Method and apparatus for dyeing a textile substrate

A base fabric and textile technology, applied in the field of equipment implementing the method, can solve the problems of time-consuming and water-consuming, and achieve the effects of reducing environmental burden, favorable cost structure, and reducing the amount of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

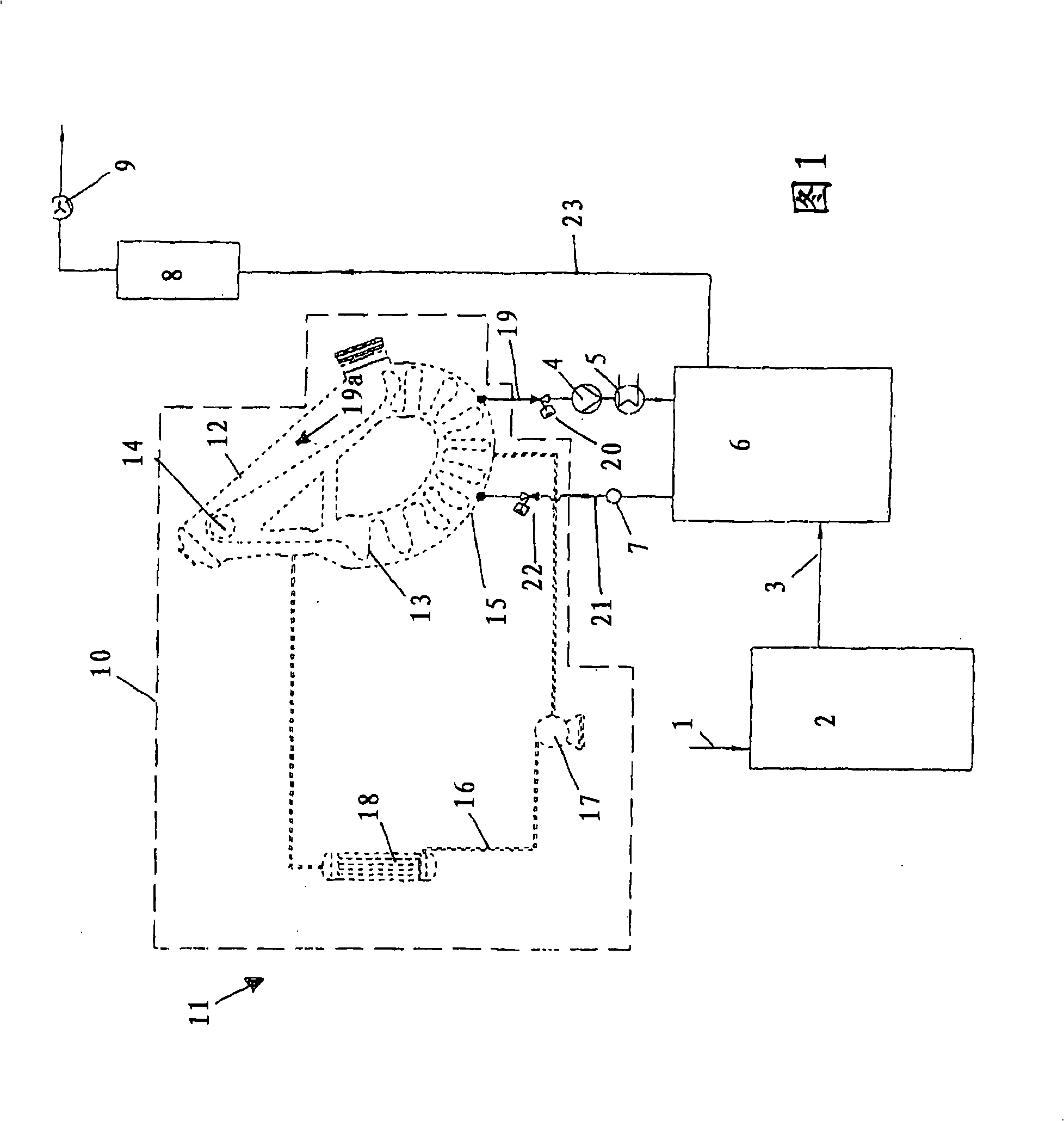

[0044] The embodiment of the apparatus shown generally at 11 in the single figure has a conventional dyeing device 10 provided with a container 12 for holding a skein 13 of fabric to be dyed. During the dyeing and rinsing process, the fabric skein 13 is conveyed continuously through the container 12 , wherein in the embodiment shown a driven capstan 14 is used for conveying the fabric skein 13 .

[0045] A dye liquor circulation system 16 is assigned to the bottom region 15 of the container 12, wherein via the dye liquor circulation system 16 the corresponding treatment liquor is discharged from the container 12 by means of a dye liquor circulation pump 17 and a heat exchanger and is discharged in the dye liquor circulation system 16. The liquid is re-introduced in the container 12 after heating. The fabric skeins 13 are conveyed during the treatment by means of the capstan 14 at a predetermined speed in the direction of the arrow 19a, wherein the conveying speed usually varie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com