Production process of thin nylon elastic adhesive-bonded interlining

A production process, a technology of adhesive interlining, applied in the fiber type, the device that coats the liquid on the surface, clothing, etc., can solve the problems of unsatisfactory resilience, uncomfortable wearing, high pressing temperature, and achieve good dry cleaning effect, Comfortable to wear and the effect of improving the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In this embodiment, the production process of the present invention is described in detail by taking the PA30DX40D product as an example.

[0016] (1) Grey cloth inspection

[0017] Inspection items: broken warp, broken weft, oily yarn, broken slub, dragging yarn, temple defect, sundries, fabric structure, density, strength, width.

[0018] (2) Turning, printing, sewing

[0019] The cloth is turned neatly, the batches and boxes are accurate, the printing is clear, the seal is 10-15 cm away from the cloth head, fill in the card carefully, the seam head should be straight and firm, no leakage, the needle density is 3.5-4 stitches / cm, within 2 cm of both sides Encryption needles are 6-7 stitches / cm, the small braids on both sides of the seam are not more than 3 cm, and the two sides of the seam are wrapped with cloth "△" to prevent the head from being folded.

[0020] (3) Relaxation and dyeing

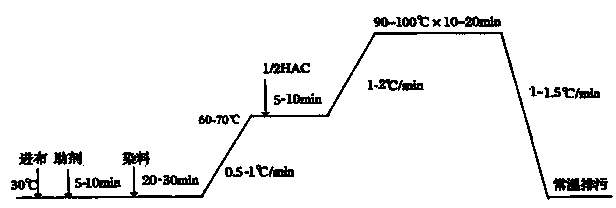

[0021] see attached figure 1 , Introduce the grey fabric withdrawn into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com