Patents

Literature

46results about How to "Full compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

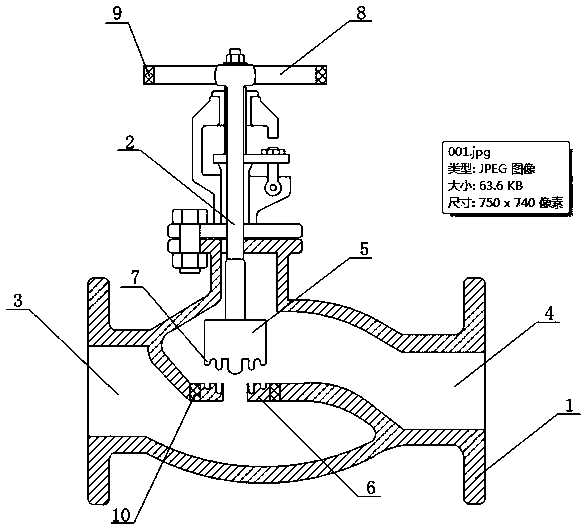

Rotary control type stop valve

InactiveCN103671985AEasy to useExtended service lifeOperating means/releasing devices for valvesLift valveEngineeringPhysics

Owner:CHONGQING JUKANG BUILDING MATERIAL

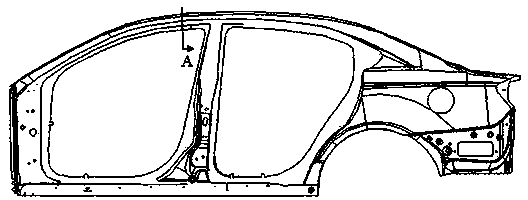

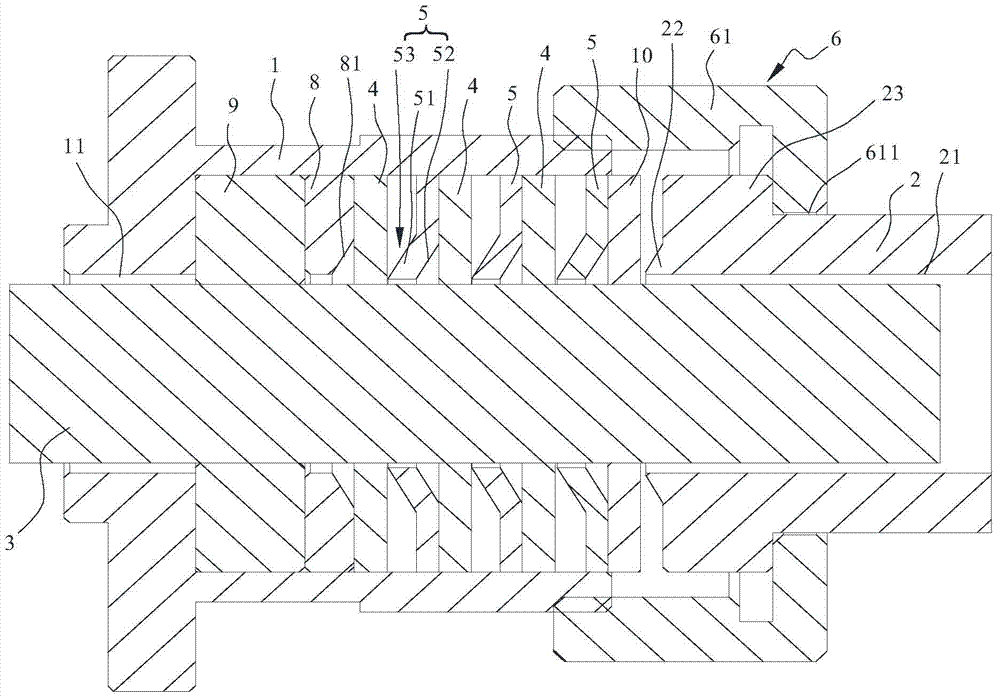

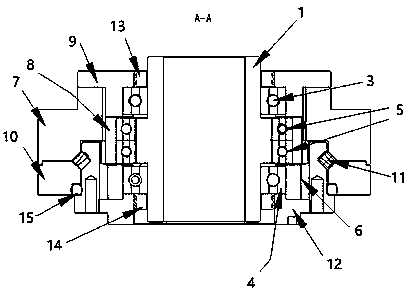

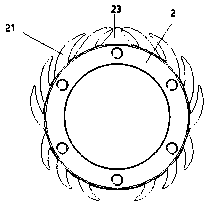

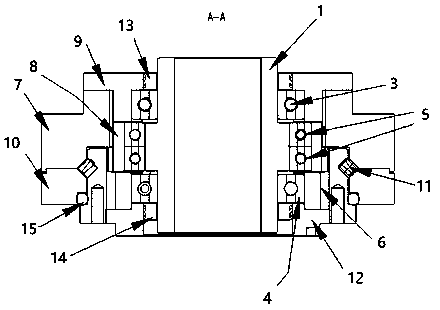

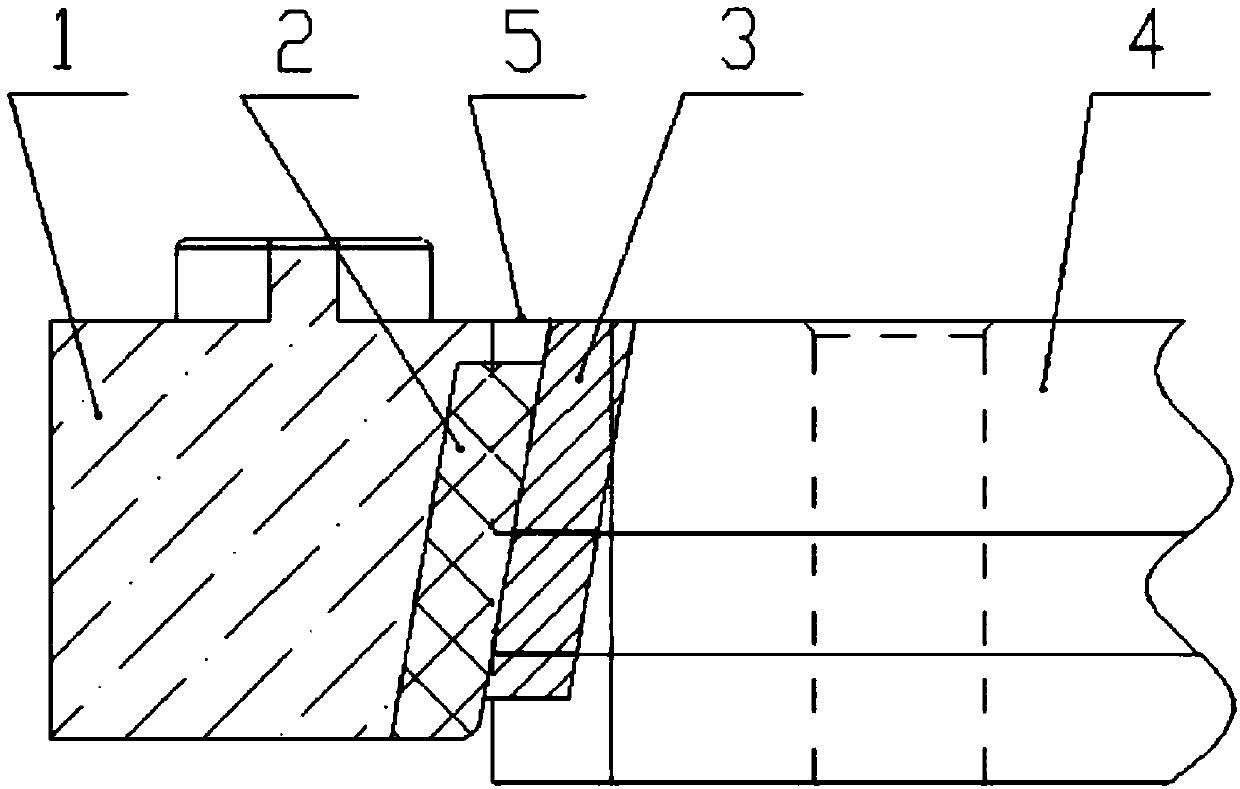

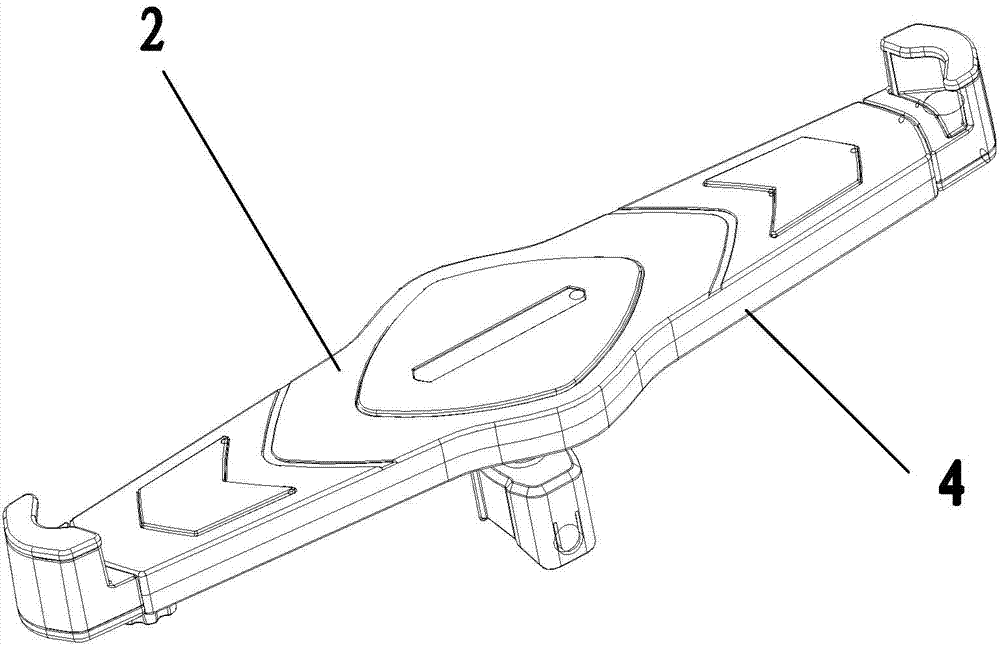

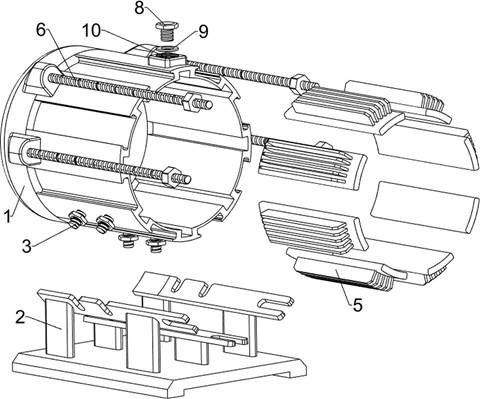

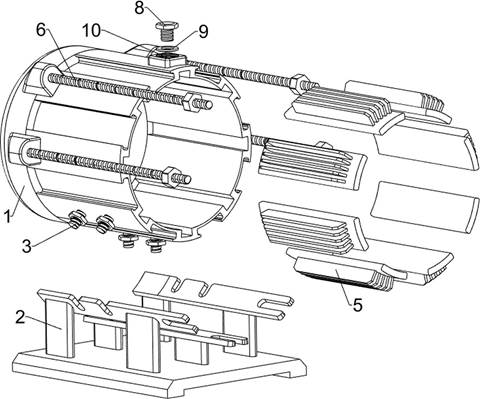

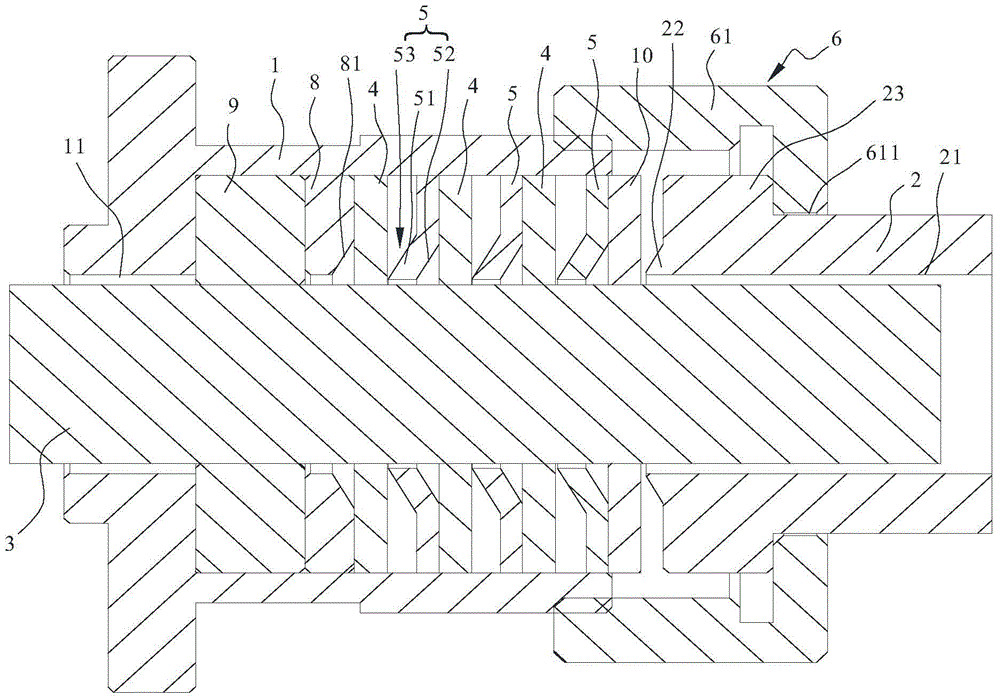

Wedge side-shaping die

InactiveCN103817239AFull compressionAvoid deformationShaping toolsEngineeringPerpendicular direction

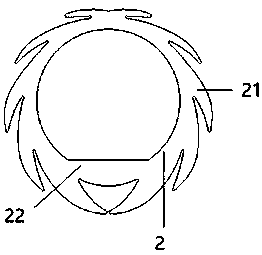

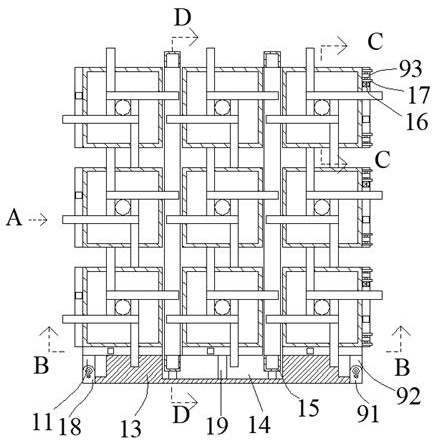

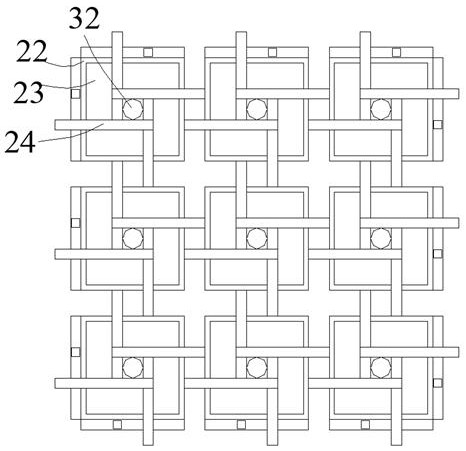

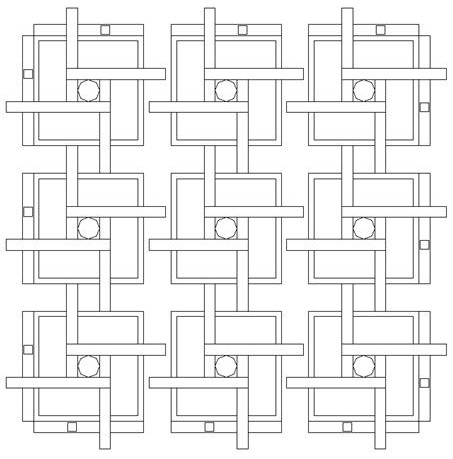

The invention relates to a wedge side-shaping die which comprises a first wedge driving block (1), male dies (2 and 22), wedge sliders (3 and 23), second wedge driving blocks (5 and 25), auxiliary pressing cores (6 and 26), primary pressing cores (7and 27) and side shaping female die inserts (9 and 29). The first wedge driving block (1) drives the male dies (2 and 22) to move, the second wedge driving blocks (5 and 25) drive the auxiliary pressing cores (6 and 26) and the wedge sliders (3 and 23) to move, workpieces are arranged on the male dies (2 and 22), the auxiliary pressing cores (6 and 26) press laterally along the direction of wedge side-shaping, and the primary pressing cores (7 and 27) press along the perpendicular direction. The wedge side-shaping die is characterized in that stress springs (8 and 28) of the auxiliary pressing cores (6 and 26) are fixed on the wedge sliders (3 and 23), the auxiliary pressing cores (6 and 26) laterally press along the second wedge driving blocks (5 and 25) through the springs (8 and 28) so as to guarantee that the workpieces are sufficiently pressed during side shaping, and deformation of the workpieces is effectively avoided.

Owner:CHERY AUTOMOBILE CO LTD

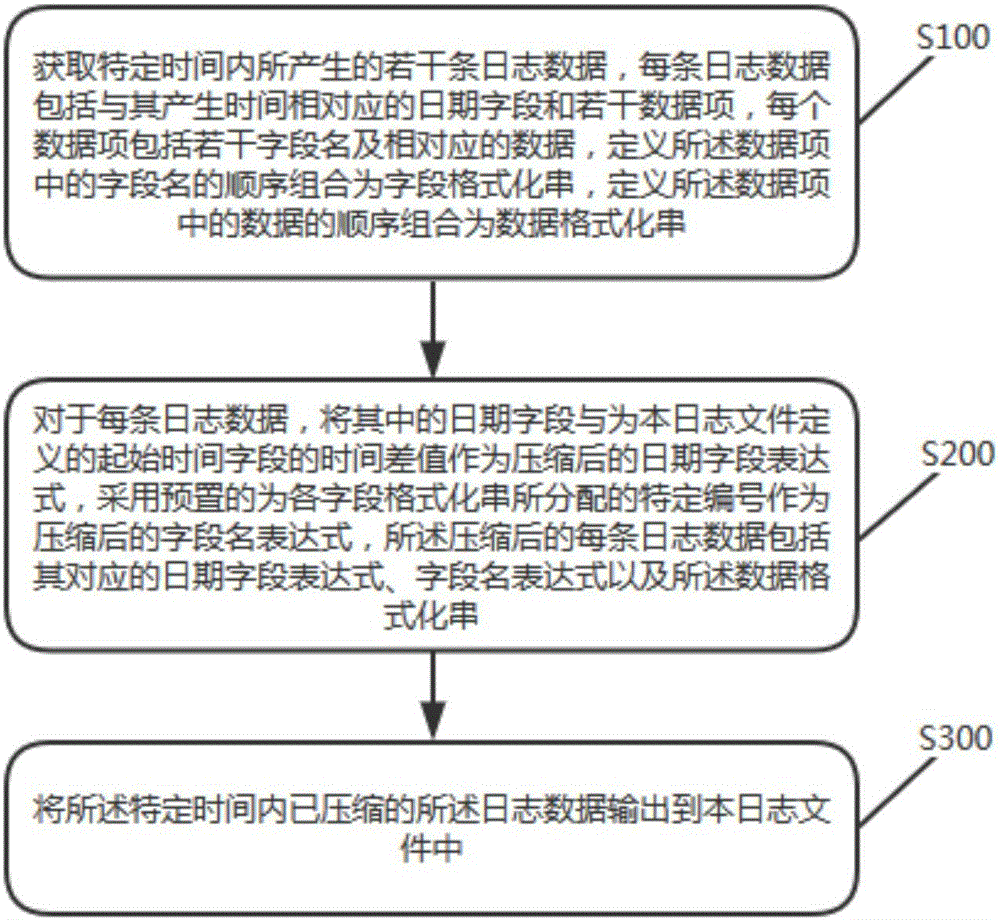

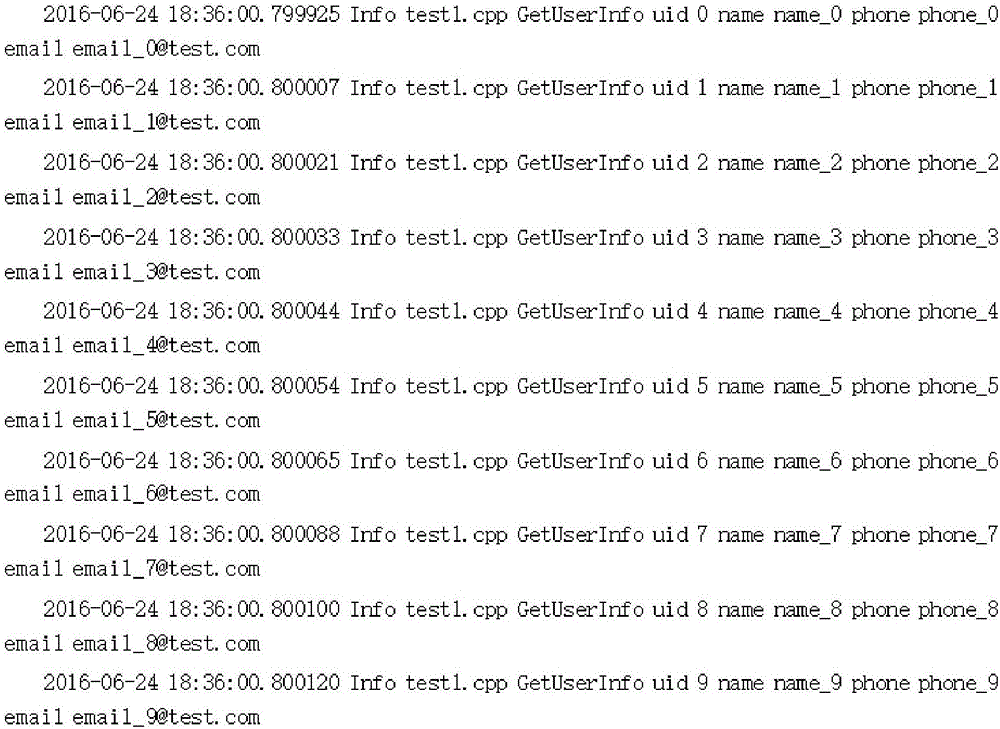

Program compression log file output method and device

ActiveCN106354617AReal-time compression effectReduce occupancyHardware monitoringStart timeTime difference

The invention relates to the technical field of computers, and particularly discloses a program compression log file output method and device. The method includes the steps: acquiring a plurality of log data generated within specified time; taking the time difference between a date field and a starting time field defined for a log file as a compressed date field expression for each log datum, and taking specified numbers allocated by preset field format strings as a compressed field name expression; outputting the log data compressed within the specified time to the log file. Each log datum comprises a plurality of data items and the date field corresponding to the generation time. By replacing format line information with a large number of repeating fields in the log data, the log data are compressed in real time, IO resources occupied by programs outputting the log file are decreased, storage space occupied by a large number of log files is saved, and the running efficiency of the programs is improved.

Owner:GUANGZHOU HUADUO NETWORK TECH

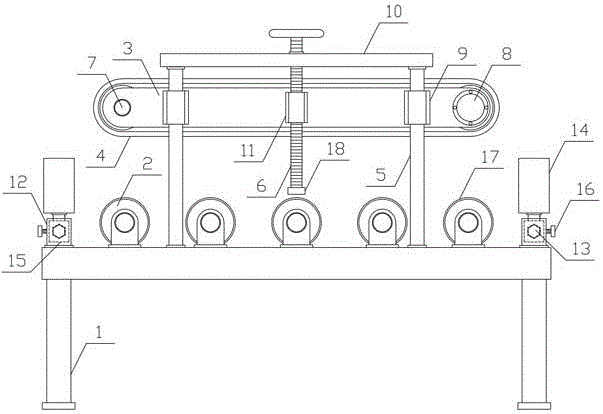

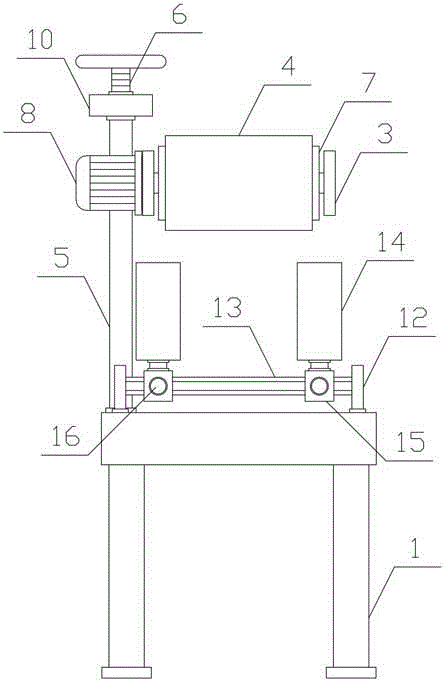

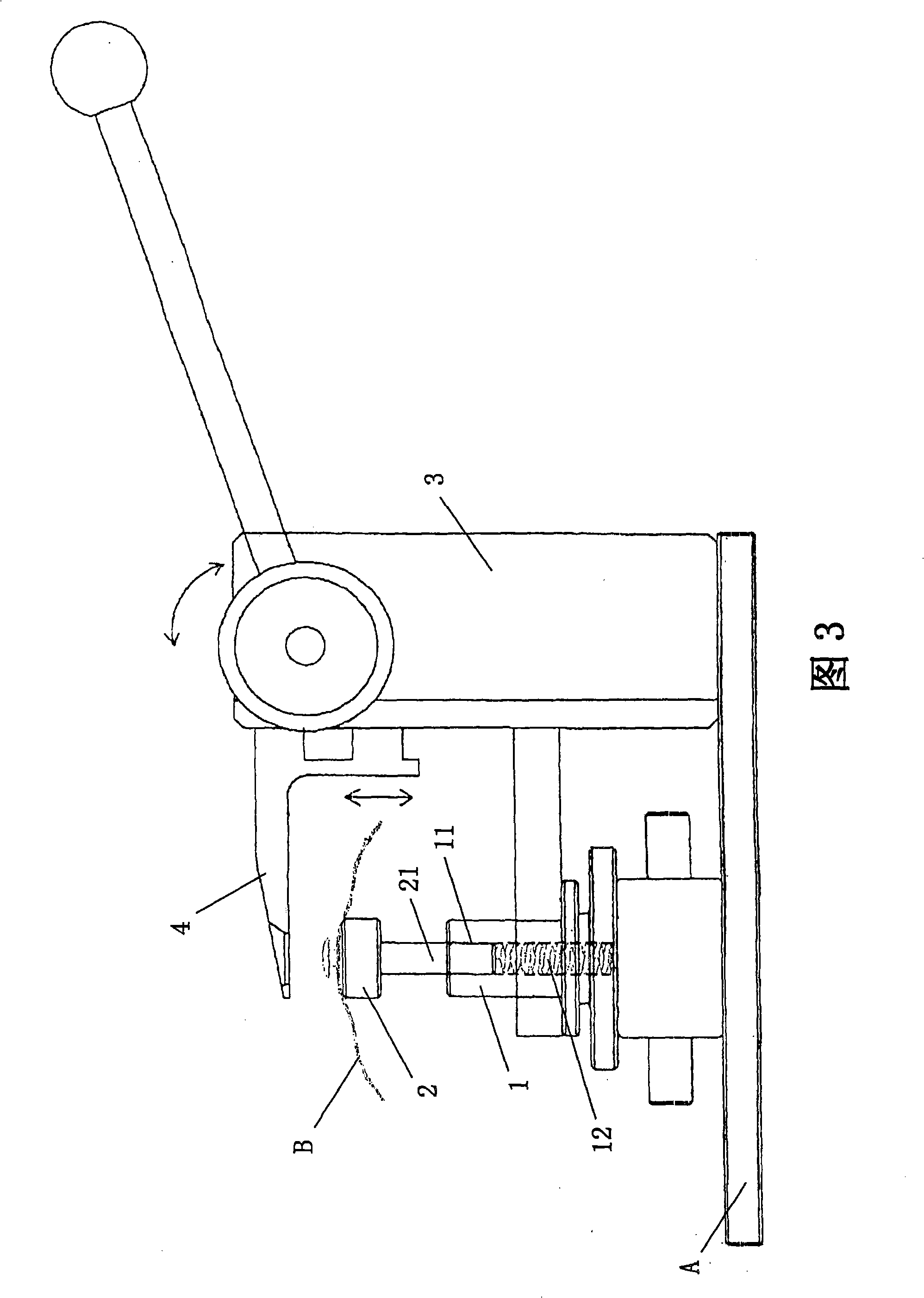

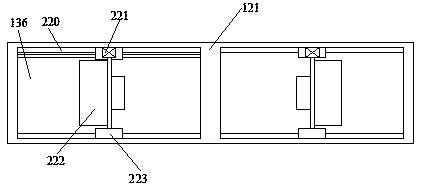

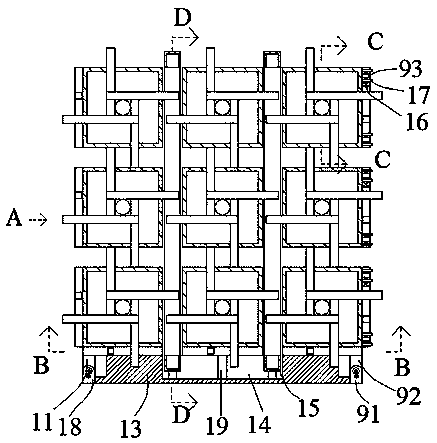

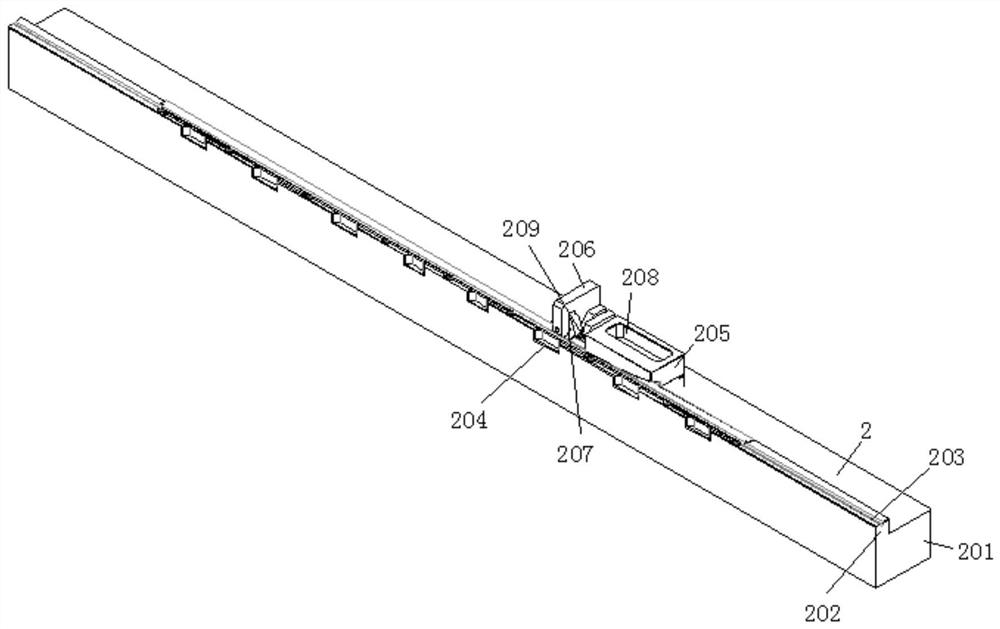

Wood plate compress-conveying mechanism

The invention discloses a wood plate compress-conveying mechanism and belongs to the field of wood processing mechanical equipment. The wood plate compress-conveying mechanism comprises a fixed base, guide rollers, a compressing support, a conveying belt, lifting guide rods and a lifting screw, the plurality of guide rollers are horizontally, evenly and rotatably connected onto the top of the fixed base along a wood plate conveying direction, conveying limit mechanisms are disposed on two sides of the upper portion of the fixed base respectively, the compressing support is horizontally disposed above the guide rollers, two ends of the compressing support are horizontally and rotatably connected with conveying rollers respectively, the conveying belt is horizontally disposed on the conveying rollers, a conveying motor drives the conveying rollers, two ends of one side of the compressing support are vertically provided with guide sleeves respectively, the lifting guide rods are vertically and downwardly passed through the guide sleeves and fixed to the top of the fixed base, the middle of one side of the compressing support is vertically provided with a lifting sleeve that is in threaded connection with the lifting screw. The wood plate compress-conveying mechanism is reasonable in structural design, can compress and convey wood plates efficiently, easily and accurately and meets the requirement for processing wood plates.

Owner:于星杰

Express item packaging method

ActiveCN108528781AAvoid the risk of openingImprove confidentialityPackaging automatic controlContainers to prevent mechanical damageAirbagAtmospheric pressure

The invention belongs to the technical field of logistics packaging, and particularly relates to an express item packaging method. The express item packaging method comprises the following steps thatan express item is placed in a logistics box with inflatable airbags and an airbag pressure detection device, and when the express item is placed in the logistics box, the airbags are in an un-inflated state; a box cover and a box body of the logistics box are buckled and are connected and fastened through a fastener; an inflation opening arranged on the outer wall of the logistics box is utilizedfor inflating the airbags in the logistics box with air, and meanwhile the airbag pressure detection device is utilized for detecting the pressure change of the airbags; and when the pressure of theairbags reaches the preset value, inflation of the airbags is stopped. The inflatable airbags and the air pressure detection device are arranged in the logistics box, it can be ensured that the airbags fully press the express item by detecting the air pressure of the airbags, the express item is prevented from shaking in the transport process, and the protection effect on the express item is effectively improved.

Owner:安徽企路石工程技术开发有限公司

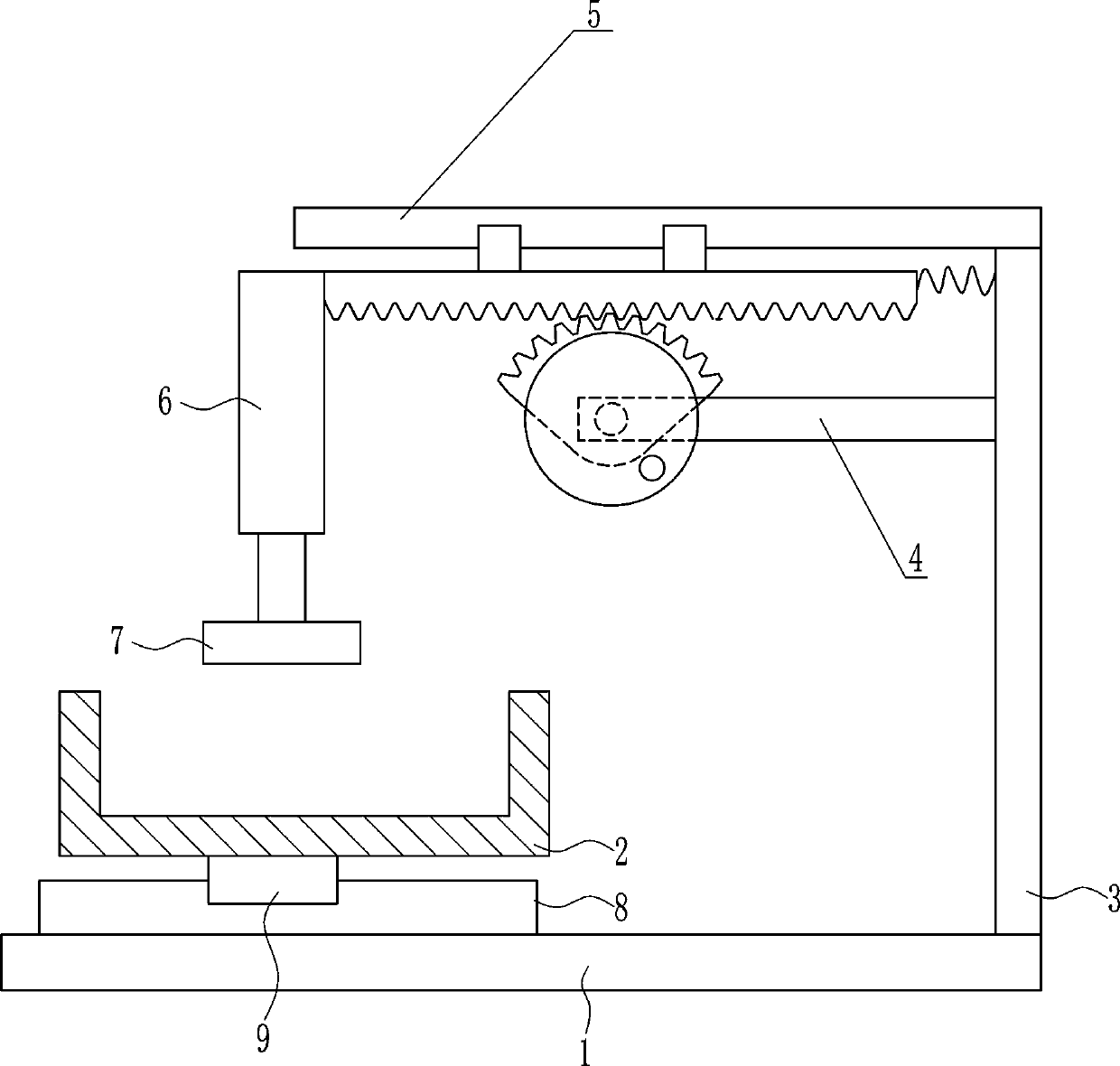

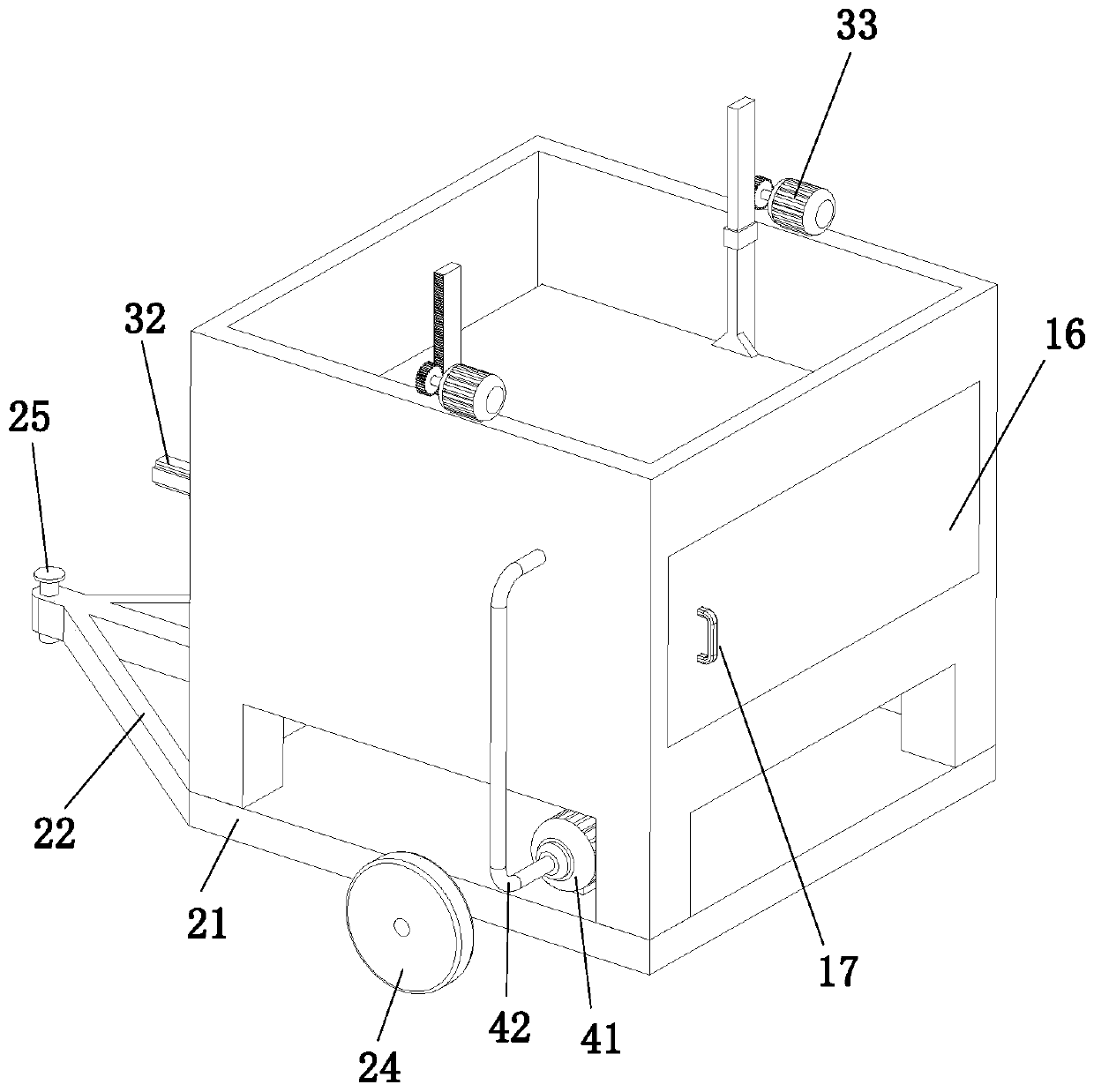

Environment-friendly type disposable meal box packing garbage quick disposal equipment

The invention relates to environment-friendly type garbage disposal equipment, in particular to environment-friendly type disposable meal box packing garbage quick disposal equipment. According to theenvironment-friendly type disposable meal box packing garbage quick disposal equipment, operation is easy, the disposal effect is good, the disposal speed is high, and the occupied space of disposable meal box garbage can be reduced. The environment-friendly type disposable meal box packing garbage quick disposal equipment comprises a bottom plate, a disposal frame, a bracket and the like; and the disposal frame and the bracket are mounted on the top of the bottom plate in a bolt connection mode, the disposal frame is located on the left side of the bracket, the bracket is vertically arranged, a driving device is arranged at the upper portion of the left side face of the bracket, and a left-right moving device is arranged on the top of the bracket. According to the environment-friendly type disposable meal box packing garbage quick disposal equipment, through mutual cooperation of a left-right moving pressing plate and the left-right moving disposal frame, the size of the garbage canbe quickly shrunk, and the effects that operation is easy, the disposal effect is good, and the disposal speed is high are achieved.

Owner:李四英

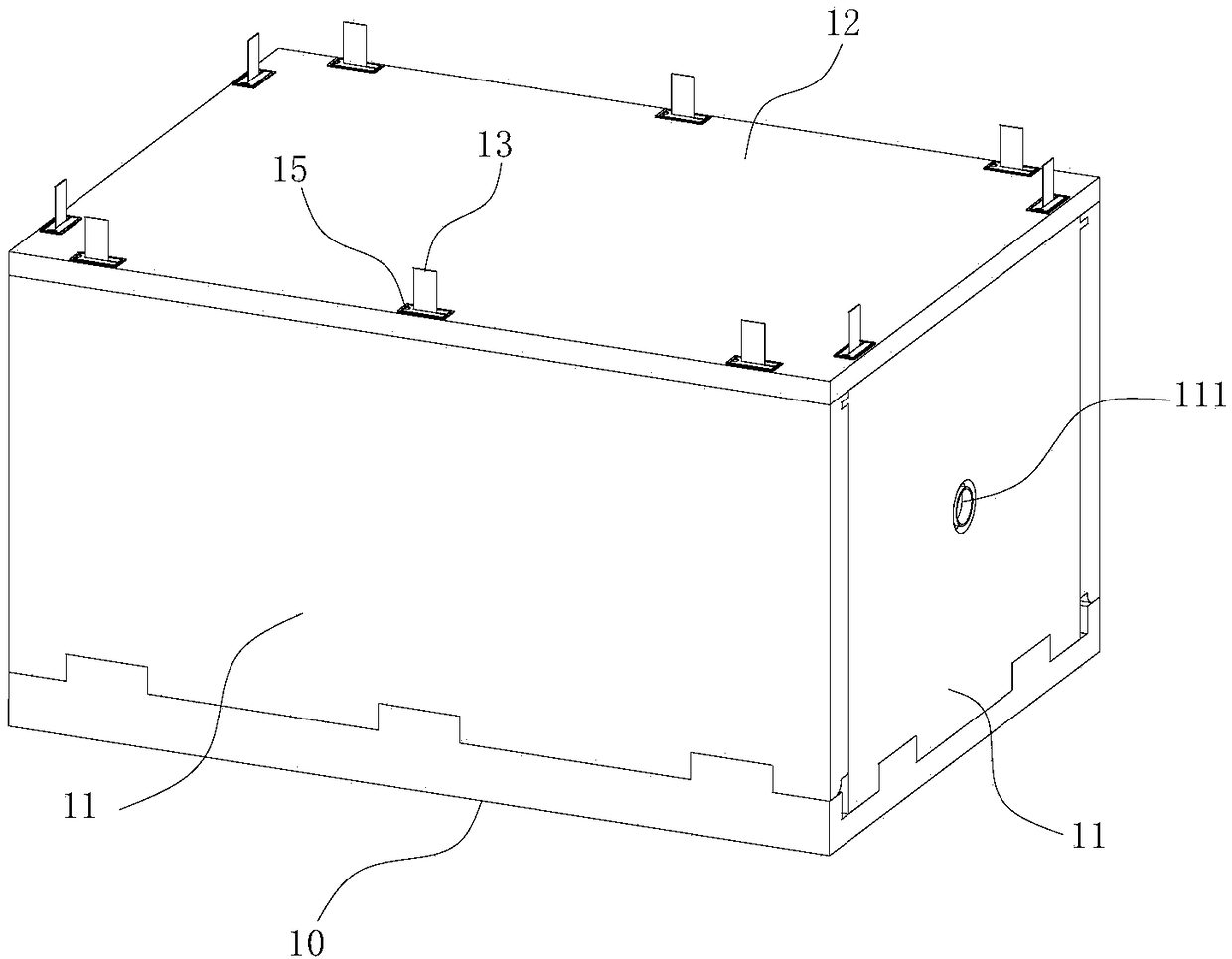

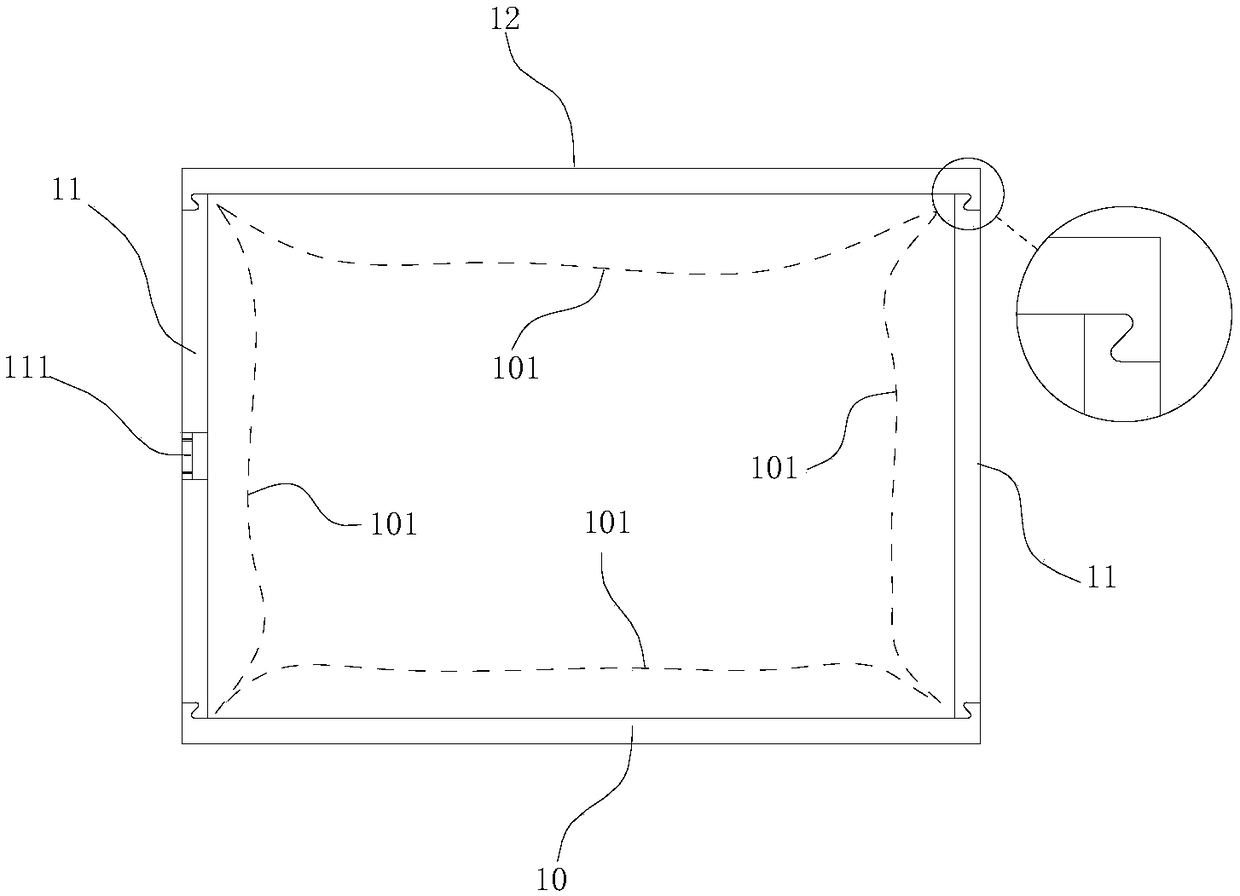

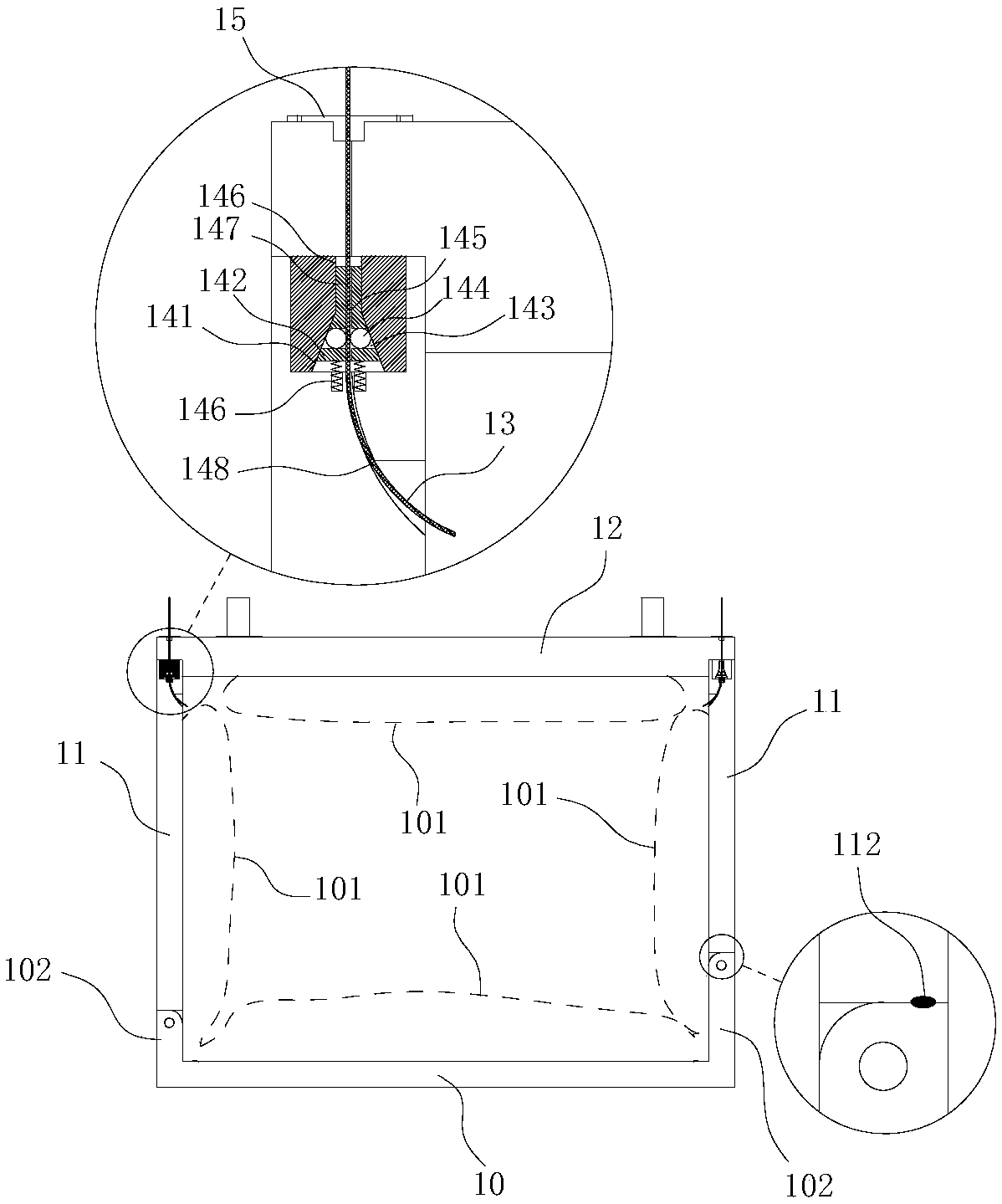

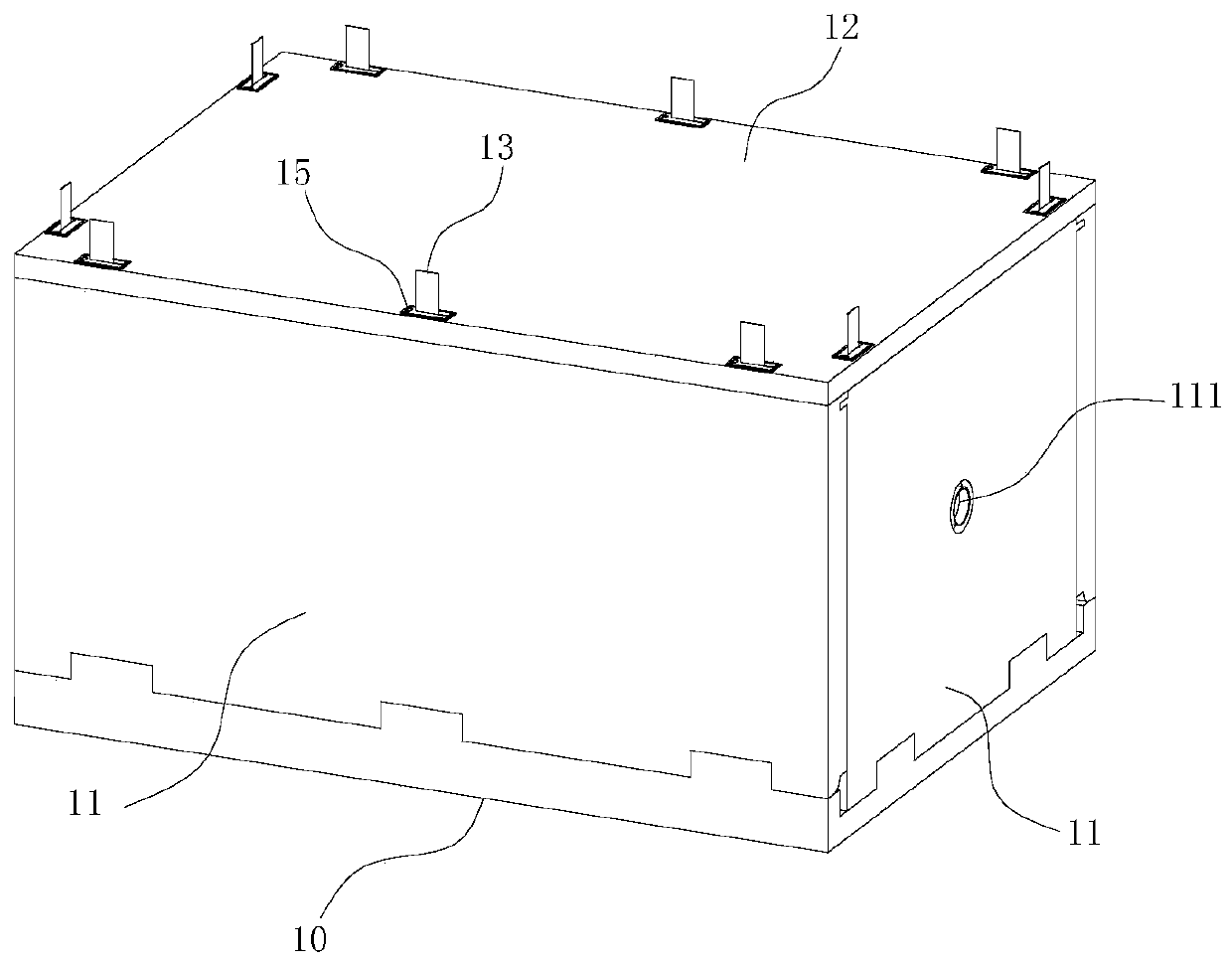

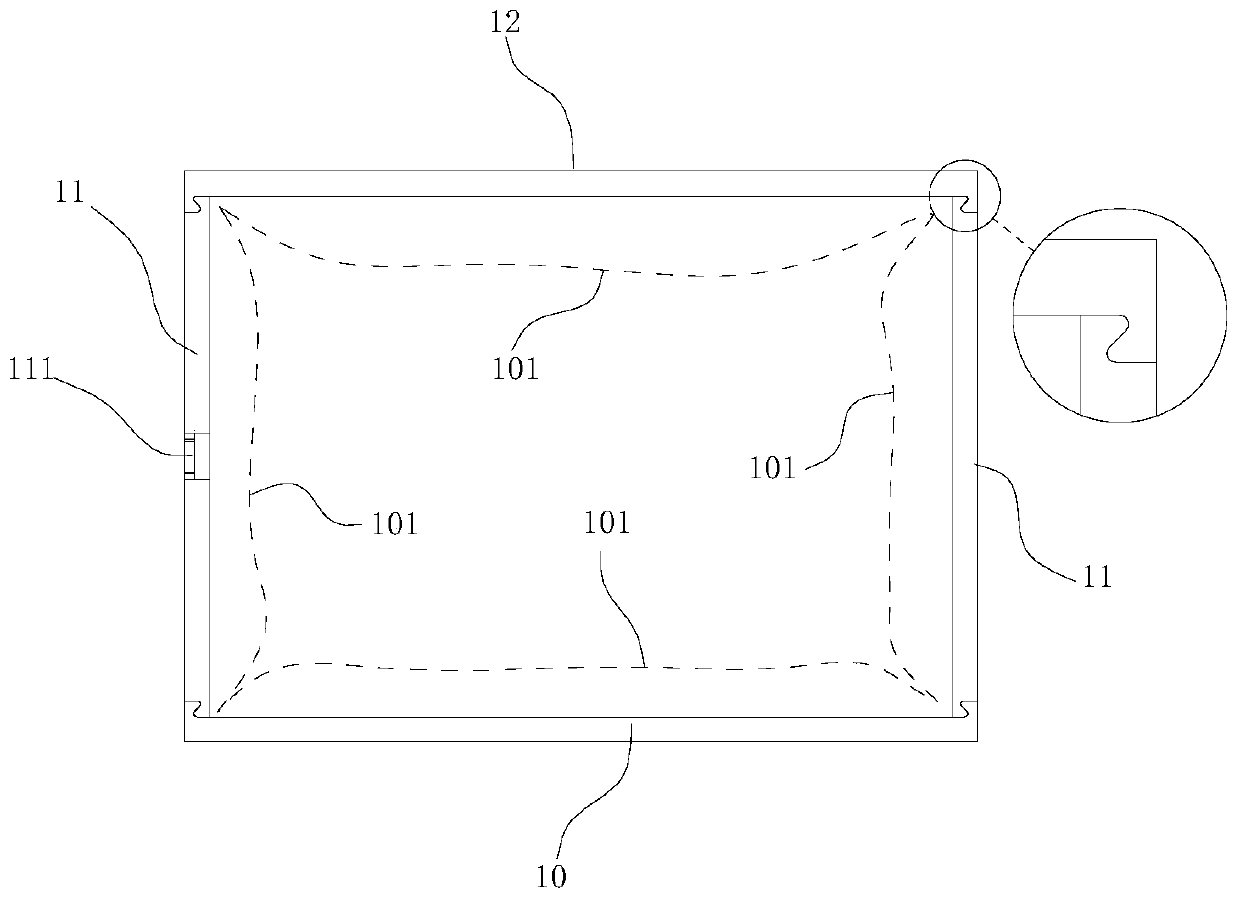

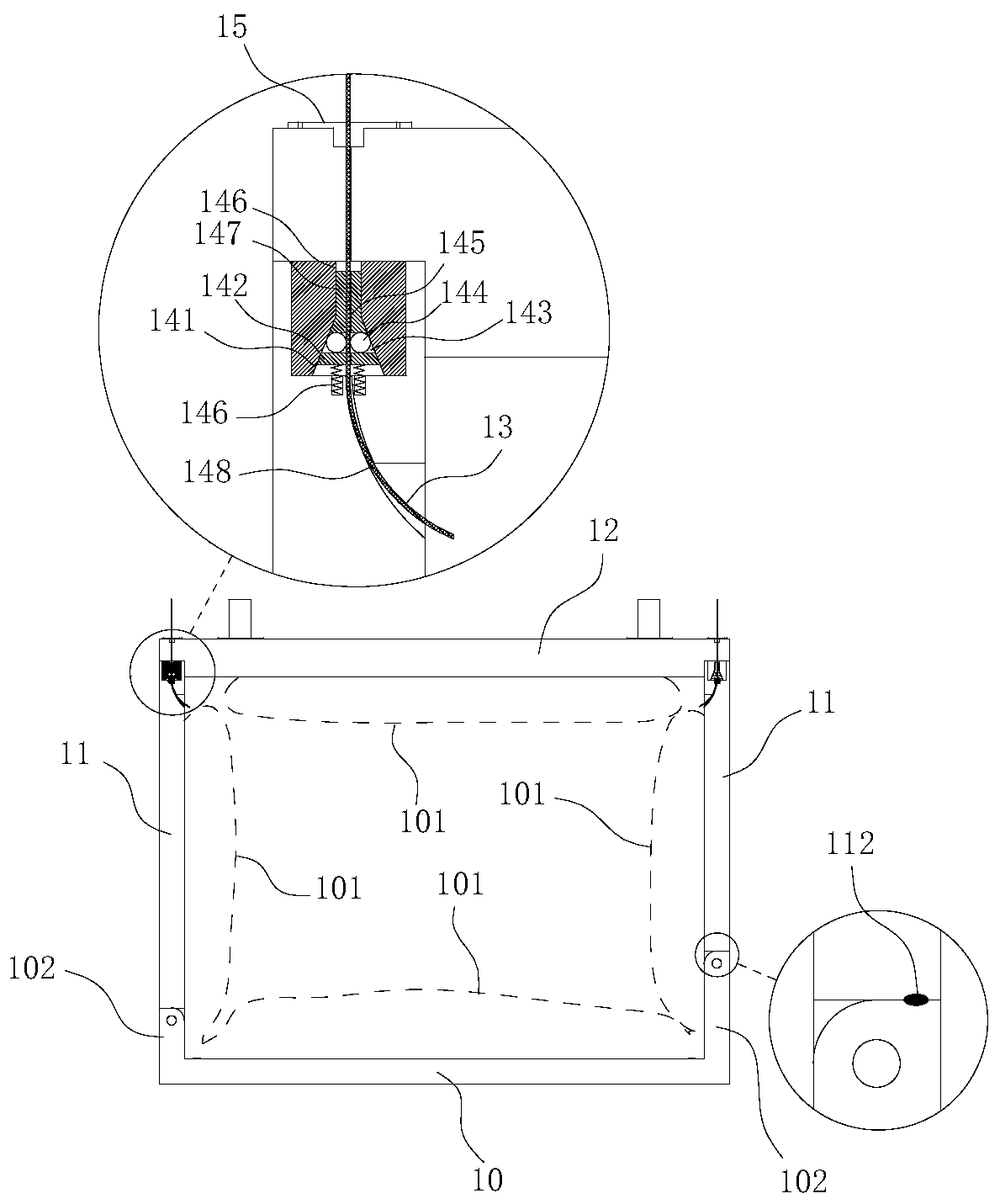

Anti-collision logistics box

ActiveCN108557259AFull compressionAvoid shakingContainers to prevent mechanical damageLogistics managementEngineering

The invention belongs to the technical field of logistics packaging, and particularly relates to an anti-collision logistics box. The anti-collision logistics box comprises a box body enclosed by a bottom wall and four side walls and a box cover arranged at the upper end of the box body to be opened or closed, inflatable airbags are arranged on at least three adjacent inner walls in the logisticsbox, inflation inlets which run through the outer walls and are communicated with inner cavities of the airbags are formed in the outer walls of the logistics box, air pressure sensors are arranged inthe airbags, and signal output interfaces of the air pressure sensors are formed in the outer walls of the logistics box. The logistics box is internally provided with the inflatable airbags and airpressure detection devices, by detecting the airbag air pressure, it is guaranteed that the airbags fully press express items, the phenomenon that the express items shake in the transportation processis avoided, and the protection effect on the express items is effectively improved.

Owner:安徽企路石工程技术开发有限公司

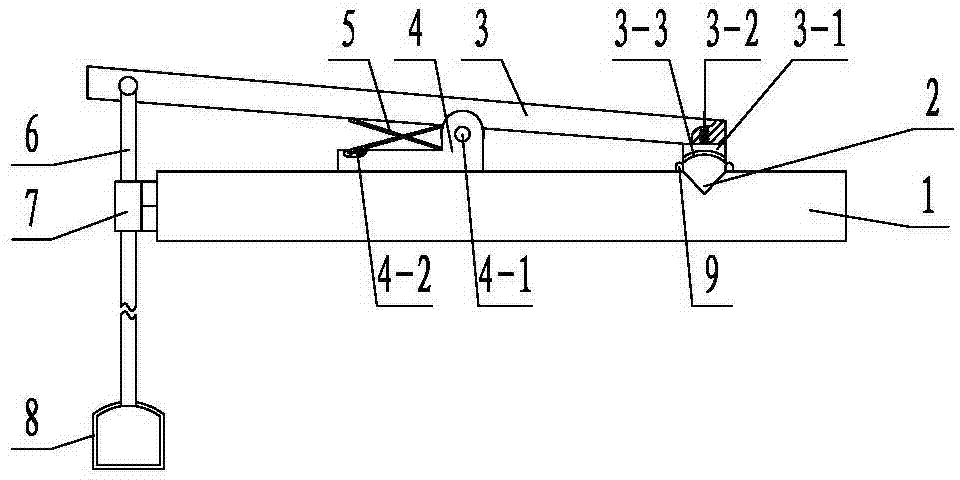

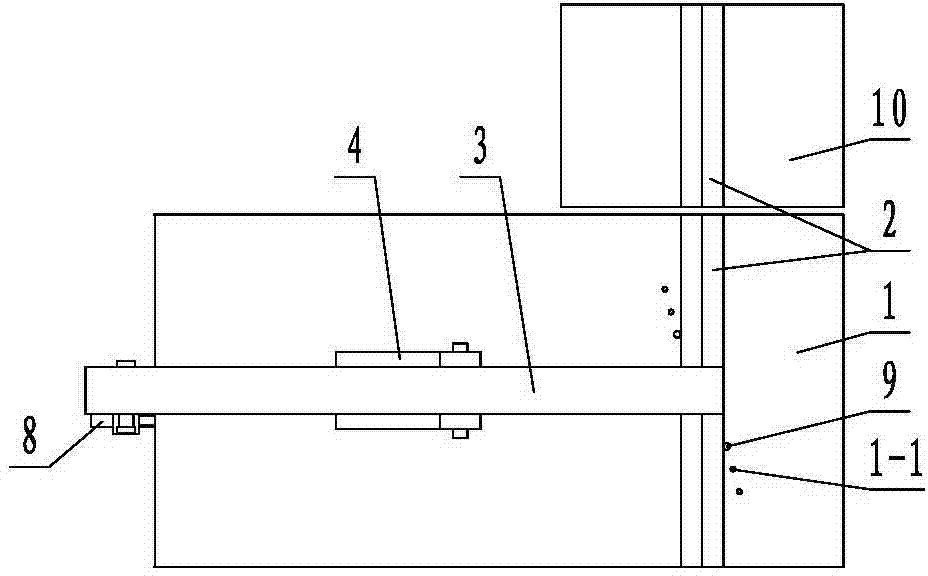

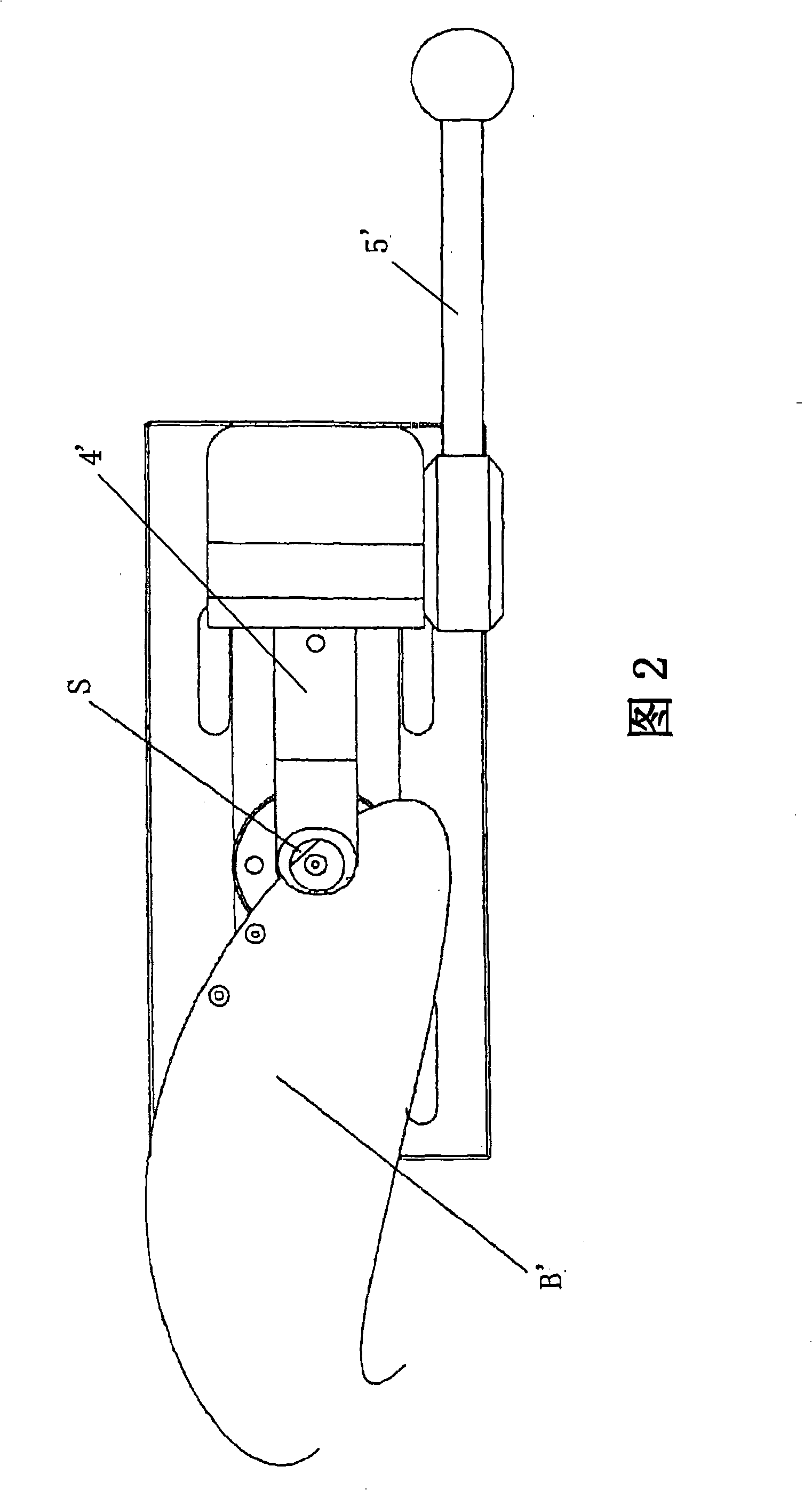

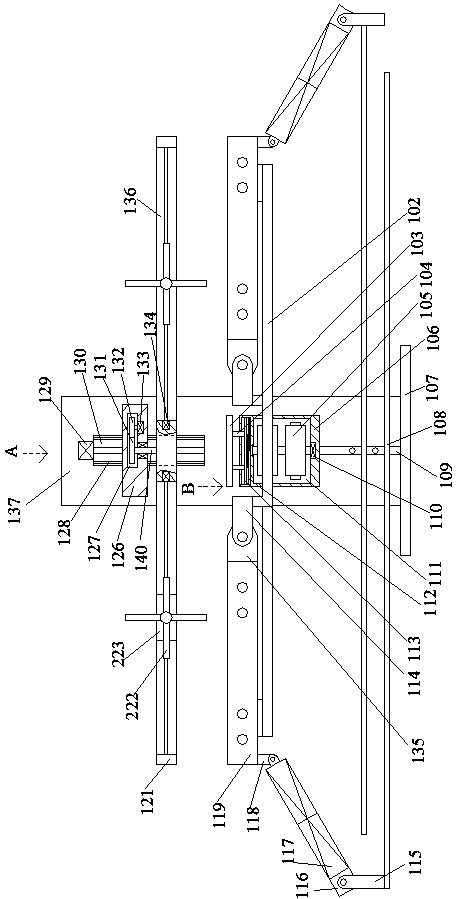

Pipe linear cutting tool

InactiveCN104708155AIncrease productivityEasy clamping and operationElectrical-based auxillary apparatusEngineeringMechanical engineering

The invention discloses a pipe linear cutting tool and relates to the technical field of auxiliary tools for linear cutting. The pipe linear cutting tool comprises a bottom plate and a support arranged on the bottom plate. The bottom plate is provided with a V-shaped groove, a cross rod is fixed to the support, a pressing rod is hinged to the cross rod, the cross rod is sleeved with at least one torsional spring, torsion arms at the two ends of the torsional spring abut against the support and the pressing rod respectively, a boom is hinged to one end of the pressing rod, a pedal is arranged at the bottom end of the boom, and the torsion arms face the end, connected with the boom, of the pressing rod; a chuck facing the V-shaped groove is arranged at the free end of the pressing rod and provided with a circular-arc-shaped groove with an opening facing downwards. The pipe linear cutting tool solves the problems that an existing linear cutting tool is not convenient to operate and is low in clamping efficiency.

Owner:LIUZHOU YONGYI MACHINERY MFG

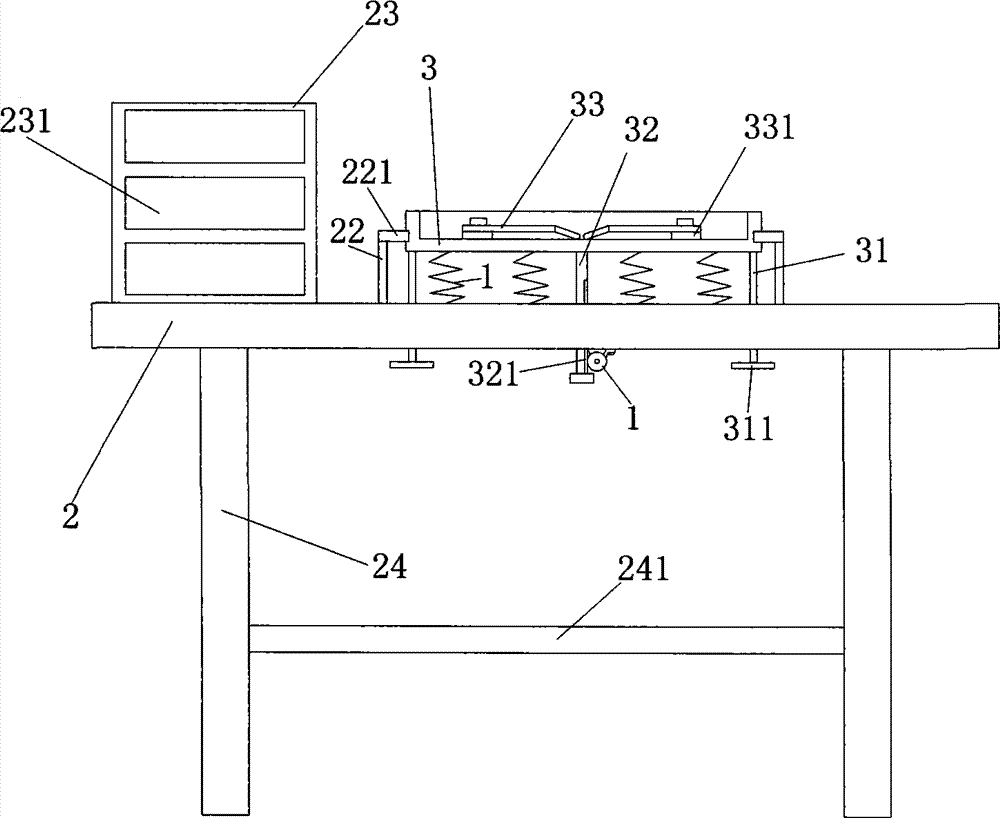

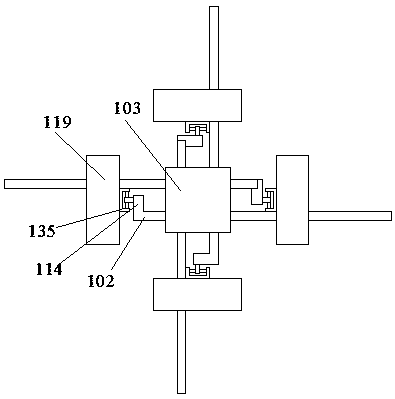

Electrical element vibration detecting device

InactiveCN104122056ARealize the vibration functionImplementation orientationVibration testingElectrical elementIndustrial engineering

The invention relates to an electrical element vibration detecting device. The electrical element vibration detecting device comprises a motor and further comprises a frame, the middle portion of the frame is fixedly connected with a spring, the upper end of the spring is provided with a lifting table, both sides of the lifting table are mounted with guide columns, the lower ends of the guide columns are provided with limiting plates, the middle portion of the lifting table is provided with a transmission column, the right of the transmission column is fixedly connected with a rack, the upper end of the lifting table is mounted with a pressing plate, the lower end of the pressing plate is provided with a protrusion block, the frame is further provided with a column, the upper end of the column is provided with a guide block, and one side of the guide block is in contact with one side of the lifting table. According to the electrical element vibration detecting device, the vibration function of the lifting table is realized by arranging the lifting table with the spring and the transmission column with the rack, the guiding and positioning function of the lifting table is realized by arranging the guide columns and the column, and a test piece can be fully pressed by arranging the protrusion block for the pressing plate which can be at a proper angle. The electrical element vibration detecting device is simple in structure, easy to operate, economical and practical.

Owner:ANHUI JIUNENG INFORMATION TECH

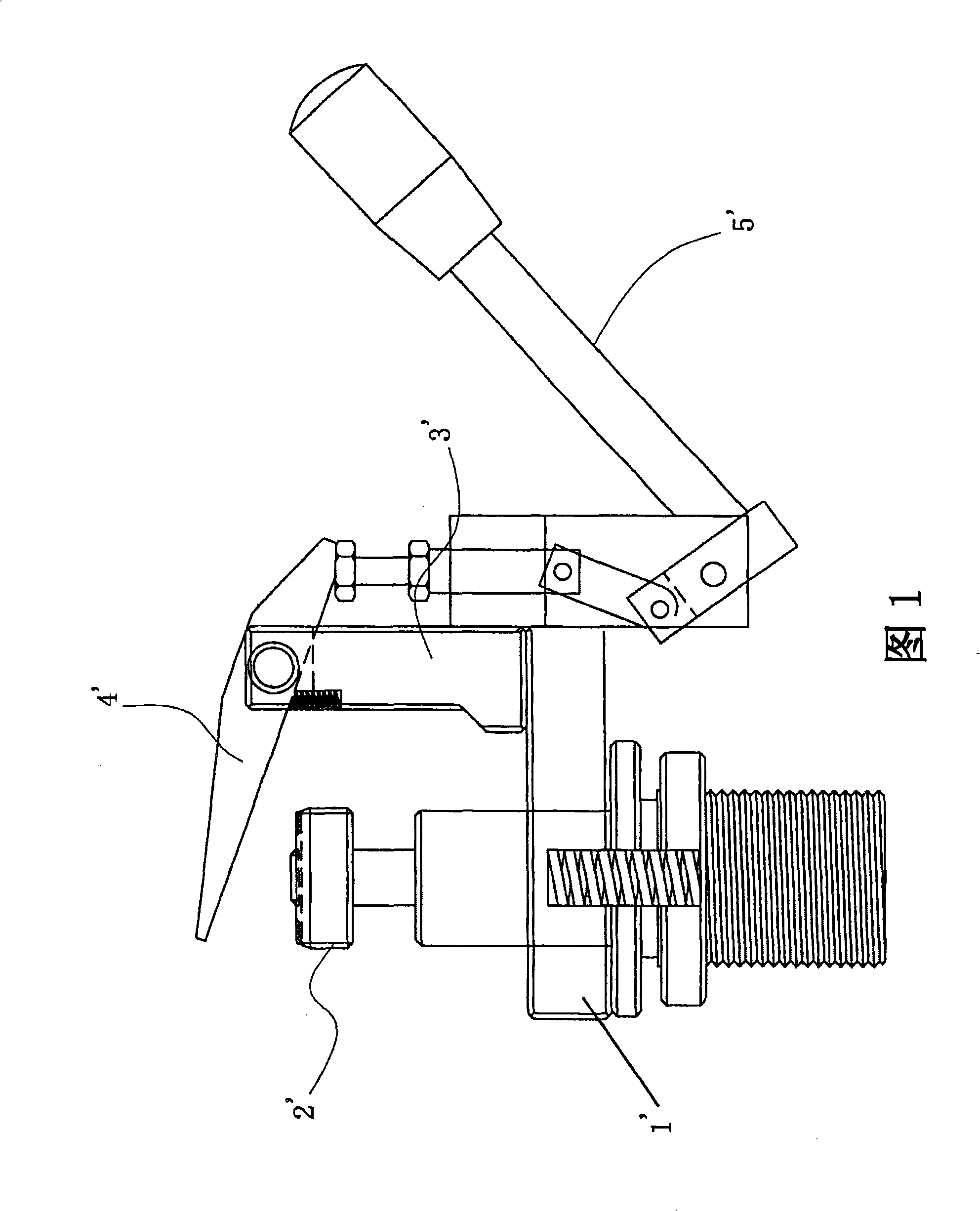

Clamp for cloth

InactiveCN101406329AWon't crushEven by forceMaterial strength using tensile/compressive forcesUsing mechanical meansTest sampleDevices fixation

The invention discloses a fabric clamp, which comprises a permanent seat which is conveniently and fixedly connected with other equipment, a positioning plate and a horizontal plate used for fixedly testing a sample, and an operating device for driving the horizontal plate to act, wherein the positioning plate is arranged on the permanent seat, and the top of the positioning plate is protruded out of the top of the permanent seat; the horizontal plate and the operating device are connected with the permanent seat of the horizontal plate; and the horizontal plate is driven by the operating device and is connected with the permanent seat of the horizontal plate in a vertical lifting mode on the whole. Therefore, the horizontal plate is operated in the vertical lifting mode, and a test sample is fixed until the horizontal plate is pressed on the positioning plate, so that the test sample can not be damaged.

Owner:TAI WAH INDAL EQUIP SUPPLIES

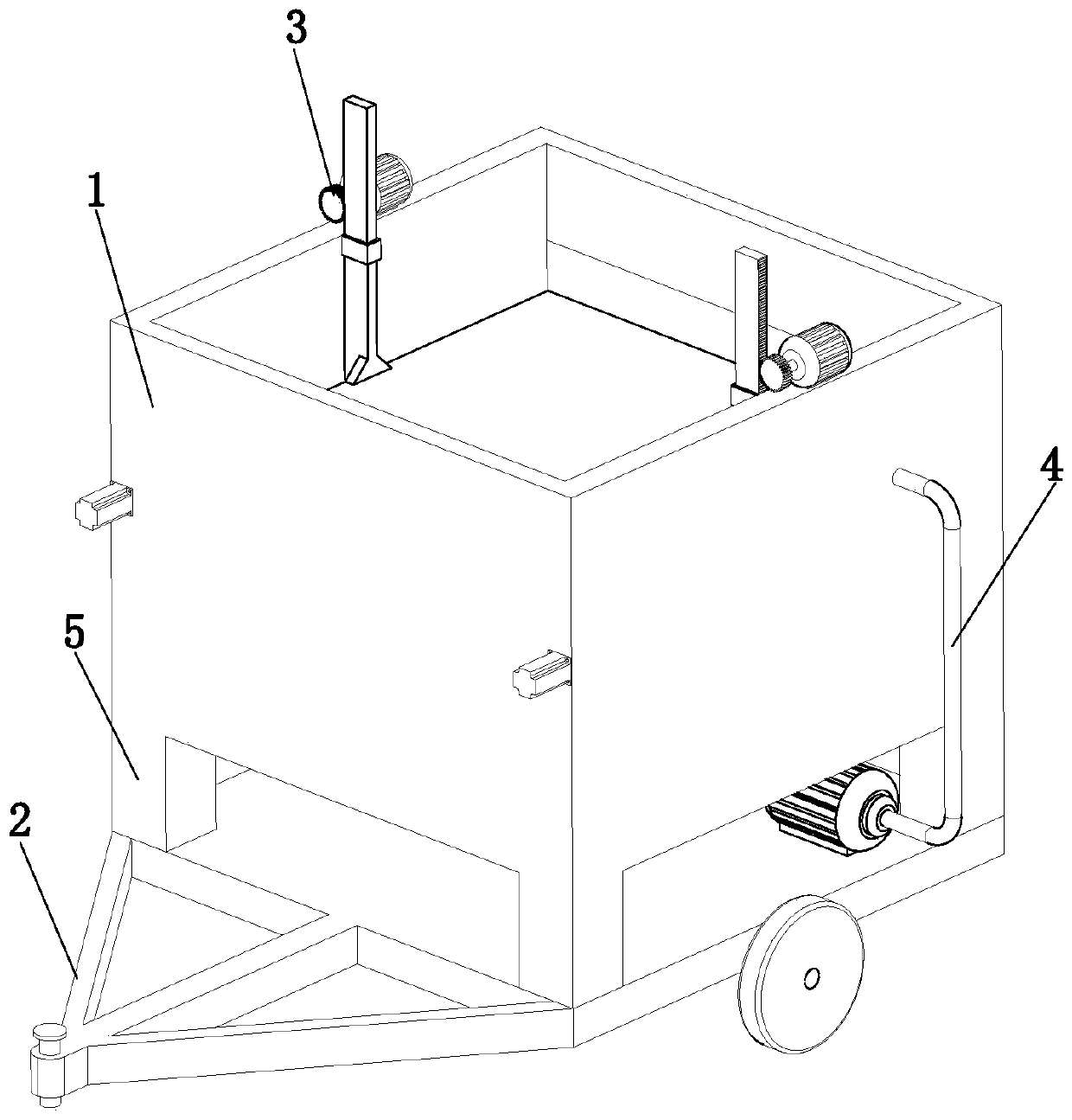

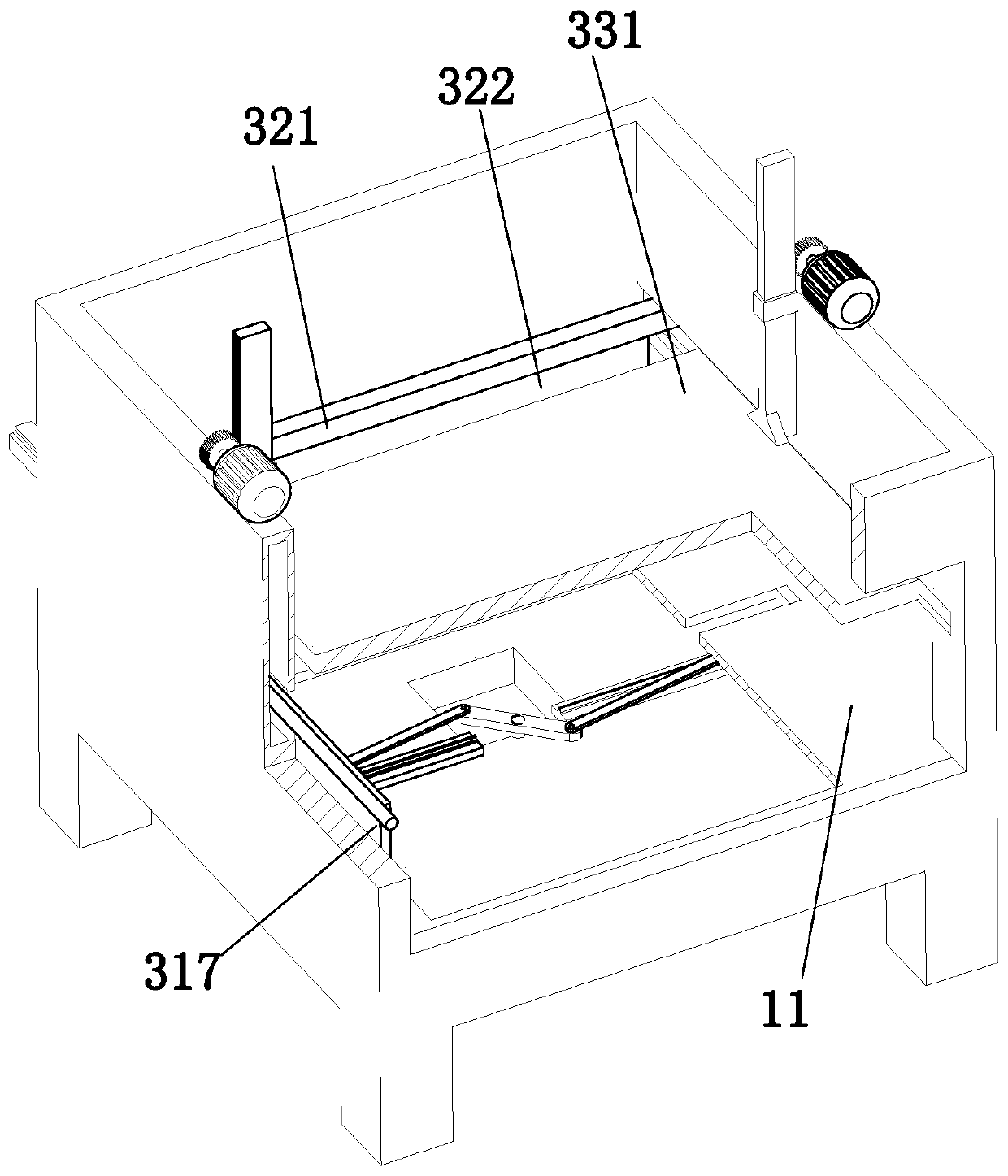

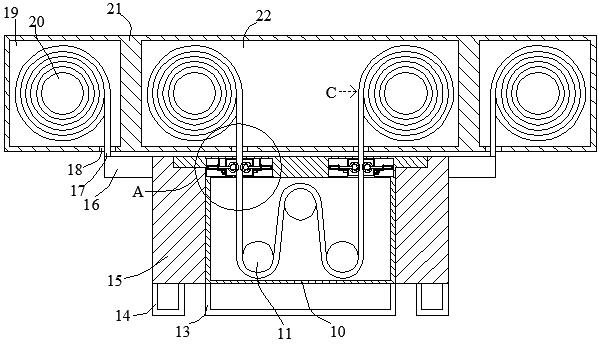

Compression device for straw baler

ActiveCN110214555AFull compressionReduce volumeAgricultural machinesBalingCompression deviceComputer engineering

The invention discloses a compression device for a straw baler and belongs to the technical field of compression devices for balers. The compression device comprises a compression box, a traveling component, a compression component, and a cleaning component; one end of the cleaning component is arranged at the top of the traveling component and positioned below a mounting frame; the other end of the cleaning component is extended into the compression box; a partition horizontally arranged is arranged on the compression box and divides the compression box into a first receiving chamber and a second receiving chamber; the compression component comprises a first compression part, a second compression part and third compression parts; the first compression part is arranged at the bottom of thecompression box and positioned in the first receiving chamber; the second compression part is arranged on the compression box and in sliding fit with the compression box; the third compression partsare arranged at the top of the compression box and are in sliding fit with the compression box. The compression device can provide comprehensive compression for straws through the first compression part, the second compression part and the third compression parts; the straws are compressed to smaller size, so that the straws can be transported and stored later easily.

Owner:ANHUI SCI & TECH UNIV +1

Bending modeling die

ActiveCN109719207ASimple equipment structureThe operation process is simpleShaping toolsMetal-working feeding devicesElectric machineryEngineering

The invention discloses a bending modeling die which comprises a bottom plate. A pressing device used for pressing a workpiece is arranged on the front side of the bottom plate. A vertical box is fixedly arranged on the upper end face of the bottom plate. A power cavity is formed in the vertical box in a communicating manner. A drive device for driving the pressing device to move up and down is arranged in the power cavity. A bending device for adjusting the mutual distance and bending the workpiece efficiently is fixedly arranged on the upper end face of the bottom plate. The bending modelingdie is simple in structure, the manner of forming and bending the workpiece at a time is adopted, when related parameters are adjusted, a corresponding motor only needs to be driven to drive relatedstructures to move to the designated position, the operation process is more convenient, in the bending process, only one set of equipment is adopted for carrying out bending machining, different diesdo not need to be replaced, meanwhile, the equipment can machine the workpieces of different sizes according to adjustment of the related structures in the equipment, on one hand, the technology range of the equipment is enlarged, and on the other hand, the practical reliability and safety of the equipment are improved.

Owner:青岛顺泰钢结构工程有限公司

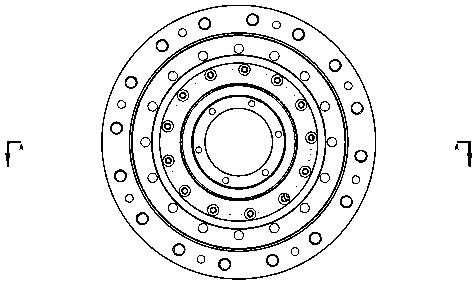

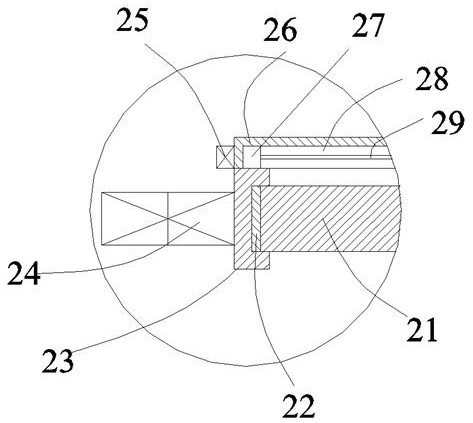

High-vacuum degree rotary sealing mechanism

The invention discloses a high-vacuum degree rotary sealing mechanism. The high-vacuum degree rotary sealing mechanism comprises a sealing sleeve, a pressure head, a rotary piece, at least one first soft sealing ring, at least one hard compression ring, and a fastener, wherein a first through hole is formed in the bottom of the sealing sleeve and the axial direction of the first through hole is parallel to that of the sealing sleeve; a second through hole is formed in the pressure head to penetrate through the pressure head; the rotary piece is put through and pivoted in the first through hole and the second through hole; the at least one first soft sealing ring hermetically sleeves the rotary piece and is located in the sealing sleeve; each compression ring hermetically sleeves the rotary piece; each compression ring is located on one side, close to the opening of the sealing sleeve, of the corresponding first soft sealing ring; the pressure head is detachably fixed at the opening of the sealing sleeve by use of the fastener, and the fastener is used for driving the pressure head to be switched between a position where the pressure head extends into the sealing sleeve and props against the compressing ring and a position where the pressure head is far away from the sealing sleeve and separated from the compression ring. The high-vacuum degree rotary sealing mechanism is capable of keeping a relatively high vacuum degree in a vacuum chamber and realizing an excellent dynamic sealing effect under the circumstance that the rotary piece rotates.

Owner:SHENZHEN SHENGSHI INTELLIGENT EQUIP

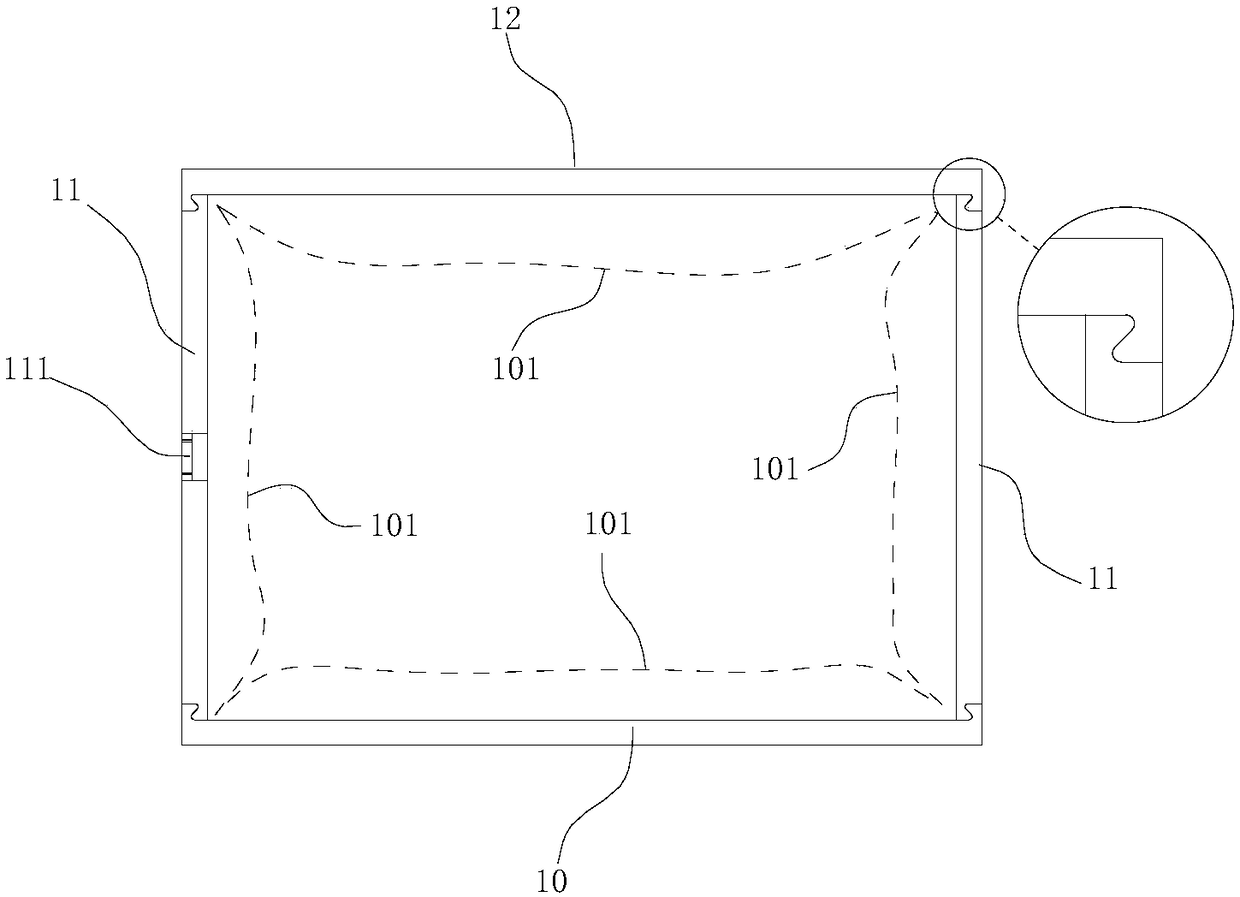

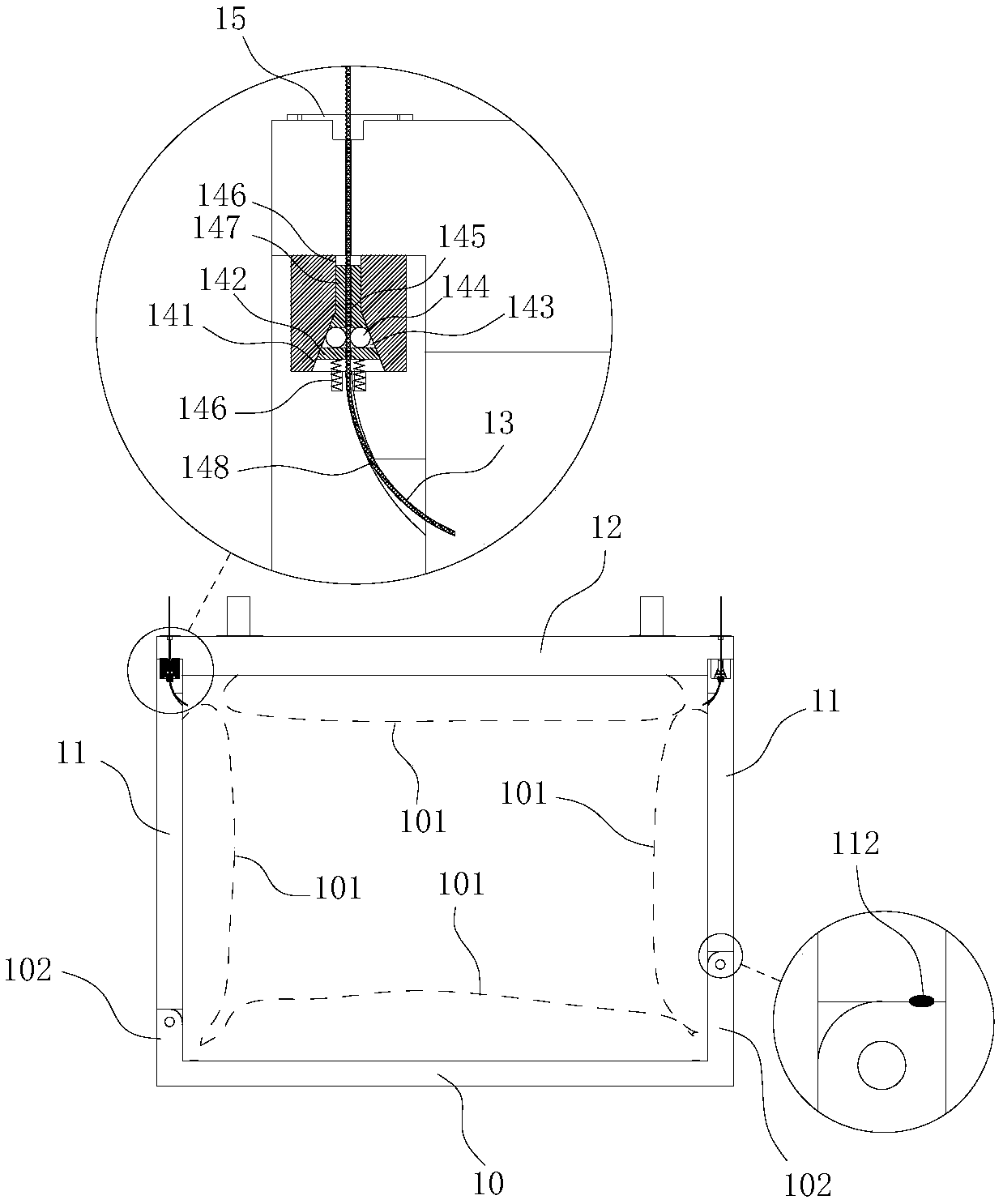

a logistics box

ActiveCN108622509BAvoid wastingReduce processing difficultyContainers to prevent mechanical damageRigid containersLogistics managementAirbag

The invention belongs to the technical field of logistics packaging, in particular to a logistics box. The logistics box can be repeatedly utilized, unnecessary resource waste is avoided, the treatment difficulty of express garbage is effectively reduced, and the positive effects on environment protection are achieved. The logistics box is arranged to be of a foldable structure, and collection andstorage of recipients are facilitated, so that express items are returned to courier services companies in a unified manner. According to the logistics box, a box body and a box cover are connected through disposable lock catch components, once the logistics box is opened, the logistics box is hard to restore without dedicated equipment, the risk that express items are opened by other people in the transport process is effectively avoided, and the confidentiality effect is improved; and inflatable airbags and an air pressure detection device are arranged in the logistics box, it can be ensured that the airbags fully presses the express items by detecting the air pressure of the airbags, the express items are prevented from shaking in the transport process, and the protection effect on theexpress items is effectively improved.

Owner:安徽企路石工程技术开发有限公司

Transformer magnetic shunt structure

InactiveCN104851564AReduce lossReduce hot spot temperature riseTransformers/inductances magnetic coresCores/yokesEngineeringConductor Coil

The invention discloses a transformer magnetic shunt structure which comprises an upper magnetic shunt mounted above a transformer pressing plate and a lower magnetic shunt mounted below the same. By the transformer magnetic shunt structure, distribution of a leakage magnetic field can be changed, hot-point temperature rise of a transformer winding can be lowered effectively, overheating of structural members can be prevented, and loss of transformer can be reduced. In addition, the transformer magnetic shunt structure is practical, reliable, low in manufacturing cost, convenient to mount and suitable for transformers different in voltage class and capacity.

Owner:CHINA XD ELECTRIC CO LTD

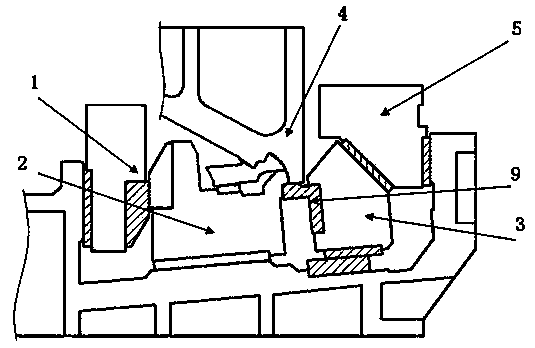

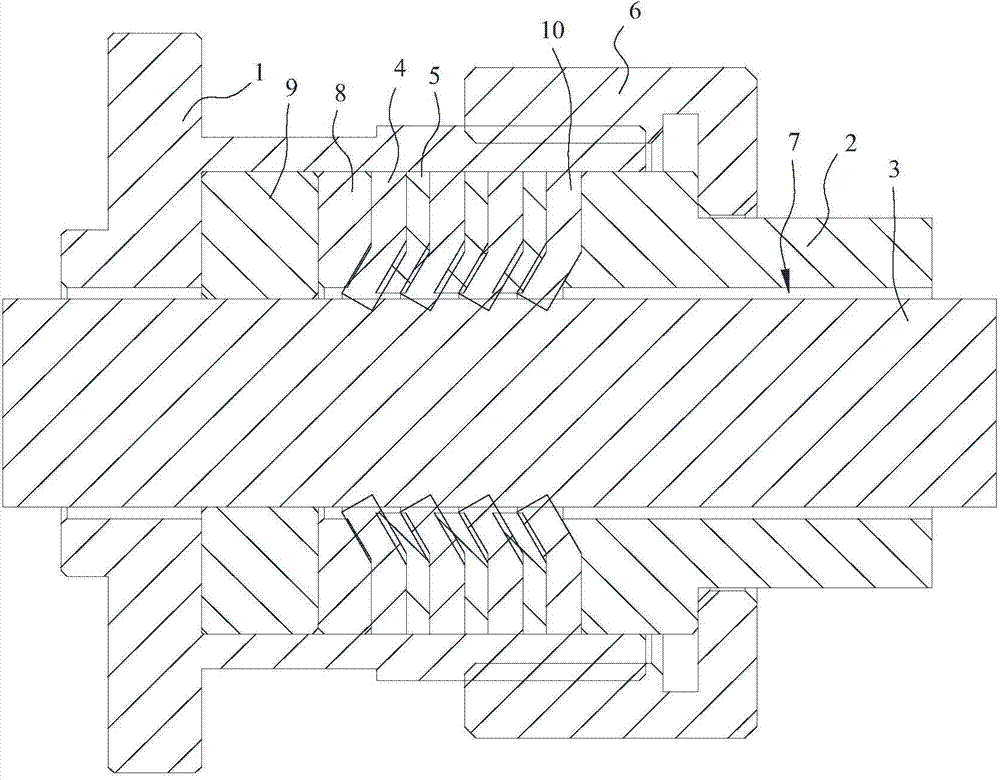

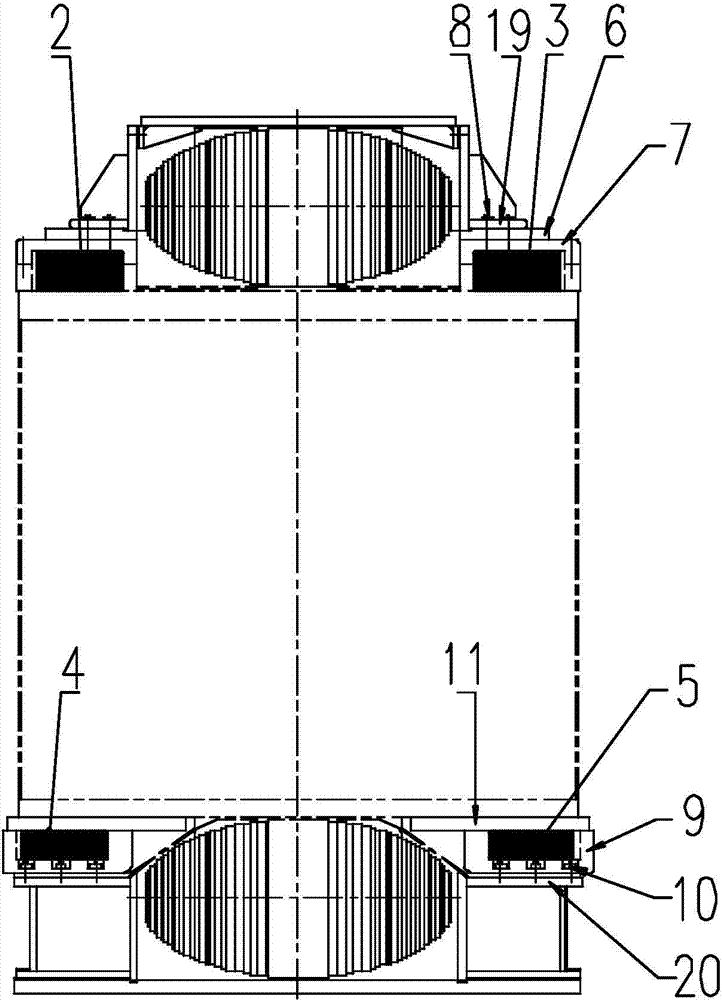

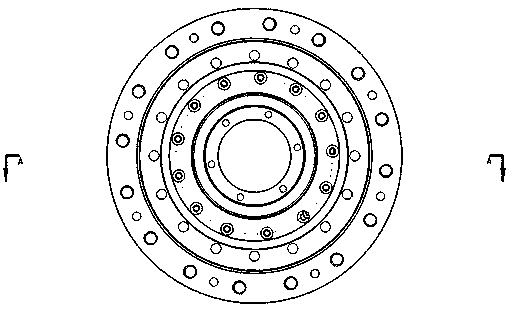

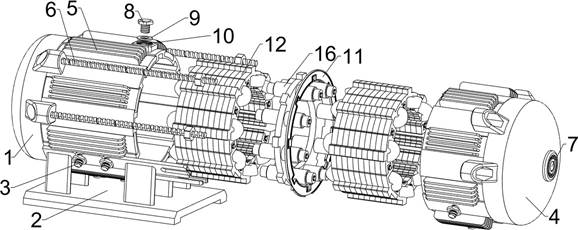

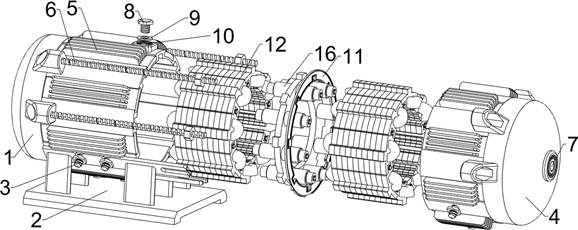

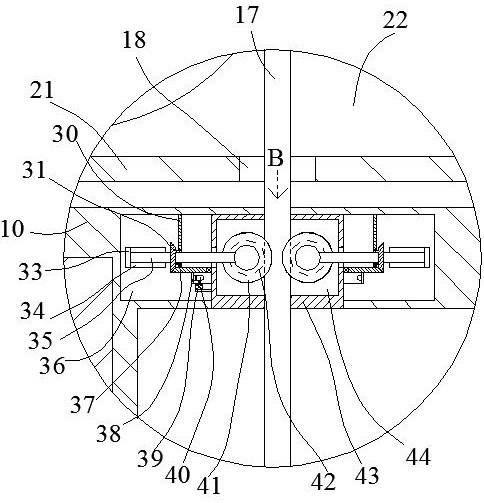

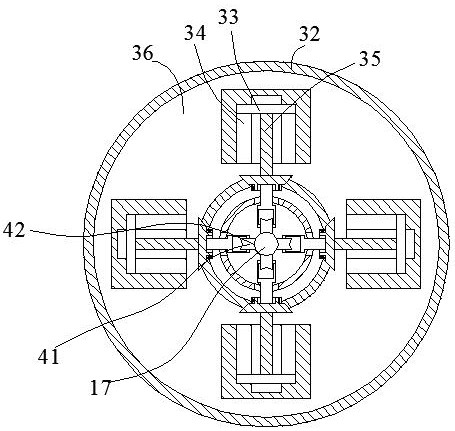

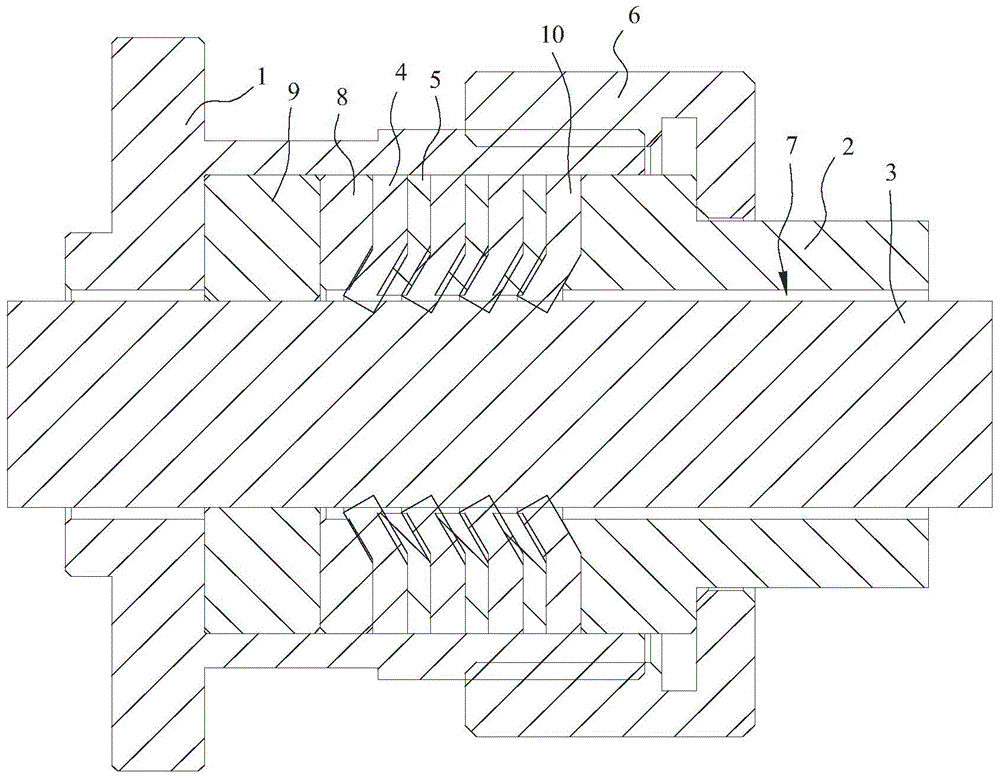

Elastic speed reducer

InactiveCN107725723ASmooth rotationFull compressionToothed gearingsGearing detailsReducerEngineering

The invention provides an elastic speed reducer which can effectively overcome errors and eliminate abnormal oscillatory waves and is high in precision and rigidity and easy to machine and produce. The elastic speed reducer comprises a power input assembly. The power input assembly comprises an input shaft and an elastic assembly arranged on the input shaft. The elastic assembly is one or more extrusion type deformable rings. Each extrusion type deformable ring comprises an annular ring body, wherein the outer ring wall and / or the inner ring wall of the annular ring body are / is provided with elastic structural body, each elastic structural body comprises two symmetrical elastic slice sets, each elastic slice set comprises a plurality of elastic slices distributed on half side of the outerring wall or the inner ring wall of the annular ring body, each elastic slice set comprises a first elastic slice started at one end of half side of the outer ring wall and the inner ring wall of theannular ring body, N middle elastic slices and an (N+2)th elastic slice stopped at the other end of the half side of the outer ring wall or the inner ring wall of the annular ring body, and N is larger than or equal to 1.

Owner:惠州恒星智达机器人有限公司

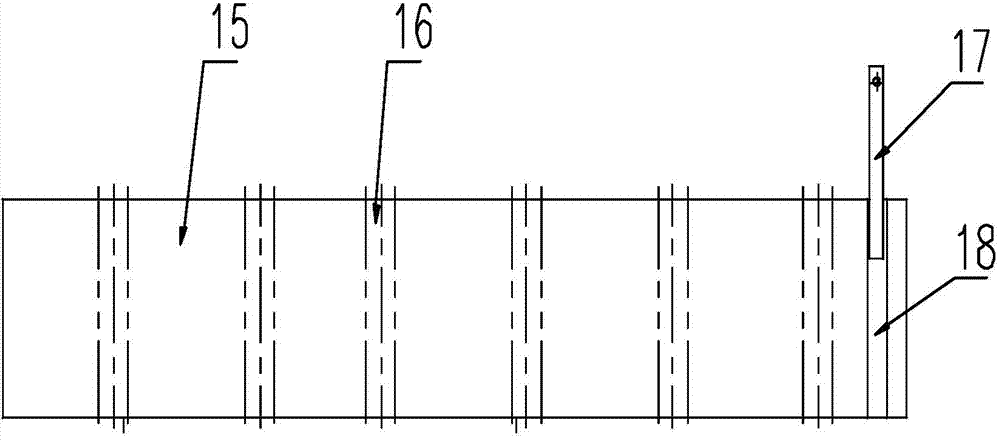

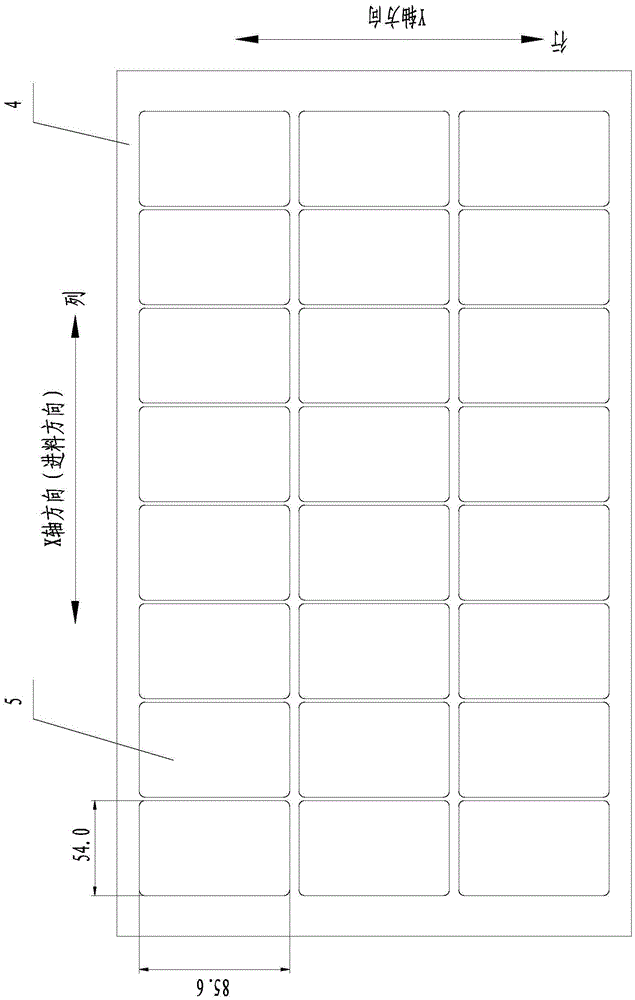

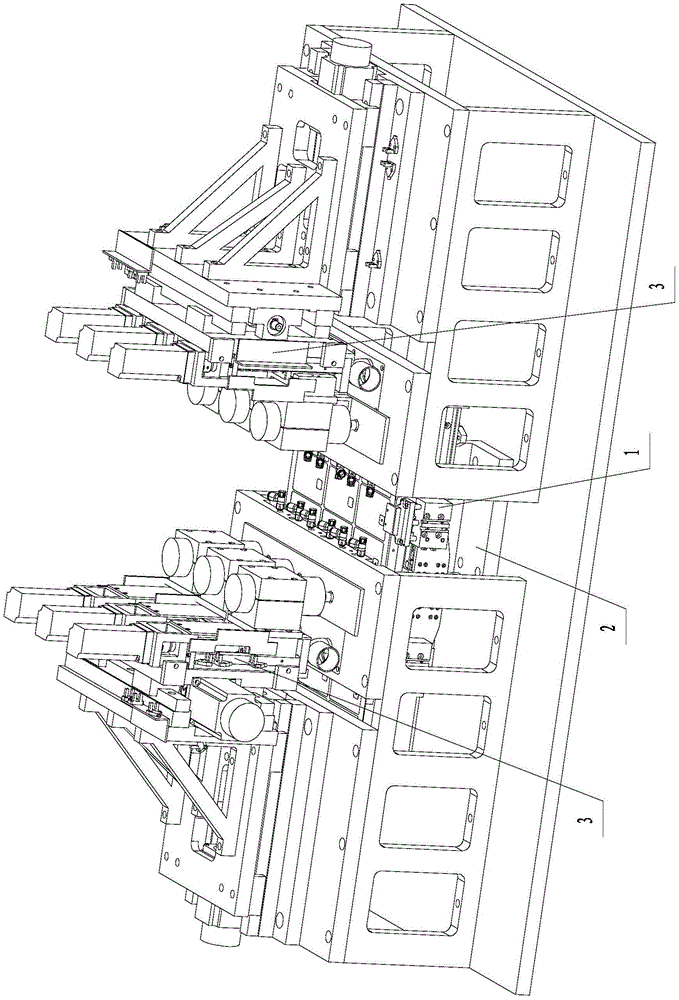

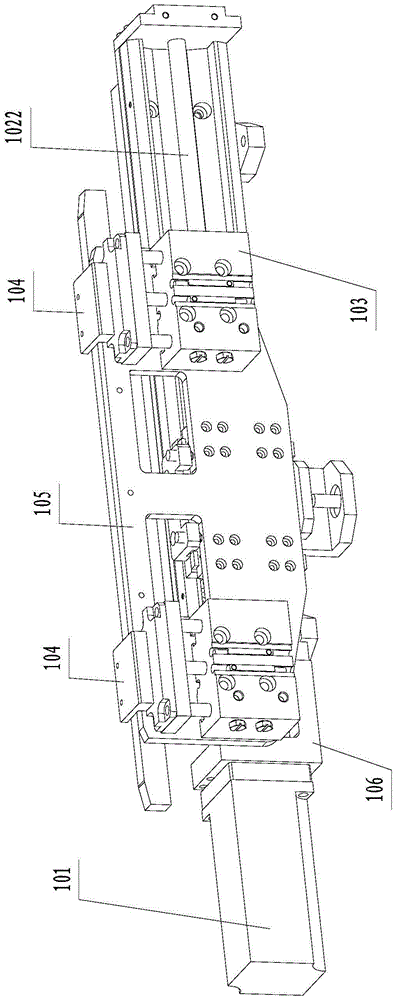

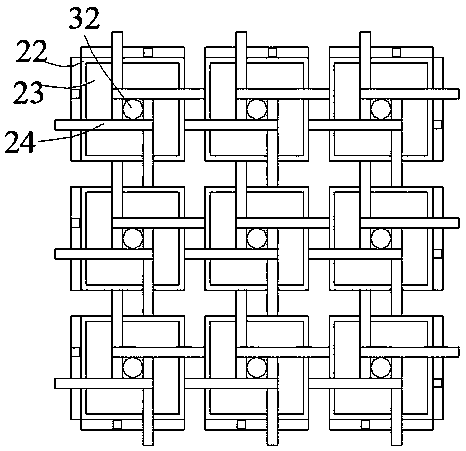

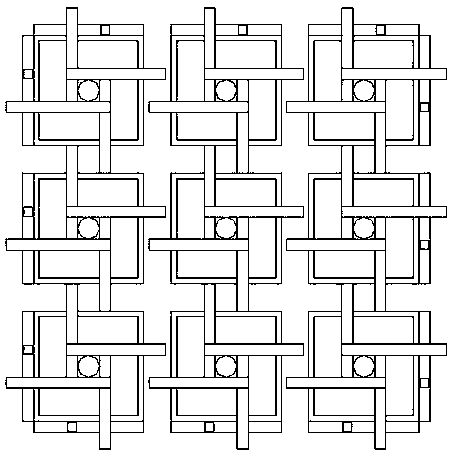

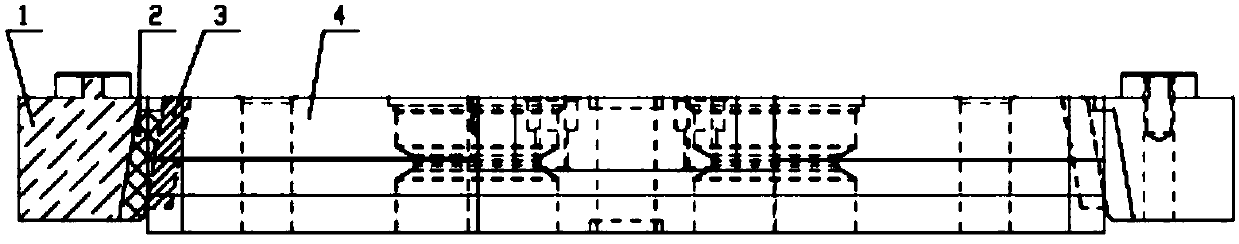

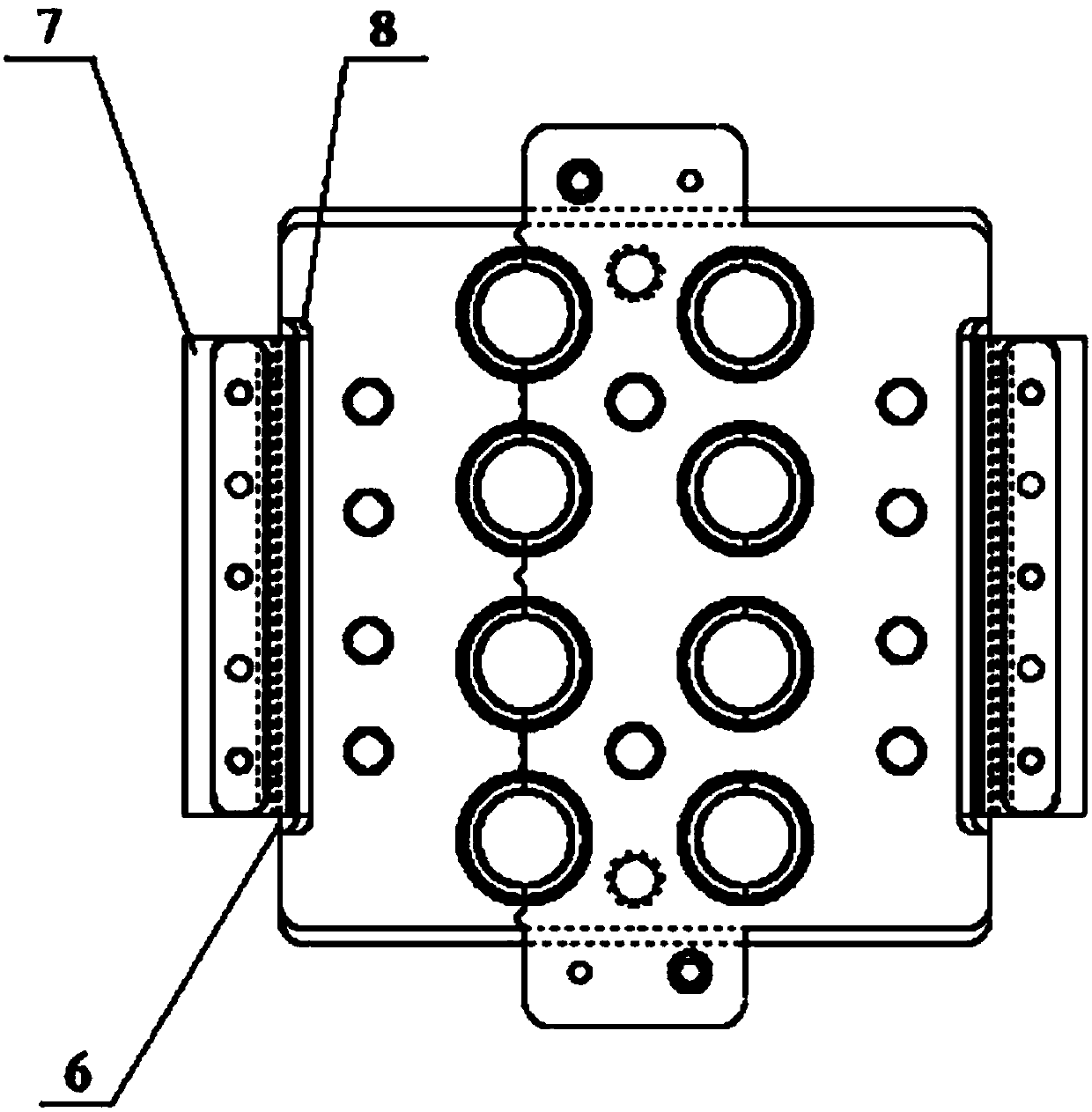

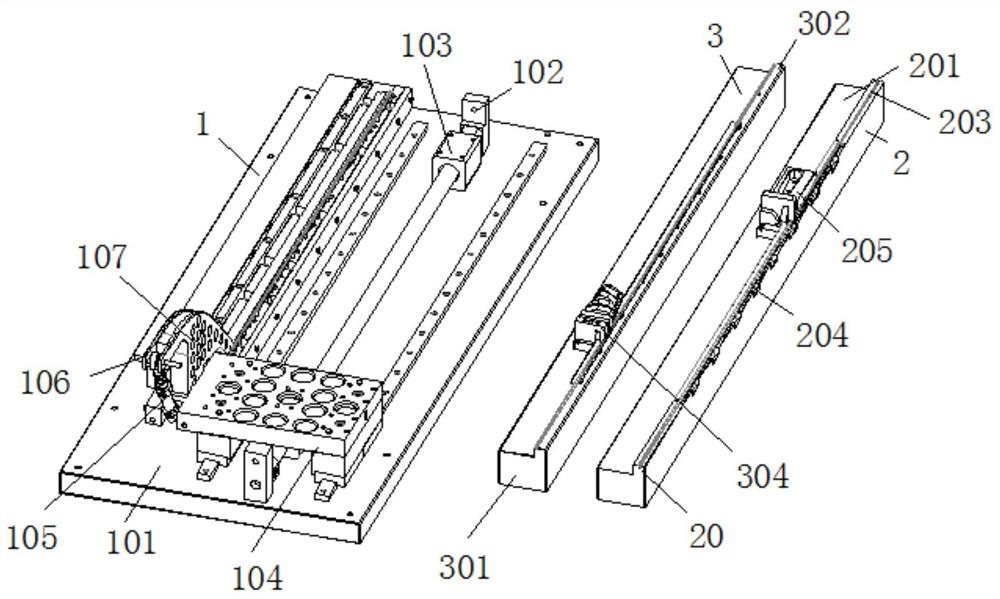

Groove milling method of whole large material of IC cards and groove milling device implementing groove milling method

ActiveCN105642980AImprove efficiencyShorten delivery timeMilling equipment detailsMain channelEngineering

The invention relates to the field of upstream making of IC cards, in particular to a groove milling method of a whole large material of IC cards and a groove milling method implementing the groove milling method. The groove milling method comprises the following steps: dividing the whole large material into a plurality of IC card bases arrayed in M lines and N rows according to printing typesetting; conveying the whole large material to a groove milling station from a main channel and then positioning the whole large material; arranging at least one row of milling heads on a groove milling part and simultaneously milling grooves in the various IC card bases in the rows, wherein the whole rows of the milling heads arranged on the groove milling part have degrees of freedom of movement in three directions of an X axis, a Y axis and a Z axis; after groove milling on the various IC card bases on one row or multiple rows of the whole large material is finished, enabling one row or multiple rows of the whole large material to move to other rows in a stepping manner for groove milling until groove milling of the various IC card bases in the M lines and the N rows of the whole large material are finished completely. By the groove milling method of the whole large material of the IC cards and the groove milling device implementing the groove milling method, card making efficiency can be improved greatly, meanwhile, conveying time is saved, the service life of equipment can be prolonged under the condition that external factors are not changed, and machining precision in a production process is improved.

Owner:沈阳友联电子装备有限公司

Elastic speed reducer

The invention provides an elastic speed reducer. The elastic speed reducer includes a power input assembly, the power input assembly includes an input shaft, and an elastic assembly arranged on the input shaft; the elastic assembly is one or more extrusion-type deformation rings, and the extrusion-type deformation ring includes An annular ring body, the outer ring wall and / or the inner ring wall of the annular ring body are provided with elastic structural members. The elastic structure body includes two mutually symmetrical shrapnel groups, each shrapnel group includes several The first shrapnel grouping and the second shrapnel grouping of the outer ring wall or the inner ring wall, the outer ring wall or the inner ring wall of the annular ring is provided with an elastic limit boss, the first shrapnel grouping and the outer ring of the annular ring The wall or the inner ring wall forms an included angle biased towards the elastic limiting boss, and the second shrapnel group forms an included angle opposite to the elastic limiting boss with the outer ring wall or the inner ring wall of the annular ring.

Owner:惠州恒星智达机器人有限公司

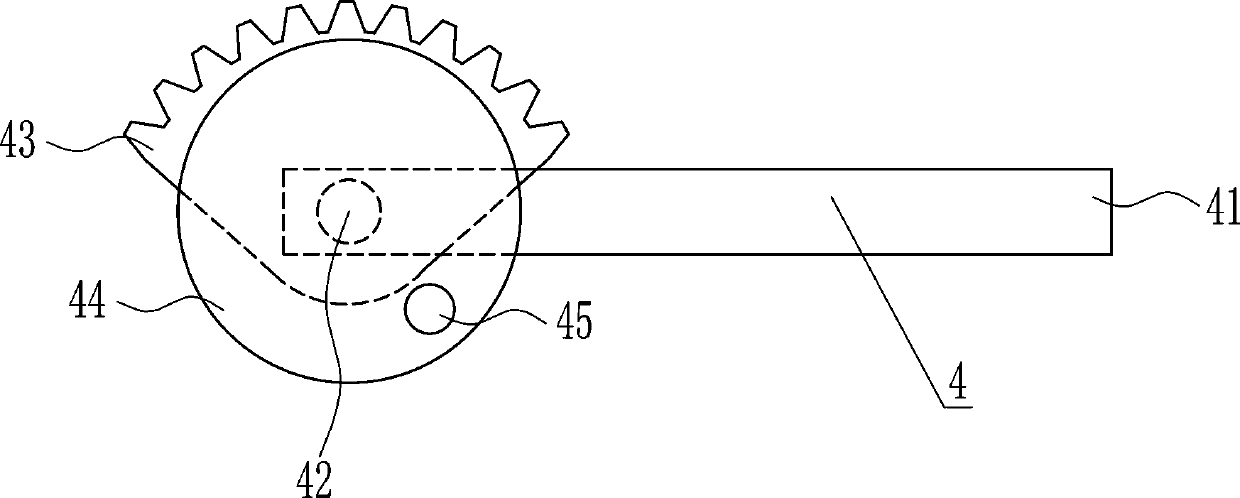

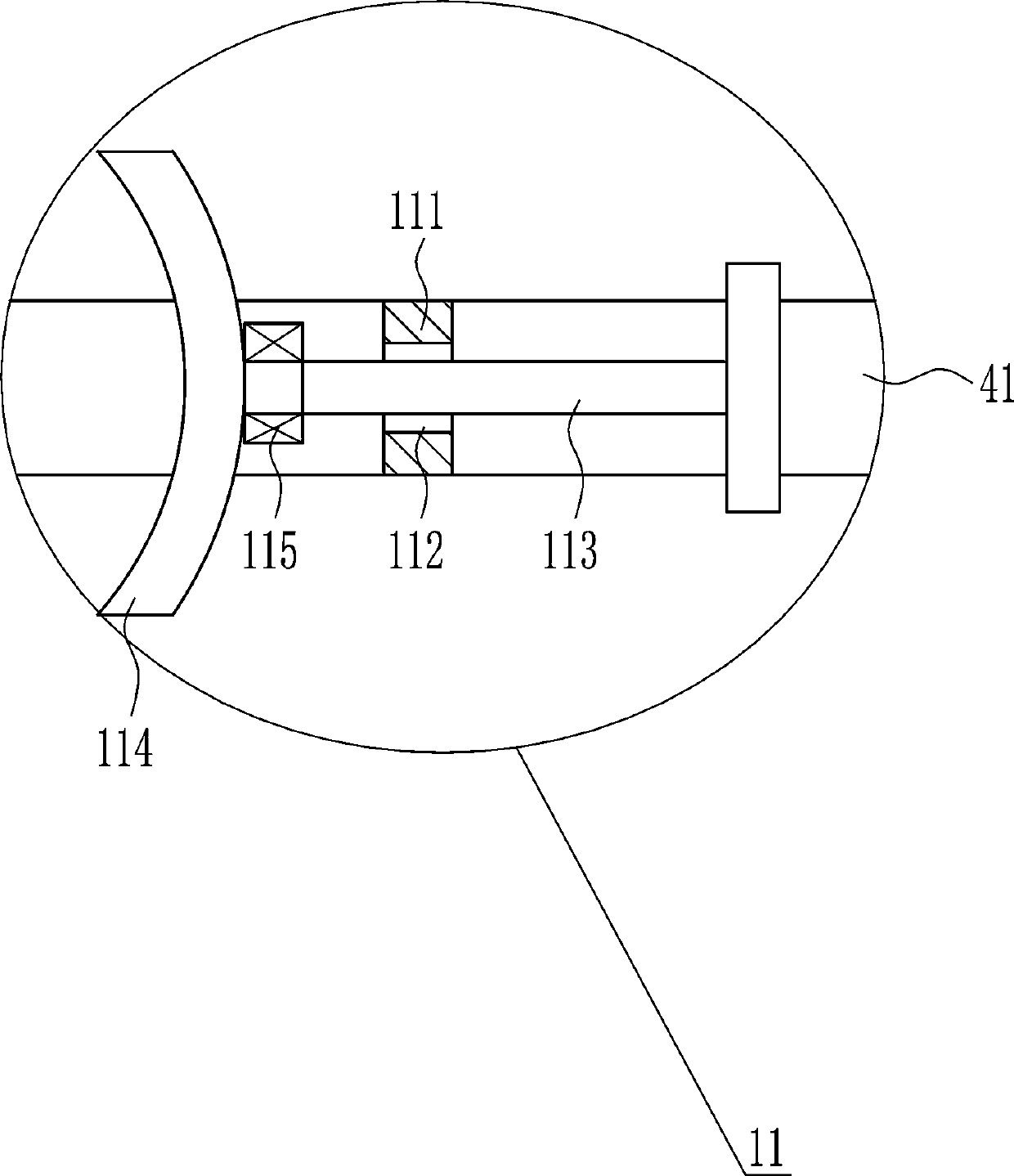

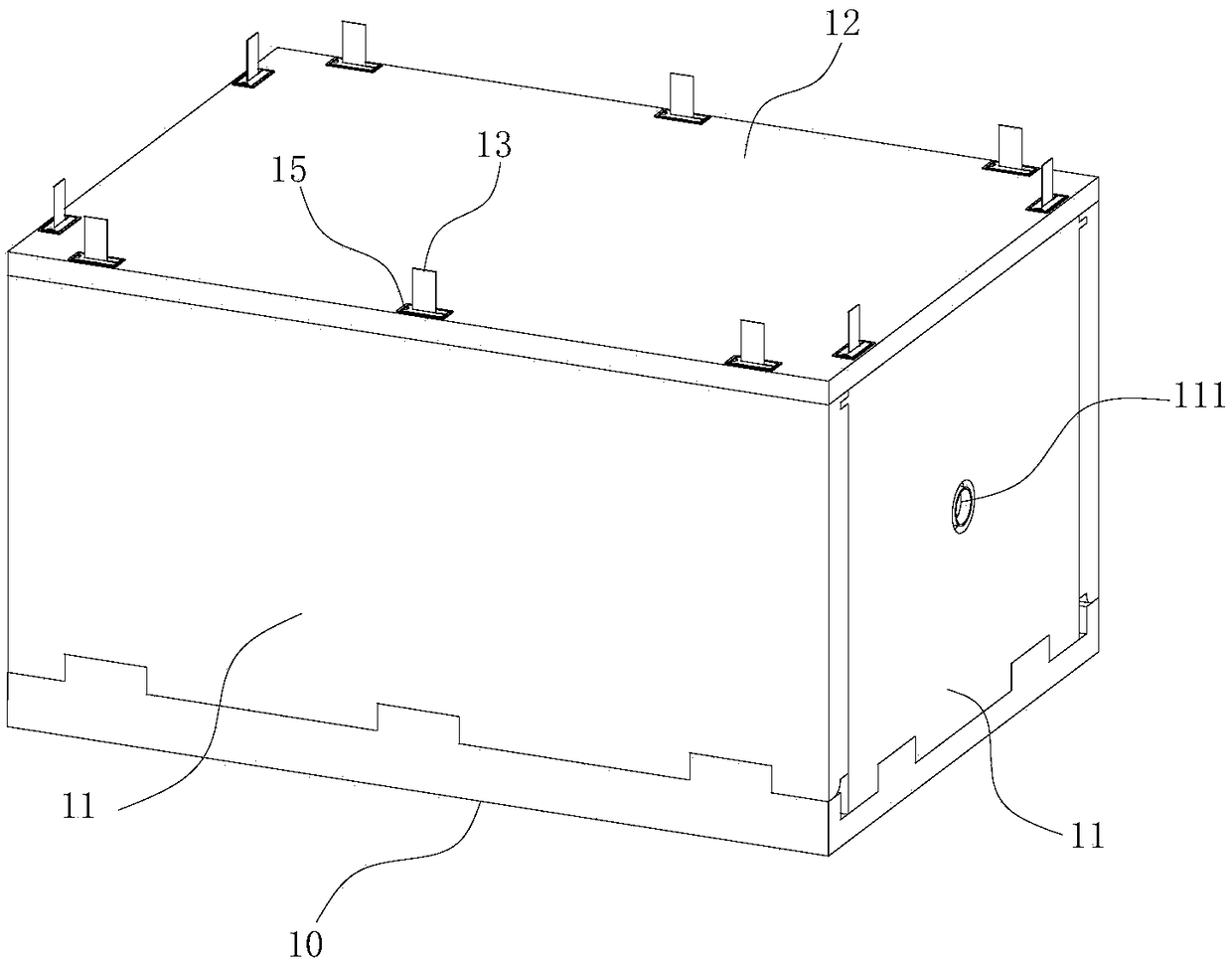

Abandoned paperboard compression packaging equipment

The invention discloses abandoned paperboard compression packaging equipment. The abandoned paperboard compression packaging equipment comprises a bottom box body. An opened bottom opened inner cavityis formed in the bottom box body, symmetrical annular box bodies are fixedly arranged in the bottom opened inner cavity, packing devices for packing abandoned paperboards fully are arranged in the annular box bodies, a plurality of structural box bodies are arranged on the upper side of the bottom box body, box body inner cavities are arranged in the structural box bodies, a plurality of fit gears are arranged in the box body inner cavities, the fit racks penetrate the box body inner cavities and the structural box bodies slidably, and power devices which drives all the fit racks to stretch out of or into the structural box bodies simultaneously are arranged in the box body inner cavities. Then, the equipment adopts a gear and rack structure, so that a container compresses the abandoned paperboards fully, and can pack the compressed abandoned paperboards quickly, and therefore, the working efficiency of the equipment is improved.

Owner:荣成市盛高包装制品有限公司

Hough mold

The invention relates to the field of molds, and discloses a Hough mold. The Hough mold comprises an upper mold and a lower mold, wherein a Hough block is arranged between the upper mold and the lowermold; the Hough mold further comprises a wedge block, a first wear-resistant block and a second wear-resistant block, wherein the wedge block, the first wear-resistant block and the second wear-resistant block are sequentially arranged, and the second wear-resistant block is arranged in a mounting groove of the Hough block; and a groove is formed in the wedge block, the first wear-resistant blockpart is located in the groove, and the first wear-resistant block extends outwards to form a first distance along the groove. The first wear-resistant block extends outwards 2 mm along the wedge block, so that the first wear-resistant block can be sufficiently pressed against the second wear-resistant block, each single Hough block is tightly fixed together, the single Hough block is not easy toloosen in the production process, and the product percent of pass is effectively improved; and the installation process of the mold is rapid and convenient, the production cost of the mold is saved, meanwhile, the machining period of the mold is shortened, the production qualified rate of products is improved, and the economic benefit is better.

Owner:余姚市奥科五金科技有限公司

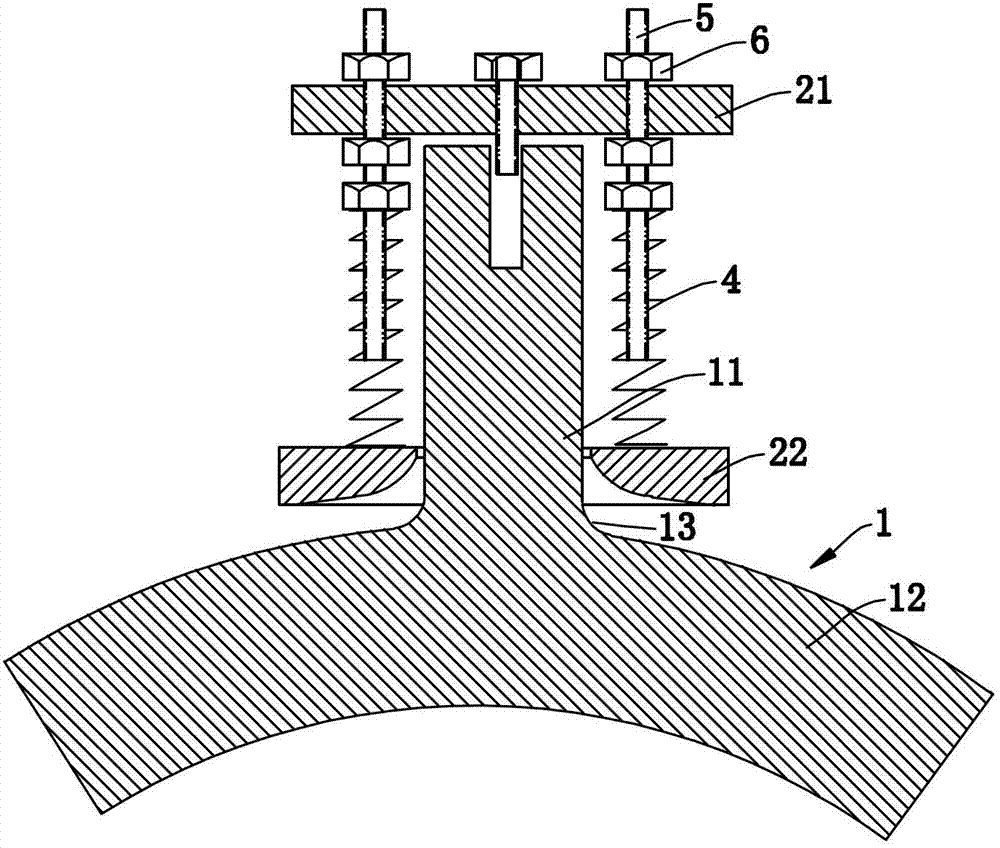

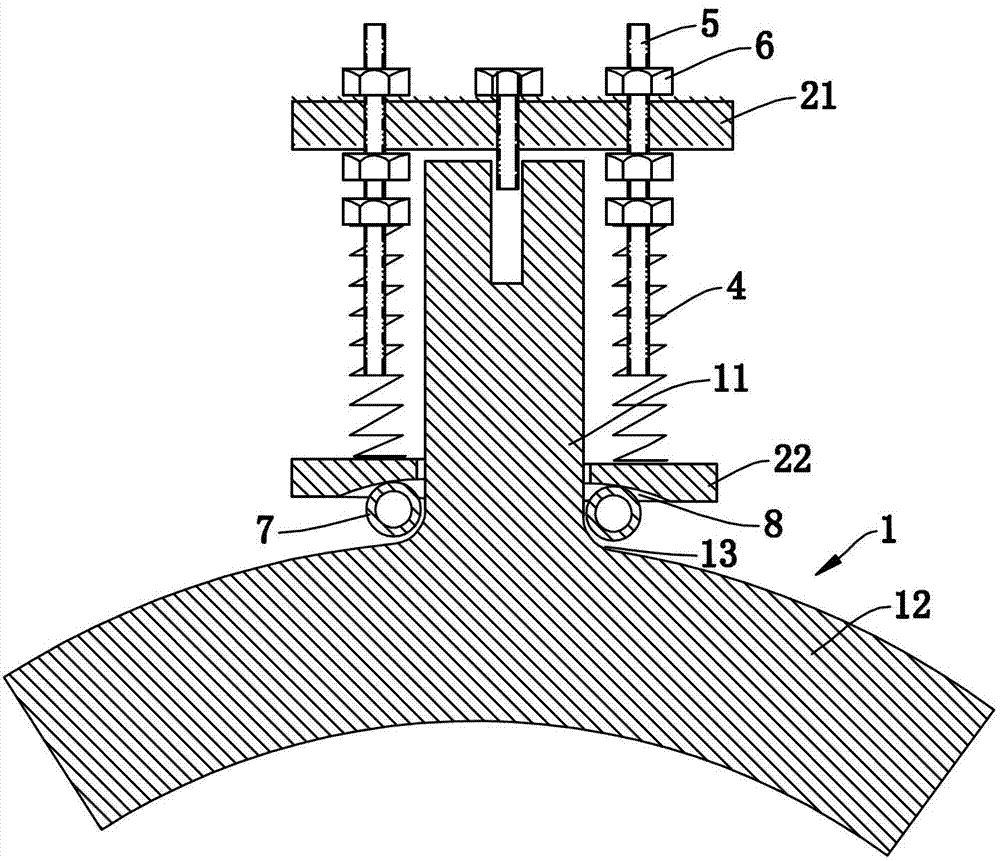

Insulating irregular part wet method forming device

ActiveCN102794930BImprove bindingImprove pass ratePaper/cardboard articlesMaterials scienceLower body

The invention discloses an insulating irregular part wet method forming device which comprises an irregular part core mold and an elastic forcing device, wherein the irregular part core mold comprises a cylindrical core mold and an arched core mold, the cylindrical core mold is arranged in the radial direction of an arc surface of the arched core mold, the combination part of the cylindrical core mold and the arched core mold is a fillet transition surface, the elastic forcing device comprises a forcing plate and an irregular part pressure plate which are oppositely arranged, the forcing plate is fixedly installed at the end of the cylindrical core mold, the irregular part pressure plate is provided with an arc surface matched with the arched core mold and a through hole for being sleeved with the cylindrical core mold, the edge of the through hole is adapted to a shape of the fillet transition surface, and a forcing spring is arranged between the forcing plate and the irregular part pressure plate. According to the insulating irregular part wet method forming device disclosed by the invention, the transition part of an upper body and a lower body is good to combine, so that the qualified rate of a product is increased.

Owner:WEIFANG HUISHENG INSULATION TECH

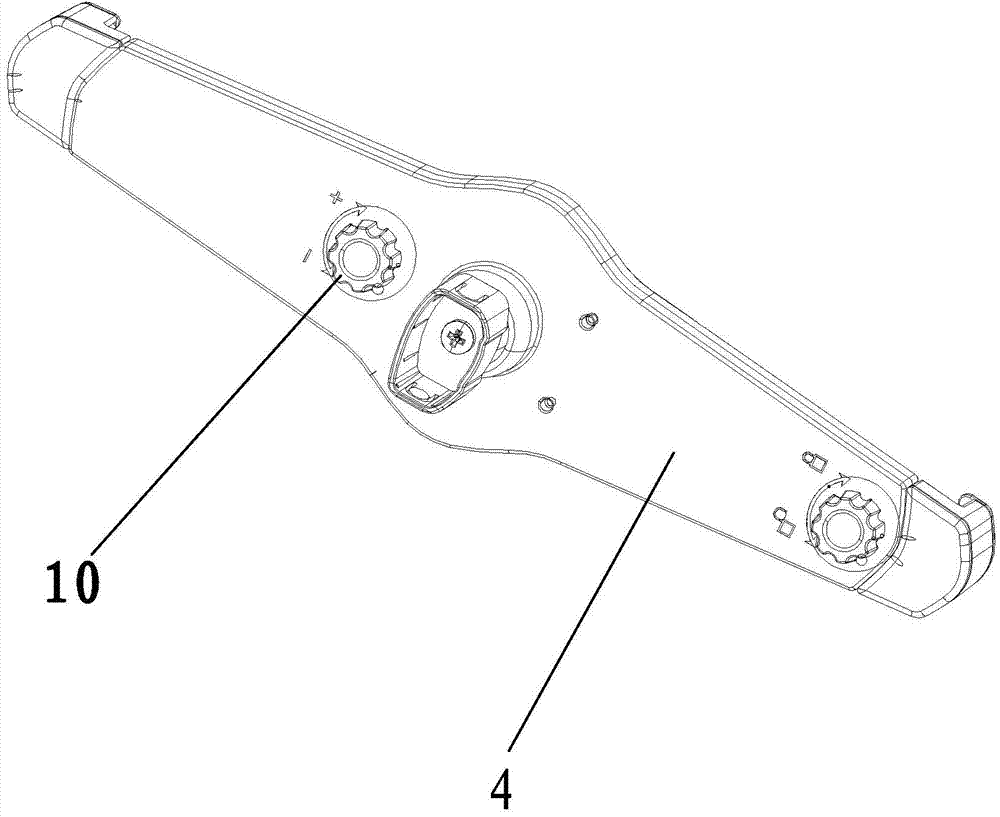

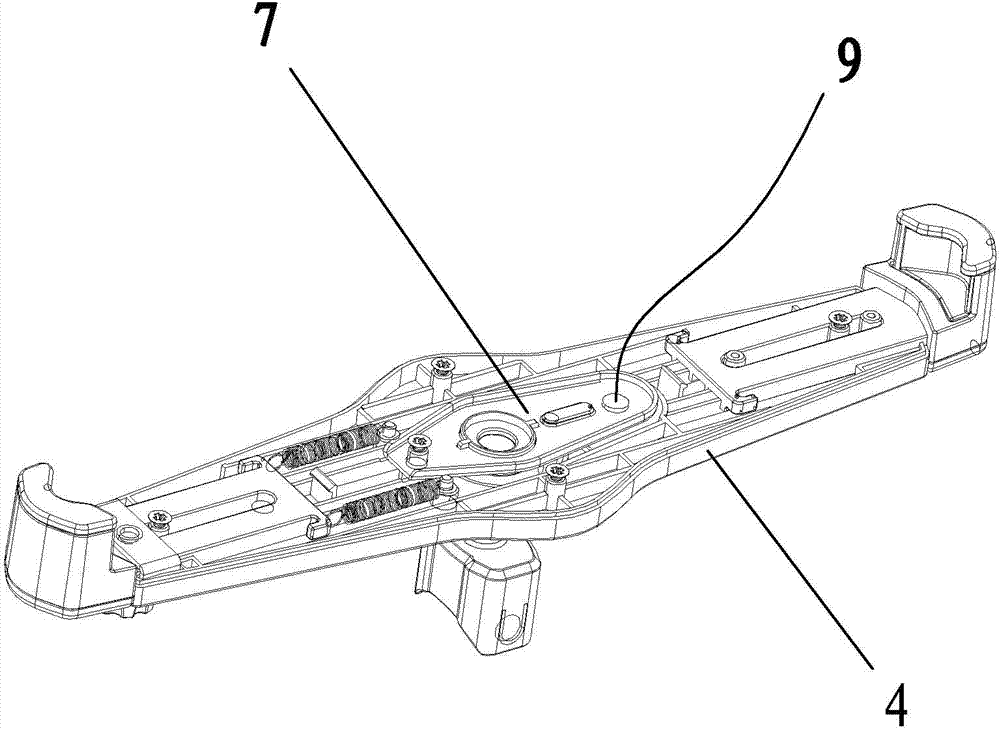

Adjusting mechanism for inclined angle of tablet personal computer

The invention provides an adjusting mechanism for an inclined angle of a tablet personal computer. The adjusting mechanism for the inclined angle of the tablet personal computer comprises a ball head, an upper cover plate and a lower cover plate, wherein a ball socket is formed in the lower cover plate, the ball head is arranged in the ball socket, a through hole is formed in the bottom of the ball socket, a connecting rod can be connected with the ball head through the through hole, a press plate is arranged above the ball socket, and is used for pressing the ball head into the ball socket, the press plate is connected with the lower cover plate through an adjustable mechanism so that the degree of pressing of the press plate to the ball head can be adjusted, and the upper cover plate and the lower cover plate are assembled to form a support which is used for installation of the tablet personal computer. Due to the facts that the structure that the press plate presses the ball head into the ball socket is stable, and the upper cover plate covers the structure in a cooperative mode, the ball head can be effectively prevented from falling off, the ball head can be comprehensively pressed through the mode of cooperation between the ball socket and the press plate, the ball head can be better wrapped, the ball head can be stressed in an all-directional mode, the ball head can be evenly stressed, and the ball head, the ball socket and the press plate can achieve better functions; due to the fact that the ball head can be comprehensively wrapped, the ball head can be easily pressed and fixed after the ball head is rotated through the adjusting mechanism.

Owner:LOCTEK ERGONOMIC TECH CORP

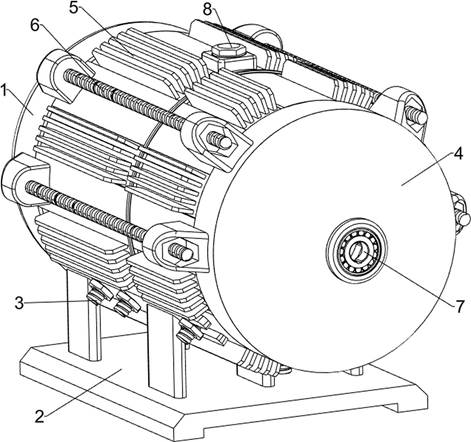

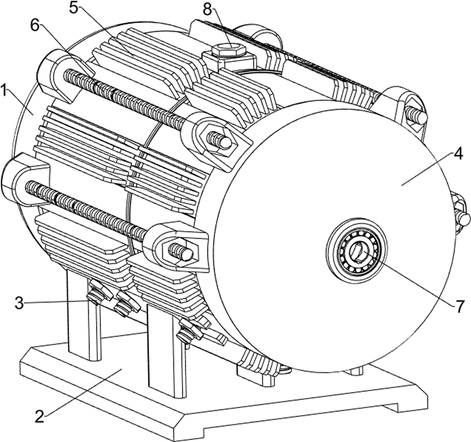

A motor casing and a motor stator structure

ActiveCN113708539BGuaranteed long-term heat dissipation requirementsThe vapor chamber is in contact with the first shell and the second shellMagnetic circuit stationary partsSupports/enclosures/casingsElectric machineEngineering

Owner:南昌耀德精密五金有限公司

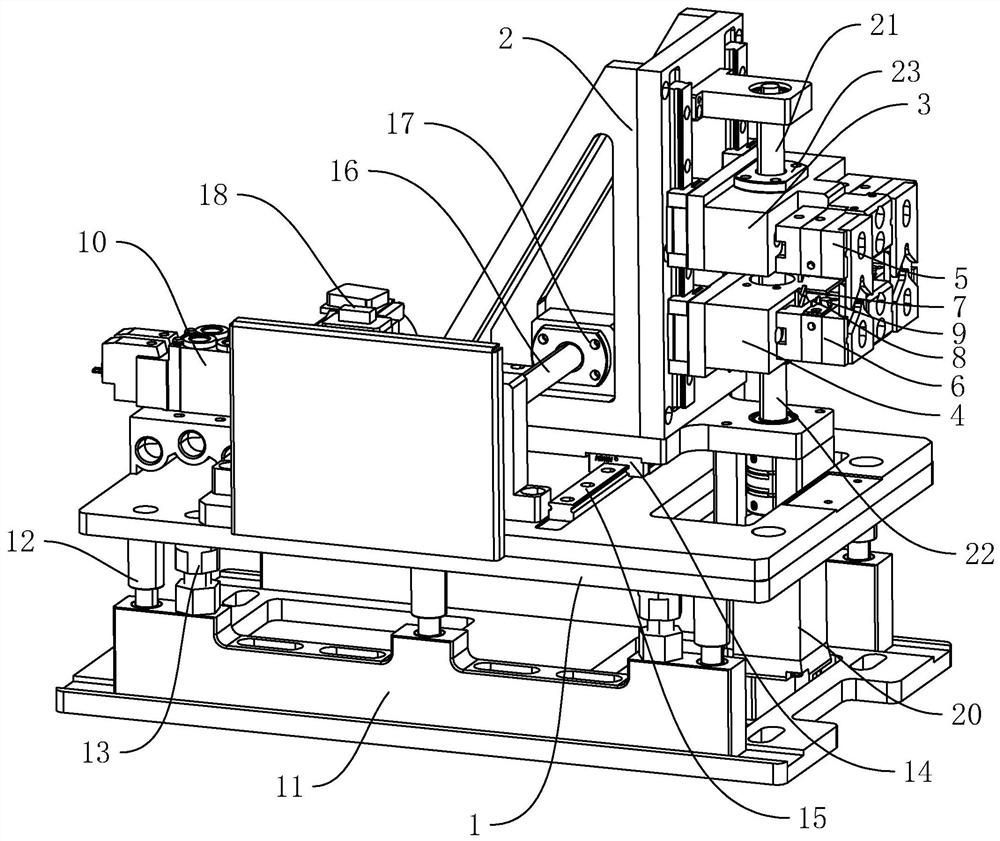

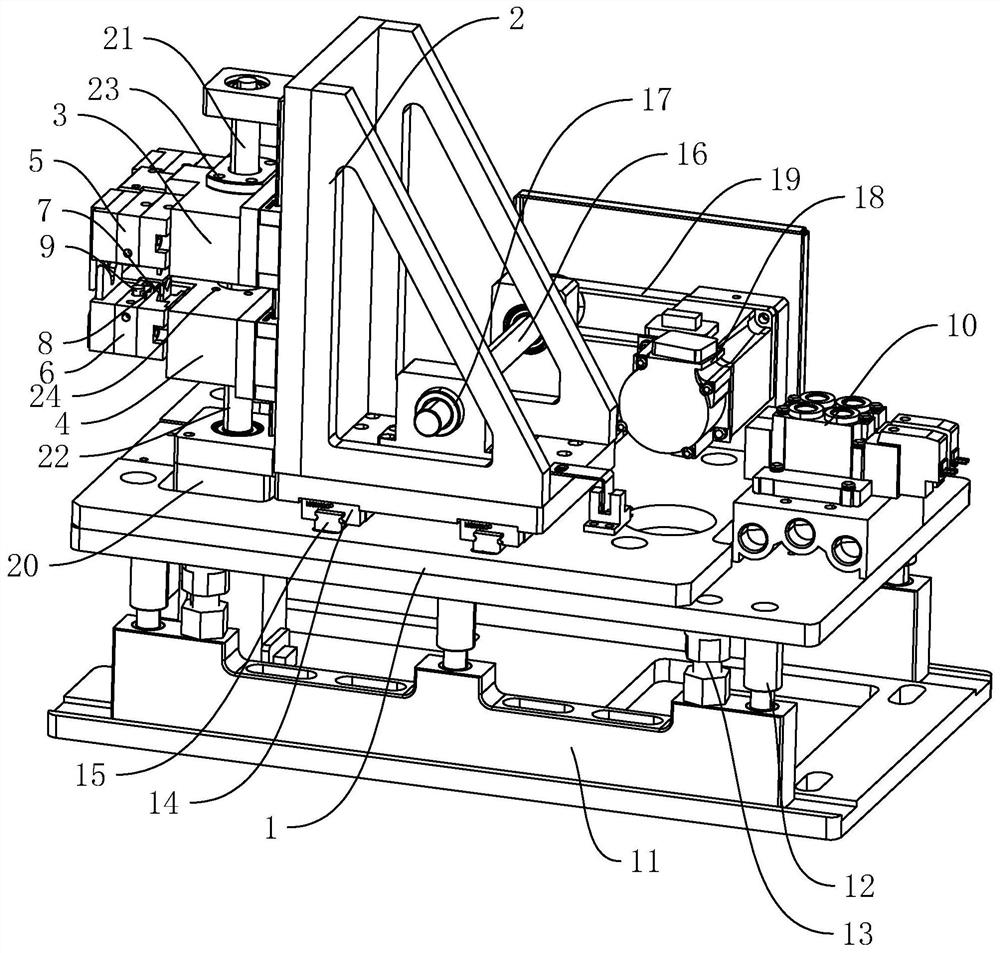

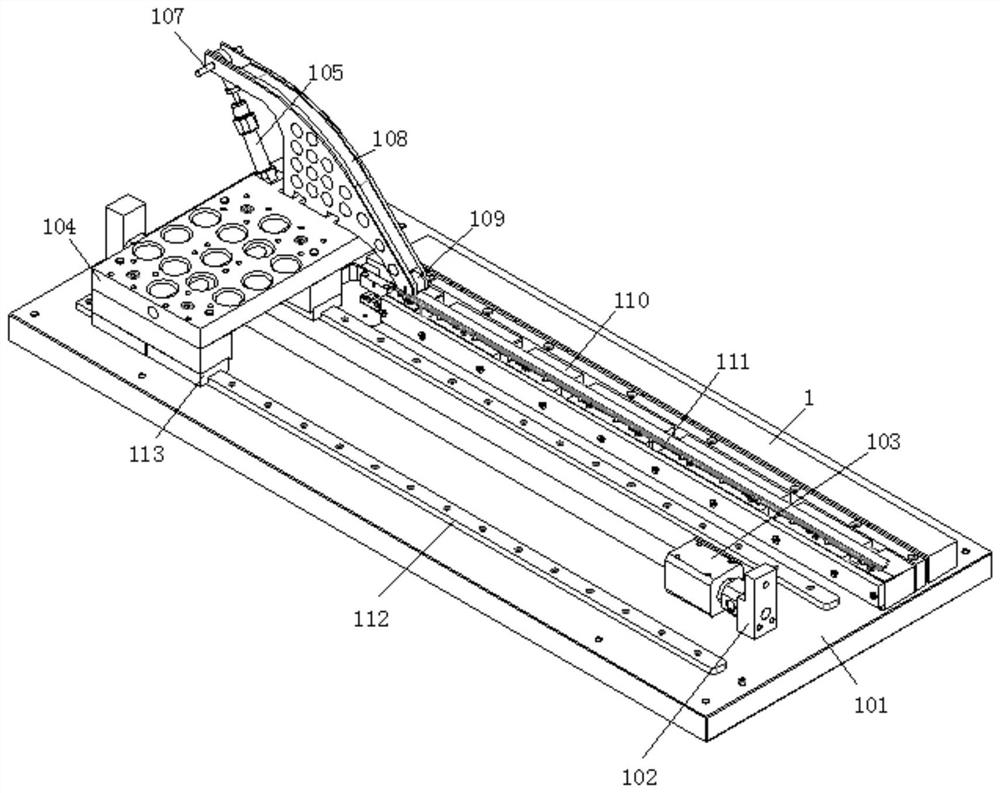

Cable conduction detection machine with compact structure

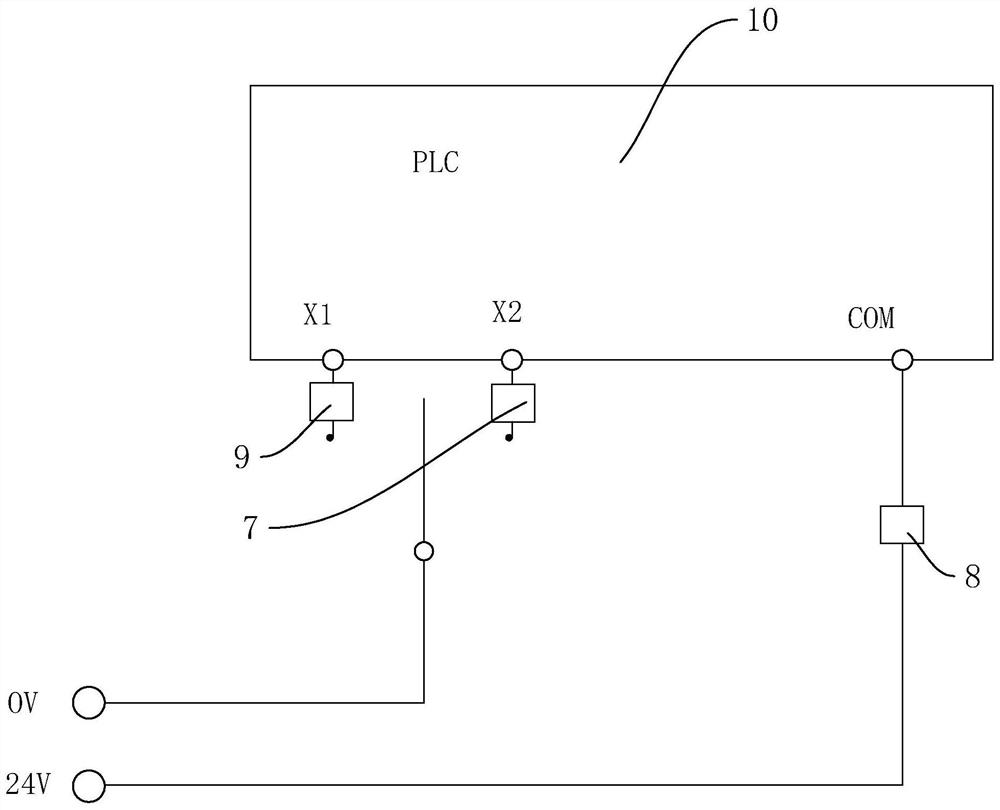

PendingCN113189516AImprove layout compactnessGuaranteed stabilityShort-circuit testingMeasurement instrument housingEngineeringKnife blades

The invention discloses a cable conduction detection machine with a compact structure, which relates to cable detection, and aims to solve the problem that a cable processing production line in the prior art lacks equipment for detecting a cable before an end is installed. Thecable conduction detection machine with a compact structure is technically characterized by comprising a mounting base, a vertical frame, an upper sliding base and a lower sliding base, wherein the upper sliding base and the lower sliding base are provided with a multi-stage contact assembly in a matched mode, the multi-stage contact assembly comprises an upper cutter set mounting base and a lower cutter set mounting base, and the upper cutter set mounting base and the lower cutter set mounting base are provided with inner core contact blades, inner insulating layer blades and shielding wire pressing heads, and the inner core contact blade, the inner insulating layer blade and the shielding wire pressure head are connected with a PLC. According to the cable conduction detection machine with the compact structure, the cable before the mounting end is mounted is detected, so that the influence on the production efficiency and the waste of raw materials caused by mounting the end at the end part of the cable which is not qualified originally are avoided.

Owner:JIAXING JUNQUAN AUTOMATION

Hot-grinding and hot-pressing equipment for fiber plates

InactiveCN111745773AImprove processing qualityEasy to put inWood working apparatusFlat articlesFiberStructural engineering

The invention discloses hot-grinding and hot-pressing equipment for fiber plates. The hot-grinding and hot-pressing equipment for the fiber plates comprises a box body, wherein a penetrating inner cavity is formed in the box body; an extrusion push plate is slidably arranged in the end wall of the inner cavity; a lifting compression device driving the extrusion push plate to compress downwards isarranged at the upper side of the box body; and a plurality of telescopic compression devices used for being placed among the fiber plates in a stacking manner and capable of carrying out telescopic movement on corresponding counter-weight structures to facilitate to compression for the fiber plates are arranged in the box body. The equipment adopts the manner of sliding a fiber plate compressionunit; on one hand, placement for the plates into the equipment is facilitated; and on the other hand, integral pressing for the stacked fiber plates is facilitated, so that the fiber plate machining quality is improved in combination with stable change after pressing for the fiber plates.

Owner:余颖

Waste Cardboard Compression Packaging Equipment

The invention discloses waste cardboard compression packaging equipment, comprising a bottom box body, an open bottom opening inner cavity is arranged in the bottom box body, a symmetrical ring-shaped box body is fixed in the bottom opening inner cavity, and a symmetrical ring-shaped box body is fixed in the ring-shaped box body. A packaging device for fully packaging waste cardboard is provided. A number of structural boxes are arranged on the upper side of the bottom box, and a box inner cavity is arranged in the inner cavity of the box, and a number of matching racks are arranged in the inner cavity of the box. The matching rack slides through the inner cavity of the box and the construction box, and the inner cavity of the box is provided with a power device that drives all the matching racks to protrude or extend into the construction box at the same time. The equipment adopts the structure of rack and pinion, so that the container can fully compress the waste cardboard, and can quickly pack the waste cardboard after compacting, which improves the working efficiency of the equipment.

Owner:荣成市盛高包装制品有限公司

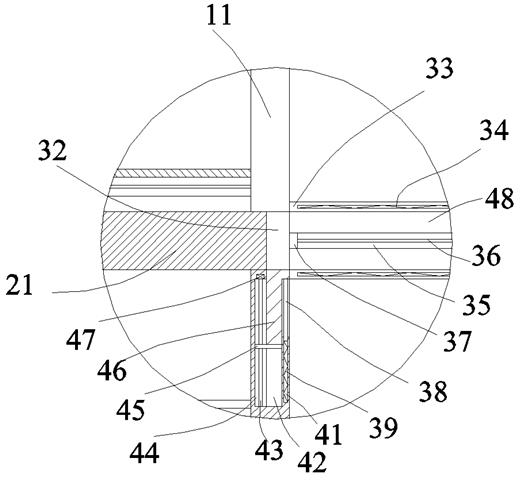

Motor shell and motor stator structure

ActiveCN113708539AGuaranteed long-term heat dissipation requirementsThe vapor chamber is in contact with the first shell and the second shellMagnetic circuit stationary partsSupports/enclosures/casingsElectric machineEngineering

The invention aims to provide a motor shell and motor stator structure, and the structure comprises a heat dissipation device and a bridging assembly; the heat dissipation device is composed of soaking plates, the soaking plates are uniformly distributed at the outer sides of a first shell and a second shell, and vertical plates at the outer sides are fully contacted with air to dissipate heat and carry out rapid heat dissipation; the bridging assembly comprises a mounting plate, a first connecting column, a second connecting column and a spring, the mounting plate is slidably mounted in the first shell, the first connecting column and the second connecting column are slidably mounted on the mounting plate after being connected through the spring, and the stator structures on the two sides are fixed under the action of the spring, so that an iron core sheet is fully pressed, and vibration is avoided. Meanwhile, the bridging assembly made of conductive materials enables the stator structures on the two sides to be communicated, and normal operation of the stator structures on the two sides is guaranteed.

Owner:南昌耀德精密五金有限公司

Special-shaped iron piece edge covering jig capable of achieving stable press fit

PendingCN112590191AIncrease the glue effectConvenient stickersCoatingsStructural engineeringManufacturing engineering

The invention discloses a special-shaped iron piece edge covering jig capable of achieving stable press fit. The special-shaped iron piece edge covering jig comprises a rubberizing jig body, a pressing jig body and an edge folding jig body; a first fixed machining table is arranged in the rubberizing jig body; a fixed mounting block is fixedly connected to the upper end of the first fixed machining table; a rodless air cylinder is fixedly connected to the inner side of the fixed mounting block; a movable end of the rodless air cylinder is fixedly connected with a positioning mounting table; asecond workpiece fixing groove is formed in the upper end of a positioning containing platform; the upper end of a third fixed machining table is slidably connected with an edge folding sliding block;the outer side of the edge folding sliding block is fixedly connected with a positioning mounting frame; and the interior of the positioning mounting frame is rotatably connected with a shaping rolling wheel. According to the special-shaped iron piece edge covering jig capable of achieving stable press fit, the situation that the overall pressing effect is poor due to the fact that the overall special-shaped iron piece edge covering jig cannot be fully attached is prevented, the overall rubberizing effect is improved, meanwhile, the overall service life is prolonged, the overall storage effect is improved, and therefore the overall practicability is improved.

Owner:苏州吉格尔科技有限公司

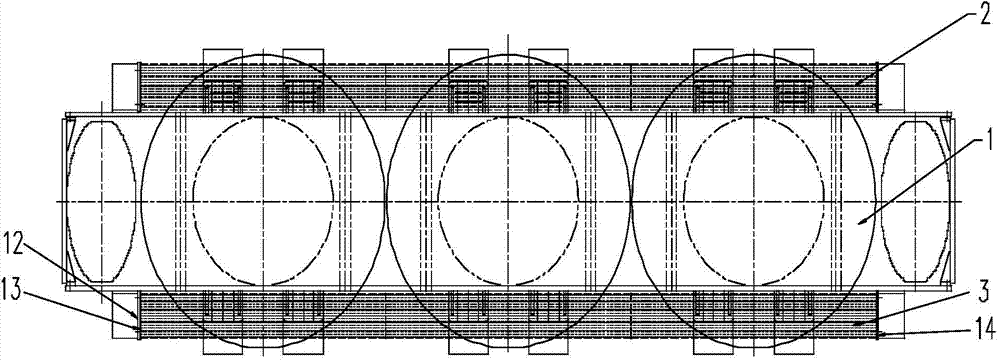

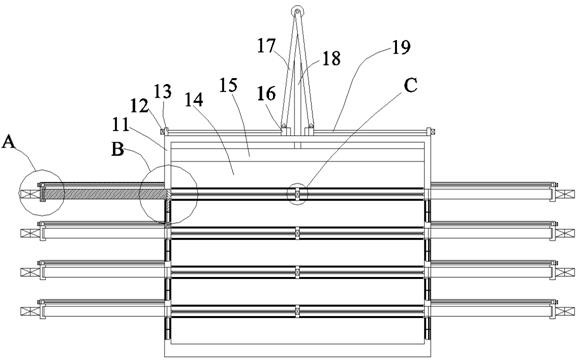

A telescopic spreader

ActiveCN111003632BSimple structureImprove firmnessLoad-engaging elementsEngineeringMechanical engineering

Owner:日照方冠机械有限公司

High vacuum rotary seal mechanism

The invention discloses a high-vacuum degree rotary sealing mechanism. The high-vacuum degree rotary sealing mechanism comprises a sealing sleeve, a pressure head, a rotary piece, at least one first soft sealing ring, at least one hard compression ring, and a fastener, wherein a first through hole is formed in the bottom of the sealing sleeve and the axial direction of the first through hole is parallel to that of the sealing sleeve; a second through hole is formed in the pressure head to penetrate through the pressure head; the rotary piece is put through and pivoted in the first through hole and the second through hole; the at least one first soft sealing ring hermetically sleeves the rotary piece and is located in the sealing sleeve; each compression ring hermetically sleeves the rotary piece; each compression ring is located on one side, close to the opening of the sealing sleeve, of the corresponding first soft sealing ring; the pressure head is detachably fixed at the opening of the sealing sleeve by use of the fastener, and the fastener is used for driving the pressure head to be switched between a position where the pressure head extends into the sealing sleeve and props against the compressing ring and a position where the pressure head is far away from the sealing sleeve and separated from the compression ring. The high-vacuum degree rotary sealing mechanism is capable of keeping a relatively high vacuum degree in a vacuum chamber and realizing an excellent dynamic sealing effect under the circumstance that the rotary piece rotates.

Owner:SHENZHEN SHENGSHI INTELLIGENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com