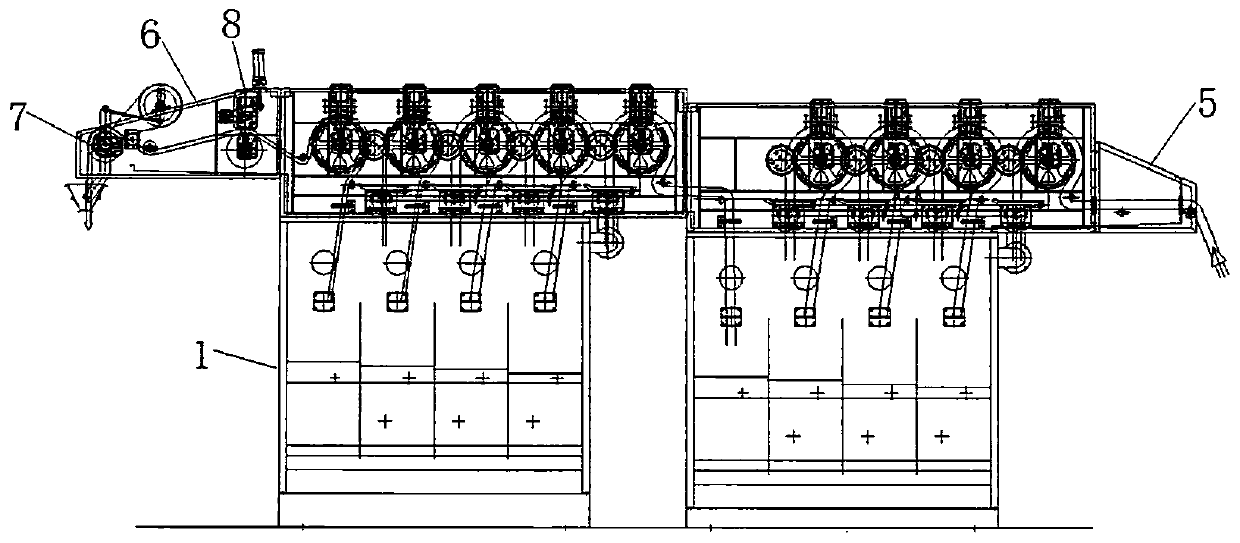

Continuous rope-shaped jetting water washer

A water-washing machine and rope-like technology, which is applied in liquid/gas/vapor rope-like fabric processing, textile material carrier processing, textile material processing equipment configuration, etc. It can reduce the energy consumption of equipment operation, save floor space and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

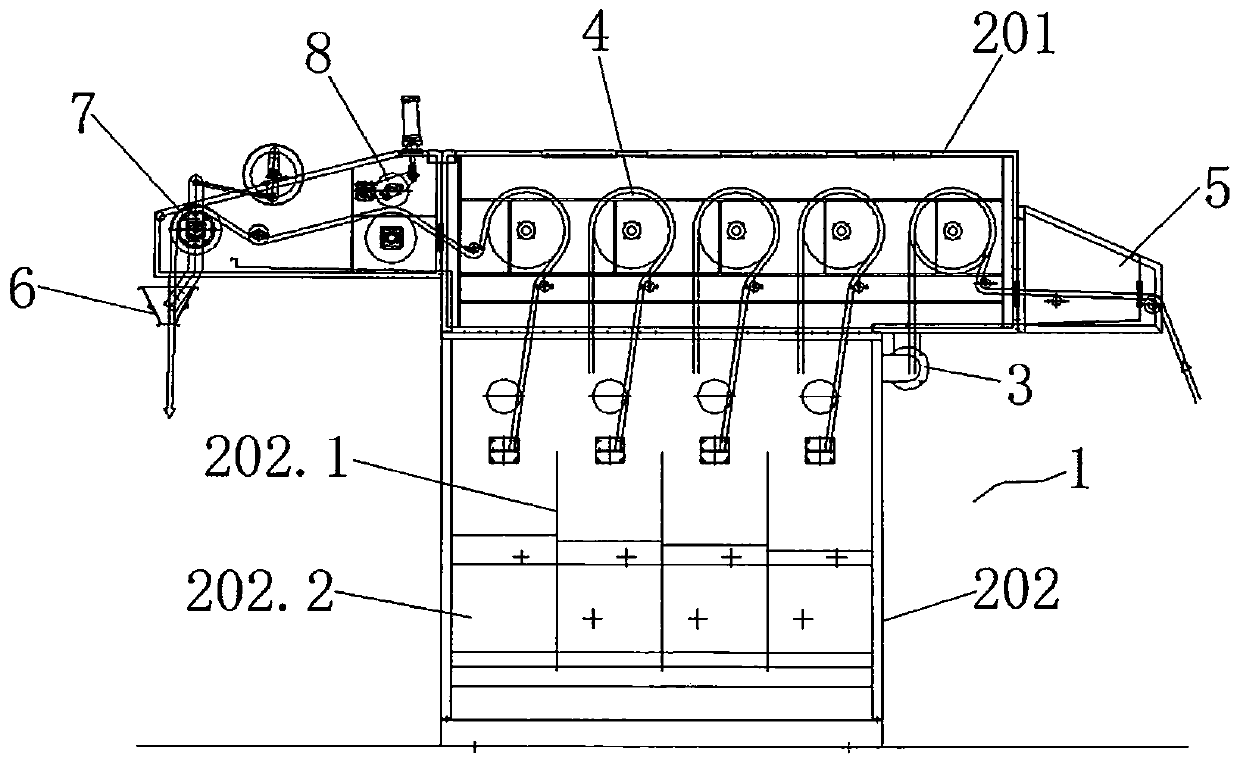

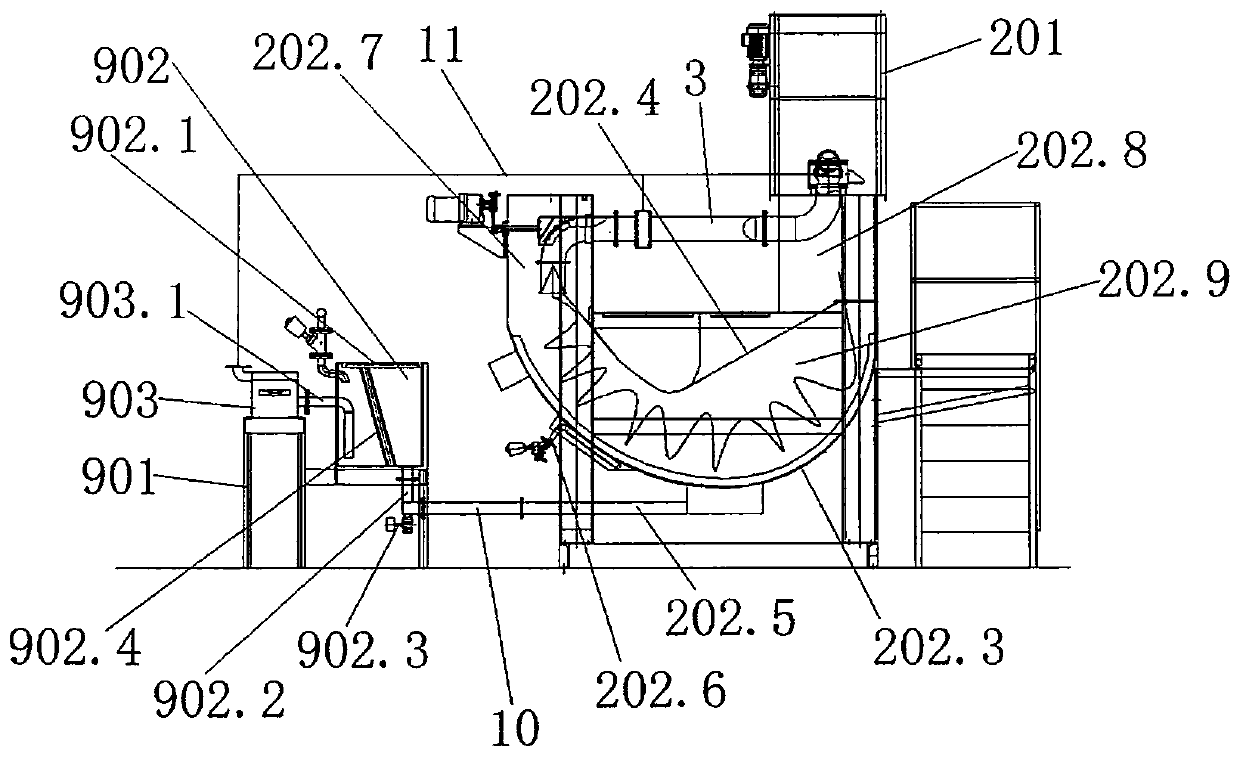

Embodiment 1

[0071] The cloth lifting mechanism 4 includes a pressure roller assembly 402A arranged up and down and a cloth lifting wheel assembly 401A. The cloth lifting wheel assembly 401A includes a transmission shaft 401.1A, and the transmission shaft 401.1A is arranged on the left and right boxes of the upper box body 201. Between the walls, one end of the transmission shaft 401.1A is provided with a driving motor 401.3A, and the middle part of the transmission shaft 401.1A is provided with a cloth lifting wheel 401.2A. The disc 401.2.1A on the shaft 401.1A, a plurality of rungs 401.2.2A are arranged between the left and right discs 401.2.1A, the plurality of rungs 401.2.2A are located on the same circumference, and the plurality of rungs 401.2.2A Arranged at intervals, there is a gap between every two adjacent crosspieces 401.2.2A;

[0072] The pressure roller assembly 402A includes a cylinder base 402.2A, on which a cylinder 402.1A is hinged, and the cylinder 402.1A is installed on ...

Embodiment 2

[0077] The cloth lifting mechanism 4 includes a cloth lifting wheel assembly 401B, and the cloth lifting wheel assembly 401B includes a transmission shaft 401.1B, and the transmission shaft 401.1B is arranged between the left and right box walls of the upper box body 201, and the transmission shaft One end of 401.1B is provided with a driving motor 401.3B, and the middle part of the transmission shaft 401.1B is provided with a cloth lifting wheel 401.2B. .1B, multiple crosspieces 401.2.2B are arranged at intervals between the left and right discs 401.2.1B, the multiple crosspieces 401.2.2B are located on the same circumference, and there are embedded between two adjacent crosspieces 401.2.2B Outwardly protruding rubber strips 401.2.3B;

[0078] The disc 401.2.1B and the crosspiece 401.2.2B are made of stainless steel.

[0079] Since the outer surface of the cloth lifting wheel is evenly embedded with a plurality of raised rubber strips, when the fabric is wrapped around the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com