Machine for the discontinuous dyeing of fabric products

A product and dyeing solution technology, which is applied in the field of discontinuous dyeing machines, can solve the problems of increased overall cost, imbalance, and increased energy consumption, and achieve reduced process and energy costs, stable and constant motion, and reduced time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

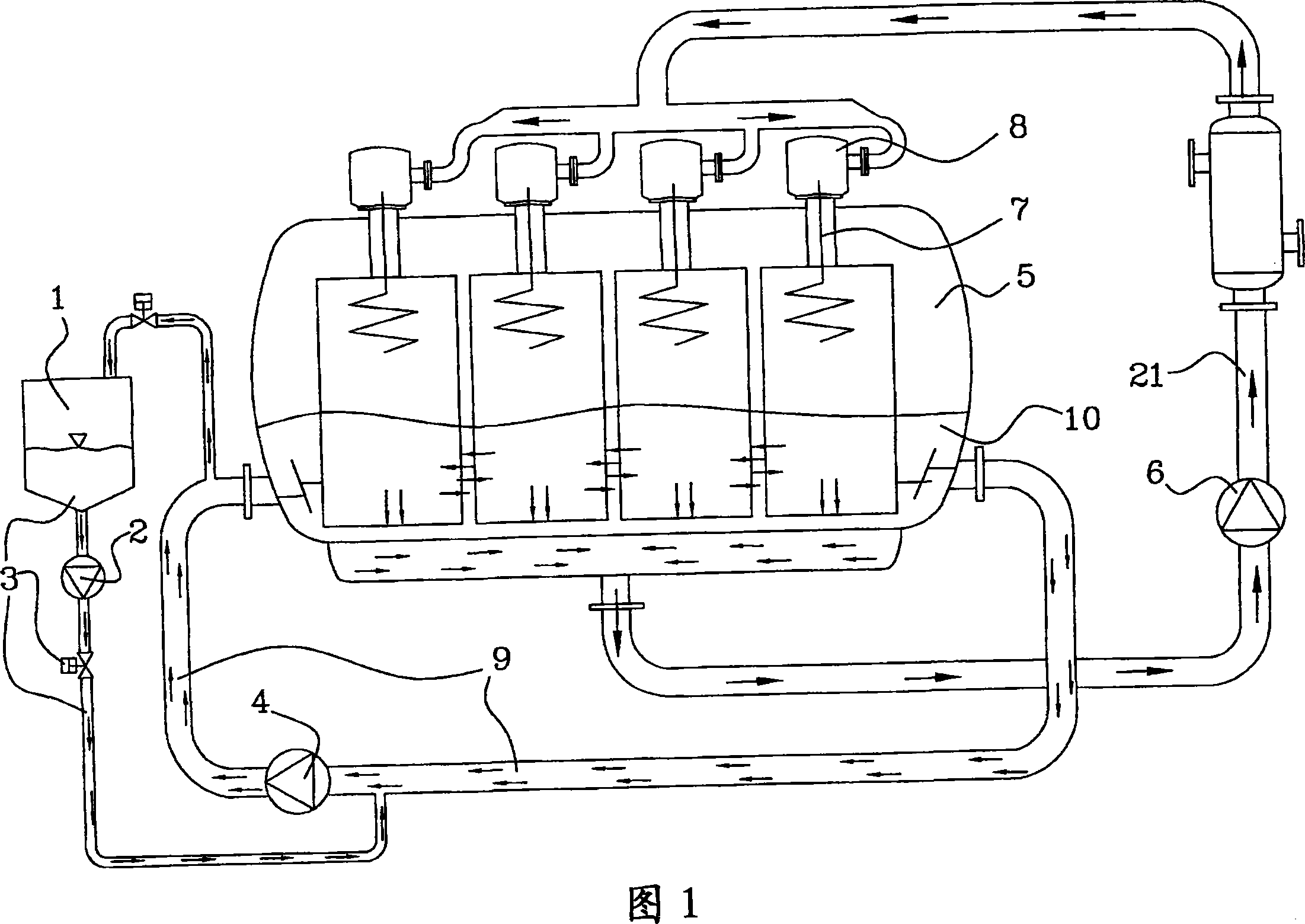

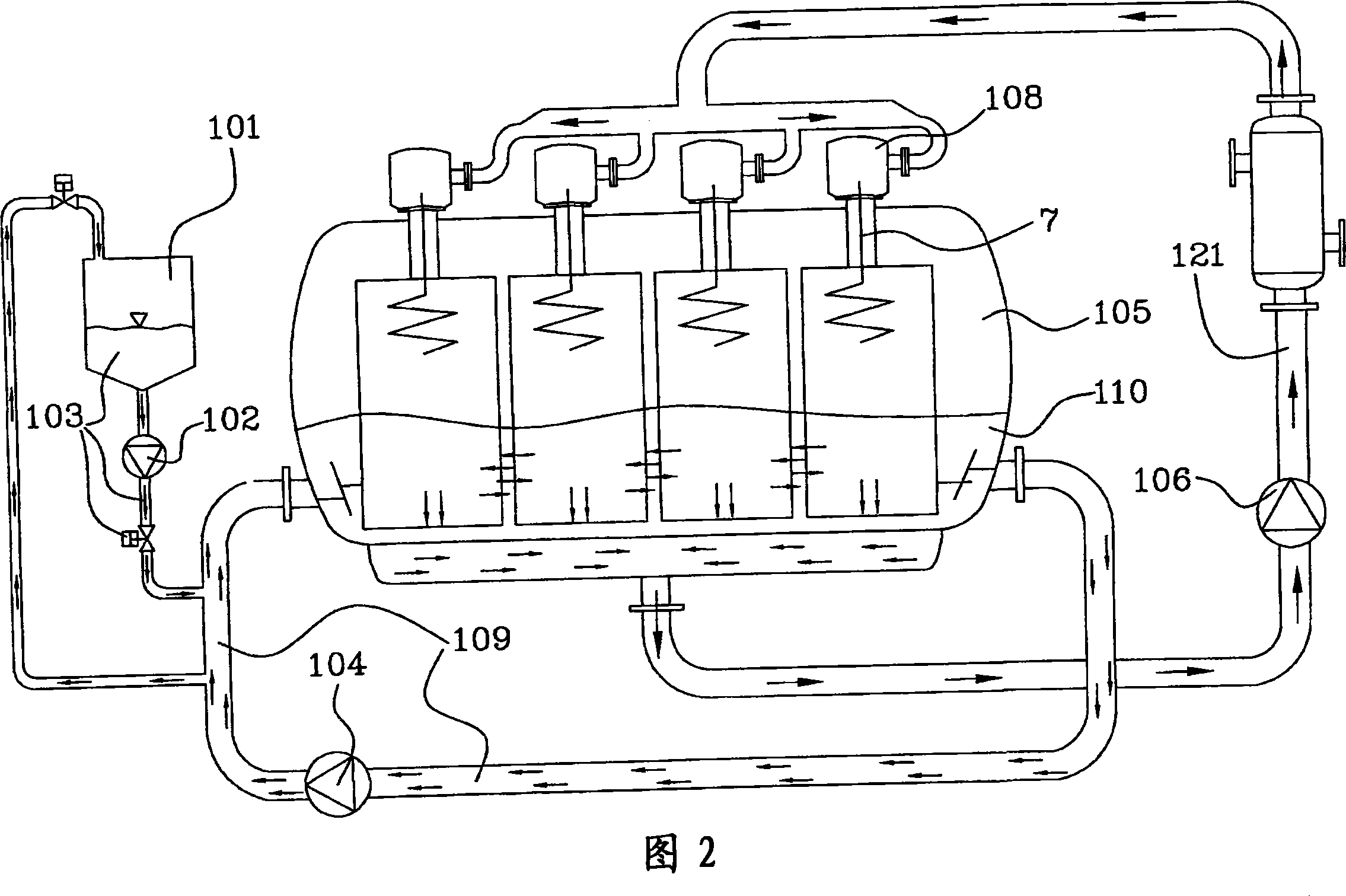

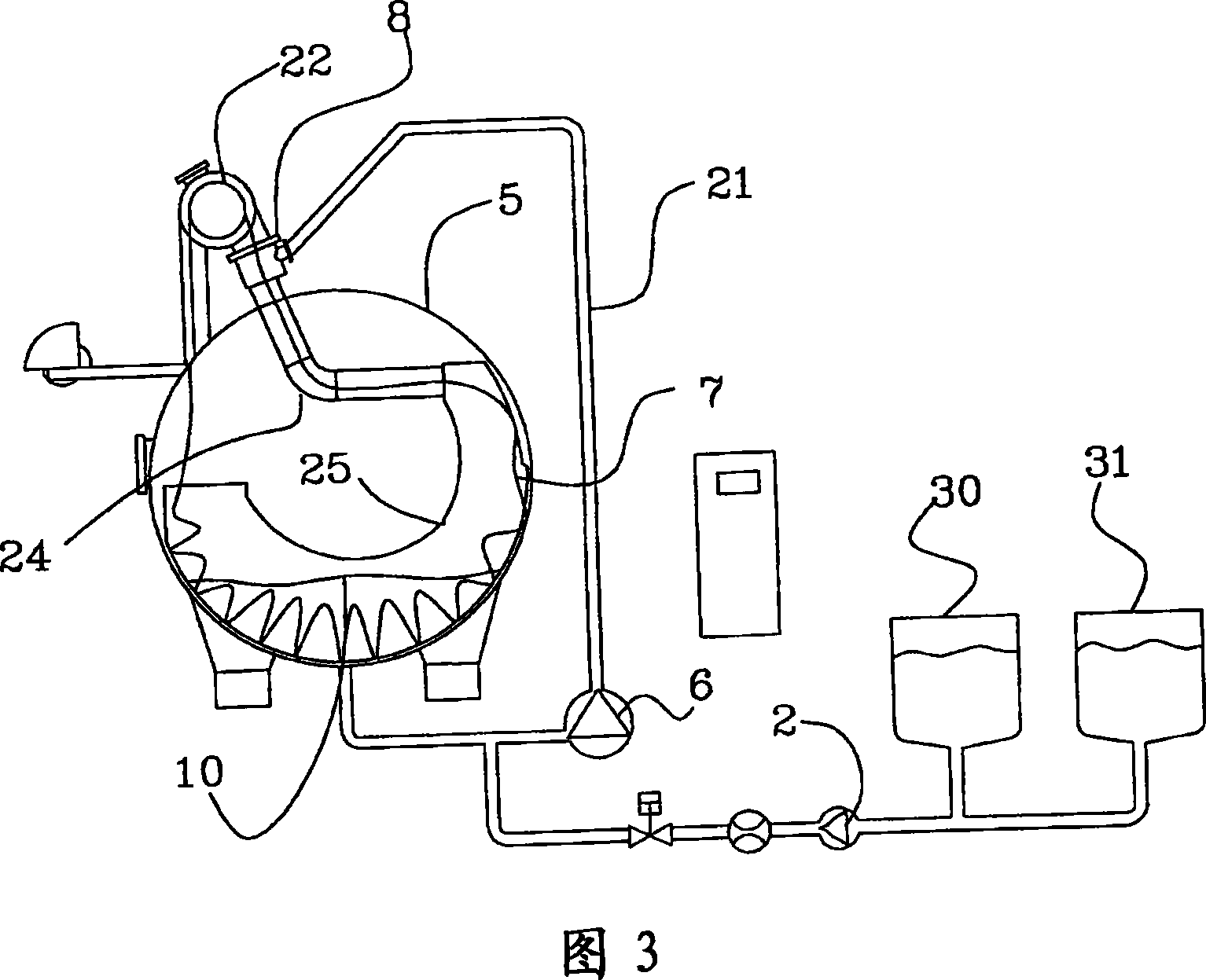

[0020] In FIGS. 1 and 3 , identical or substantially equivalent parts of the known machine and the machine of the invention are indicated by the same reference numerals for ease of comparison. In FIG. 2 , numbers corresponding to components in FIG. 1 are increased by 100.

[0021] Referring to FIG. 1 , in addition to the main elements already described with reference to FIG. 3 , the machine according to the invention provides a system for introducing articles comprising: comprising one or more tanks, generally designated by the reference numeral A unit denoted by 1; a pump 2 for introducing the product; and a control system generally denoted by reference numeral 3 for controlling the quantity introduced per unit of time.

[0022] Said system for introducing the articles feeds the articles into the inlet side of the mixing system for the dye liquor contained in the dyeing autoclave 5 . The mixing system for the dye liquor comprises a mixing pump 4 and a piping system 9 with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com