Insulating irregular part wet method forming device

A technology of wet forming and special-shaped parts, which is applied in the direction of cardboard articles, etc., which can solve the problems of difficult joint of transition fillet parts, easy delamination and cracking, and unqualified product quality, so as to avoid local deformation, uniform force and improve quality and the effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

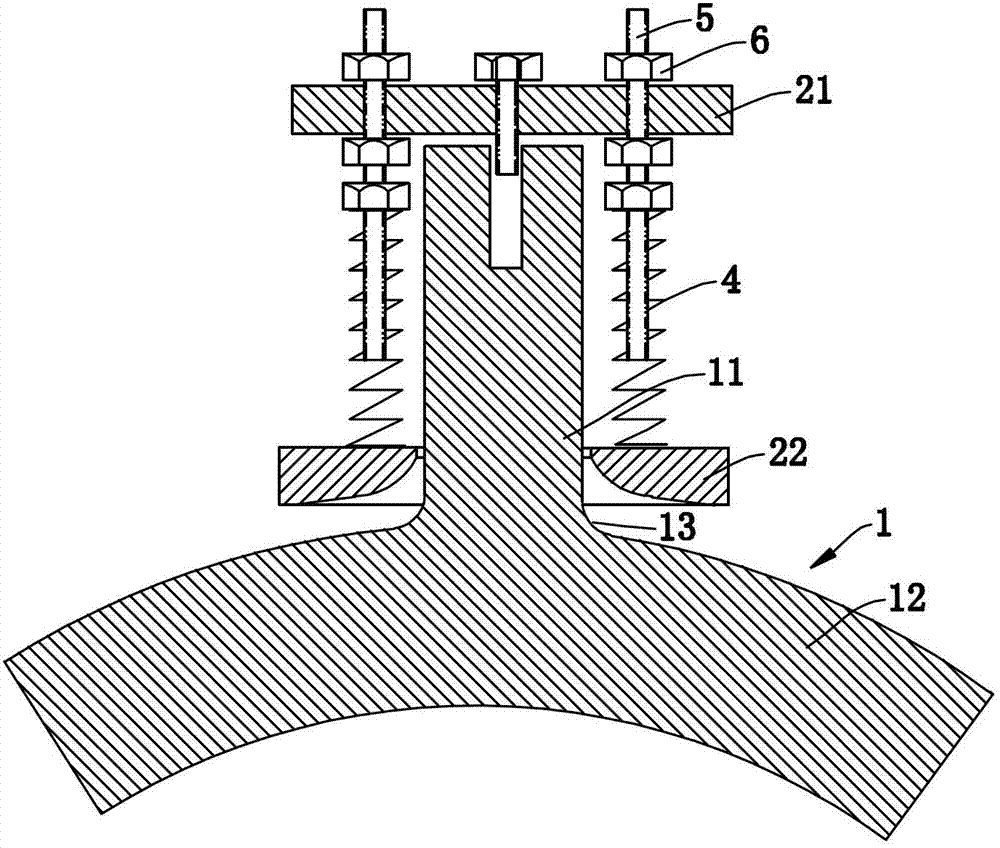

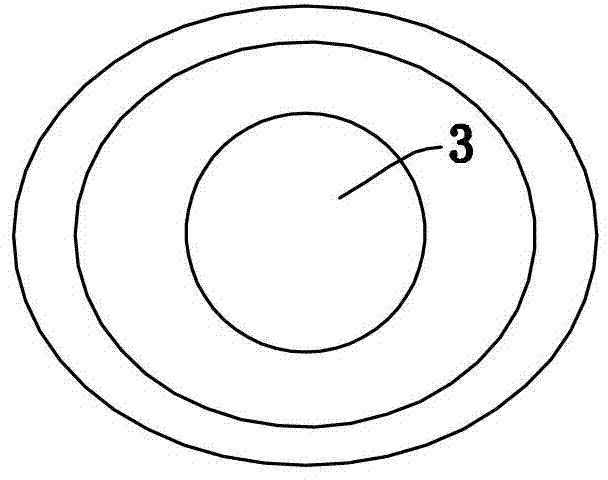

[0019] Such as figure 1 and figure 2 Commonly shown, a wet forming device for insulating special-shaped parts, including: a mandrel 1 for special-shaped parts and an elastic force applying device. The special-shaped mandrel 1 includes a columnar mandrel 11 and an arched mandrel 12, the columnar mandrel 11 is arranged on the radial direction of the arc surface of the arched mandrel 12, the junction of the columnar mandrel 11 and the arched mandrel 12 It is a rounded transition surface 13; the elastic force applying device includes a force applying plate 21 and a special-shaped piece pressing plate 22 which are arranged oppositely. The arc surface of the mandrel 12 is matched, and the through hole 3 for fitting the cylindrical mandrel 11 is opened on the pressure plate 22 of the special-shaped part. A force applying spring 4 is arranged between the piece pressing plates 22, and the force applying spring 4 is sleeved on the stud 5, and the stud 5 is threadedly connected with t...

Embodiment 2

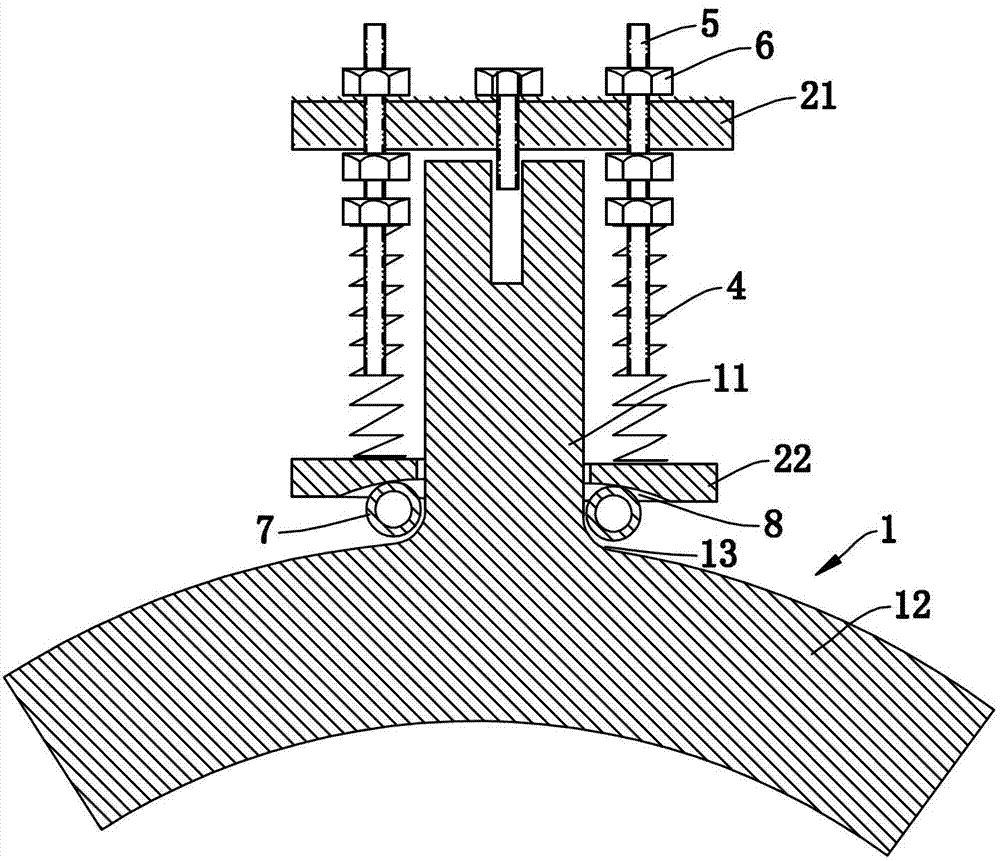

[0022] Such as image 3 and Figure 4 Commonly shown, a wet forming device for insulating special-shaped parts, its structure is basically the same as that of Embodiment 1, the difference is that an annular elastic body 7 is provided between the special-shaped part pressing plate 22 and the rounded transition surface 13, and the corresponding , the edge of the through hole 3 is provided with a cavity 8 for accommodating the annular elastic body 7, by means of the contraction and expansion of the annular elastic body 7, the wet cardboard layer between the special-shaped piece pressing plate and the fillet transition surface 13 can be more effectively The combination is good, the elastic deformation of the annular elastic body 7 changes with the thickness of the product during the drying process, the applied force is more uniform, and the compressed state is always maintained to ensure the product quality. The shape of the two end surfaces 9 of the cavity 8 located on the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com