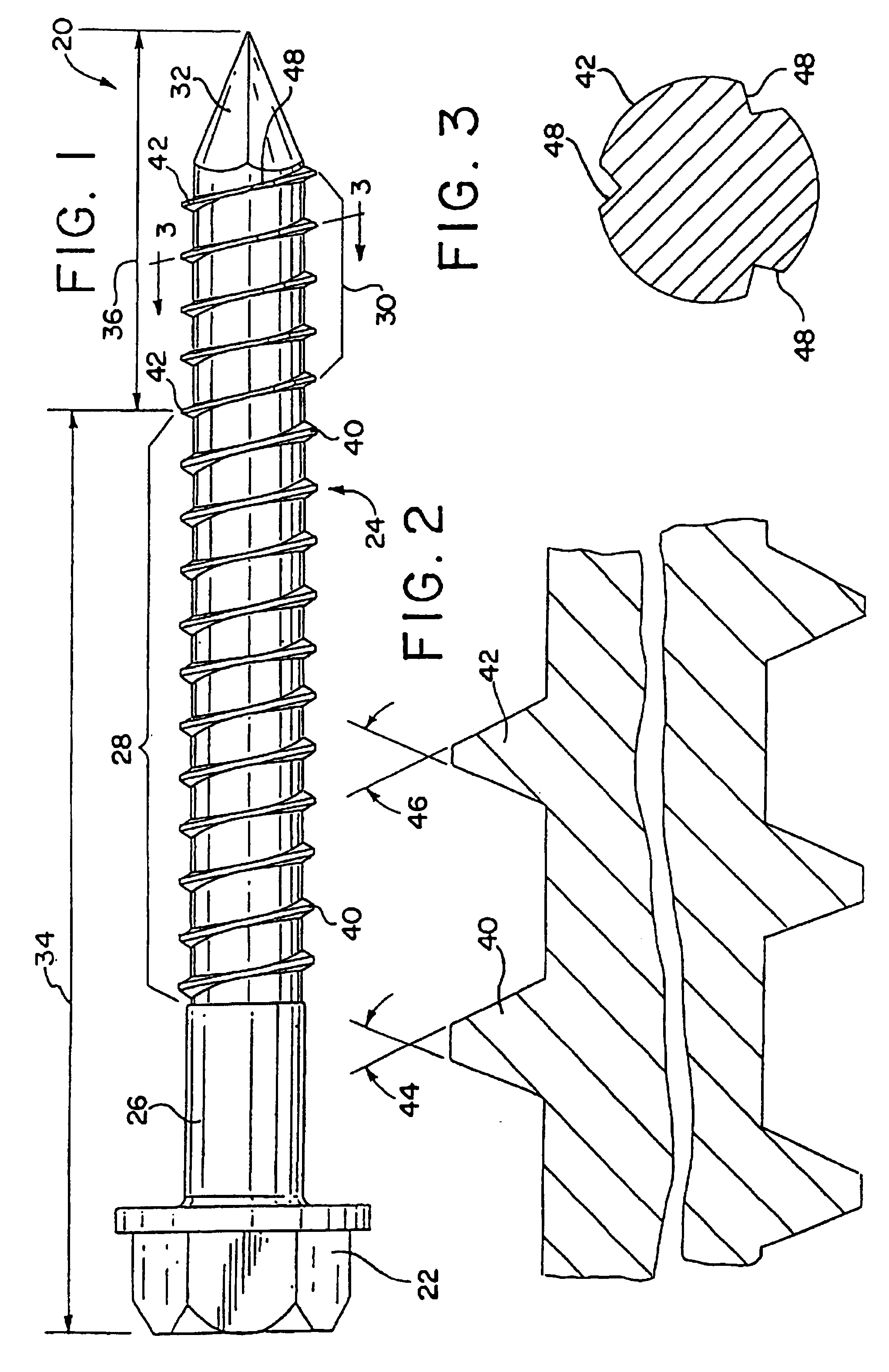

[0017]The present invention provides a novel anchor device or fastening member 20 which is particularly suited for use in the attachment of various fixtures and equipment to masonry, concrete, and other hard and / or friable substrates (not shown). The fastening member 20 may be a screw.

[0018]The fastening member 20 includes a head 22 which has a shank 24 depending therefrom. The head 22 may take a variety of forms and is dependant on the application. As shown in FIG. 1, the shank 24 includes an unthreaded portion 26 which extends from the head 22, a first threaded portion 28 which extends from the unthrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com