Rope-shaped washing machine

A water washing machine and rope-like technology, which is applied in liquid/gas/steam rope-like fabric processing, liquid/gas/steam processing transmission devices, etc., can solve problems such as inconvenient operation, potential safety hazards, time-consuming and labor-intensive, and save labor , ensuring safety and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

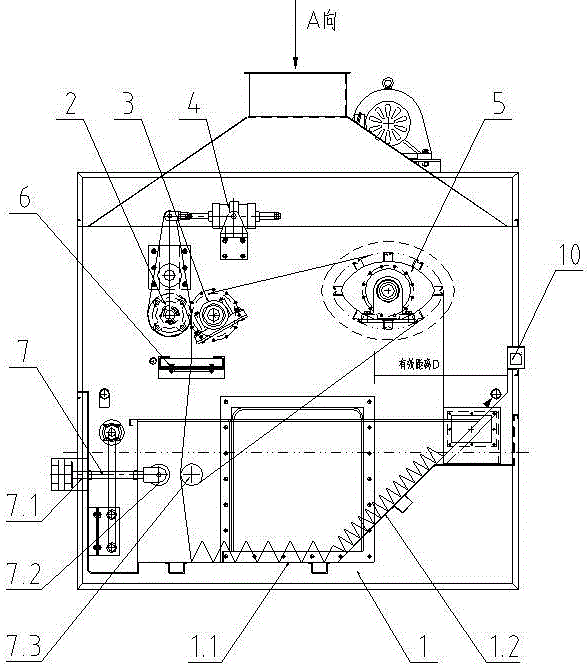

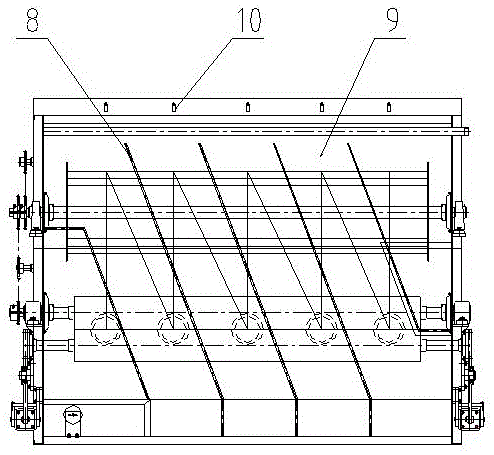

[0037] like figure 1 , figure 2 As shown, a rope-shaped washing machine in this embodiment includes a plurality of unit tanks, the unit tanks include a water tank 1, and a roller group and a doffing roller 5 are arranged above the water tank 1. The roller group and The doffing roller 5 is provided with a partition 8, which divides the roll group, the doffing roll 5 and the water tank 1 below it into a plurality of cells 9, and one side of the roll group of each cell 9 is provided with Brake assembly 7, a distance measuring device 10 is provided on one side of the cloth doffing roller 5. During operation, when the effective distance between the distance measuring device 10 and the fabric in a certain cell 9 exceeds the set value (the 500mm), that is, when the capacity of the cell 9 is insufficient, the distance measuring device 10 of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com