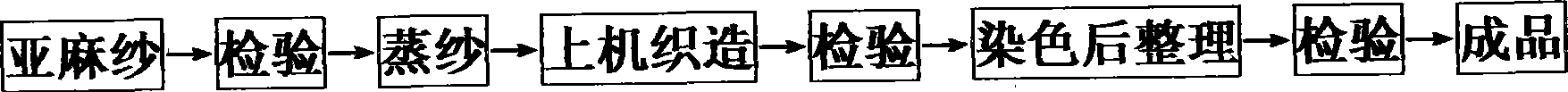

Production method of flax knitted fabrics

A production method and linen fabric technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of unevenness, difficulty in bending yarn into loops, and weak elasticity, so as to achieve smooth looping and reduce Fabric holes and the effect of reducing the defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is an example of a single-sided plain weave linen fabric with a finished door width of 26 inches×2, a finished product grammage of 190 grams / square meter, a transverse density of 40 mesh / 5 cm, and a longitudinal density of 66 mesh / 5 cm. as follows:

[0014] Steamed yarn: After many times of strict weaving tests, the yarn count of flax yarn is finally selected as 28n / l. The flax yarn of this yarn count is more stable and has good spinnability. Steaming process is carried out before the machine, choose the appropriate temperature and time for steaming, steaming process: steaming at 100°C for 1 hour and then heat preservation for 1 hour, in order to increase the humidity, strength and softness of flax, so as to facilitate the bending of the yarn loop during knitting .

[0015] Weaving on the machine: After several strict weaving tests, the machine-on process of the single-sided plain linen fabric is set at a transverse density of 40 mesh / 5 cm and a longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com