Mist spraying dyeing machine

A dyeing machine and dyeing tube technology, applied in the field of spray dyeing machines, can solve problems such as uneven dyeing, poor effect, and increased production costs of enterprises, and achieve the goals of increasing spraying area, reducing dye liquor sewage, and enhancing adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

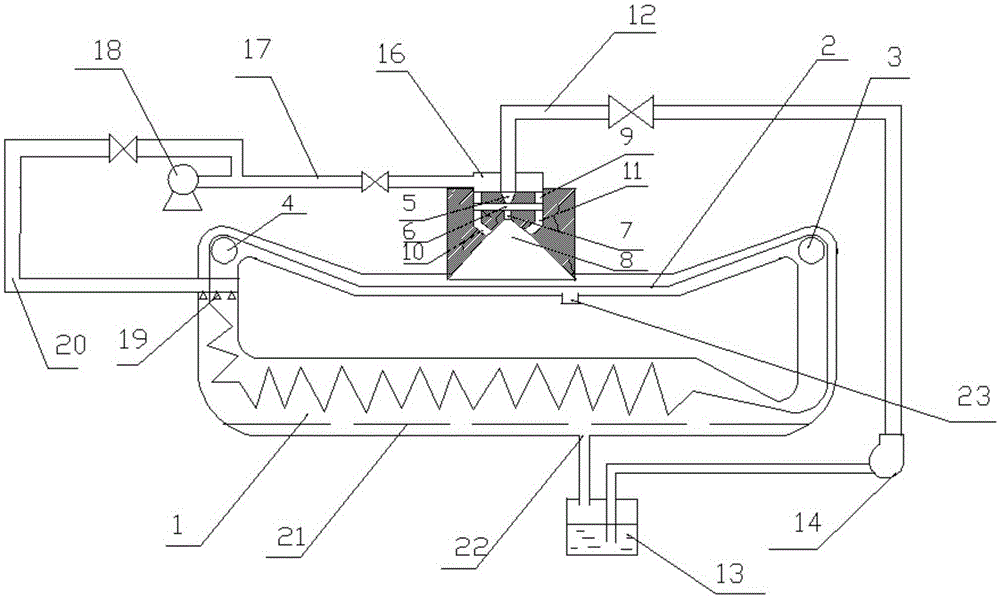

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0021] see figure 1 As described above, a dyeing machine for dyeing fabrics includes a U-shaped fabric storage pipe 1 and a dyeing pipe 2 horizontally arranged above the fabric storage pipe, and the two ends of the dyeing pipe are respectively inclined upward at 10-30 degrees relative to the horizontal direction. The extension is connected with the two ends of the U-shaped fabric storage pipe, and the two ends of the U-shaped fabric storage pipe are connected with the two ends of the dyeing pipe. The first rotating roller 3 for driving the fabric from the fabric storage pipe into the dyeing pipe and for Drive the fabric out of the dyeing pipe and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com