Pipe linear cutting tool

A wire-cut tooling and pipe technology, applied in the direction of attachments, manufacturing tools, electric processing equipment, etc., can solve the problems of low clamping efficiency and inconvenient operation of wire-cut tooling, and achieve improved production efficiency, convenient clamping operation, Avoid the sloshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

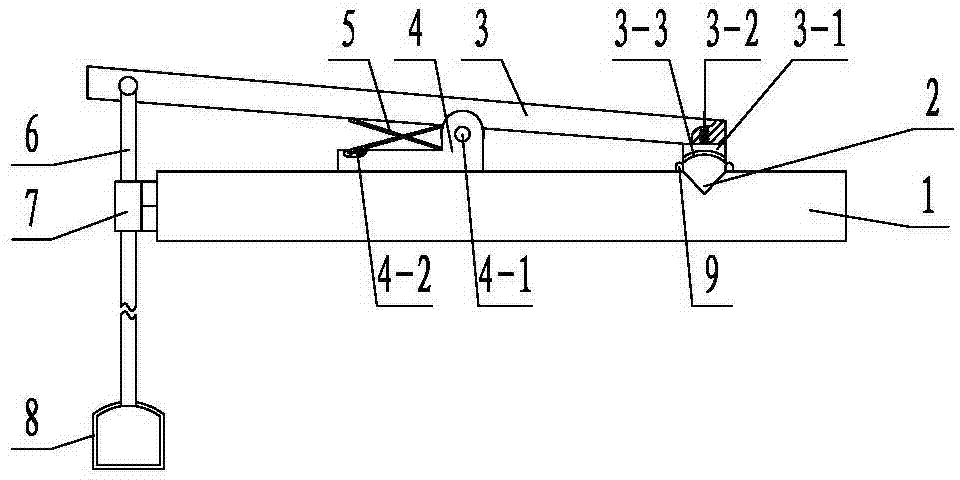

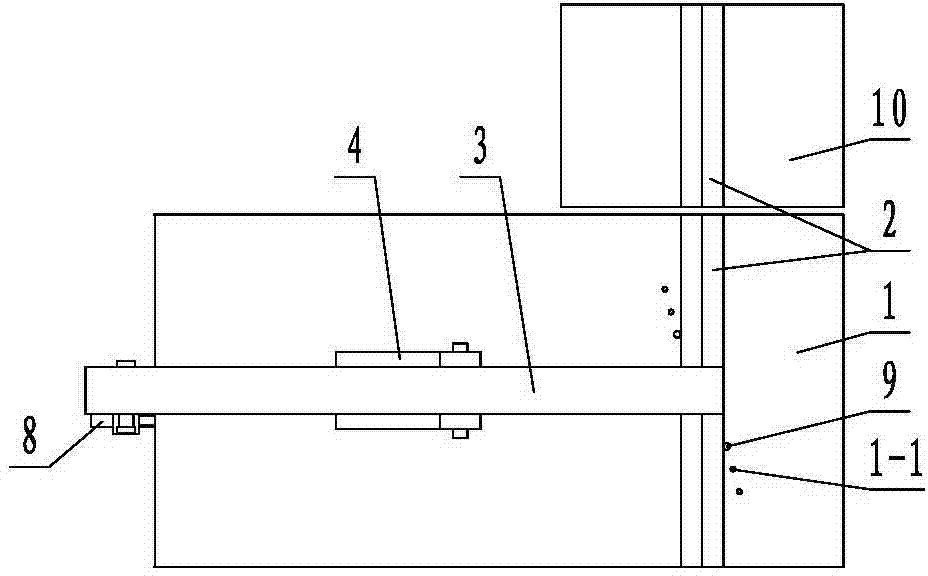

[0020] figure 1 and figure 2 The pipe wire cutting tool shown mainly includes a support plate 10, a base plate 1, a pressure bar 3, a support 4, a cross bar 4-1, a torsion spring 5, a boom 6 and a pedal 8, and the support plate 10 and the base plate 1 are horizontally spaced Setting, the base plate 1 and the support plate 10 are provided with a V-shaped groove 2 for placing pipes, the bottom of the V-shaped groove of the base plate 1 and the V-shaped groove of the support plate 10 are on the same vertical plane, and the base plate 1 is fixed with a support Seat 4, a pair of lugs are arranged on the top of the support 4, a cross bar 4-1 is connected between the ear plates, the pressure bar 3 and the cross bar 4-1 are hinged, and a torsion spring 5 is set on the cross bar 4-1 , the torsion arms at both ends of the torsion spring 5 abut against the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com