Transverse squeezing type rope washing machine

A water washing machine and water rolling technology, which is applied in the treatment of liquid/gas/vapor rope-like fabrics, etc., can solve the problems of easy crushing of hands, hidden dangers, and unprotected safety of workers, so as to ensure safety and shorten distances. , the effect of reducing the height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

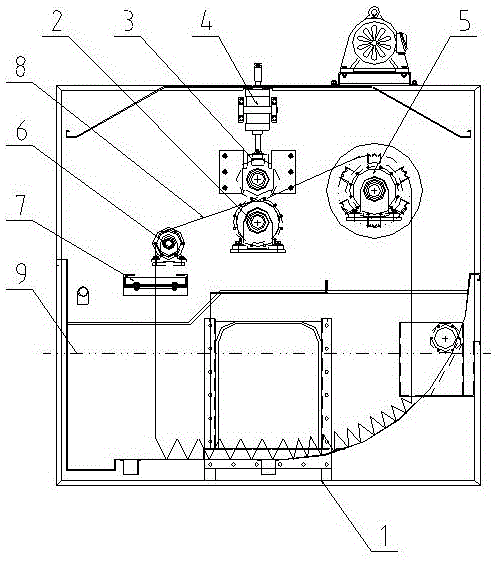

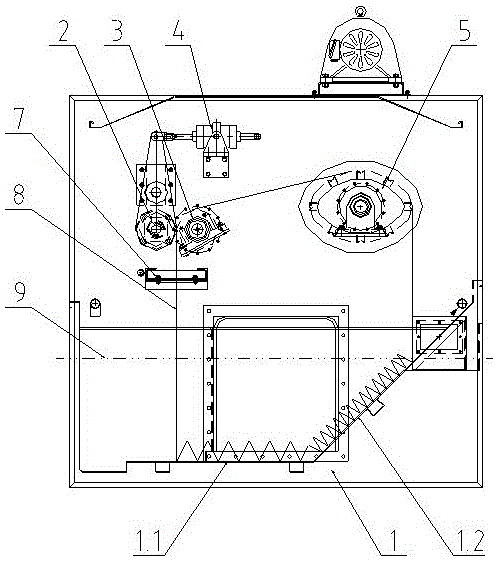

[0029] like figure 2 As shown, a kind of horizontal rolling type rope washing machine in this embodiment includes a plurality of unit tanks, and the unit tanks include a water tank 1, and above the water tank 1, a set of rolls and a doffing roller 5 are arranged. The doffing roller 5 is located on one side of the roller group, and the roller group includes a passive roller 2 and a driving roller 3, and the passive roller 2 and the driving roller 3 are arranged side by side, and a cloth guide ring 6 is arranged below the roller group. The intervention point 8 is located below the cloth guide ring 6 .

[0030] A pneumatic actuator 4 is connected to the passive roll 2, and the pneumatic actuator 4 is arranged along the horizontal direction.

[0031] The doffing roller 5 is oval.

[0032] The bottom of the tank 1 is composed of a horizontal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com